- DL manuals

- Keithley

- Multimeter

- 2010

- Service Manual

Keithley 2010 Service Manual

www.keithley.com

2010-902-01 Rev. D / October 2003

A G R E A T E R M E A S U R E O F C O N F I D E N C E

Summary of 2010

Page 1

Www.Keithley.Com model 2010 multimeter service manual 2010-902-01 rev. D / october 2003 a g r e a t e r m e a s u r e o f c o n f i d e n c e.

Page 2: Warranty

Warranty keithley instruments, inc. Warrants this product to be free from defects in material and workmanship for a period of one (1) year from date of shipment. Keithley instruments, inc. Warrants the following items for 90 days from the date of shipment: probes, cables, software, rechargeable batt...

Page 3

Model 2010 multimeter service manual ©1996, keithley instruments, inc. All rights reserved. Cleveland, ohio, u.S.A. Fourth printing, october 2003 document number: 2010-902-01 rev. D.

Page 4: Manual Print History

Manual print history the print history shown below lists the printing dates of all revisions and addenda created for this manual. The revision level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released between revisions, contain important change inf...

Page 5: Safety Precautions

Safety precautions 11/07 the following safety precautions should be observed before using this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions may be present. Thi...

Page 6

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under test. Always remove power from the entire test system and discharge any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching c...

Page 7: Table of Contents

Table of contents 1 performance verification introduction ................................................................................ 1-2 verification test requirements .................................................... 1-2 environmental conditions ...............................................

Page 8: Routine Maintenance

Front panel calibration ................................................................ 2-6 preparing the model 2010 for calibration ........................... 2-6 front panel short and open calibration ................................ 2-7 dc volts calibration ........................................

Page 9: Troubleshooting

4 troubleshooting introduction ................................................................................ 4-2 repair considerations ................................................................. 4-2 power-on self-test ...................................................................... 4-...

Page 10: Specifications

A specifications accuracy calculations ................................................................ A-5 calculating dc characteristics accuracy ............................ A-5 calculating ac characteristics accuracy ............................ A-5 additional derating factors .....................

Page 11: List of Illustrations

List of illustrations 1 performance verification figure 1-1 connections for dc volts verification ..................................................... 1-6 figure 1-2 connections for ac volts verification ..................................................... 1-7 figure 1-3 connections for dc current...

Page 12: List of Tables

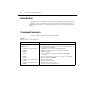

List of tables 1 performance verification table 1-1 recommended verification equipment .................................................... 1-3 table 1-2 dcv reading limits .................................................................................. 1-6 table 1-3 acv reading limits ..............

Page 13: Replaceable Parts

Table 4-9 Ω2/Ω4 reference switching .................................................................... 4-15 table 4-10 dca signal switching ............................................................................ 4-15 table 4-11 aca signal switching ...............................................

Page 14: Performance

1 performance verification 1 performance verification.

Page 15: Introduction

Introduction use the procedures in this section to verify that the model 2010 multimeter accuracy is within the limits stated in the instrument’s one-year accuracy specifications. You can perform verification procedures: • when you first receive the instrument to make sure that it was not damaged du...

Page 16: Line Power

Also, allow the test equipment to warm up for the minimum time specified by the manufacturer. Line power the model 2010 multimeter requires a line voltage of 100v/120v/220v/240v, ±10% and a line frequency of 45hz to 66hz and 360hz to 440hz. Recommended test equipment table 1-1 summarizes recommended...

Page 17: Verification Limits

Verification limits the verification limits stated in this section have been calculated using only the model 2010 one-year accuracy specifications. All ranges do not include the verification equipment’s uncertainty. If a particular measurement falls slightly outside the allowable range, recalculate ...

Page 18: Test Summary

Performing the verification test procedures test summary verification test procedures include: • dc volts • ac volts • dc current • ac current • resistance • temperature • frequency • ratio if the model 2010 is not within specifications and not under warranty, see the calibration procedures in secti...

Page 19: Verifying Dc Voltage

Verifying dc voltage check dc voltage accuracy by applying accurate voltages from the dc voltage calibrator to the model 2010 input jacks and verifying that the displayed readings fall within specified limits. Follow these steps to verify the dc voltage: caution do not exceed 1000v peak between inpu...

Page 20: Verifying Ac Voltage

Verifying ac voltage check ac voltage accuracy by applying accurate ac voltages at specific frequencies from the ac voltage calibrator to the model 2010 inputs and verifying that the displayed readings fall within specified ranges. Caution do not exceed 1000v peak between input hi and input lo, or 8...

