Propane vapor withdrawal or natural gas congratulations! You have purchased the finest circulating heater available. Your new l.B. White heater incorporates the benefits from the most experienced manufacturer of heating products using state-of-the-art technology. We, at l.B. White, thank you for you...

Warning fire and explosion hazard ■ not for home or recreational vehicle use. ■ installation of this heater in a home or recreational vehicle may result in a fire or explosion. ■ fire or explosions can cause property damage or loss of life. For your safety if you smell gas: 1. Open windows. 2. Don't...

Section page general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 heater specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

4 ts080 ts170 propane natural propane natural gas gas gas gas maximum input (btuh/kw) 80,000/23.4 170,000/49.8 burner manifold pressure (inches w.C./kpa) 10.0/2.49 4.0/1.0 10.0/2.49 4.0/1.0 max. 13.5/3.36 min. 12.0/2.99 8.0/1.99 11.0/2.74 7.0/1.74 fuel consumption per hour 3.71 lbs./1.68 kg 80 cu.Ft...

Propane gas and natural gas have man-made odorants added specifically for detection of fuel gas leaks. If a gas leak occurs, you should be able to smell the fuel gas . That’s your signal to go into immediate action! ■ do not take any action that could ignite the fuel gas. Do not operate any electric...

1. Do not attempt to install, repair, or service this heater or the gas supply line unless you have continuing expert training and knowledge of gas heaters. Qualifications for service and installation of this equipment are as follows: a. To be a qualified gas heater service person, you must have suf...

1. Read all safety precautions and follow l.B. White recommendations when installing this heater. If during the installation or relocating of heater, you suspect that a part is damaged or defective, call a qualified service agency for repair or replacement. 2. The heating equipment must be properly ...

Recommended propane gas supply average temp º f/ºc 50/10 40/4.4 30/-1.1 20/-6.7 10-12.2 0/-17.8 010/-23 number of 100 lb. Ts080 1 1 2 2 2 2 2 /45 kg cylinders to use per heater ts170 2 2 3 3 3 3 3 * cylinders must be manifolded together to allow simultaneous vapor withdrawal from all cylinders. Prop...

Ts170g-02 regulator storage bracket cage nuts hose hanger flat washer bolt thermostat storage bracket (installed with internal support to the left) screws handle bracket extend handle until it snaps into retaining hole retaining hole at underside snap button at underside the premier 170 is equipped ...

Spacer washer 5/16 (quantity 8) handle - u, with 8" legs hub cap (press on) nuts 5/16-18 (2 per side) install cage nuts as shown before bolting support to heater remove case screw at each end of heater (both sides) before installing u-handles. Handle - u with 8 1/2" legs and axle hole 1 bolt 5/16-18...

11 hose and regulator assembly 1. Connect male plug on heater into female side of series tap plug on thermostat. See fig. 8. 2. Plug male side of series tap plug into grounded, heavy-duty, electrical extension cord. Plug extension cord into approved electrical outlet. Fig. 8 thermostat assembly rigi...

12 side w all 10 ft clearance earlier style ducting duct kit assembly accessory 26346 fasten wing screws into cage nuts at blower outlet and tighten install tab at bottom of collar into slot at bottom of outlet before fastening wing screws slots for installing earlier style ducting side w all 1. Ext...

13 ■ only use the l.B. White regulator supplied with the heater. ■ the heater must be regulated at all times for proper operation. ■ the regulator must be installed so its vent are directed downward. ■ leak check all regulator connections whenever the regulator is connected to the gas supply. Propan...

14 1. Connect the electrical cord to an approved electrical outlet. A selector switch located on the back of the heater allows heater operation in either heating or ventilation (no heat) modes. See fig. 15. A. Heat mode operation a. Open all manual fuel supply valves. Check for gas leaks using an ap...

14 1. The area surrounding the heater shall be kept clear and free from combustible materials, gasoline, and other flammable vapors and liquids. 2. Have your gas supplier check all gas piping annually for leaks or restrictions in gas lines. 3. Regulators must be periodically inspected to make sure t...

16 1. Open louvered access panel opposite burner end of heater. Disconnect motor leads. 2. Remove screws securing motor mounting plate to housing. 3. Pull fan and motor assembly from housing. 4. Loosen set screws on fan wheel. 5. Pull fan wheel from motor shaft. 6. Remove the four nuts securing moto...

Front view top view mounting bracket 1 1/2 in. Distance from igniter to "v" of burner casting igniter bracket mounting screws igniter/sensor mounting screws electrode gap is1/8" & centered over burner port burner port igniter and flame sensor assembly 1. See fig. 18 or 19, depending on heater m...

