- DL manuals

- La San Marco

- Coffee Maker

- New 105 Touch SEries

- Use And Maintenance

La San Marco New 105 Touch SEries Use And Maintenance

Summary of New 105 Touch SEries

Page 1

English use and maintenance new 105 touch series.

Page 2

2 english manual code: 7770.032 revision 05/2010 index 1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag. 3 1.1 using the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 3: 1. Introduction

3 english 1. Introduction before using the machine, carefully read all of the instructions contained in this machine. 1.1 using the manual this manual contains all information required for the installation, use and maintenance of the cof- fee machine. This manual is an integral part of the machine; ...

Page 4

4 english • allmodificationstothemachineand/orfailuretoperformthescheduledmaintenanceoperationsrelievetheman- ufacturerofanyliabilityforanydamageensuedandnullifiesthedeclarationofconformityandtheguarantee. • performingoperationsonthemachinewhichhavenotbeenauthorisedisstrictlyforbidden;contactthemanu...

Page 5

5 english 2. Description of the machine note:thetermsusedinthisdescriptionwillcommonlybeusedthroughoutthefollowingpages. New 105 touch key: 1) main switch 2) espresso coffee serving unit 3) filter cup with handle 4) double-scale pressure gauge 5) lower tray + cup support grille 6) electronic level 7...

Page 6

6 english 2.1 general water system diagram new 105 models new 105 dtc models.

Page 7

7 english 2.2 water system diagram key: 1) water softener 2) water softener outflow valve 3) water softener outflow valve 4) supply from water mains 5) electric motor pump 6) pressure gauge 7) non-return and safety valve 8) automatic level control valve 9) filter 10) automatic level solenoid valve 1...

Page 8: 3. Installation

8 english 3. Installation • installationmustbecarriedoutbyskilledauthorisedlasanmarcospatechnical personnel. • the coffee machine is delivered in suitable packaging. The packaging contains the machine and its accessories, the user manual and the conformity declaration. After opening the packaging, m...

Page 9

9 english note: thewatersoftenerisconsideredanessentialdevicetoguaranteeaproperoperationoftheespressocoffee machine.Awatersofteningsystemshouldbeprovidedinordertoguaranteetheefficiency,performance and duration of the components in the machine. 3.4 installation of water system internal pump 1) use th...

Page 10

10 english • ifitisnecessarytouseadapters,multipleplugs andextensions,onlyproductsmeetingapplicablesafetystandardsmustbeused. • toavoidanyoverheatingofthepowercable,unwinditcompletely. Connect the power cable to the electrical mains as shown in the attached diagram: blue black brown black ye/gr new ...

Page 11: 4. Start-Up

11 english 4. Start-up • theespressocoffeemachinemustbestartedbyqualifiedtechnicalpersonnelauthor- isedbylasanmarcospa. • oncetheelectricandhydraulicconnectionsarecompleted,theuserisadvisedtostart theespressocoffeemachinewiththefollowingprocedureinordertoavoiddamaging the appliance. 4.1 filling the ...

Page 12

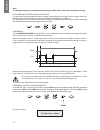

12 english 5.1 adjustment of boiler water level probe the level probe is normally placed in a standard position for all the models in the new 105 series. However, if the customer so desires, the amount of water in the boiler can be increased or decreased by adjusting the level probe as shown in the ...

Page 13

13 english 5.4 temperature adjustment of dispensing units: in the new 105 t models (except for the new 105 t dtc models), the espresso coffee dispensing tempera- ture can be adjusted without changing the internal pressure of the boiler. A valve (flow variator) is fitted to the tip of the dispensing ...

Page 14: 6. Operating Instructions

14 english 5.6 hot water temperature adjustment the new 105 touch models feature a mixer that makes it possible to adjust the temperature of the hot water for the preparation of infusions. The mixer can be calibrated by turning the adjustment screw, which is accessed from the upper tray (figure 17)....

