La Marzocco SWIFT EPSB Manual

La Marzocco Technical Center

s.r.l.

Via Bolognese

68

- Loc. Pian Di San Bartolo

50010

Firenze, Italy

t: +39.

055.4026358

f: +39.

055.4026359

e-mail: martech@lamarzocco.com

www.lamarzocco.com

La Marzocco International

L.L.C.

®

Introduction

2

Components

3

Specifications

4

Installation

5

Engaging the Portafilter

7

Operating the Swift

8

Adjusting Coffee Coarseness

10

Adjusting Dose Quantity

11

Daily Cleaning

13

Burr Change-Out

19

Chute Clean-Out Tool

25

Fuse Replacement and Reset Switches

26

Tips and Troubleshooting

28

Electrical Diagrams

31-32

Approvals

inside back cover

C o n t e n t s

C o n t e n t s

SWIFT EPS

B

English

Summary of SWIFT EPSB

Page 1

La marzocco technical center s.R.L. Via bolognese 68 - loc. Pian di san bartolo 50010 firenze, italy t: +39. 055.4026358 f: +39. 055.4026359 e-mail: martech@lamarzocco.Com www.Lamarzocco.Com la marzocco international l.L.C. ® introduction 2 components 3 specifications 4 installation 5 engaging the p...

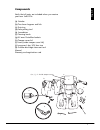

Page 3: Components

A. B. B. C. D. E. G. F. H. J. D, e, i, j, k . Inside tamper cover k. Components verify that all parts are included when you receive your new swift eps b . (a) grinder (b) two bean hoppers and lids (c) drip tray (d) fuse pulling tool (e) screwdriver (f) cleaning brush (g) 22 mm. Portafilter baskets (...

Page 5: Installation

Installation the swift eps b is easy to install. However, there are several important considerations to keep in mind. The swift eps b requires a grounded 110v, 15 amp (or 220v, 7.5 amp) power supply. It also requires a minimum 16” x 16” (406 mm x 406 mm) space on the counter. Since the unit is 26” (...

Page 7: Engaging The Portafilter

There is no need to force it into position engage portafilter gently engaging the portafilter the portafilter engages directly to the swift eps b . Since the swift eps b has no watertight seal, it is not necessary to force the portafilter into place. Engage the portafilter with only a light amount o...

Page 8: Operating The Swift Eps

Select the right or left bean hopper remove prepared portafilter operating the swift eps b once the portafilter is engaged, press one of the start buttons located at the front of the swift eps b . The right and left buttons correspond to the right and left bean hoppers. Coffee will be ground, dosed,...

Page 9: Flashing Indicator Lights

Blinking indicator lights relay information flashing indicator lights the red indicator lights will flash for a number of reasons. These are summarized below: • you attempted to start the process with a full portafilter. • the safety timer has run out due to an empty bean hopper, a closed bean gate,...

Page 10: Adjusting Coffee Grind

Adjusting coffee grind to achieve your desired brew time and coffee consistency, a manual adjustment can be made to the grinder to modify the grind of the coffee. (the tamping pressure is not adjustable and remains constant). Rotate the adjustor knobs as described below. (1) locate the grinder adjus...

Page 11: Adjusting Dose Quantity

Adjusting dose quantity the swift eps b is set to dose approximately 16 to 18 grams of coffee in 22mm basket provided with the grinder. It is possible to change the dosage quantity by raising or lowering the height of the impeller. Additionally, the swift eps b is able to dose different quantities u...

Page 12

(4) to increase the dosage amount, turn the impeller clockwise, as viewed from below. To decrease the dosage amount, turn the impeller counter-clockwise, as viewed from below. Note: one 360° turn is equal to approximately 1 gram of coffee. 12 increase the dosage english decrease the dosage hold tamp...

Page 13: Daily Cleaning

Daily cleaning daily cleaning of the swift eps b is important to the quality of your coffee beverages and to the mechanical life of the equipment. When the cleaning instructions are carried out each day, there will be little chance of old coffee residue spoiling the flavor of your espresso drinks, o...

Page 15: Caution

Caution do not operate without bean hoppers in place and safety screws tightened 15 english wipe vacuum www.Lamarzocco.Com (7) vacuum coffee fragments and loose grounds from the burr chamber. (8) wipe the inside of the bean hopper with a soft cloth to remove coffee oils. (9) repeat for both right an...

Page 17

17 english remove the reverse-threaded impeller www.Lamarzocco.Com (4) with your thumb and forefinger, press against the impeller flats. Turn the impeller clockwise, as viewed from below, to remove..

Page 19: Burr Change-Out

Burr change-out periodic burr replacement is required. While the ceramic burrs used in the swift eps b have a much longer life expectancy than normal steel burrs, it is still necessary to watch your coffee for the tell-tale signs of burr wear. These signs include inconsistent shot extraction times, ...

Page 21

21 english remove adjusting mechanism loosen adjustor clamp www.Lamarzocco.Com (6) remove adjustor clamp from grinder head and remove adjusting mechanism..

Page 23

23 english remove upper screws remove lower screws wipe clean www.Lamarzocco.Com (9) clean burr engagement surface with a towel or brush. (8) remove the three burr mounting screws from both upper and lower burrs..

Page 25: Chute Clean-Out Tool

Chute clean-out tool occasionally the chute between the grinders and tamping chamber may become clogged, causing the fuse (resettable or replacable) to trip. In addition to replacing or resetting the fuse, it is important to remove the clogged grounds. On machines with serial numbers above 656, a ch...

Page 26: Warning

Fuse replacement and reset switches the swift eps b has four fuses located at the rear of the machine behind the removable panel. These correspond to each of the grinder motors, the tamping motor, and the electronic controls. Occasionally it may be necessary to replace a fuse. When switching fuses b...

Page 27

27 english replace cover www.Lamarzocco.Com (5) replace the damaged fuse with the correctly rated fuse. (see electrical schematic, page 31-32) (4) remove the fuse using the tool provided. Note: a damaged fuse is identifiable by a broken filament and discoloration of the fuse glass. (6) replace cover...

Page 28: Tips and Troubleshooting

Tips and troubleshooting what is the ideal shot time? Shot time varies with all roasts and brew temperatures used to brew espresso. Most likely, a minimum shot time is 18 seconds and a maximum is somewhere in the 30 to 35 second range. The ideal brew time for your coffee depends the coffee roast and...

Page 29: Troubleshooting Guide

Troubleshooting guide (* items are for techs) push start buttons and nothing happens. - check that the electrical plug is fully inserted - switch the on/off switch to the on position (the light should be lit) *check fuses push the start button and the lights flash. - the portafilter is not fully eng...

Page 30

One grinding motor does not run (serial numbers after 656) - press the reset button that corresponds with the motor that does not run - if the reset button pops out again, turn the grind adjust knob 4 rotations in the faster pour direction, insert the clean out rod (see manual) remove the clean out ...

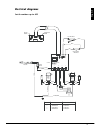

Page 31: Electrical Diagrams

Electrical diagrams serial numbers up to 655 31 english 1 on/off switch green cap. Grinder motor black white white red yellow/green yellow/green white red white black motor tamper cap. White white red black white 2 black grinder motor cap. 3 4 right left p2 tamper time delay off p time-out grinder r...

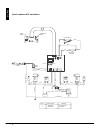

Page 32

32 english 1 115/230 vac on/off switch green or green/yellow cap. Grinder motor black red white red yellow/green yellow/green white red red black motor tamper cap. White white red black white 2 black grinder motor cap. Red porta-filter in limit switch white full limit switch white blue fuse no. 1 2 ...