- DL manuals

- KEM

- Engine

- KODIAK MARINE

- Installation Instructions Manual

KEM KODIAK MARINE Installation Instructions Manual

Summary of KODIAK MARINE

Page 1

Kodiak marine certified supercharged 6.2l lsa ersonal injury kem equipment inc 10800 sw herman rd. Tualatin, or. 97062 ph# (503) 692-5012 fax# (503) 692-1098 www.Kemequipment.Com km10929.

Page 2

2.

Page 3: Kodiak

3 kodiak supercharged lsa marine engine critical fuel system installation instructions for the builder/installer kem equipment inc. Would like to congratulate you on your decision to recommend the supercharged lsa marine engine to your valued customer. The kodiak 6.2l lsa supercharged marine fuel sy...

Page 4

4 plumbing: the fuel supply pick up tube, fuel lines, and fittings shall be no smaller than ½” inside diameter between the fuel tank and aero motive high-pressure fuel pump. The fuel pump must also have the supplied 100 micron filter installed on the inlet side of the fuel pump. When using an auxili...

Page 5

5 warning: carbon monoxide exposure carbon monoxide is an odorless, colorless and tasteless gas that cannot be smelled, seen or tasted. Over exposure to carbon monoxide gas may lead to brain damage, unconsciousness or even death. Carbon monoxide is a hazardous gas that is produced when items contain...

Page 6

6 warning: electrical shock hazard the ignition system can cause severe shock if proper precautions are not taken. Warning: overspeed protection the engine is equipped with an overspeed shutdown mode to protect against damage to the engine with possible personal injury, loss of life, or property dam...

Page 7

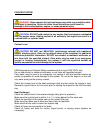

7 a warning: indicates a potentially hazardous situation, which, if not avoided, could result in death or serious injury. A caution: indicates a potentially hazardous situation, which, if not avoided, could result in damage to engine or property . A note: provides other helpful information that does...

Page 8

8 table of contents introduction page 10 how to use this manual engine identification page 12-14 model identification parts and service service literature component identification malfunction indicator light (mil) page 15 starting the engine page 16 stopping the engine page 17 normal conditions main...

Page 9

9 fuel injection system page 24-26 fuel pump fuel filter fuel pressure regulator fuel pressure fuel recommendations fuel type fuel quality changes power loss at higher elevations ignition systems page 27 type of ignition system spark plugs storage page 28-31 lay up inspections troubleshooting page 3...

Page 10

10 introduction please read and follow any and all specific warnings , cautions and notes that are contained in this manual. Kem equipment, inc. Is pleased that you have selected a kodiak engine for your requirements. Kem equipment, inc. Takes great pride in our tradition of quality products produce...

Page 11

11 how to use this manual this manual contains instructions on the safe operation and preventive maintenance of your kodiak marine engine. We urge you to read this manual prior to start up of the engine. The table of contents permits you to quickly open the manual to any section. Kem equipment, inc....

Page 12

12 engine identification model identification an identification placard is affixed to the engine. The label contains the engine family number and a model, which identifies the engine from other kem engines. The engine model number and serial number are required when seeking information concerning th...

Page 13

13 component identification.

Page 14

14 1 heat exchanger (intercooler/oil cooler) 2 heat exchanger (engine main) 3 water pump (intercooler) 4 reservoir (intercooler) 5 pump / heat exchanger mount 6 coolant tee 7 coolant transfer pipe (out) 8 coolant transfer pipe (in) 9 coolant overflow reservoir 10 coil pack 11 mefi v ecm 12 ecm vibra...

Page 15

15 malfunction indicator light note: if the check engine light is illuminated, it will remain on until the problem is corrected and the engine has gone through three consecutive warm up cycles, or if the light has been cleared by a service technician with a scan tool. One warm up cycle is a starting...

Page 16

16 starting the engine prior to starting the engine the following must be performed. Check engine oil level. Check for fuel leaks. Run bilge blower for a minimum of 10 minutes. Run bilge pump to remove any excess water, follow and repair any leaks. Warning: the bilge can accumulate explosive fumes. ...

Page 17

17 stopping the engine warning: the engine may continue to run after ignition is turned off, turn the ignition switch immediately to onand allow the engine to idle until it has cooled enough to stop. Warning: avoid injury when checking a hot engine. Allow the engine to cool down before removing the ...

Page 18

18 maintenance instructions caution : neglecting proper maintenance can cause premature engine component failures. Initial start-up maintenance the initial start-up checks must be made before putting the engine into service. Please refer to the maintenance schedule on page 37 and perform the initial...

Page 19

19 adding engine oil it is normal to add some oil in the period of time between oil changes. The amount will vary with the severity of operation. When adding or replacing engine oil, be sure the oil meets or exceeds the recommended specification. Note: use only mobil 1 5w-30 full synthetic or equiva...

