- DL manuals

- KEM

- Engine

- KODIAK MARINE

- Operator's Manual

KEM KODIAK MARINE Operator's Manual

Summary of KODIAK MARINE

Page 1

Kodiak marine marine operators manual 4.3l 5.3l and 6.2l sidi injected marine engines kem equipment inc 10800 sw herman rd tualatin, or. 97062 phone (503) 692-5012 fax (503) 692-1098 km 10875.

Page 2

2.

Page 3

Warning—danger of death or personal injury warning: extreme high fuel rail pressure. The sidi fuel injectors and fuel rail have extreme high fuel pressures. Do not attempt to remove or service these parts. This poses a potentially hazardous situation that if not avoided, could result in severe perso...

Page 4

Warning: proper use any unauthorized modifications to or use of this engine outside its specified mechanical, electrical, or other operating limits may cause personal injury and/or property damage, including damage to the engine. Any such unauthorized modifications: (i) constitute "misuse" and/or "n...

Page 5

Warning: engine damage may occur: all generation v gm engines must be vacuum filled with coolant. If you need assistance or have questions call your local service dealer. Failure to vacuum fill this engine with the recommended coolant may void all warranty (see page 58) caution: welding when welding...

Page 6

Table of contents introduction page 8-9 safety summary how to use this manual sidi fuel injection engine identification page 10-12 engine id component id pre operational inspection page 14-16 engine fluid levels belts battery connections hoses flame arrestor malfunction indicator light (mil) startin...

Page 7

Fuel injection system page 29-30 fuel filter fuel recommendation fuel type fuel quality changes power loss at higher elevations ignition system page 31 troubleshooting page 32-36 engine does not crank engine will crank intermittently when the engine makes a stuttering or chattering noise engine cran...

Page 8

Introduction kem equipment, inc. Is pleased that you have selected a kodiak engine for your requirements. Kem equipment, inc. Takes great pride in our tradition of quality products produced from the gm powertrain line of marine gasoline engines. Kem equipment, inc. Engines are inspected and tested b...

Page 9

How to use this manual this manual is designed to help you get to know your engine and become familiar with the engines various controls. During instruction, you will learn how to take care of your engine and what services need to be performed to keep it in excellent running condition. The table of ...

Page 10

Engine identification model identification an identification placard is affixed to the engine. The label contains the engine family number and a model, which identifies the engine from other kem engines. The engine model number and serial number are required when seeking information concerning the e...

Page 11

Component identification 11.

Page 12

Component identification the illustrations above show the general location of engine controls, engine components and their functions. These illustrations will help identify where these parts are located on the engine. Locations will vary from engine to engine. 12.

Page 13

Parts and service replacement parts can be obtained through your local kodiak engine dealer. Kodiak dealers are equipped to perform major and minor repairs. They are anxious to see that all of your maintenance and service needs are quickly and courteously completed. Please contact kem equipment inc....

Page 14

Pre-operational inspection warning: remove the key from the ignition prior to any engine check or operation. Do not energize any engine prior to performing any of the following. Your kodiak marine engine was inspected and test run before leaving the factory. Before operating a new engine, you must f...

Page 15

Inspect the spark arrester for any obstructions (bugs, leaves etc.,) clean or replace as needed. 11. Check the exterior of the heat exchanger. Follow and fix any leaks before continuing. 12. Check the alternator belt for any extra play; adjust as necessary. Does not apply to all engines. 13. Tighten...

Page 16: Caution-

Malfunction indicator light caution- notice to builder/installer this engine requires use of a mil. A mil (malfunction indicator lamp) must be installed with this engine to be in compliance with epa and carb regulations. There are two lights on the dash to indicate engine related problems. The opera...

Page 17

Starting the engine prior to starting the engine the following must be performed. 1. Check engine oil level. 2. Check for fuel leaks. 3. Run bilge blower for a minimum of 10 minutes 4. Check coolant level 5. Check bilge for excess water before starting engine warning: the bilge can accumulate explos...

Page 18

Warning: extreme high fuel rail pressure. The sidi fuel injectors and fuel rail have extreme high fuel pressures. Do not attempt to remove or service these parts. This poses a potentially hazardous situation that if not avoided, could result in severe personal injury or death, damage to engine and o...