Page 21: Verifying Dc Current

Verifying dc current check dc current accuracy by applying accurate dc currents from the dc current calibrator to the amps input of the model 2010 and verifying that the displayed readings fall within specified limits. Follow these steps to verify dc current accuracy: 1. Connect the model 2010 amps ...

Page 22: Verifying Ac Current

Verifying ac current check ac current accuracy by applying accurate ac current at specific frequencies from the ac current calibrator to the model 2010 input and verifying that the displayed readings fall within specified limits. Follow these steps to verify ac current: 1. Connect the model 2010 amp...

Page 23: Verifying Resistance

Verifying resistance check resistance by connecting accurate resistance values to the model 2010 and verifying that its resistance readings are within the specified limits. Caution do not apply more 1000v peak between input hi and lo or more than 350v peak between sense hi and lo, or instrument dama...

Page 24

6. Source the nominal full-scale resistance values for the 10 Ω -10m Ω ranges summarized in table 1-6 , and verify that the readings are within calculated limits. 7. Connect the model 2010 input and sense jacks to the calibrator as shown in figure 1-6 . 8. Disable external sense on the calibrator. 9...

Page 25: Verifying Temperature

Verifying temperature thermocouple and rtd temperature readings are derived from dc volts and ohms readings respectively. For this reason, it is not necessary to independently verify the accuracy of temperature measurements. As long as the dc volts and ohms functions meet or exceed their respective ...

Page 26: Rtd Temperature

Rtd temperature 1. Connect the precision decade resistance box (listed in table 1-1 ) to the model 2010 input and sense jacks using 4-wire connections. (see figure 1-1 for a similar connecting scheme.) 2. Configure the model 2010 temperature function for °c units and rtd temperature sensor ( α =0.00...

Page 27: Verifying Frequency

Verifying frequency follow the steps below to verify the model 2010 frequency function. 1. Connect the frequency synthesizer to the model 2010 input jacks. See figure 1-7 . 2. Set the synthesizer to output a 1khz, 1v rms sine wave. 3. Select the model 2010 frequency function by pressing the freq key...

Page 28: Calibration

2 calibration 2 calibration.

Page 29: Introduction

Introduction use the procedures in this section to calibrate the model 2010. Calibration procedures include: • comprehensive calibration: calibrate dc and ac voltages, dc and ac currents, and resistance values. • manufacturing calibration: usually only performed at the factory warning the informatio...

Page 30: Calibration Considerations

Calibration considerations when performing the calibration procedures: • make sure that the equipment is properly warmed up and connected to the appropriate input jacks. Also make sure that the correct input jacks are selected with the inputs switch. • make sure the calibrator is in operate before y...

Page 31: Remote Command Code

4. The model 2010 lets you define a new calibration code. Use the up and down range keys to toggle between yes and no. Choose n if you do not want to change the code. Choose y if you want to change the code. The unit then prompts you to enter a new code. Enter the code, and press enter. Remote comma...

Page 32: Recommended Equipment

Recommended equipment table 2-1 lists the recommended equipment you need for comprehensive, dc only, and ac only calibration procedures. You can use alternate equipment, such as a dc transfer standard and characterized resistors, as long as that equipment has specifications at least as good as those...

Page 33: Front Panel Calibration

Front panel calibration use the following steps for comprehensive, dc-only, and ac-only calibration procedures. The procedures for front panel calibration include: • preparing the model 2010 for calibration • front panel short and open calibration • dc voltage calibration • resistance calibration • ...

Page 34: Model 2010

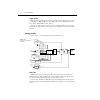

Front panel short and open calibration at the model 2010 prompt for a front panel short, perform the following: 1. Connect the model 8610 low-thermal short to the instrument front panel input and sense terminals as shown in figure 2-1 . Make sure the inputs button is not pressed in so that the front...

Page 35: Dc Volts Calibration

Dc volts calibration after the front panel short and open procedure, the unit will prompt you for the first dc voltage: +10v. Perform the following: 1. Connect the calibrator to the model 2010 as shown in figure 2-2 . Wait three minutes to allow for thermal equilibrium before proceeding. Note althou...

Page 36: Resistance Calibration

Note if your calibrator cannot output the values recommended in table 2-3 , use the left and right arrow keys, and the up and down range keys to set the model 2010 display value to match the calibrator output voltage. Resistance calibration completing the 100v dc calibration step ends the dc voltage...