Page 20

20 changing engine oil and filter engine oil quality note: to achieve proper engine performance and durability, it is important that you use only engine lubricating oils of the correct type in your engine. Quality oil also provides maximum efficiency for crankcase ventilation systems, which reduces ...

Page 21

21 engine flame arrestor caution: service the flame arrestor more frequently under severely dusty or dirty conditions. Your flame arrestor filters air entering the engine induction system and acts as a silencer. Air that contains dirt and grit produces an abrasive fuel mixture and can cause severe d...

Page 22

22 cooling system warning: never remove the heat exchanger cap under any condition while the engine is operating. Failure to follow these instructions could result in damage to the cooling system, engine, or cause personal injury. Caution: do not add coolant to any engine that has become overheated ...

Page 23

23 heat exchanger plumbing serpentine belt some gm powertrain engines utilize serpentine belts on the front of the engine. This type of belt system incorporates a belt-tensioning device that keeps the belt adjusted to the proper tension. No manual adjustments are necessary. This belt should be inspe...

Page 24

24 fuel injection system caution: failure to change the fuel system filter as recommended can result in premature failure of fuel injection system components. Warning: use extreme care when changing the fuel filter. Gasoline is highly flammable and under pressure. It should not be exposed to open fl...

Page 25

25 fuel filter a fuel filter is used in the fuel supply line to the engine. This helps to prevent any contaminates from entering or plugging the fuel injectors. The fuel filter is located in the supply line between the fuel tank, fuel pump and the engine. This filter is a user serviceable filter and...

Page 26

26 fuel recommendation warning: use extreme care when changing the fuel filter. Gasoline is highly flammable and under pressure. It should not be exposed to open flame, sparks, or hot engine components. Allow the engine to cool to ambient temperature prior to changing fuel filters. Warning: the bilg...

Page 27

27 ignition system warning: high voltage ignition system. Electrical shock hazard. Warning: the bilge can accumulate explosive fumes. The bilge blower will evacuate the fumes. The bilge blower must be run for a minimum of 10 minutes prior to cranking the engine. Type of ignition system this engine i...

Page 28

28 storage (lay-up)-one month caution: make sure the water side of heat exchanger are drained when ambient temperature is below 32 degrees f. Start the engine open throttle for a short burst of speed shut off fuel supply to the engine, run engine until completely out of gasoline. Shutoff engine. Lea...

Page 29

29 100,300,500,700,900-hour inspection warning: make sure key is not in ignition and no electrical equipment is energized prior to any engine check or operation. Do not energize engine prior to performing the following steps. Open engine hatch cover and let compartment air out for ten minutes or mor...

Page 30

30 400-hour inspection perform the following inspection on your engine at the 400-hour interval. Warning: make sure key is not in ignition and no electrical equipment is energized prior to any engine check or operation. Do not energize engine prior to performing the following steps. Open engine hatc...

Page 31

31 800 hour inspection perform the following inspection at 800-hour intervals. Warning: make sure key is not in ignition and no electrical equipment is energized prior to any engine check or operation. Do not energize engine prior to performing the following steps. Open engine hatch cover and let co...

Page 32

32 troubleshooting warning: the bilge can accumulate explosive fumes. The bilge blower will evacuate the fumes. The bilge blower must be run for a minimum of 10 minutes prior to cranking the engine. The largest percentage of all malfunctioning equipment will be due to simple or small problems. Most ...

Page 33

33 diagnosis warning: make sure there are no fuel leaks before going any further. Clean up any spills and always work in a well-ventilated area. Warning: to avoid any electrical injuries always replace any broken wires before proceeding. Warning: the bilge can accumulate explosive fumes. The bilge b...

Page 34

34 engine cranks, does not start caution: failure to change the fuel system filter as recommended can result in premature failure of fuel injection system components. Warning: use extreme care when changing the fuel filter. Gasoline is highly flammable and under pressure. It should not be exposed to...

Page 35

35 engine runs hot warning: never remove the radiator cap under any condition while the engine is operating. Failure to follow these instructions could result in damage to the cooling system, engine, or cause personal injury. Warning: the bilge can accumulate explosive fumes. The bilge blower will e...

Page 36

36 specifications quick reference guide engine 6.2l engine oil mobil 1 5w-30 only oil filter (remote mount) pf-2 in-line fuel filter km10122 water separator 3120r-rac-32 spark arrester n7600esv38 spark plugs 11610259 spark plug gap .040 fuel pump 1824270300-7 fuel pressure regulator 1544270200-5 mai...