Page 19

Stopping the engine normal conditions let the engine idle for at least one minute prior to stopping the engine to reduce residual heat in engine components. Not doing this will not harm anything, but gives the engine a chance to reduce the temperature of many components. Stopping the engine under ab...

Page 20

Maintenance instructions warning: extreme high fuel rail pressure. The sidi fuel injectors and fuel rail have extreme high fuel pressures. Do not attempt to remove or service these parts. This poses a potentially hazardous situation that if not avoided, could result in severe personal injury or deat...

Page 21

4.3l sidi general engine specifications engine type gm lv1 v6 ohv coolant capacity 4 us gallons recommended coolant dexcool 50/50 mix high pressure fuel filter/regulator napa #3737 spark plugs ac delco #41-114 gm #12622441 spark plug gap 1.025 mm .040 +/- .002 spark arrestor a7600esv38 oil pan capac...

Page 22

5.3l sidi general engine specifications engine type gm l83 v8 ohv coolant capacity 5 us gallons recommended coolant dexcool 50/50 mix high pressure fuel filter/regulator napa #3737 spark plugs ac delco #41-114 gm #12622441 spark plug gap 1.025 mm .040 +/- .002 spark arrestor a7600esv38 oil pan capac...

Page 23

6.2l sidi general engine specifications engine type gm l86 v8 ohv coolant capacity 5 us gallons recommended coolant dexcool 50/50 mix high pressure fuel filter/regulator napa #3737 spark plugs ac delco #41-114 gm #12622441 spark plug gap 1.025 mm .040 +/- .002 spark arrestor f040j6 oil pan capacity ...

Page 24

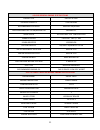

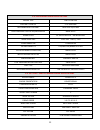

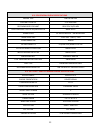

Maintenance schedule engine check points service interval daily every 25 hours every 50 hours every 75 hours every 100 hours every 150 hours every 200 hours every 300 hours every 400 hours general maintenance inspect fuel system for leaks prior to any service or maintenance activity inspect engine f...

Page 25

Changing engine oil and filter under normal operating conditions, the engine oil and filter must be changed every 100 hours or every 12 months whichever occurs first. Use of premium quality oil and filters is recommended. The oil and filter should be changed more often if the engine is operating in ...

Page 26

Oil filter note: ensure the old filter gasket is removed prior to installing the new filter. The kodiak gm powertrain engines use an ac delco (or equivalent) oil filter as original equipment. An equivalent oil filter must be used when servicing the engine (see engine specifications starting on page ...

Page 27

Cooling system kem equipment and gm powertrain recommends the use of dex cool coolantin all gm engines. A 50/50 mixture is recommended. Warning: engine damage may occur: all generation v gm engines must be vacuum filled with coolant. If you need assistance or have questions call your local service d...

Page 28

Heat exchanger 1. Check the coolant level in the heat exchanger daily (prior to operation) 2. Make sure the coolant level is within ¾ to 1-½ inches below the filler neck seat 3. Check the condition of the rubber seal on the coolant filler cap 4. Make sure the rubber seal is clean and free of any dir...

Page 29

Fuel injection system warning: extreme high fuel rail pressure. The sidi fuel injectors and fuel rail have extreme high fuel pressures. Do not attempt to remove or service these parts. This poses a potentially hazardous situation that if not avoided, could result in severe personal injury or death, ...

Page 30

Fuel recommendation warning: use extreme care when changing the fuel filter. Gasoline is highly flammable and under pressure. It should not be exposed to open flame, sparks, or hot engine components. Allow the engine to cool to ambient temperature prior to changing fuel filters. Warning: the bilge c...

Page 31

Ignition system warning: high voltage ignition system. Electrical shock hazard. Warning: the bilge can accumulate explosive fumes. The bilge blower will evacuate the fumes. The bilge blower must be run for a minimum of 10 minutes prior to cranking the engine. Type of ignition system the ignition on ...

Page 32

Troubleshooting warning: the bilge can accumulate explosive fumes. The bilge blower will evacuate the fumes. The bilge blower must be run for a minimum of 10 minutes prior to cranking the engine. Note: a malfunction indicator light must be installed with this engine to be compliant with epa and carb...

Page 33

Engine does not crank warning: make sure there are no fuel leaks before going any further. Clean up any spills and always work in a well-ventilated area. Warning: to avoid any electrical injuries always replace any broken wires before proceeding. Warning: the bilge can accumulate explosive fumes. Th...