Page 37: Dc Current Calibration

Dc current calibration after the 1m Ω resistance point has been calibrated, the unit will prompt you for 10ma. Follow these steps for dc current calibration: 1. Connect the calibrator to the amps and input lo terminals of the model 2010 as shown in figure 2-3 . 2. Calibrate each current step summari...

Page 38: Ac Voltage Calibration

Ac voltage calibration follow these steps for ac voltage calibration: 1. Connect the calibrator to the model 2010 input hi and lo terminals as shown in figure 2-4 . 2. Perform the calibration steps summarized in table 2-6 . For each step: • set the calibrator to the indicated value, and make sure th...

Page 39: Ac Current Calibration

Ac current calibration after the 700v ac at 1khz point has been calibrated, the unit will prompt you for 100ma at 1khz. Follow these steps for ac current calibration: 1. Connect the calibrator to the amps and input lo terminals of the model 2010 as shown in figure 2-3 . 2. Perform the calibration st...

Page 40: Remote Calibration

Remote calibration use the following steps to perform comprehensive, dc-only, and ac-only calibration procedures by remote. See appendix b for a detailed list and description of scpi calibration commands. When sending calibration commands, be sure that the model 2010 completes each step before sendi...

Page 41: Short and Open Calibration

Preparing the model 2010 for calibration 1. Connect the model 2010 to the ieee-488 bus of the computer using a shielded ieee-488 cable, such as the keithley model 7007, or connect the unit to a computer through the rs-232 port using a straight-through 9-pin to 9-pin cable (use a 9-25-pin adapter if ...

Page 42: Dc Volts Calibration

Dc volts calibration after front panel short and open steps, perform the following: 1. Connect the calibrator to the model 2010 as shown in figure 2-2 . Allow three minutes for thermal equilibrium. Note although 4-wire connections are shown, the sense leads are connected and disconnected at various ...

Page 43: Resistance Calibration

Resistance calibration follow these steps for resistance calibration: 1. Set the calibrator to the resistance mode, and turn on external sensing. Note use external sense (4-wire Ω ) when calibrating all resistance ranges. Be sure that the calibrator external sense mode is turned on, 2. Perform the c...

Page 44: Dc Current Calibration

Dc current calibration after the 1m Ω resistance point has been calibrated, follow these steps for dc current calibration: 1. Connect the calibrator to the amps and input lo terminals of the model 2010 as shown in figure 2-3 . 2. Perform the calibration steps listed in table 2-10 . For each step: • ...

Page 45: Ac Voltage Calibration

Ac voltage calibration follow these steps for ac voltage calibration: 1. Connect the calibrator to the model 2010 input hi and lo terminals as shown in figure 2-4 . Note disconnect any sense leads from the calibrator to the model 2010 when calibrating or verifying ac volts. Even though some calibrat...

Page 46: Saving Calibration Constants

Programming calibration dates program the present calibration date and calibration due date by sending the following commands: :cal:prot:date , , :cal:prot:ndue , , for example, the following commands assume calibration dates of 12/15/95 and 3/14/96 respectively: :cal:prot:date 1995, 12, 15 :cal:pro...

Page 47: Manufacturing Calibration

Manufacturing calibration the manufacturing calibration procedure is normally performed only at the factory, but the necessary steps are included here in case the unit is repaired, and the unit requires these calibration procedures. Note if the unit has been repaired, the entire comprehensive calibr...

Page 48: Test Equipment Connections

Test equipment connections connections for firmware revision a14 and higher connections for steps requiring the calibrator are shown in figure 2-5 , and figure 2-6 shows function generator connections. Refer to the test procedures for specific steps. Figure 2-5 calibrator connections for manufacturi...

Page 49

Connections for firmware revision a13 and lower figure 2-7 shows synthesizer connections for revision a13 and lower. Figure 2-7 synthesizer connections for manufacturing calibration (firmware revision a13 and lower) unlocking manufacturing calibration to unlock manufacturing calibration, press and h...

Page 50

7. After the last ac current calibration step, the instrument will prompt you to enter 10hz at 1v rms and 1khz with the following prompts: • low-frequency cal: connect the calibrator to the front panel input jacks ( figure 2-5 ). Select the front input jacks with the inputs switch. Set the calibrato...

Page 51

8. Connect the function generator to the model 2010 input jacks as shown in figure 2-6 . 9. Set the generator to output a 1v rms, 1khz sine wave, then send the following command: :cal:prot:ac:step15 1e3 10. Send the following commands to set calibration dates, save calibration, and lock out calibrat...

Page 52

Remote manufacturing calibration (firmware a13 and lower) 1. Connect the low-thermal short to the rear panel input jacks, and select the rear inputs with the inputs switch. Allow three minutes for thermal equilibrium. 2. Press in and hold the open key while turning on the power. 3. Enable calibratio...

