- DL manuals

- Laars

- Boiler

- MASCOT LX

- Installation And Operation Instructions Manual

Laars MASCOT LX Installation And Operation Instructions Manual

Installation and Operation Instructions

Document 1285A

H2364000A

WARNING

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or loss of life.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of

this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the fire department.

Installation and service must be performed

by a qualified installer, service agency, or gas

supplier.

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in hot water boiler and heater installation and maintenance. Improper installation and/or operation

could create carbon monoxide gas in flue gases which could cause serious injury, property damage, or

death. Improper installation and/or operation will void the warranty.

AVERTISSEMENT

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion

ou pour éviter tout dommage matériel, toute

blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ou ni

d’autres vapeurs ou liquides inflammables dans

le à proximité de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE

GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous servir

des téléphones dans le bâtiment où vous vous

trovez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualifié

ou par le fournisseur de gaz.

Installation and Operation

Instructions for

M

ASCOT

®

LX

Wall-Mounted, Modulating

Boiler

Model MLXH

50, 75, 100, 125, 150, 175,

& 220 MBH

Combination Boiler

Model MLXC

125, 150 and 175 MBH

Summary of MASCOT LX

Page 1

Installation and operation instructions document 1285a h2364000a warning if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors and liquids in the vicin...

Page 2

Laars heating systems pr 15, july 22nd 2014 table of contents section 1. General information 1.1 introduction ........................................................ 1 1.2 to open the mascot lx ...................................... 1 1.3 rating plate ..................................................

Page 3

Mascot lx boilers and water heaters section 8. Control setup and operation 8.1 digital display ................................................... 31 8.2 controller modes ..................................... 32 8.3 user mode ........................................................ 33 8.4 installer ...

Page 4

Laars heating systems m ascot lx figure 1. Opening the mascot lx. The top and bottom panels come off when pulled forward. This is true for all sizes. Start-up instructions section 1. General information warning mascot lx units must be installed in accordance with the procedures detailed in this manu...

Page 5

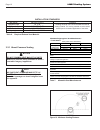

Mascot lx boilers and water heaters page 1 figure 1. Opening the 100, 125, 150, 175, and 220 figure 2. Model nomenclature 2 3 4 5 6 7 8 9 10 11 12 13 l x a x n series laars heat exchanger label mascot usage h - hydronic c - combi unit sizes mbtu/h 5 0 7 5 1 0 0 1 2 5 1 5 0 1 7 5 2 2 0 fuel n - natur...

Page 6

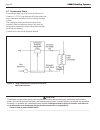

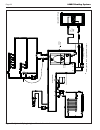

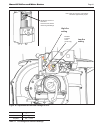

Laars heating systems page 2 figure 3. Location of components 1.5 mascot lx, overview central heat in connection (return water) central heat in connection (return water) central heat out connection (supply water) central heat out connection (supply water) shown with the front panels off, and a side ...

Page 7

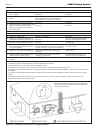

Mascot lx boilers and water heaters page 3 figure 4. Start up / shut down instructions (decal) (3).Turn manual gas cock "off" h23377- qualified service technician to inspect the appliance and to replace any gas control which c. Do not use this appliance if any part has been under water. Immediately ...

Page 8

Laars heating systems page 4 314" 8 314" 8 734" 20 n 17" 43 top m o 834" 22 234" 7 gas gas hydronic outlet hydronic outlet elimination air air vent inlet exhaust vent hydronic inlet hydronic inlet h f g e a d c condensate trap mascot lx boiler models, piping install location dim a hydronic out dim b...

Page 9

Mascot lx boilers and water heaters page 5 table 1. Dimensional tables, all sizes table 2. Piping type and sizes dimension model a b c d e f g h j * k l m n o 50, 75 mbh 1" (3) 15-3/4" (40) 3-3/4" (9) 9-1/4" (24) 8" (20) 1-1/2" (4) 5-3/4" (14) 15-1/2" (39) -- -- -- 30-1/2" (78) 15-1/4" (39) 4-5/8" (...

Page 10

Laars heating systems page 6 figure 6. Contents of the hardware shipping package some accessory items may be shipped in separate packages. Verify receipt of all packages listed on the packing slip. Inspect everything for damage immediately upon delivery, and advise the carrier of any shortages or da...

Page 11

Mascot lx boilers and water heaters page 7 section 2. Locating the appliance 2.1 locating the appliance the mascot lx is designed for indoor wall-mounted installations only. The mascot lx must be mounted to a suitable wall by a qualified heating contractor under the guidelines of a wall mounted boil...