1. Open the burner end access doorand remove gas hose from heater. 2. Remove the elbow and all screws at inlet of gas control valve. See fig. 21. Fig. 21 3. Remove the burner retaining bolt at the underside of the heaters base. For premier 170 heaters, the bolt is accessible through an opening in th...

4. Pivot the gas control assembly to expose the burner orifice. See fig. 24. Replace components as needed. Fig. 24 5. When assembling the control valve to manifold, the valve must be offset 8 degrees from the orifice holder to ensure the control valve aligns to its mounting holes. See fig. 25. Fig. ...

On off attention ■ the following explains a typical procedure to be followed in checking gas pressures. ■ the gas pressures will vary depending upon fuel type. ■ consult the dataplate on the heater or page 4 in this manual for specific pressures to be used in conjunction with this procedure. ■ gas p...

Read this entire section before beginning to troubleshoot problems. The following troubleshooting guide provides systematic procedures for isolating equipment problems. This guide is intended for use by a qualified gas heater service person. Do not attempt to service these heaters unless you have be...

22 all lights are on power status light not on normal operation hea ting mode is cir cuit break er closed? R eset break er . Det ermine casue of break er tripping no is thermostat set abo ve room te m perature? Set thermostat abo ve room te m perature. No ye s ye s is po w er delie vered t o thermos...

Def ectiv e ignition contr ol. R eplace contr ol. Does ignition contr ol send pr oper v oltage t o mo tor fr om t erminal ind on contr ol? Is fan loose on mo tor shaf t? Ye s ye s no no no r epair of replace as needed. 23 air proving status light is not on. Does fan mo tor star t? Ye s no ye s r epa...

24 gas control status light is not on. Is ignition contr ol sending out 2 4 v olts fr om t erminal mv on contr ol? Ye s def ectiv e ignition contr ol. R eplace contr ol. No is high limit at f an end receiving 2 4 v olts fr om ignition contr ol? No ye s def ectiv e wire or terminal connection. R epai...

All lights are on, but burner does not light.. Is fuel supply v alv e open? Ye s ye s open fuel supply v alv es t o heat er no is ignit or pr operly gapped? Check iignit er gap and regap t o specif ications. No ye s 25 does ignit or spark? Is ignit er high v oltage lead connect ed? No no connect hig...

26 pr ob lem m ot or d oes n ot r un is heat er plugged in? Is select or switch set t o vent? Plug heat er in. Mo ve the select or switch t o the vent position. Ye s no ye s ye s is pr oper v oltage supplied fr om select or switch to mo tor? R eplace select or switch check all electrical connections...

Electrical connection and ladder diagram 27 premier 80/170 f (150 electrical ladder diagram / diagramme en escalier / diagrama elÈctrico de escalera electrical connection diagram / connexions electriques / diagrama de conexiones elÈctricas c). If any of the original wiring as supplied with the heate...

28 air proving switch safety device used to insure that the proper air flow is being achieved before the gas valve is opened. Burner cast iron component used to channel gas and provide an area at which the fuel may ignite. Burner orifice brass metering device used to feed gas to burner at a specific...

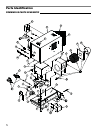

29 premier 80 parts schematic parts identification 18 47 13 45 46 44 43 42 41 40 39 38 37 36 35 33 32 31 30 29 27 28 26 25 24 22 23 20 21 19 17 16 15 14 12 11 10 9 7 6 5 4 3 2 1 8 34 ts080g.

Premier 80 parts list 30 item description part number 1 regulator propane gas 26377 natural gas 21999 2 handwheel w/ spring propane gas 26395 3 universal hose kit, 4.57 m. Hose w/ adapters 24600 4 adapter 1/2 npt x 5/8 - 18 06655 5 ell 09309 6 screw 09425 7 valve, gas control propane gas 522076 natu...

20 31 premier 170 part schematic 36 17 16 10a 10a 10a 51 49 48 47 46 45 44 43 42 41 39 38 37 35 34 33 32 31 30 29 27 26 25 24 23 21 20 19 15 14 13 12 11 10 9 8 7 5 6 4 3 2 1 50 28 22 18 52 40

Premier 170 parts list item description part number 1 regulator propane gas 26419 natural gas 09795 2 hand wheel with spring propane gas 26395 3 universal hose kit, 4.57m. Hose w/ adapters 24600 4 wheel kit 26418 5 axle 26415 6 cotter pin 26417 7 kit, leg bracket 26413 8 bolt and washer 25866 9 hand...

Premier 170 parts list (continued) item description part number 45 motor 520169 46 mount, motor 25835 47 fan 570481 48 switch, high limit, motor end (190°f) 571400 49 switch, air proving 09925 50 housing, fan 26440 51 base 26414 52 handle,door 26479 contact your local l.B. White dealer for replaceme...