- DL manuals

- Kemppi

- Welding System

- MasterCool 10

- Operating Manual

Kemppi MasterCool 10 Operating Manual

Operating manual • English

Käyttöohje • Suomi

Bruksanvisning • Svenska

Bruksanvisning • Norsk

Brugsanvisning • Dansk

Gebrauchsanweisung • Deutsch

Gebruiksaanwijzing • Nederlands

Manuel d’utilisation • Français

Manual de instrucciones • Español

Instrukcja obsługi • Polski

Инструкции по эксплуатации • По-русски

操作手册

•

中文

Manual de utilização • Português

Manuale d’uso • Italiano

EN

FI

SV

NO

DA

DE

NL

FR

ES

PL

RU

ZH

Master MLS™

MasterTig MLS™

MasterCool™

2500, 3500

3000, 4000

10

PT

IT

Summary of MasterCool 10

Page 1

Operating manual • english käyttöohje • suomi bruksanvisning • svenska bruksanvisning • norsk brugsanvisning • dansk gebrauchsanweisung • deutsch gebruiksaanwijzing • nederlands manuel d’utilisation • français manual de instrucciones • español instrukcja obsługi • polski Инструкции по эксплуатации •...

Page 3: Operating Manual

Operating manual english m ast er , m ast er tig , m ast erc ool 10 / © kemppi o y / 1112.

Page 4

En contents 1. Preface ................................................................................................................................ 3 1.1 general .........................................................................................................................................

Page 5

En 1. Preface 1.1 general congratulations on choosing the master/mastertig mls™ equipment. Used correctly, kemppi products can significantly increase the productivity of your welding, and provide years of economical service. This operating manual contains important information on the use, maintenanc...

Page 6

En 2. Installation 2.1 removal from packaging the equipment is packed in durable packages designed especially for it. However, it is necessary to check the equipment before using it to make sure that the equipment or any part of it has not got damaged during transportation. Also check that the deliv...

Page 7

En 2.5 installation of the panel 1. Fasten the cable connectors of the function panel to the power source (2 pieces). 2. Place the bottom edge of the panel behind the securing clips on the machine. Remove the fixing pin from the top edge with, for example, a screwdriver. Then gently push the upper p...

Page 8

En 2.8 welding cable connections 2.8.1 choosing welding polarity in mma welding you can change the welding polarity by choosing (+) or (-) cable connector. 2.8.2 earthing if possible, always fasten the earth clamp of return current cable directly onto work piece. 1. Clean contact surface of earth cl...

Page 9

En installing gas-cooled torch installing water-cooled torch connect the red water hose to the upper connector and blue one to the lower connector.. 2.10 shield gas note! Handle gas bottle with care. There is a risk for injury if gas bottle or bottle valve is damaged! Use inert gases such as argon, ...

Page 10

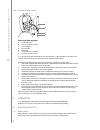

En 2.10.1 installation of gas bottle e b d g a f c parts of gas flow regulator a. Gas bottle valve b. Pressure regulation screw c. Connecting nut d. Hose spindle e. Jacket nut f. Gas bottle pressure meter g. Gas hose pressure meter note! Always fasten gas bottle properly in vertical position in a sp...

Page 11

En 3.1.2 tig welding mastertig mls power sources are designed especially for tig welding. They are equipped with hf spark ignition and versatile panel functions depending on the panel used. The panels predominantly for tig welding are mtl, mtx, mtz and mtm. Also the mel and mex panel on master mls p...

Page 12

En mma welding panel mel 1. 2. 3. 4. 5. 6. 7. 8. 1. Remote/local control switch 2. Welding current potentiometer 3. Contact tig welding 4. Mma welding 5. Arc force 6. Hot start 7. Digital display and amperage/voltage switch 8. Welding current table 10 m ast er , m ast er tig , m ast erc ool 10 / © k...

Page 13

En mma welding panel mex 1. 2. 6. 5. 7. 3. 4. 8. 9. Mex panel is available separately. The functions of mex panel are described in the operating manual delivered with the panel. 1. Indicator lights: main switch, overheating, wrong mains voltage 2. Mode button for welding method selection: mma, conta...

Page 14

En tig welding panel mtl – basic functions 2. 3. 4. 7. 5. 9. 6. 8. 14. 13. 12. 11. 10. 1. 1. Selection of mma welding 2. Selection of arc force (mma) and pedal low/high (minimum and maximum welding current) displays and regulation (tig welding) 3. Selection of hot start (mma) and gas test (tig weldi...