Page 12

Laars heating systems page 8 figure 8. Mounting detail. Note: mascot lx bracket and wall bracket are purposely offset. Bracket factory- mounted on back of mascot wall bracket pro- vided by laars wall to which mascot lx is mounted anchor / fastener provided by installer - appropriate for 250 lbs (114...

Page 13

Mascot lx boilers and water heaters page 9 table 4. Vent / air pipe sizes vent system vent system intake / exhaust max equivalent * vent and air pipe length (each) standard optional size 2" dia 5.1cm 3"/5" dia 7.6/12.7cm 125 40 ft 12.2m 40 ft 12.2m installations in the u.S. Require exhaust vent pipe...

Page 14

Laars heating systems page 10 3.2 venting (exhaust) the flue temperature of the mascot lx changes dramatically with changes in operating water temperature. Therefore, it is necessary to assess the application of the boiler to determine the required certified vent class. If the mascot lx is installed...

Page 15

Mascot lx boilers and water heaters page 11 notice for category ii and iv boilers, be installed so as to prevent accumulation of condensate; and for category ii and iv boilers, where necessary, have means provided for drainage of condensate. Avis les chaudières de catégories ii et iv doivent être in...

Page 16

Laars heating systems page 12 figure 10. Minimum venting distance. Notice do not common vent mascot lx units. Mascot lx units are never permitted to share a vent with category i appliances. Avis ne pas Évent commune mascotte lx unitÉs. Mascotte lx unités ne sont jamais autorisés à partager un évent ...

Page 17

Mascot lx boilers and water heaters page 13 figure 11. Combustion air and vent through roof. 3.3.2 side wall combustion air terminal the laars side wall combustion air terminal, or concentric terminal ( see table 5 ), must be used when the heater takes air from a side wall. Consider the following wh...

Page 18

Laars heating systems page 14 *when vent terminal is less than 10 feet (3m) horizontally from a forced air inlet, the terminal must be at least 3 feet (0.9m) above the air inlet. Figure 12. Combustion air and vent through side wall. U.S. Installations (see note 1) canadian installations (see note 2)...

Page 19

Mascot lx boilers and water heaters page 15 3.3.3 vertical vent terminal when the unit is vented through the roof, the vent must extend at least 3 feet (0.9m) above the point at which it penetrates the roof. It must extend at least 2 feet (0.6m) higher than any portion of a building within a horizon...

Page 20

Laars heating systems page 16 notice at the time of removal of an existing boiler, the following steps shall be followed with each appliance remaining connected to the common venting system placed in operation, while the other appliances remaining connected to the common venting system are not in op...

Page 21

Mascot lx boilers and water heaters page 17 warning: open flame can cause gas to ignite and result in property damage, severe injury, or loss of life. Note: the mascot lx appliance and all other gas appliances sharing the gas supply line must be firing at maximum capacity to properly measure the inl...

Page 22

Laars heating systems page 18 mascot lx natural gas required size cu ft / hr input rate. 50 50 75 75 100 100 125 125 150 150 175 175 220 220 to size piping: measure linear distance from meter outlet to last boiler. Add total input of all boilers and divide by 1000 to obtain cu ft / hr required. Add ...

Page 23

Mascot lx boilers and water heaters page 19 note: laars supplied pumps are not all capable of maintaining the reduced temperature rise required with glycol concentrations greater than 35%. Notice different glycol products may provide varying degrees of protection. Glycol products must be maintained ...

Page 24

Laars heating systems page 20 caution condensate is mildly acidic (ph=5), and may harm some floor drains and/or pipes, particularly those that are metal. Ensure that the drain, drainpipe, and anything that will come in contact with the condensate can withstand the acidity, or neutralize the condensa...

Page 25: Cot

Mascot lx boilers and water heaters page 21 figure 14. Hydronic piping — high and low temp zones. 6.8 piping schematics figure 14 through figure 19 illustrate typical piping configurations for mascot lx boilers. These diagrams are only meant as a guide. All components or piping required by local cod...

Page 26: T Lx

Laars heating systems page 22 figure 15. Hydronic piping (only) — with an indirect tank as a zone. M as co t lx - r es id en tia l h ig h an d low te m p. Zo nes w / i nd ire ct w ater h eat er h ea ting s upp ly a ir e lim inat or s edi m ent tra p 1" pi pi ng to d h w ind irec t d w h t ank 18" he...