Page 53: Routine

3 routine maintenance 3 routine maintenance.

Page 54: Introduction

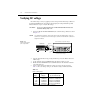

Introduction this section describes routine type maintenance that can be performed by the operator and includes procedures for replacing both the line fuse and the amps fuse. Setting the line voltage and replacing the line fuse warning disconnect the line cord at the rear panel, and remove all test ...

Page 55: Replacing The Amps Fuse

2. Remove the fuse, and replace it with the type listed in table 3-1 . Caution for continued protection against fire or instrument damage, replace the fuse only with the type and rating listed. If the instrument repeatedly blows fuses, locate and correct the cause of the trouble before replacing the...

Page 56: Troubleshoot-

4 troubleshooting 4 troubleshoot- ing.

Page 57: Introduction

Introduction this section of the manual will assist you in troubleshooting and repairing the model 2010. Included are self-tests, test procedures, troubleshooting tables, and circuit descriptions. It is left to the discretion of the repair technician to select the appropriate tests and documentation...

Page 58: Front Panel Tests

Front panel tests there are two front panel tests: one to test the functionality of the front panel keys and one to test the display. In the event of a test failure, refer to display board checks for details on troubleshooting the display board. Key test the key test allows you to check the function...

Page 59: Principles of Operation

Principles of operation the following information is provided to support the troubleshooting tests and procedures covered in this section of the manual. Refer to the following block diagrams: figure 4-1 — power supply block diagram figure 4-2 — digital circuitry block diagram figure 4-3 — analog cir...

Page 60

Fuse power switch line voltage switch power transformer cr104 c175, c156 u144 +5vd d common cr116, cr117 c108 u101 cr102 c131, c148 u179, u180 cr103 c146 u124 +37v d common +15v a common -15v +5v, +5vrl a common +18v a common -18v -25v a common +25v u187 c279 c281 +20v a common cr102, cr136 cr137, c...

Page 61: Display Board

Display board display board components are shown in the digital circuitry block diagram in figure 4-2 . Microcontroller u401 is the display board microcontroller that controls the display and interprets key data. The microcontroller uses three internal peripheral i/o ports for the various control an...

Page 62

Memory circuits roms u156 and u157 store the firmware code for instrument operation. U157 stores the d0-d7 bits of each data word, and u156 stores the d8-d15 bits. Rams u151 and u152 provide temporary operating storage. U152 stores the d0-d7 bits of each data word, and u151 stores the d8-d15 bits. S...

Page 63: Analog Circuitry

Trigger circuits buffering for trigger link input and output is performed by u146. Trigger input and output is controlled by the irq4 and pb3 lines of the mpu. U164 provides additional logic for the trigger input to minimize mpu control overhead. At the factory, trigger output is connected to line 1...

Page 64

Amps input the aca or dca input signal is applied to the current shunt circuit, which is made up of k103, q165, q164, r205, r450, r386, and r158. U178 controls if either q164 or q165 is turned on. For the 3a and 1a dca ranges and all aca ranges, 0.1 Ω (r158) is shunted across the input (k103 off). F...

Page 65: Troubleshooting

Troubleshooting troubleshooting information for the various circuits is summarized below. See analog signal switching states for additional information regarding the analog circuitry. Display board checks if the front panel disp test indicates that there is a problem on the display board, use table ...

Page 66: Power Supply Checks

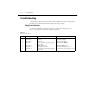

Power supply checks power supply problems can be checked using table 4-3 . See principles of operation for circuit theory on the power supply. Table 4-3 power supply checks step item/component required condition remarks 1 2 3 4 5 6 7 8 9 10 11 12 13 line fuse line voltage line power u144, pin 2 u101...

Page 67: Digital Circuitry Checks

Digital circuitry checks digital circuit problems can be checked using table 4-4 . See principles of operation for a digital circuit description. Table 4-4 digital circuitry checks step item/component required condition remarks 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 power-on test u157 pin 16 u157...

Page 68

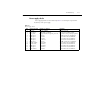

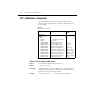

Analog signal switching states table 4-5 through table 4-11 provide switching states of the various relays, fets, and analog switches for the basic measurement functions and ranges. These tables can be used to assist in tracing an analog signal from the input to the a/d multiplexer. Table 4-5 dcv si...