Page 37

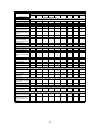

37 daily every 25 hours every 50 hours every 75 hours every 100 hours every 150 hours every 200 hours every 300 hours every 400 hours inspect fuel system for leaks inspect engine for fluid leaks x check engine oil x replace engine oil and filter x inspect accessory drive belts x x x inspect ecm isol...

Page 38

38 kodiak marine engine warranty 1 year limited parts warranty “supercharged engines” • kodiak marine dealer; this limited warranty applies to the first retail purchaser and each subsequent owner during the applicable warranty time period. • kodiak marine will repair or replace, at its option, any p...

Page 39

39 exclusions: this warranty does not extend to the following: • conditions caused by lack of routine maintenance (as outlined in the operator’s manual) • conditions caused by the use of an impeller or impellers that do not allow the inboard engine to run in its recommended full throttle rpm range •...

Page 40

40 diagnostic error codes warning: fire, shock, and burn danger: when performing any diagnostics or service work use caution. This system has extreme fuel pressures and a high voltage ignition. Caution : electronic controls contain static-sensitive parts. Observe the following precautions to prevent...

Page 41

41 if the scan tool does not power up, refer to scan tool does not power up . Ignition on, engine off, verify communication with all of the control modules on the vehicle. If the scan tool does not communicate with one or more of the expected control modules, refer to scan tool does not communicate ...

Page 42

42 spn 94 spn descriptors spn 94 fmi 3: fuel pressure sensor voltage above normal or shorted high spn 94 fmi 4: fuel pressure sensor voltage below normal or shorted low spn 94 fmi 15: fuel pressure data valid but above normal range-least severe level spn 94 fmi 17: fuel pressure data valid but below...

Page 43

43 spn 108 spn descriptors spn 108 fmi 2: barometric pressure (baro) sensor voltage data erratic, intermittent or incorrect spn 108 fmi 3: barometric pressure (baro) sensor voltage above normal or shorted high spn 108 fmi 4: barometric pressure (baro) sensor voltage below normal or shorted low spn 1...

Page 44

44 spn 651, 652, 653, 654, 655, 656, 657, or 658 spn descriptors spn 651 fmi 3: fuel injector 1 voltage above normal or shorted high spn 651 fmi 5: fuel injector 1 current below normal or open circuit spn 652 fmi 3: fuel injector 2 voltage above normal or shorted high spn 652 fmi 5: fuel injector 2 ...

Page 45

45 spn 65541, 65542, 65543, 65544, 65545, 65546, 65547, or 65548 spn descriptors spn 65541 fmi 4: ignition coil 1 voltage below normal or shorted low spn 65541 fmi 5: ignition coil 1 current below normal or open circuit spn 65542 fmi 4: ignition coil 2 voltage below normal or shorted low spn 65542 f...

Page 46

46 spn 65570 spn descriptors spn 65570 fmi 2: cam phaser w data erratic, intermittent, or incorrect spn 65570 fmi 4: cam phaser w voltage below normal or shorted low spn 65570 fmi 5: cam phaser w short high or open spn 65570 fmi 7: cam phaser w accuracy mechanical system not responding or out of adj...

Page 47

47 spn 65601, 65602, or 65610 spn descriptors spn 65601 fmi 2: throttle position (tp) sensor 2 data erratic, intermittent or incorrect spn 65602 fmi 2: throttle position (tp) sensor 1 data erratic, intermittent or incorrect spn 65610 fmi 2: throttle position (tp) sensor 1 and 2 data erratic, intermi...

Page 48

48 spn 65701 or 65702 spn descriptors spn 65701 fmi 31: general warning sensor 1 not available spn 65702 fmi 31: general warning sensor 2 not available spn 65710 spn descriptors spn 65710 fmi 31: emergency stop warning not available spn 65723 spn descriptors spn 65723 fmi 2: camshaft position (cmp) ...

Page 49

49 spn 66005 spn descriptor spn 66005 fmi 3: governor status lamp (gsl) voltage above normal or shorted high spn 66005 fmi 5: governor status lamp (gsl) current below normal or open circuit spn 66006 spn descriptor spn 66006 fmi 3: dtc lamp 3 voltage above normal or shorted high spn 66006 fmi 5: dtc...

Page 50: United States

50 united states oregon bend all season rv & marine 541-382-5009 central lake marine 541-385-7791 clackamas portland performance marine 503-650-0001 central point rick's boat repair 541-664-8022 coos bay y marina 541-888-5501 corvallis southside marine 541-753-4241 eugene clemens marine 541-688-5483...

Page 51: United States

51 united states (continued) washington chinook chinook marine repair 360-777-8361 longview columbia marine services 360-430-1010 seattle coastal marine engine 206-784-3703 tacoma harbor services 888-627-3066 washougal riverside marina 360-835-8553 woodinville doug's boats 800-215-3684 3 rivers mari...