Page 27: Ulti M

Mascot lx boilers and water heaters page 23 figure 16. Hydronic piping — mlxc multi boilers for large homes with long / multiple baseboard zones. Zones with: -zone v alv es 24v -balancing v alv es air seperator dhw 1- 1 4 " primary loop m ulti m ascot lxs for large house residential w ith long / mul...

Page 28: Ulti M

Laars heating systems page 24 figure 17. Hydronic piping — mlxc multi boilers for large homes with long / multiple radiant zones. Zones with: -zone v alv es 24v -balancing v alv es 1- 1 4 " primary loop m ulti m ascot lx boilers for large house residential w ith long / muliple radiant zones * closel...

Page 29

Mascot lx boilers and water heaters page 25 figure 18. Hydronic piping — mlxc heating zones piped with zone pumps. Mascot lx com bi -hydronic piping -heating zones piped with zone pum ps water feed controls ex pansion tank air v ent purge/drain v alv es dhw 1 1 4 " primary loop increase from 3 4 to ...

Page 30

Laars heating systems page 26 figure 19. Hydronic piping — heating zones piped with zone valves. Ex pansion tank air v ent purge/drain v alv es dhw 1 1 4 " primary loop sedim ent trap * closely spaced tee's - 4 pipe diam eters apart increase from 3 4 to 1 1 4 manifold size based on num ber of zones ...

Page 31

Mascot lx boilers and water heaters page 27 section 7. Electrical connections warning the appliance must be electrically grounded in accordance with the requirements of the authority having jurisdiction or, in the absence of such requirements, with the latest edition of the national electrical code,...

Page 32

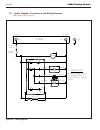

Laars heating systems page 28 figure 20. Ladder diagram. System sensor flame rod hi limit switch bldg mgmt system in field interlocks air pressure switch outdoor sensor h-x/dhw sensor tank aquastat cond. Level switch blocked vent sw hi-lo gas press sw water press switch x11-7 x2-3 x11-14 x2-6 24 vac...

Page 33

Mascot lx boilers and water heaters page 29 figure 21. Field wiring connections high voltage field connections (located behind the inside lower panel) shown at actual size shown at actual size low voltage field connections (located on the front of the inside lower panel) outdoor sensor system sensor...

Page 34

Laars heating systems page 30 figure 22. Wiring diagram. Bo ile r pum p sy st em p um p re la y c ir c ui t br ea ke r c ir c ui t br ea ke r fl o w sw itc h a ir pr ess ur e s w itc h bl o c ke d v en t sw l o w w a te r c ut o ff s pa rk ig n ito r h- x/ dh w sens o r o pe r. C o n tr o l s a fe t...

Page 35

Mascot lx boilers and water heaters page 31 section 8. Control setup and operation the mascot lx control is an integrated electronic control that includes flame control, safety device monitoring and pump regulating functions. The control regulates the heat input by controlling the blower speed and a...

Page 36

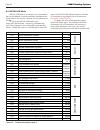

Laars heating systems page 32 8.2 controller modes three control modes can be displayed: user, installer, and service. User mode is for a homeowner or service technician to adjust the most common operating parameters ( see table 14 ). Installer mode allows an installer access to all of the parameter...

Page 37

Mascot lx boilers and water heaters page 33 8.3 user mode the user mode is for a homeowner or service technician to adjust the most common operating parameters ( see table 14 ). In the user mode, when the boiler is on and operating normally, the user can scroll up and down using the arrow keys. Of t...

Page 38

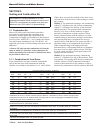

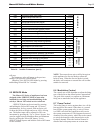

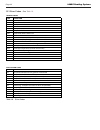

Laars heating systems page 34 table 15. Installer parameters (part 1) laars sit parameters page 1 user mode parameter description default parameter u000 dhw set point 120 °f ushwdem u001 ch set point 130 ° f us1setp u002 installer password 15 uspwd u003 display timeout 60 sec dui1 u004 unit temperat...

Page 39

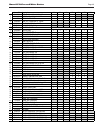

Mascot lx boilers and water heaters page 35 laars sit parameters page 2 p49 ch priority time over dhw 0 min switchovtch p50 dhw priority time over ch 55 min * displayed as seconds switchovthw p51 dhw tank setpoint 180 ° f hwtnksetp p52 stop dhw tank demand offset 0 ° f hwdemstop p53 start dhw tank d...

Page 40

Laars heating systems page 36 8.8 high limit the control uses a dual thermistor sensor to monitor the mascot lx's maximum temperature. The high limit sensor is installed in the outlet water. A dual thermistor sensor is used, so that the two temperatures can be monitored and compared to confirm accur...