Page 69

Table 4-7 Ω 2 signal switching range k104 q101 q102 q114 q136 q109 k101* k102* q113 q105 q104 q108 q153 q167 10 Ω 100 Ω 1k Ω 10k Ω 100k Ω 1m Ω 10m Ω 100m Ω reset reset reset reset reset reset reset reset on on on on on on on on on on on on on on on on off off off off off off off off off off off off ...

Page 70

Table 4-9 Ω 2/ Ω 4 reference switching range u133 pin 8 u133 pin 1 q123 q125 q124 q126 10 Ω 100 Ω 1k Ω 10k Ω 100k Ω 1m Ω 10m Ω 100m Ω off on on off on on off off on off off on off off on on on on on off off off off off on on on off off off off off off off off on on on on on off off off on on on on o...

Page 71

Table 4-12 through table 4-16 can be used to trace the analog signal through the a/d multi- plexer (u163) to the final amplifier stage. These tables show the mux lines (s3, s4, s6, s7) that are selected for measurement during the signal phase of the multiplexing cycle. Also included are switching st...

Page 72

Figure 4-3 provides a block diagram of the analog circuitry. Table 4-17 is provided to show where the various switching devices are located in the block diagram. Table 4-15 Ω 2 signal multiplexing and gain range signal (u163) u176 pin 1 u176 pin 8 u176 pin 9 gain (u177) u176 pin 16 10 Ω 100 Ω 1k Ω 1...

Page 73: No Comm Link Error

No comm link error a “no comm link” error indicates that the front panel processor has ceased communication with the main processor, which is located on the mother board. This error indicates that there may be a problem with the cable connection from the front panel display or one of the main proces...

Page 74: Disassembly

5 disassembly 5 disassembly.

Page 75: Introduction

Introduction this section explains how to handle, clean, and disassemble the model 2010 multimeter. Disassembly drawings are located at the end of this section. Handling and cleaning to avoid contaminating pc board traces with body oil or other foreign matter, avoid touching the pc board traces whil...

Page 76: Static Sensitive Devices

Static sensitive devices cmos devices operate at very high impedance levels. Therefore, any static that builds up on you or your clothing may be sufficient to destroy these devices if they are not handled properly. Use the following precautions to avoid damaging them. Caution many cmos devices are i...

Page 77: Case Cover Removal

Case cover removal follow the steps below to remove the case cover to gain access to internal parts. Warning before removing the case cover, disconnect the line cord and any test leads from the instrument. 1. Remove handle — the handle serves as an adjustable tilt-bail. Adjust its position by gently...

Page 78: Motherboard Removal

1. Remove the cover from the instrument as explained in case cover removal. 2. The resistors used to select the trigger link lines are located next to the trigger link connector as shown in figure 5-1 . The “resistors” are actually solder beads that bridge pc-board pads. If the factory default lines...

Page 79: Front Panel Disassembly

Remove all the connections except the front amps connection by pulling the wires off the pin connectors. To remove the front panel amps input wire (white), first remove the amps fuse holder, and then use needle-nose pliers to grasp the amp wire near fuse housing. Push the wire forward and down to sn...

Page 80

3. Using a thin-bladed screw driver, pry the plastic pc board stop (located at the bottom of the display board) until the bar separates from the casing. Pull the display board from the front panel. 4. Remove the switch pad by pulling it from the front panel. Main cpu firmware replacement changing th...

Page 81: Removing Power Components

Removing power components the following procedures for removing the power transformer and/or power module require that the case cover and motherboard be removed, as previously explained. Power transformer removal perform the following steps to remove the power transformer: 1. Remove motherboard. 2. ...

Page 82: Instrument Re-Assembly

3. Disconnect the power module's ground wire. This green and yellow wire connects to a threaded stud on the chassis with a kep nut. 4. Squeeze the latches on either side of the power module while pushing the module from the access hole. Warning to avoid electrical shock, which could result in injury...

Page 83

Confidential proprietary.

Page 87: Replaceable

6 replaceable parts 6 replaceable parts.

Page 88: Introduction

Introduction this section contains replacement parts information and component layout drawings for the model 2010. Parts lists the electrical parts lists for the model 2010 are shown in tables 4-1 to 4-3. For part numbers to the various mechanical parts and assemblies, use the miscellaneous parts li...

Page 89

Table 6-1 mother board parts list circuit desig. Description keithley part no. At101 c101,103,111,116,118,122,124, 128,133,135,136,138,139,142, 149,152,153,159-163,167-170, 173,174,178,180,183,186,187, 190,193,197,198,201-208,210, 212-218,221,223,225,227,230, 232,233,249,250,290,299 c102 c104 c105 c...

