- DL manuals

- Kemppi

- Welding System

- FastMig KM300

- Operating Manual

Kemppi FastMig KM300 Operating Manual

Gebruiksaanwijzing • Nederlands

Manuel d’utilisation • Français

Manual de instrucciones • Español

Instrukcja obsługi • Polski

Инструкции по эксплуатации • По-русски

Käyttöohje • Suomi

Bruksanvisning • Svenska

Bruksanvisning • Norsk

Brugsanvisning • Dansk

Operating manual • English

Gebrauchsanweisung • Deutsch

1903310

0901

FI

SV

NO

DA

EN

DE

NL

FR

ES

PL

RU

F

AST

M

IG™

KM 300

KM 400

KM 500

Summary of FastMig KM300

Page 1

Gebruiksaanwijzing • nederlands manuel d’utilisation • français manual de instrucciones • español instrukcja obsługi • polski Инструкции по эксплуатации • По-русски käyttöohje • suomi bruksanvisning • svenska bruksanvisning • norsk brugsanvisning • dansk operating manual • english gebrauchsanweisung...

Page 3: Operating Manual

En operating manual english fastm ig km 300, 400, 500 / © kemppi o y /0901 fi sv no da en de nl fr es pl ru.

Page 4: Contents

Contents 1. Preface ....................................................................................................... 3 1.1 general ................................................................................................................................................... 3 1.2 safety i...

Page 5: Preface

1. Preface 1.1 general congratulations on your choice of the fastmig™ km-series power source. Reliable and durable, kemppi products are affordable to maintain, and they increase your work productivity. This user manual contains important information on the use, maintenance, and safety of your kemppi...

Page 6

Spatter and fire safety • welding is always classified as hot work, so pay attention to fire safety regulations during welding and after it. • remember that fire can break out from sparks even several hours after the welding work is completed. • protect the environment from welding splatter. Remove ...

Page 7

• protect the machine from sand and dust during use and in storage. • the recommended operating temperature range is -20 to +40 °c. The machine’s operation efficiency decreases and it becomes more prone to damage if used in temperatures in excess of 40 °c. • place the machine so that it is not expos...

Page 8

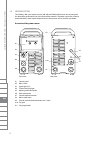

1.3 introduction the fastmig™ km-series power sources 300, 400, and 500 are mig power sources designed for demanding professional use in the three-phase network. The power source has a control panel that allows ready control of the functions of the power source and the wire feeder. Overview of the p...

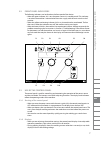

Page 9: Installation

2. Installation 2.1 positioning of the machine place the machine on a sturdy, level surface that is dry and does not release dust or other impurities to the suction air through the fan grill. 60˚ notes for positioning of the machine • preferably, situate the machine somewhat above floor level. • the...

Page 10: Machine Use

The table below lists the fuse sizes for 100% load in a 400-v three-phase network with 4 x 10-mm² cable for different power source models. Model fuse km 300 20 a delayed km 400 25 a delayed km 500 35 a delayed 2.3 welding and earthing cables the device has a welding cable connection both in the fron...

Page 11

3.2 front panel indicators the following indicators can be found on the front panel of the device: • when the green indicator, a3, is on, the power source is in standby mode. This indicator is on when the machine is connected to the mains supply with the main switch in the ‘i’ position. • when the y...

Page 12

3.3.3 control knobs • the left-hand control knob (p8) allows adjustment of the speed of wire feeding. The selected speed is shown on the display on the left-hand side (p2). • the control knob on the right-hand side (p9) allows you to adjust the welding voltage. The selected voltage is shown on the r...

Page 13

3.3.10 setting of the mig operating mode button p7 allows you to set the mig welding gun to either two-sequence or four-sequence mode. The indicator shows the mode selected. • in two-sequence mode (2t), welding is started by pressing the gun switch and stopped by releasing the switch. • in four-sequ...

Page 14: Troubleshooting

3.3.12 calibration of the wire feed speed when factory settings are used, the wire feed speed can be adjusted to between 4 and 100 without a unit of measurement. Only the led symbol indicates that wire feed speed is the parameter to be set. The unit of the wire feed speed (m/min) is shown once the w...

Page 15

4.3 electric network overvoltage or undervoltage if the power source is used in an electric network with insufficient voltage (less than 300 v), the control features of the device are disabled automatically. The primary circuits of the power source are protected against power spikes. The product’s m...

Page 16: Maintenance

Err201 use of pmt gun is prevented the machine is intended for use with mmt guns. When a pmt gun is used, the gun’s jumpers must be set to ‘fu’. This error code may appear also if the contacts of the gun trigger are stained or there are problems with the trigger leads. Check the trigger’s leads. Oth...

Page 17: Disposal Of The Machine

6. Disposal of the machine do not dispose of electrical equipment with normal waste! In observance of european directive 2002/96/ec on waste electrical and electronic equipment, and its implementation in accordance with national law, electrical equipment that has reached the end of its life must be ...

Page 18: Warranty Policy

External dimensions length 590 mm 590 mm 590 mm width 230 mm 230 mm 230 mm height 430 mm 430 mm 430 mm weight 34 kg 35 kg 36 kg voltage supply for auxiliary devices 24 vdc 24 vdc 24 vdc voltage supply for cooling unit 1~, 400 v / 250 va 1~, 400 v / 250 va 1~, 400 v / 250 va 9. Warranty policy kemppi...

Page 20

Www.Kemppi.Com kemppi oy pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 www.Kemppi.Com kemppikoneet oy pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 734 8398 e-mail: myynti.Fi @kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel +46 8 590...