Page 15

En 3. Hot start when pressing the hot start button, you will see on the display the numerical value corresponding to the mma hot start pulse. You can adjust the value by turning the potentiometer. In tig mode you can select gas test function. 4. Tig welding is selected welding torch switch 2 sequenc...

Page 16

En tig welding panel mtx – pulsed tig functions 1. 2. 3. 4. 5. 6. 7. 8. 9. 1. 4t-log 2. Selection for spot, synergetic quick pulse and long pulse 3. Search arc 10 – 80 % of welding current 4. Pulse current 10 a – max. 5. Pulse ratio 10 – 70 % of pulse time 6. Frequency 0.2 – 300 hz 7. Base current 1...

Page 17

En long pulse long pulse method gives you the possibility to adjust all pulse parameters (pulsing frequency, pulse ratio, pulse current and pause current). You can also adjust the welding current, in which case you receive a new pulse current value. Pulse ratio and pause current percentage remain co...

Page 18

En tig welding panel mtm – pulsed tig and minilog function with memory 1. 2. 3. 4. 5. 1. Minilog 2. Selection of memory function 3. Selection of channel in memory function 4. Minilog 10 – 90 % of welding current 5. Save minilog operation when torch switch is pressed gas flow starts. When you release...

Page 19

En if the saved settings need to be adjusted the led has to be moved from on to set position in order to select parameters. Press the save button. It is also possible to save the currently used parameters by pressing set when the memory function is in off state (no lights on). Channel is cleared if ...

Page 20

En 3.2.7 foot pedal control r11f first read under ”3.2.2.4. Tig welding panel mtl” point ”6. Remote control” for installing the remote control ready for operation. Foot pedal r11f is used in tig welding, and its control range is adjustable. The minimum value of control range is set with the panel po...

Page 21

En 4.1.2 service contract kemppi service workshops make special service contracts with customers about regular maintenance. All parts are cleaned, checked and if necessary, repaired. Also the operation of welding machine is tested. 4.2 troubleshooting power on light is not lit. There is no power in ...

Page 22

En 5. Ordering numbers master mls™ 2500 6104250 welding cable 35 mm² 2.5 m 6184301 earth cable 25 mm² 2.5 m 6184311 electric plug 16 a 5-poles 9770812 master mls™ 3500 6104350 welding cable 50 mm² 2.5 m 6184501 earth cable 50 mm² 2.5 m 6184511 electric plug 16 a 5-poles 9770812 mastertig mls™ 3000 6...

Page 23

En panels mel mma 6106000 mex mma 6106010 mtl tig 6116000 mtx tig 4t-log 6116005 mtz tig minilog 6116015 mtm tig memory 6116010 optional device tig torch controls rtc 10 6185477 rtc 20 6185478 remote control r 10 6185409 r11t 6185442 r11f 6185407 transport unit t100 6185250 t110 6185251 t130 6185222...

Page 24

En 6. Technical data power source master mls™ 2500 connection voltage 3~50/60 hz 400v -15 %...+20 % rated power at max. Current 40% ed mma 9.4 kva 30% ed tig 8.4 kva connection cable ho7rn-f 4g1.5(5m) fuse (delayed) 10 a duty cycle 40 °c mma 10 a/20.5 v...250 a/30.0 v tig 5 a/10.0 v...300 a/22.0 v m...

Page 25

En power source mastertig mls™ 3000 connection voltage 3~ 50/60 hz 400v –15%…+20% rated power at max. Current 30% ed tig 8.4 kva 40% ed mma 9.4 kva connection cable ho7rn-f 4g1.5(5m) fuse (delayed) 10 a duty cycle 40 °c mma 10 a/20.5 v...250 a/30.0 v tig 5 a/10.0 v...300 a/22.0 v max welding voltage...

Page 26

En cooling unit (tig-welding) mastercool 10 operating voltage 400v –15%…+20% connection capacity 100 % ed 250 w cooling power 1 kw start pressure, max 0.4 mpa cooling liquid 20% – 40 % etanol-water tank volume 3 l external dimensions lxwxh 500x180x260 mm weight 11 kg power source and cooling unit op...

Page 27

En 25 m ast er , m ast er tig , m ast erc ool 10 / © kemppi o y / 1112.

Page 28

1910031 1112 www.Kemppi.Com kemppi oy hennalankatu 39 pl 13 fin-15801 lahti finland tel +358 3 899 11 telefax +358 3 899 428 export@kemppi.Com www.Kemppi.Com kotimaan myynti: tel +358 3 899 11 telefax +358 3 734 8398 myynti.Fi@kemppi.Com kemppi sverige ab box 717 s-194 27 upplands vÄsby sverige tel ...