Page 90

C296,297 c298 c306,307 cr102,103 cr104 cr106 cr110,118 cr111,112,116,117,119,126,133 ,134,142,143 cr120,122 cr121,123,127,128,131 cr132 cr135-141 e101,102 j1006 j1007 j1008 j1014 j1015 j1016 j1017 j1034 k101,102,104 k103 l101-106 l107,108 l109,111 l110 ls101 q101,102,153 q103,112,128,130, 147,171,18...

Page 91

Q125 q129,141,166,172 q137,138 q140,188 q142,148 q143,149 q144,150 q145,146 q151,168,169,175-178 q154,155 q156 q160 q162 q163,189,191,192,196 q164,165 q184 q187 r101,102 r104,105 r106 r109,134,329,382 r110,133 r111,122,140,165,182,190,200, 256,272,279,284,288,290,296, 298,299,358,380,391,398,408, 41...

Page 92

R147 r153 r155,169,339,387,388,427 r157,342 r158 r172 r185,372,385,398 r189 r194 r195 r196,212,217,220,221,264 r201,204,229,231,233, 238,244 r202,319,327,328,337,338,389, 390,433,445 r205 r214,218,422,441 r215 r216 r225,283 r226,228,235,237,245, 250,252, 255 r234 r241 r243,259,317,320 r246 r249 r261...

Page 93

R331 r332,365 r333,334,336 r335,400 r341,344 r345 r350 r353 r359 r360 r366,373 r368 r371,392,421 r384 r386 r405,407 r406 r412 r413 r414 r419 r423 r425,446 r428 r429 r430 r431 r444 r450 s101 tp102-106 u101 u102,118 u103,105,111 u104,170,171 u106,109,121,130, 134,182 u107,108,172 u110 u112 res, 1.8m, ...

Page 94

U114,168,173 u115,120 u116 u117,145 u123 u124 u131,178 u133,176 u135 u136 u137,184 u138 u139,166 u141 u142 u144 u146 u147,164,192 u148,153 u149 u150,155 u151,152 u154 u156 u157 u158 u159 u160 u161 u163 u165 u167 u174,177 u179 u180 u185 u187 u188,189 u190 ic, dual j-fet op-amp, op-282gs ic, quad comp...

Page 95

Vr103,104 vr105,106 vr112,113 vr115,121 vr116,119 vr120,vr102 vr122 vr123,124 vr125,126 y101 y102 diode, zener, 6.8v, mmsz5235bt1 diode, zener, 11v, mmsz11t1 diode, zener, 6.2v, mmsz6v2 diode, zener, 5.1v, bzx84c5v1 diode, zener, 3.3v, mmbz5226bl diode, zener, 6.2v, bzx84b6v2 diode, zener, 6.4v, in4...

Page 96

Table 6-2 display board parts list circuit desig. Description keithley part no. C413 c401,402,411 c406,408 c414 c403-405,407,409, 410,412 cr401,402 ds401 p1014 r419 r405,408,410,412 r420,421 r413 r401-404,406,409, 411,415,416 u401 u402,403 y401 cap, 22uf, 20%, 6.3, tantalum cap, .1uf, 20%, 50v, cera...

Page 97

Table 6-4 mechanical parts list description keithley part no. Banana jack, push-in, black banana jack, push-in, red bezel, rear card guide/shield chassis chassis assembly chassis assembly contact, current input cover cover panel, scanner display lens foot foot, extruded foot, rubber front panel fron...

Page 98

Confidential proprietary.

Page 99

Confidential proprietary.

Page 101: Specifications

A specifications a specifications.

Page 102: Specifications

Keithley instruments, inc. Cleveland, ohio 44139 drn. Ckd. App. Date date date part number ltr revisions app. Date form 28777a-sbg bruning 40-21 62198-sbg purchased item specifications 2010 low-noise multimeter hw 9/5/03 rev. C dc characteristics conditions: med (1 plc) 1 or slow (5 plc) test input ...

Page 103: Specifications

Keithley instruments, inc. Cleveland, ohio 44139 drn. Ckd. App. Date date date part number ltr revisions app. Date form 28777a-sbg bruning 40-21 62198-sbg purchased item specifications 2010 low-noise multimeter hw 9/5/03 rev. C high crest factor additional error ±(% of reading) 7 crest factor: 1–2 2...

Page 104: Specifications

Keithley instruments, inc. Cleveland, ohio 44139 drn. Ckd. App. Date date date part number ltr revisions app. Date form 28777a-sbg bruning 40-21 62198-sbg purchased item specifications 2010 low-noise multimeter hw 9/5/03 rev. C frequency and period characteristics 1,2 resolution accuracy acv frequen...

