Installation and operation instructions document 1230a h2338100a warning if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors and liquids in the vicin...

Laars heating systems page 2 table of contents section 1. General information 1.1 introduction ........................................................ 4 model nomenclature ......................................... 4 1.2 model identification ............................................ 4 1.3 applian...

Mascot ii boilers and water heaters page 3 section 9. Modes of operation 9.1 hydronic heating demand .............................. 30 9.2 hydronic heating with outdoor reset ............. 30 9.3 hydronic heating using external modulation control .......................................... 30 9.4 hyd...

Laars heating systems page 4 section 1. General information warning mascot ii units must be installed in accordance with the procedures detailed in this manual, or the laars heating systems warranty will be voided. The installation must conform to the requirements of the local jurisdiction having au...

Mascot ii boilers and water heaters page 5 include the serial number and model (this information can be found on the rating plate), installation date, and name of the installer. Shipping costs are not included in the warranty coverage. Some accessory items may be shipped in separate packages. Verify...

Laars heating systems page 6 figure 2. Location of components..

Mascot ii boilers and water heaters page 7 figure 3. Dimensional drawing. Cond. Hydronic dhw 2nd gas hydronic dhw 2nd outlet return inlet return supply supply outlet supply 3/4" 3/4" 1/2" 3/4" 1/2" 3/4" 1/2" 3/4" pvc copper npt copper npt npt npt copper.

Laars heating systems page 8 section 2. Locating the appliance 2.1 locating the appliance mascot ii is for indoor installations only. The appliance should be located to provide clearances on all sides for maintenance and inspection. It should not be located in an area where leakage of any connection...

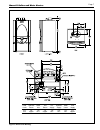

Mascot ii boilers and water heaters page 9 figure 5. Mounting detail. Figure 6. Wall template (not to scale). Full-size template is included with the unit. Note: mascot ii bracket and wall bracket are purposely offset. Note: mascot ii models include 16" on-center mounting holes on upper rear of boil...

Laars heating systems page 10 enclosure shall be provided. The openings shall communicate directly, or by ducts, with the outdoors or spaces that freely communicate with the outdoors. When directly communicating with the outdoors, or when communicating to the outdoors through vertical ducts, each op...

Mascot ii boilers and water heaters page 11 installation standards material united states canada stainless steel ul 1738 venting must be ulc-s636 certified for use as pvc, sch 40 ansi/astm d178 venting material. The venting material must be chosen cpvc, sch 40 ansi/astm f441 based upon the intended ...

Laars heating systems page 12 important note about common venting: a single vent that is shared by multiple mascot ii units must be engineered by a competent venting specialist, and involves the selection of draft inducing equipment, hardware and controls to properly balance flue gas pressures. Do n...

Mascot ii boilers and water heaters page 13 *when vent terminal is less than 10 feet (3m) horizontally from a forced air inlet, the terminal must be at least 3 feet (0.9m) above the air inlet. Figure 9. Combustion air and vent through side wall. U.S. Installations (see note 1) canadian installations...

Laars heating systems page 14 figure 10. Vent dimensions, 2-pipe system. 3.3.3 vertical vent terminal when the unit is vented through the roof, the vent must extend at least 3 feet (0.9m) above the point at which it penetrates the roof. It must extend at least 2 feet (0.6m) higher than any portion o...

Mascot ii boilers and water heaters page 15 following steps shall be followed with each appliance remaining connected to the common venting system placed in operation, while the other appliances remaining connected to the common venting system are not in operation. 1. Seal any unused openings in the...

Laars heating systems page 16 sched 40 metal pipe capacity for 1.50 specific gravity undiluted propane nominal pipe size @ 11" w.C. Inlet and 0.5" w.C. Pressure drop size 1/2" 3/4" length maximum capacity in thousands of btu per hour 20 200 418 40 137 287 60 110 231 80 94 197 100 84 175 notes: 1. Fo...

Mascot ii boilers and water heaters page 17 section 5. Pump capacity 5.1 mascot ii heating system pump capacity (see figure 11) heating dhw size conn size conn size 125 3/4" 1/2" table 7. Water connection pipe sizes. Section 6. Water connections 6.1 central heat system piping note: this appliance mu...

Laars heating systems page 18 air circulation must be equipped with flow control valves or other automatic means to prevent gravity circulation of the boiler water during the cooling cycle. A boiler installed above radiation level, or as required by the authority having jurisdiction, must be provide...

Mascot ii boilers and water heaters page 19 important notes: different glycol products may provide varying degrees of protection. Glycol products must be maintained properly in a heating system, or they may become ineffective. Consult the glycol specifications, or the glycol manufacturer, for inform...

Laars heating systems page 20 figure 15. Hydronic piping — low temp system. Inlet temperature °f 50°f 60°f 70°f gpm temp rise °f 1.0 100 90 81 2.0 90 83 79 3.0 78 76 68 4.0 59 56 51 inlet temperature °c 10°c 16°c 21°c lpm temp rise °c 4 56 50 45 8 50 46 44 11 43 42 38 15 33 31 28 table 8. Dhw and pu...

Mascot ii boilers and water heaters page 21 figure 16. Hydronic piping — multi boilers for large homes with long / multiple baseboard zones. Installer to provide dhw (anti-scald) thermostatic mixing valve..

Laars heating systems page 22 figure 17. Hydronic piping — multi boilers for large homes with long / multiple radiant zones. Installer to provide dhw (anti-scald) thermostatic mixing valve..

Mascot ii boilers and water heaters page 23 figure 18. Hydronic piping — heating zones piped with zone pumps. Installer to provide dhw (anti-scald) thermostatic mixing valve..