Page 41

Mascot lx boilers and water heaters page 37 outlet setpoint. The 0-10v signal may also be used to create a heat demand eliminating the need to supply a separate “tt call”. 9.3.A external signal to control modulation. Installer parameter p25 “0-10v to power (fan speed)” – this is the default 0-10vdc ...

Page 42

Laars heating systems page 38 9.7.1 cascade manual configuration in some applications it may be necessary to configure the cascade system manually. To do this, the boilers should be wired as shown in the auto cascade section of the manual. Then each individual control in the cascade must have a spec...

Page 43

Mascot lx boilers and water heaters page 39 the highest point in the circulating loop, then the system is ready for operation. 12. Refer to local codes and the make-up water valve manufacturer’s instructions as to whether the make- up water valve should be left open or closed. 13. After placing the ...

Page 44

Laars heating systems page 40 4. Mascot lx will enter the start sequence. Blower and pump will energize for pre-purge, then the ignition sequence starts. After all safety devices are verified, the gas valve opens. If ignition doesn’t occur, turn off the mascot lx, check that there is proper gas supp...

Page 45

Mascot lx boilers and water heaters page 41 gas type co2 (%) range ) natural 8.9 __ 9.9 propane 9.9 __ 10.9 table 17. Co 2 range and pressure settings. Figure 26. Adjustment screws and settings for co 2 manifold pressure screw (under cap) high-fire setting adjustment screws on gas valve close door f...

Page 46

Laars heating systems page 42 section 11. Maintenance warning disconnect all power to the appliance before attempting any service to the appliance. Contact with electricity can result in severe injury or death. 11.1 system maintenance (yearly, unless otherwise noted) 1. If a strainer is employed in ...

Page 47

Mascot lx boilers and water heaters page 43 the fastening points on the right side of the control to remove the hooks from the control panel. To replace the control repeat the steps above in the reverse order making sure to connect all wires in the proper location. Place the appliance in operation f...

Page 48: Natural

Laars heating systems page 44 warning failure to rinse the debris from the heat exchanger and temporary drain line may lead to clogged condensate lines, traps and neutralizers. Condensate pumps (if used) may also be damaged from the debris left behind, possibly causing property damage. 10. Install a...

Page 49

Mascot lx boilers and water heaters page 45 section 12. Troubleshooting 12.1 sequence of operation mascot lx is a cold start appliance that should start only on a call for heat from a tank aquastat, room thermostat, zone valve end switch or other space temperature control device (flow switch for dhw...

Page 50

Laars heating systems page 46 lockout codes code description e001 memory error lockout e002 fan speed error e003 flame present when not in run e004 outlet auto-reset hi limit e005 water pressure switch error e006 safety switch - tbd e007 optional low-water cutoff error e008 field interlock error e00...

Page 51

Mascot lx boilers and water heaters page 47.

Page 52

Laars heating systems page 48 section 13. Replacement parts 13.1 exploded parts views, and their laars part numbers 4 see figure 31, for blower and combustion parts figure 30. Parts 12 11 42 43 44 45 13 10 14 46 47 26 40 7 38 39 35 37 41 6 3 1 2 27 30 5 4 32 28 31 29 33 34.

Page 53

Mascot lx boilers and water heaters page 49 2-jun-14 ref laars pn description 50 75 100 125 150 175 220 12p9102 1 p2067603 pipe, pvc, 3/4" sch 40 x 6" long x x x x 2 s2116300 o-ring, -120, 1" id x 1-3/16" od x x x x 3 a2117500 trap, condensate x x x x 3 r2076000 trap kit, condensate - large x x x 1...

Page 54

Laars heating systems page 50 4 figure 31. Parts, blowers and combustion 20 18 15 16 26 24 25 27 22 23 21 19.

Page 55

Mascot lx boilers and water heaters page 51 2-jun-14 ref laars pn description 50 75 100 125 150 175 220 12p9102 1 p2067603 pipe, pvc, 3/4" sch 40 x 6" long x x x x 2 s2116300 o-ring, -120, 1" id x 1-3/16" od x x x x 3 a2117500 trap, condensate x x x x 3 r2076000 trap kit, condensate - large x x x 1...

Page 56

Laars heating systems h2364000a customer service and product support: 800.900.9276 • fax 800.559.1583 headquarters: 20 industrial way, rochester, nh 03867 • 603.335.6300 • fax 603.335.3355 1869 sismet road, mississauga, ontario, canada l4w 1w8 • 905.238.0100 • fax 905.366.0130 www.Laars.Com litho in...