Page 105: Accuracy Calculations

Specifications a-5 accuracy calculations the following information discusses how to calculate accuracy for both dc and ac characteristics. Calculating dc characteristics accuracy dc characteristics accuracy is calculated as follows: accuracy = ±(ppm of reading + ppm of range) (ppm = parts per millio...

Page 106: Additional Derating Factors

A-6 specifications additional derating factors in some cases, additional derating factors must be applied to calculate certain accuracy values. For example, an additional derating factor of 0.02ppm/v must be added to dcv specifications for voltages over 500v. Before calculating accuracy, study the a...

Page 107: Calibration

B calibration command reference b calibration command ref- erence.

Page 108: Introduction

Introduction this appendix contains detailed information about the various model 2010 remote calibration commands. Section 2 of this manual covers detailed calibration procedures. For information about additional commands to control other instrument functions, refer to the model 2010 user's manual. ...

Page 109

:calibration :protected :dc :step0 :step1 :step2 :step3 :step4 :step5 :step6 :step7 :step8 :step9 :step10 :step11 :step12 :step13 :ac :step1 :step2 :step3 :step4 :step5 :step6 :step7 :step8 :step9 :step10 :step11 :step12 :step13 :step14 :step15 dc cal steps. Rear terminal short step. 1 front termina...

Page 110

Miscellaneous calibration commands miscellaneous commands perform miscellaneous calibration functions such as programming the calibration code and date. These commands are discussed in detail in the following paragraphs. :code (:calibration:protected:code) purpose to program the calibration code or ...

Page 111

:init (:calibration:protected:initiate) purpose to initiate comprehensive and factory calibration procedures. Format :cal:prot:init description the :init command enables model 2010 calibration when performing these procedures over the bus. This command must be sent to the unit after sending the :cod...

Page 112

:save (:calibration:protected:save) purpose to save calibration constants in eerom after the calibration procedure. Format :cal:prot:save description the :save command stores internally calculated calibration constants derived during both comprehensive and manufacturing calibration in eerom. (eerom ...

Page 113

:ndue (:calibration:protected:ndue) purpose to send the next calibration due date to the instrument. Format :cal:prot:ndue , , parameters = 1995 to 2094 = 1 to 12 = 1 to 31 query format :cal:prot:ndue? Response , , description the :ndue command allows you to store the date when calibration is next d...

Page 114: Dc Calibration Commands

Dc calibration commands the :dc commands perform calibration of the dcv, dci, and ohms functions. Table b-2 summarizes these calibration commands along with parameter limits. :step1 (:calibration:protected:dc:step1) purpose to perform front terminal short-circuit calibration. Format :cal:prot:dc:ste...

Page 115

:step2 (:calibration:protected:dc:step2) purpose to perform front terminal open-circuit calibration. Format :cal:prot:dc:step2 description :step2 performs the open-circuit calibration step in the comprehensive calibration procedure. Disconnect all cables and accessories from the input jacks before s...

Page 116

:step6 (:calibration:protected:dc:step6) purpose to program the 10 Ω 4-wire comprehensive calibration step. Format :cal:prot:dc:step6 parameter = 9 to 11 [ Ω ] description :step6 programs the 10 Ω 4-wire resistance comprehensive calibration step. The allowable range of the calibration resistance par...

Page 117

:step10 (calibration:protected:dc:step10) purpose to program the 1m Ω comprehensive calibration step. Format :cal:prot:dc:step10 parameter = 900e3 to 1.1e6 [ Ω ] description :step10 programs the 1m Ω comprehensive calibration step. The allowable range of the calibration resistance parameter is from ...

Page 118: Ac Calibration Commands

Ac calibration commands the :ac commands perform comprehensive (user) calibration of the acv and aci functions. Table b-3 summarizes these calibration commands. Table b-3 ac calibration commands command description :calibration :protected :ac :step 1 2 3 4 5 6 7 8 9 10 11 12 13 10mv ac at 1khz calib...

Page 119

:ac:step (calibration:protected:ac:step) purpose to program individual ac calibration steps. Format :cal:prot:ac:step parameters 1 10mv ac at 1khz calibration step. 2 100mv ac at 1khz calibration step. 3 100mv ac at 50khz calibration step. 4 1v ac at 1khz calibration step. 5 1v ac at 50khz calibrati...