Page 15

15 english thesteamermustbeusedwithcare:contactoftheskinwiththesteamspoutorwiththejetof steamitselfcancauseseriousburns.Griptheburnprotectionsheathtochangethepositionof thesteamdrawingspout.Neveraimthejetofsteamatpersonsoratobjectswhicharenotcon- nectedtotheusedescribedinthismanual. Note: beforeusin...

Page 16

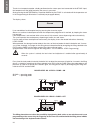

16 english as specified in more detail in the relevant paragraph, some keys in the unit 1 push button panel perform specific functions (other than dispensing) when the appliance is in programming mode. Key additional function function description k1gr1 + (plus) function to "increase" the numerical v...

Page 17

17 english the display shows xxx°c hh:mm la san marco where hh = current time in hours (0 ÷ 23) mm = current time in minutes la san marco = customer's name as desired stopping to stop the dosage function, keep the k5gr1 key pressed first, followed immediately by the k3gr1 key. 2° 1° to switch to the...

Page 18

18 english note: the dosage permits the contemporary dispensing of coffee from all the units envisaged by dosage. Stop dispensing coffee while in progress it is possible to interrupt dispensing while in progress before the pulses relating to the volumetric meter pro- grammed are achieved. Simply pre...

Page 19

19 english to interrupt dispensing in continuous mode, stop the dosage by pressing the same key k5grx . This de- energises the solenoid valve and the pump, and the signal led is consequently turned off. Dispensing in continuous mode stops automatically (if it is not stopped) when the maximum product...

Page 20

20 english thanks to a temperature probe suitably positioned on the steam spout and connected to the stlvap input, the temperature of the liquid heated by the steam is measured. So by pressing the autosteam key in position k6grx key the evvap is activated until the temperature set in the programming...

Page 21

21 english on commissioning the water level in the boiler, the system waits for the level probe to be covered before activating the on/off relay. The sensitivity of the level probes can be varied using a parameter in the technical level programming, in the following cases: -> low sensitivity 150kΩ f...

Page 22

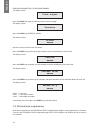

22 english 7.4 programming and readings programming coffee doses the quantities relating to the volumetric coffee doses can be modified and stored by following the procedure set out below in idle-on status, press the k5grx (1..3) key and keep pressing it for 5 seconds; make sure that the lighting of...

Page 23

23 english important: the programming made on the first unit is not automatically transferred to all the other units. To copy the doses onto the other units, press the related continuous keys. This does not however affect the possibility of programming the remaining units independently from the firs...

Page 24

24 english in idle-on status, press the k5grx (1..3) key and keep pressing it for 10 seconds; make sure that the lighting of the leds l5grx (1..3) switches from fixed to flashing. The display shows doses setting select within30s within 30 seconds (time-out to quit the programming phase), press the k...

Page 25

25 english auto on/off- automatic starting and stopping designed to set the automatic starting and stopping times of dosage and the weekly closing day. The display shows auto on/off aaa : hh.Mm the following are programmed in order: - on time in hours (aaa = on) - on time in minutes (aaa = on) - off...

Page 26

26 english reading consumption, litres, maintenance the display shows clock adjust press the k5gr1 key again to move on to the counters reading: the display shows counters press the k3gr1 key (enter) to confirm the display shows litres xxxxx the litres used up until that time are shown. Press the k5...

Page 27

27 english press in off status for 10 seconds k5gr1 note: access to technical level programming and the programming operations can only be done from the push button panel related to unit 1. By accessing the technical level programming in the method described above, the display shows the first techni...

Page 28

28 english the display shows doses setting xxxxxxxx where xxx can be either “disable” or “enable” if you wish to modify the parameter, press the k1gr1 (+) or k2gr1 (-) keys. Once the setting has been made, press the k5gr1 key (menu) to switch to a display which allows you to enable or disable the co...

Page 29

29 english the display shows prebrew. Xx sec yyyyy z.Z where: xx = on or off zz = total prebrewing on time yyyyy = espresso, 2 espressos, coffee or 2 coffees values from 0.1÷5 in 0.1 sec steps if you wish to modify the parameter, press the k1gr1 (+) or k2gr1 (-) keys to increase or decrease the valu...

