- DL manuals

- Kemppi

- Welding System

- FastMig KM300

- Operating Manual

Kemppi FastMig KM300 Operating Manual - Operating Manual

Summary of FastMig KM300

Page 1

Fastmig km 300, 400, 500 operating manual käyttöohje bruksanvisning bruksanvisning brugsanvisning gebrauchsanweisung gebruiksaanwijzing manuel d’utilisation manual de instrucciones instrukcja obsługi Инструкции по эксплуатации 操作手册 manual de utilização manuale d’uso en fi sv no da de nl fr es pl ru ...

Page 3: Operating Manual

En operating manual english.

Page 4

En contents 1. Johdanto ....................................................................................... 3 1.1 yleistä .......................................................................................................................................... 3 1.2 laitteen esittely ..............

Page 5

En 1. Preface 1.1 general congratulations on choosing the fastmig™ km equipment. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on the use, maintenance and safe...

Page 6

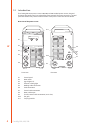

En 1.2 introduction the fastmig km-series power sources 300, 400, and 500 are mig power sources designed for demanding professional use in the three-phase network. The power source has a control panel that allows ready control of the functions of the power source and the wire feeder. Overview of the...

Page 7

En 2. Installation 2.1 positioning of the machine place the machine on a firm, dry and level surface. Where possible, do not allow dust or other impurities to enter the machines cooling air flow. Preferably site the machine above floor level; for example on a suitable carriage unit. Notes for positi...

Page 8

En 2.3 connection to mains fastmig km power sources are connected to the 400-v three-phase network using the mains cable supplied with the machine. The machine is equipped with a five-metre mains cable that does not have a plug. Before use, check the mains cable and install a mains plug. If the cabl...

Page 9

En 3. Machine use 3.1 starting of the power source start the power source by turning the main switch (a2) on the front panel to the ‘i’ position. The standby indicator (a3) turns on. The control panel and wire feeder are not operational yet, and the text ‘off’ is shown on the control panel display. ...

Page 10

En 3.3 use of the control panel the control panel is used for controlling and monitoring the operation of the power source and the wire feeder. The buttons are used for adjusting functions. The displays and indicators reflect the operating modes of the machine. 3.3.1 starting of the control panel • ...

Page 11

En 3.3.7 selection of liquid- or gas-cooled mig gun you can select a mig gun cooled with liquid or gas by pressing buttons 3 and 5 simultaneously and holding them down for at least one second. • when the display reads ‘gas’, you can use a gas-cooled mig gun with the equipment. • when the display rea...

Page 12

En the table below lists the operation parameters and their possible values. Name of parameter name displayed parameter values factory values description pre gas time prg 0.0 – 9.9 s 0.1 s pre-welding gas time in seconds post gas time pog aut, 0.1 – 32.0 s aut post-welding gas time in seconds or aut...

Page 13

En 18.0 m/min). 10. Repeat steps 6 – 8 for this higher calibration point. 11. The message ‘suc ces’ appears on the display to indicate that calibration has ended successfully. At the same time, the device exits calibration mode and returns to basic operation mode. 12. In order to increase the accura...

Page 14

En 4.5 machine error codes the machine always checks its operation automatically during start-up and reports any failures detected. If failures are detected during start-up, they are shown as error codes on the control panel display. Power source error codes err3 power source overvoltage the machine...

Page 15

En 5. Maintenance the utilisation level of the power source and its working environment should be taken into consideration in planning the frequency of maintenance of the machine. Appropriate use and preventive maintenance guarantee the trouble-freest use of the equipment. This allows you to avoid i...

Page 16

En 6. Disposal of the machine do not dispose of electrical equipment with normal waste! In observance of european directive 2002/96/ec on waste electrical and electronic equipment, and its implementation in accordance with national law, electrical equipment that has reached the end of its life must ...

Page 17

En fastmig™ km 300 km 400 km 500 connection voltage, 3~50/60 hz 400 v, -15 ... +20% 400 v, -15 ... +20% 400 v, -15 ... +20% rated power 60 % ed - - 25.9 kva 80 % ed - 18.5 kva - 100% ed 12.9 kva 16.9 kva 20.1 kva connection cable ho7rn-f 4g6 (5 m) ho7rn-f 4g6 (5 m) ho7rn-f 4g6 (5 m) fuse (delayed) 2...

Page 18

Www.Kemppi.Com kemppi oy kempinkatu 1 pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 export@kemppi.Com www.Kemppi.Com kotimaan myynti: tel +358 3 899 11 telefax +358 3 734 8398 myynti.Fi@kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel +46 8 590 783 00...