Page 120: Remote Error Reporting

Manufacturing calibration commands the following three calibration steps are only performed at the factory or when the unit has been repaired: :calibration:protected:ac:step14 1v ac at 3hz :calibration:protected:ac:step15 1v ac at 1khz :calibration:protected:dc:step0 rear terminal short circuit :ac:...

Page 121: Error Summary

Error summary table b-4 summarizes model 2010 calibration errors. Table b-4 calibration error summary error number description +400 +401 +402 +403 +404 +405 +406 +407 +408 +409 +410 +411 +412 +413 +414 +415 +416 +417 +418 +419 +420 +421 +422 +423 +424 +425 "10 vdc zero error" "100 vdc zero error" "1...

Page 122

+454 +455 +456 +457 +458 +459 +460 +461 +462 +463 +464 +465 +466 +467 +468 +469 +470 +471 +472 +473 +474 +475 +476 +477 +478 +479 +480 +481 +482 +483 +484 +485 +486 +487 +490 +499 "100m vac zero error" "100m vac full scale error" "1 vac zero error" "1 vac full scale error" "1 vac noise error" "10 va...

Page 123: Error Queue

Error queue as with other model 2010 errors, any calibration error will be reported in the bus error queue. You can read this queue by using the :syst:err? Query. The model 2010 will respond with the appropriate error message, as summarized in table b-4 . Status byte eav (error available) bit whenev...

Page 124: Using The *opc Command

Using the *opc command the *opc (operation complete) command can also be used to detect the completion of each calibration step. To use *opc to detect the end of each calibration step, you must do the following: 1. Enable operation complete by sending *ese 1. This command sets the opc (operation com...

Page 125: Calibration

C calibration program c calibration program.

Page 126: Introduction

Introduction this appendix includes a calibration program written in basic to help you in calibrate the model 2010. Refer to section 2 for more details on calibration procedures, equipment, and connections. Computer hardware requirements the following computer hardware is required to run the calibra...

Page 127: General Program Instructions

General program instructions 1. With the power off, connect the model 2010 and the calibrator to the ieee-488 interface of the computer. Be sure to use shielded ieee-488 cables for bus connections. 2. Turn on the computer, the model 2010, and the calibrator. Allow the model 2010 and the calibrator t...

Page 128

Program c-1. Qbasic calibration program ' model 2010 calibration program for use with the fluke 5700a calibrator. ' rev. 1.0, 9/11/95 open "ieee" for output as #1 ' open ieee-488 output path. Open "ieee" for input as #2 ' open ieee-488 input path. Print #1, "interm crlf" ' set input terminator. Prin...

Page 129

Case 11, 14, 24 j$ = "amps" if i = 14 then j$ = "input hi" print #1, "output 4;stby" print "connect calibrator to "; j$; " and input lo jacks." gosub keycheck print #1, "output 4;"; msg$ print #1, "output 4;oper" end select if i > 2 then gosub settle print #1, "output 16;"; c$; cmd$; ";*opc" ' send ...

Page 130

Print #1, "output 16;:syst:err?" ' query error queue. Print #1, "enter 16" input #2, e, err$ if e 0 then beep: print err$: goto errcheck' display error. Return ' settle: ' calibrator settling routine. Do: print #1, "output 4;isr?" ' query status register. Print #1, "enter 4" input #2, s loop until (...

Page 131: Index

Index a aborting calibration 2-5 ac calibration commands b-12 ac current calibration 2-12, 2-18 ac voltage calibration 2-11, 2-18 accuracy calculations a-5 additional derating factors a-6 amps input 4-9 analog circuitry 4-8 analog signal switching states 4-13 assembly drawings 5-3 c calculating ac c...

Page 132

M main cpu firmware replacement 5-7 manufacturing calibration 2-20 manufacturing calibration commands b-14 measuring synthesizer signal amplitude 2-24 memory circuits 4-7 microcontroller 4-6 microprocessor 4-6 miscellaneous calibration commands b-4 motherboard removal 5-5 multiplexer and a/d convert...

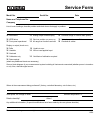

Page 133: Service Form

Service form model no. Serial no. Date name and telephone no. Company list all control settings, describe problem and check boxes that apply to problem. ❏ intermittent ❏ analog output follows display ❏ particular range or function bad; specify ❏ ieee failure ❏ obvious problem on power-up ❏ batteries...

Page 134

Specifications are subject to change without notice. All keithley trademarks and trade names are the property of keithley instruments, inc. All other trademarks and trade names are the property of their respective companies. A g r e a t e r m e a s u r e o f c o n f i d e n c e keithley instruments,...