Page 30

30 english if you wish to modify the parameter, use the k1gr1 (+) or k2gr1 (-) keys. Once the setting has been made, press the k5gr1 key (menu) to switch to a display of the parameters for pid type thermostating: the display shows kp ki kd xx.X y.Yy zz.Z where xx.X is the proportional correction con...

Page 31

31 english the display shows water filter xxxxx where xxxxx is a selectable value of between 0 ÷ 5000 in steps of 1 litre if you wish to modify the “water filter” parameter relating to the litres counted, use the k1gr1 (+) or k2gr1 (-) keys to increase or decrease the value. Press the k5gr1 key (men...

Page 32

32 english boiler temperature probe short-circuited / overheated if the boiler temperature probe is short-circuited or if the temperature exceeds a given value for 5 seconds consecutively, an alarm is signalled through all the leds flashing. The alarm threshold is 140°c. All the main functions of th...

Page 33

33 english no pulses from volumetric meter (5 seconds) when the display shows alarm flow meter gr.X this means no pulses are arriving from the volumetric meter corresponding to the activated unit (x). Indeed, after starting up every volumetric dose (evx + pump both in dispensing and in programming m...

Page 34

34 english k1gr1 k2gr1 the display shows service reset resetting the total individual doses the counting of individual doses can be reset to reset this signal, go to the technical level programming in the total reading menu and press the k1gr1 and k2gr1 keys simultaneously for 3 seconds the display ...

Page 35

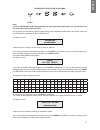

35 english press - in on status - the following keys simultaneously: k1gr1 + k3gr1 + k5gr1 only unit 1 push button panel k1gr1 k3gr1 k5gr1 press simultaneously in on status once preset is complete, the display shows: the display shows preset of values complete to return to normal operation, turn the...

Page 36: 8. Routine Maintenance

36 english 8. Routine maintenance • nopanelorfixedguardoftheappliancebodymayberemovedfromtheittocarryout the routine maintenance. • donotuseharshorharmfuldetergentssuchasalcohol,petrolorsolventstocleanthe coffee machine; use water and neutral detergents. Note: dailycleaningoperationsmustbecarriedout...

Page 37: 9. Idle Periods

37 english 3) open a steam drawing valve to facilitate the draining of the water until the end of the operation. 4) when water no longer comes out of the boiler, close the boiler drain and the steam drawing tap. 5) fill the coffee machine with water as instructed in the paragraph entitled “filling t...

Page 38: 11. Safety Devices

38 english 11. Safety devices 11.1 manual reset safety thermostat the safety thermostat is located next to the control unit and can be accessed by removing the left side panel from the coffee machine. The thermostat probe, placed inside the electric heating elements, cuts the electric power supply a...

Page 39: 13. Guarantee

39 english 13. Guarantee the guarantee becomes void if: • theinstructionsinthismanualarenotcompliedwith. • thescheduledmaintenanceandrepairsarecarriedoutbyunauthorisedpersonnel. • themachineisusedforanyotherthanitsintendedpurposes. • theoriginalpartsarereplacedwithpartsfromdifferentmanufacturers. • ...

Page 40: 15. Troubleshooting

40 english 15. Troubleshooting problem cause solution 1. •theboilerisfullofwater and the water flows out of the safety valve. •oneoftheoutflowlinesfrom the boiler or from a circuit of the unit has a leak. •checktheautolevelcircuit,the manual charging button, and the boiler heat exchangers. •replacew...

Page 41

41 english problem cause solution 9. •overfillalarm •malfunctioninautomaticlevel circuit. •leakinbuttonformanual water filling. •leakinheatexchangers. •checkthehydrauliccircuitofthe autolevel. 10. •themachineisswitched on (the main switch is in position 1 or 2 and the signal light is lit) but the el...

Page 42

42 english problem cause solution 19. •darkcream(thecoffee drips out of the spout). •finegrinding. •highpressingpressure. •largequantityofground coffee. •excessivetemperature. •pumppressurebelow9bar. •sprinklerfilteronunitclogged. •filterholesclogged(filtercup). •coarsergrinding. •reducethepressure....