- DL manuals

- Laars

- Boiler

- NTH

- Installation And Operation Instructions Manual

Laars NTH Installation And Operation Instructions Manual

Installation and Operation Instructions

Document 1330A

H2374100A

WARNING

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or loss of life.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the fire department.

Installation and service must be performed

by a qualified installer, service agency, or gas

supplier.

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in hot water boiler and heater installation and maintenance. Improper installation and/or operation

could create carbon monoxide gas in flue gases which could cause serious injury, property damage, or

death. Improper installation and/or operation will void the warranty.

AVERTISSEMENT

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion

ou pour éviter tout dommage matériel, toute

blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inflammables dans

le voisinage de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous

servir des téléphones dansle bâtiment où vous

vous trouvez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualifié ou

par le fournisseur de gaz.

Installation and Operation

Instructions for

N

EO

T

HERM

®

with Touchscreen Display

Modulating Boiler

Model NTH

Sizes 285–850 MBTU/h

Water Heater

Model NTV

Sizes 150–850 MBTU/h

Summary of NTH

Page 1

Installation and operation instructions document 1330a h2374100a warning if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors and liquids in the vicin...

Page 2

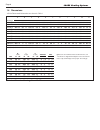

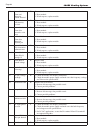

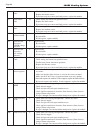

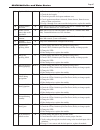

Laars heating systems section 1 - general information 1.1 introduction ....................................................... 1 1.2 modelidentification ........................................... 1 1.3 applianceoverview .......................................2-5 1.4 warranty ..........................

Page 3

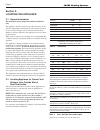

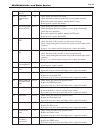

Neotherm boilers and water heaters ii section 9 - first start up and adjustment 9.1 fillingtheboilersystem ................................. 54 9.2 firstoperation ................................................ 54 9.3 shuttingdowntheneothermunit ................. 55 9.4 restartingtheneothermunit .....

Page 4

Laars heating systems.

Page 5

Page 1 n eo t herm boilers and water heaters section 1 - general information warning neotherm units must be installed in accordance with the procedures detailed in this manual, or the laars heating systems warranty will be voided. The installation must conform to the requirements of the local jurisd...

Page 6

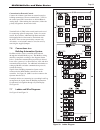

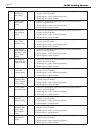

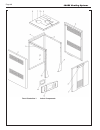

Page 2 laars heating systems figure 1. Locationofcomponents,sizes150-210 figure 2. Locationofcomponents,size285 exhaust vent connection gas connection air pressure switch touchscreen heat exchanger gas valve venturi air/ gas blower pressure relief valve water inlet water outlet air inlet connection ...

Page 7

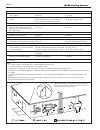

Page 3 n eo t herm boilers and water heaters figure 4. Locationofcomponents,size399 exhaust vent connection gas connection touchscreen heat exchanger manual shutoff gas valve venturi air/ gas blower pressure relief valve water inlet water outlet air inlet connection drain valve condensate trap gas v...

Page 8

Page 4 laars heating systems figure 5. Locationofcomponents,size600 exhaust vent connection gas connection pressure relief valve touchscreen heat exchanger manual shutoff gas valve venturi air/ gas blower air pressure switch water inlet water outlet air inlet connection drain valve condensate trap g...

Page 9

Page 5 n eo t herm boilers and water heaters figure 6. Locationofcomponents,sizes750and850 water inlet water outlet air inlet drain valve condensate trap air/ gas blower pressure relief valve touchscreen heat exchanger exhaust vent connection venturi gas valve gas connection manual shutoff gas valve...

Page 10

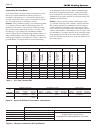

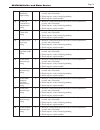

Page 6 laars heating systems table1. Dimensiondrawing,sizes150-850 a b c d e f g j k m n size/model in cm in cm in cm in cm in cm in cm in cm in cm in cm in cm in cm 150 ntv 13¼ 34 5¼ 14 19 48 3¼ 8 10¾ 28 7½ 19 14¼ 36 19½ 49 7½ 19 15¼ 39 13 33 199 ntv 20½ 52 5¼ 14 19 48 3¼ 8 17¾ 45 7½ 19 14¼ 36 19½ ...