Page 34

Engine cranks but does not start caution: failure to change the fuel system filter as recommended can result in premature failure of the fuel injection system components. Warning: use extreme care when changing the fuel filter. Gasoline is highly flammable and under pressure. It should not be expose...

Page 35

Engine runs hot warning: never remove the radiator cap under any condition while the engine is operating. Failure to follow these instructions could result in damage to the cooling system, engine, or cause personal injury. Warning: the bilge can accumulate explosive fumes. The bilge blower will evac...

Page 36

Emissions warning: proper use any unauthorized modifications to or use of this engine outside its specified mechanical, electrical, or other operating limits may cause personal injury and/or property damage, including damage to the engine. Any such unauthorized modifications: (i) constitute "misuse"...

Page 37

Storage (lay-up) one month 1. Check coolant protection and fluid levels. 2. Add proper amount of marine formula stabil fuel additive or equivalent to the fuel tank. 3. Start the engine 4. Treat upper cylinders by spraying engine fogger or equivalent into the air intake for about one minute. 5. Allow...

Page 38

100, 400, 500, 800, 900, hour inspection warning: make sure key is not in ignition and no electrical equipment is energized prior to any engine check or operation. Do not energize engine prior to performing the following steps. 1. Open engine hatch cover and let compartment air out for ten minutes o...

Page 39

800 hour inspection warning: make sure key is not in ignition and no electrical equipment is energized prior to any engine check or operation. Do not energize engine prior to performing the following steps. 1. Open engine hatch cover and let compartment air out for ten minutes or more. 2. Make sure ...

Page 40

California emission control warranty statement your warranty rights and obligations the california air resources board and kem equipment, inc. / kodiak marine are pleased to explain the emission control system warranty on your 2011 model year inboard/stern drive engine. In california, new inboard/st...

Page 41

General emissions warranty coverage kem equipment, inc. / kodiak marine warrants to the ultimate purchaser and each subsequent purchaser that this engine is: (1) designed, built and equipped so as to conform with all applicable regulations adopted by the air resources board pursuant to its authority...

Page 42

(7) kem equipment, inc. / kodiak marine is liable for damages to other engine components proximately caused by a failure under warranty of any warranted part. (8) throughout the engine’s warranty period defined above, kem equipment, inc. / kodiak marine will maintain a supply of warranted parts suff...

Page 43

Exclusions the repair or replacement of any warranted part otherwise eligible for warranty coverage may be excluded from such warranty coverage if kem equipment, inc. / kodiak marine demonstrates that the engine has been abused, neglected, or improperly maintained, and that such abuse, neglect, or i...

Page 44: 3 Year Limited Warranty

Kodiak marine engine warranty 3 year limited warranty effective january 1 st , 2011 products covered length of warranty (from date of original retail purchase) non-commercial non-rental commercial/rental inboard engines 2011 and newer 36 months/480 hours 12 months/480 hours • the kodiak marine inboa...

Page 45

This warranty does not extend to the following: • conditions caused by lack of routine maintenance (as outlined in the operator’s manual) • conditions caused by the use of an impeller or impellers that do not allow the inboard engine to run in its recommended full throttle rpm range • all electrical...

Page 46

On board diagnostic (obd) mefi controlled marine engine warning: fire, shock, and burn danger: when performing any diagnostics or service work use caution. This system has extreme fuel pressures and a high voltage ignition. Caution: electronic controls contain static-sensitive parts. Observe the fol...

Page 47

7. Inspect for aftermarket devices that could affect the operation of the system. 8. Search for applicable service bulletins. 9. Install a scan tool. Verify that the scan tool powers up. 10. Ignition on, engine off, verify communication with all of the control modules on the vehicle. 11. Verify that...

Page 48

Diagnostic error codes: spn 94 spn descriptors spn 94 fmi 3: fuel pressure sensor voltage above normal or shorted high spn 94 fmi 4: fuel pressure sensor voltage below normal or shorted low spn 94 fmi 15: fuel pressure data valid but above normal range-least severe level spn 94 fmi 17: fuel pressure...

Page 49

Spn 108 spn descriptors spn 108 fmi 2: barometric pressure (baro) sensor voltage data erratic, intermittent or incorrect spn 108 fmi 3: barometric pressure (baro) sensor voltage above normal or shorted high spn 108 fmi 4: barometric pressure (baro) sensor voltage below normal or shorted low spn 108 ...