Laars heating systems page 24 figure 19. Hydronic piping — heating zones piped with zone valves. Installer to provide dhw (anti-scald) thermostatic mixing valve..

Mascot ii boilers and water heaters page 25 section 7. Electrical connections warning the appliance must be electrically grounded in accordance with the requirements of the authority having jurisdiction or, in the absence of such requirements, with the latest edition of the national electrical code,...

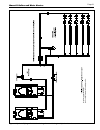

Laars heating systems page 26 figure 21. Ladder diagram. Port 1 (mb1) terminal a of the first boiler to modbus port 1 (mb1) terminal a of the second boiler. B. If there are more boilers in the system connect a wire from modbus port 1 terminal a of boiler 2 to modbus port 1 terminal a of boiler 3. C....

Mascot ii boilers and water heaters page 27 figure 22. Wiring diagram..

Laars heating systems page 28 section 8. Control setup and operation the mascot ii control is an integrated electronic control that replaces many of the individual components found on older appliances. The control acts as the ignition control, pump control, high limit and cascading/ lead lag control...

Mascot ii boilers and water heaters page 29 for established flame. If flame is sensed the control enters "run" to satisfy the demand. If flame is not established the control enters a retry, starting from step 2. If flame has not been established in the appropriate number of retries the control will ...

Laars heating systems page 30 section 9. Modes of operation the mascot ii control allows the boiler to operate in many different modes of operation. The mode must be selected based upon the requirements of the installation. The following sections describe the basic operation of the mascot ii in each...

Mascot ii boilers and water heaters page 31 monitors the flame signal, call for heat, safeties, and water temperatures. The boiler setpoint is used to limit the maximum water temperature leaving the boiler only. The modulation rate is controlled by a 4-20ma (0- 10vdc using converter) signal supplied...

Laars heating systems page 32 12. Refer to local codes and the make-up water valve manufacturer’s instructions as to whether the make-up water valve should be left open or closed. 13. After placing the unit in operation, the ignition system safety shutoff device must be tested. First, shut off the m...

Mascot ii boilers and water heaters page 33 proper gas supply. Wait 5 minutes and start the unit again. 5. Turn mascot ii on. 6. After placing the appliance in operation, the burner safety shutoff device must be tested: (a) close gas shutoff valve with burner operating. (b) flame will go out and blo...

Laars heating systems page 34 gas type high fire, co 2 % low fire, co 2 % natural 9.0 9.0 propane 10.0 10.0 table 13. Co 2 range. Figure 25. Adjustment screws and settings for co 2 ..

Mascot ii boilers and water heaters page 35 section 11. Maintenance warning disconnect all power to the appliance before attempting any service to the appliance. Contact with electricity can result in severe injury or death. 11.1 system maintenance (yearly, unless otherwise noted) 1. If a strainer i...

Laars heating systems page 36 ignitor assembly in the reverse order if the old assembly is determined defective. Replace gasket if necessary. 11.2.4 flame sensor the flame sensor is a single rod system. To replace the flame sensor electrode, shut off the 120 volt power supply to the boiler. Turn off...

Mascot ii boilers and water heaters page 37 installation of this kit. The installation is not proper and complete until the operation of the converted appliance is checked as specified in the manufacturer's instruction supplied with the kit. Avertissement ce conversion doit être installé par un orga...

Laars heating systems page 38 code# problem probable cause solution common lockout codes 27 internal error flame rod to ground check wiring / probe grounded, dirty probe 47 flame rod to ground leakage faulty flame detector clean or replace flame detector 49 24vac voltage low/high faulty transformer ...

Mascot ii boilers and water heaters page 39 49 maximum cycle count control operates correctly, was reached however the cycle count will not increment any higher than 999,999 cycles replace controller or adjust the count using blue display 50 maximum hours count control operates correctly, was reache...

Laars heating systems page 40 13.2 parts list item description size 125 panel assemblies – see figures 27-30 1 panel, front, top, assy 12h3005 1a panel, top, upper 12h7001 1b screw, captive, .19 x .54 fast lead, phil pan hd f2028100 1c screw, #8-32 x 3/8", phil pan hd f2027100 1d gasket, strip, foam...

Mascot ii boilers and water heaters page 41 item description size 125 item description size 125 burner components - see figure 33 1 burner, main r2069102 2 gasket, burner rs2108500 3 tile, refractory, front, combustion chamber rt2109000 4 ignitor, spark, w/gasket r2069300 5 flame sensor, w/gasket r2...

Laars heating systems page 42 figure 28. Panel assembly, door top..

Mascot ii boilers and water heaters page 43 figure 29. Panel assembly, door middle..

Laars heating systems page 44 figure 30. Panel assembly, door bottom..

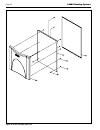

Mascot ii boilers and water heaters page 45 figure 31. Base jacket assembly..

Laars heating systems page 46 figure 32. Heat exchanger cabinet, fan..

Mascot ii boilers and water heaters page 47 figure 33. Heat exchanger burner components..

Laars heating systems page 48 figure 34. Pump assembly components..

Mascot ii boilers and water heaters page 49 figure 35. Plumbing components..

Laars heating systems page 50

Mascot ii boilers and water heaters page 51.

H2338100a 800.900.9276 • fax 800.559.1583 (customer service, service advisors) 20 industrial way, rochester, nh 03867 • 603.335.6300 • fax 603.335.3355 (applications engineering) 1869 sismet road, mississauga, ontario, canada l4w 1w8 • 905.238.0100 • fax 905.366.0130 www.Laars.Com litho in u.S.A. © ...