- DL manuals

- La Marzocco

- Coffee Maker

- SWIFT EPSB

- Troubleshooting Manual

La Marzocco SWIFT EPSB Troubleshooting Manual

Summary of SWIFT EPSB

Page 1

1 swift eps troubleshooting manual.

Page 2: Table of Contents

2 table of contents 1. Manufacturer’s introduction..................................................3 2. Legend of symbols ........................................................................3 3. Important safety information & general precautions from the manufacturer ..............................

Page 3: 2. Legend Of Symbols

3 1. Manufacturer’s introduction introduction swift espresso preparation system the swift eps b grinds, doses and tamps coffee directly into the portafilter, eliminating the need to do this manually. It measures and doses by volume, not time, so waste and product inconsistency are reduced. At the sa...

Page 4: Manufacturer

4 3. Important safety information & general precautions from the manufacturer warning equipment contains dangerous voltages and can be hazardous if installed or operated incorrectly. Non-compliance with warnings or failure to follow the instructions contained in this manual can result in loss of lif...

Page 5

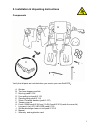

5 5. Installation & unpacking instructions components verify that all parts are included when you receive your new swift eps b . A. Grinder b. Two bean hoppers and lids c. Drip tray part# 5.336 d. Fuse pulling tool part# 5.123 e. Cleaning brush part# 5.118 f. 22mm. Portafilter baskets (part# 5.127) ...

Page 6

6 overview 1. Left bean hopper 2. Left bean hopper gate (not visibile) 3. Left grind adjust knob 4. Left grinder start button 5. Bayonet ring 6. Foot plate 7. Right bean hopper 8. Right hopper bean gate 9. Right grind adjust knob 10. Right grinder start button 11. Power cord 12. Main power switch 13...

Page 7

7 6. Equipment operating instructions engaging the portafilter the portafilter engages directly to the swift eps b . Since the swift eps b has no watertight seal, it is not necessary to force the portafilter into place. Engage the portafilter with only a light amount of force. If the grinder shifts ...

Page 8

8 blinking indicator lights the indicator lights will flash for a number of reasons. These are summarized below: • you attempted to start the process with a full portafilter. • the safety timer has run out due to: empty hopper; closed bean gate; or plugged hopper chute. • there is no portafilter eng...

Page 9

9 7. Equipment care & cleaning daily cleaning daily cleaning of the swift eps b is important for the quality of your coffee beverages and for the mechanical life of the equipment. When the cleaning instructions are carried out each day, there will be little chance of old coffee residues spoiling the...

Page 10

10 6 7 6. Vacuum out the burr area. 7. Using a clean towel, wipe the inside of each hopper. Pay close attention to the bean gate area. 8. Reassemble and test for proper operation. Cleaning the impeller 2 3 5 1. Unplug the swift. 2. Remove the tower cover. 3. Push the shaft brake backwards and hold. ...

Page 11

11 6 7 8 6. Insert the brush into the collection area above the impeller and again wipe away loose grounds. 7. Clean the impeller with a soft dry cloth. 8. Reinstall the impeller by turning counter-clockwise. Using the clean-out tool if either grinder motor fails to operate, the usual cause is a clo...

Page 12

12 3. Rotate the cover to the grind chute to access the grinding chute hole inside to clean the grinder. 4. Locate the clean-out tool access hole on either side of the coffee chute. 5. Gently and with caution insert insert the clean-out tool into the hole and apply forward pressure until the tool is...

Page 13

13 8. Parts description and identification.

Page 14

14.

Page 15

15.

Page 16

16.

Page 17

17.

Page 18

18.

Page 19

19.

Page 20

20 warning technician tasks only to be completed by qualified and skilled service personnel. Electronics.

Page 21

21 9. Preventative maintenance details warning technician tasks only to be completed by qualified and skilled service personnel. Bi annual preventative maintenance checklist la marzocco swift eps service . Confirm serial number of grinder: #________________ . Clean hoppers . Replace all coffee baske...

Page 22

22 warning technician tasks only to be completed by qualified and skilled service personnel. Grinding burr replacement periodic burr replacement is required. While the ceramic burrs used in the swift eps b have a much longer life expectancy than normal steel burrs, it is still necessary to watch you...

Page 23

23 warning technician tasks only to be completed by qualified and skilled service personnel. 9 10 11 9. Remove the adjustment gear assembly from the upper burr carrier 10. Rotate the upper burr carrier anticlockwise until the threads are free allowing removal 11. Remove the upper burr carrier 12. Us...

Page 24

24 warning technician tasks only to be completed by qualified and skilled service personnel. 17 18 19 17. Rotate the carrier clockwise until you see the lower mill move 18. Once you locate the point in which the two grinding burrs come into contact with one another, turn the upper carrier counter cl...

Page 25

25 10. Troubleshooting guide (* items are for technicians) warning technician tasks only to be completed by skilled service personnel pushing start buttons and nothing happens. -check that the electrical plug is fully inserted -switch the on/off switch to the on position (the light should be lit) *c...

Page 26

26 warning technician tasks only to be completed by skilled service personnel safety micro switch impeller micro-switch - 1 this micro-switch is activated by the impeller disc. The impeller disc rises upward as coffee is dosed into the portafilter. When sufficient coffee has been ground and dosed, t...

Page 27

27 warning technician tasks only to be completed by skilled service personnel fuse replacement and reset switches the swift epsb has four fuses located at the rear of the machine behind the removable panel. These correspond to each of the grinder motors, the tamping motor, and the electronic control...

Page 28

28 warning technician tasks only to be completed by skilled service personnel adjusting finish height of the impeller to ensure consistency of the shot time and shot quality, the tamping impeller must be adjusted to the proper height. Follow the steps below to determine the impeller's height 1 2 3 1...

Page 29

29 warning technician tasks only to be completed by skilled service personnel coffee dose too high. Impeller must be lowered. The diffuser screen is pressed into the coffee puck, evidenced by a pronounced ring from the diffuser screen around the circumference of the portafilter.(1) there is also a d...

Page 30

30 warning technician tasks only to be completed by skilled service personnel 3 4 3. Using a long-arm l-key 3/32 hex size (part# 5.129 in your kit), loosen the screw several turns. It is not necessary to completely remove the screw. 4. Pulling the shaft brake, u se your other hand to rotate the impe...

Page 31

31 11. Equipment specifications.

Page 32: 12. Wiring Diagram

32 12. Wiring diagram.