Käyttöohje • suomi bruksanvisning • svenska bruksanvisning • norsk bruksanvisning • dansk operation instructions • english gebrauchsanweisung • deutsch gebruiksaanwijzing • nederlands manuel d’utilisation • français manual de instrucciones • español Инструкции по эксплуатации • По-русски 1910190 061...

© kemppi oy 0615 minarctig tm 180 1 en operation instructions english.

Minarctig tm 180 © kemppi oy 0615 en contents 1. Introduction .................................................................................3 1.1. General product profile .......................................................................3 1.2. About welding performance .........................

© kemppi oy 0615 minarctig tm 180 en 1. Introduction congratulations on purchasing the kemppi minarctig tm 180 tig/mma machine. Minarctig tm 180 is designed as a professional welding tool, and with correct use and maintenance, the robust design will provide reliable service throughout its life. Plea...

Minarctig tm 180 © kemppi oy 0615 en tig welding in tig welding, the welding arc is formed between a non-consumable tungsten electrode and the work piece. The resulting high temperature arc melts the work piece to form a molten pool into which a consumable filler wire, of a similar alloy composition...

© kemppi oy 0615 minarctig tm 180 en do not move the shielding gas cylinder when the reducing valve/regulator is connected and open. Always fix the gas cylinder securely in an upright position, against a cylinder wall rack or purpose made cylinder cart. Always close the gas cylinder valve after use....

Minarctig tm 180 © kemppi oy 0615 en 3. Machine use 3.1. Before commissioning machine minarctig tm is packed in purpose made, recyclable packaging. However, always ensure that the equipment has not been damaged in transportation. Please ensure that any damage to the equipment is notified to your sup...

© kemppi oy 0615 minarctig tm 180 en 3.2. General view of the machine 1. Welding torch 2. Earth return clamp 3. On/off main switch (16 amp mains supply should also be switched at the socket) 4. Supply voltage cable 5. Shielding gas hose snap connector 3.3. Cable connections connection to the mains t...

8 minarctig tm 180 © kemppi oy 0615 en earth return cable connect the earth return cable to the negative pole when welding with an mma electrode. Connect the earth return cable to the positive pole when welding with the tig process. Clean the work piece surface and fix the earth return clamp to the ...

© kemppi oy 0615 minarctig tm 180 en 1. Connect the hose to the reduced pressure side of the cylinder regulator, or flow meter and tighten the connector. 2. Adjust the shielding gas flow rate with the flow regulation adjustment screw. A suitable gas flow rate of between 8–15 l/min. 3. Close the cyli...

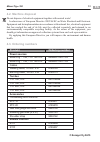

10 minarctig tm 180 © kemppi oy 0615 en and also the correct welding current selection, to ensure the core electrode filler material and flux coating melt and burn efficiently for effective welding. The following table provides a selection of welding current ranges for the various electrode sizes co...

© kemppi oy 0615 minarctig tm 180 11 en 9. Digital welding current meter and parameter value display. Displays time or amperes. 10. Thermal temperature indicator lamp. Switching the machine on when you switch the machine on, a green standby light is illuminated. The main power switch indicator lamp ...

1 minarctig tm 180 © kemppi oy 0615 en gas time elapses as set. Hf or contact ignition selection the tig arc can be established with or without an hf pulse. If the hf lamp is not illuminated the arc can be established by lightly contacting the tungsten electrode to the work piece. Press the torch tr...

© kemppi oy 0615 minarctig tm 180 1 en 4.2. Machine disposal do not dispose of electrical equipment together with normal waste! In observance of european directive 2002/96/ec on waste electrical and electronic equipment and its implementation in accordance with national law, electrical equipment tha...

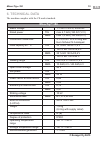

1 minarctig tm 180 © kemppi oy 0615 en 5. Troubleshooting problem cause main switch indicator light does not switch on the machine has no supply voltage • check supply voltage fuses • check supply voltage cable and plug machine welds badly welding outcome is influenced by several • check that the ea...

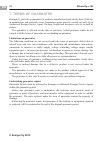

© kemppi oy 0615 minarctig tm 180 1 en 6. Technical data the machine complies with the ce mark standards. Minartig tm 180 mains voltage 1 ~ 230 v ±15%, 50/60 hz rated power tig max 6,7 kva (180 a/17,2 v) mma max 7,0 kva (140 a/25,6 v) connection cable/fuse 3 × 2,5 mm 2 s–3 m long with euro schuko/16...

1 minarctig tm 180 © kemppi oy 0615 en 7. Terms of guarantee kemppi oy provides a guarantee for products manufactured and sold by them if defects in manufacture and materials occur. Guarantee repairs must be carried out only by an authorised kemppi service agent. Packing, freight and insurance costs...

Kemppi danmark a/s literbuen 11 dk – 2740 skovlunde danmark tel 44 941 677 telefax 44 941 536 e-mail: sales.Dk@kemppi.Com kemppi france s.A.S 65 avenue de la couronne des prés 78681 epone cedex france tel (01) 30 90 04 40 telefax (01) 30 90 04 45 e-mail: sales.Fr@kemppi.Com kemppi oy pl 13 fin – 158...