Page 50

Spn 651, 652, 653, 654, 655, 656, 657, or 658 spn descriptors spn 651 fmi 3: fuel injector 1 voltage above normal or shorted high spn 651 fmi 5: fuel injector 1 current below normal or open circuit spn 652 fmi 3: fuel injector 2 voltage above normal or shorted high spn 652 fmi 5: fuel injector 2 cur...

Page 51

Spn 65559 spn descriptors spn 65559 fmi 11: can bus hardware fault root cause unknown spn 65560 spn descriptors spn 65560 fmi 9: can bus governor command abnormal update rate spn 65561, 65562, 65563, or 65564 spn descriptors spn 65561 fmi 0: oxygen sensor bank a sensor 1 data valid but above normal ...

Page 52

Spn 65570 spn descriptors spn 65570 fmi 2: cam phaser w data erratic, intermittent, or incorrect spn 65570 fmi 4: cam phaser w voltage below normal or shorted low spn 65570 fmi 5: cam phaser w short high or open spn 65570 fmi 7: cam phaser w accuracy mechanical system not responding or out of adjust...

Page 53

Spn 65620 or 65621 spn descriptors spn 65620 fmi 4: 5 volt reference a circuit voltage below normal or shorted low spn 65621 fmi 4: 5 volt reference b circuit voltage below normal or shorted low spn 65671 or 65672 spn descriptors spn 65671 fmi 0: catalytic converter a temperature sensor data valid b...

Page 54

Spn 65701 or 65702 spn descriptors spn 65701 fmi 31: general warning sensor 1 not available spn 65702 fmi 31: general warning sensor 2 not available spn 65710 spn descriptors spn 65710 fmi 31: emergency stop warning not available spn 65723 spn descriptors spn 65723 fmi 2: camshaft position (cmp) sen...

Page 55

Spn 66005 spn descriptor spn 66005 fmi 3: governor status lamp (gsl) voltage above normal or shorted high spn 66005 fmi 5: governor status lamp (gsl) current below normal or open circuit spn 66006 spn descriptor spn 66006 fmi 3: dtc lamp 3 voltage above normal or shorted high spn 66006 fmi 5: dtc la...

Page 56

Spn 66018 spn descriptor spn 66018 fmi 3: tachometer voltage above normal or shorted high spn 66018 fmi 5: tachometer current below normal or open circuit spn 66019 or 66020 spn descriptors spn 66019 fmi 3: oxygen sensor bank a sensor 1 heater voltage above normal or shorted high spn 66019 fmi 5: ox...

Page 57

Spn 66040-66043 spn descriptor spn 66040 fmi 3: oem output driver 1 voltage above normal or shorted high spn 66040 fmi 5: oem output driver 1 current below normal or open circuit spn 66041 fmi 3: oem output driver 2 voltage above normal or shorted high spn 66041 fmi 5: oem output driver 2 current be...

Page 58

Notice to builders and service dealers generation v engine coolant filling procedure for the following gm engines: kodiak gm 4.3l di kodiak gm 5.3l di kodiak gm 6.2l di a heat exchanger and engine block coolant fill and air lock removal tool is necessary and must be used to purge the air lock from t...

Page 59: United States

United states alaska anchorage silver streak 907-344-6151 professional marine 907-562-2471 cordova harbor hydraulics 907-424-3472 north pole arctic marine 907-488-5242 wasilla valley diesel and marine 907-373-2613 wasilla arctic cat 907-376-5845 fairbanks boat shop inc.907-479-2518 arizona bullhead ...

Page 60: Washington

Oregon city oregon city marine 503-656-4276 portland advanced marine 503-762-2294 pacific power boats 503-288-9350 sigler marine 503-252-5431 salem dennis' boat shop 503-363-2898 south beach newport marine and rv 541-867-3704 tigard steven's marine 503-620-7023 washington chinook chinook marine repa...

Page 61

10800 sw herman rd. Tualatin, or 97062 ph: 503-692-5012 fx: 503-692-1098 www.Kemequipment.Com oem notice to all boat builder s, riggers and end users kem equipment is issuing this notice effective immediately 6/24/14 to meet epa and carb requirements: all kodiak certified marine engines sold after j...