Page 11

Page 7 n eo t herm boilers and water heaters.

Page 12

Page 8 laars heating systems section 2 - locating the appliance 2.1 general information the neotherm unit is designed for indoor installations only. The appliance should be located to provide clearances on all sides for maintenance and inspection. It should not be located in an area where leakage of...

Page 13

Page 9 n eo t herm boilers and water heaters section 3 - venting and combustion air 3.1 generalventing this product requires a special venting system. Refer to venting supplier’s instructions for complete parts list and method of installation. The manufacturers and product lines listed on the follow...

Page 14

Page 10 laars heating systems of all equipment in the enclosure. When communicating to the outdoors through horizontal ducts, each opening shall have a minimum free area of not less than 1 square inch per 2000 btu/hr (1100 square mm/kw) of total input rating of all equipment in the enclosure. Method...

Page 15

Page 11 n eo t herm boilers and water heaters other methods of introducing combustion and ventilation air are acceptable, providing they conform to the requirements in the applicable codes listed above. In canada, consult local building and safety codes or, in absence of such requirements, follow ca...

Page 16

Page 12 laars heating systems connected to the cpvc section included with neotherm sizes 80-850. The cpvc vent section included with the neotherm may be broken by cpvc fittings if necessary, but never reduced in total length. See table 3 to select the appropriate vent pipe diameter. When using polyp...

Page 17

Page 13 n eo t herm boilers and water heaters an exhaust vent terminal must be installed. If an exhaust vent terminal is not available with the certified vent system, laars suggests the use of a coupler fitting from the certified vent system into which the vent terminal screen, included with the neo...

Page 18

Page 14 laars heating systems *when vent terminal is less than 10 feet (3m) horizontally from a forced air inlet, the terminal must be at least 3 feet (0.9m) above the air inlet. (us only) figure 13. Combustionairandventthroughsidewall u.S.Installations(seenote1) canadianinstallations(seenote2) a= c...

Page 19

Page 15 n eo t herm boilers and water heaters 1. Installation of carbon monoxide detectors at the time of installation of the side wall vented gas fueled appliance, the installing plumber or gas-fitter shall observe that a hard-wired carbon monoxide detector with an alarm battery back-up is installe...

Page 20

Page 16 laars heating systems section 4 - gas supply and piping gas piping should be supported by suitable hangers or floor stands, not the appliance. Review the following instructions before proceeding with the installation. 1. Verify that the appliance is fitted for the proper type of gas by check...

Page 21

Page 17 n eo t herm boilers and water heaters sched 40 metal pipe capacity for 1.50 specific gravity undiluted propane nominal pipe size @ 11” w.C. Inlet and 0.5” w.C. Pressure drop size 1/2” 3/4” 1” 1-1/4” 1-1/2” 2” length maximum capacity in thousands of btu per hour 20 200 418 787 1616 2422 4664 ...

Page 22

Page 18 laars heating systems neotherm’s efficiency is higher with lower return water temperatures. Therefore, to get the most of low return temperature with multiple boilers, pipe as shown in figures 17-19. Neotherm ntv models 150-500 can be ordered with or without a pump included. Neotherm nth mod...

Page 23

Page 19 n eo t herm boilers and water heaters 6a.3condensatedrain a condensate drain trap is built into the neotherm unit. Connect a 3/4” pvc pipe between the drain connection and a floor drain (or a condensate pump if a floor drain is not accessible). The condensate drain must be installed so as to...

Page 24

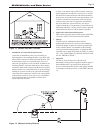

Page 20 laars heating systems figure 16. Hydronicpiping—singleboiler,zoningwithcirculators.

Page 25

Page 21 n eo t herm boilers and water heaters figure 17. Hydronicpiping—singleboiler,lowtempradiantspaceheatingusinglowlossheaderand zonevalves.

Page 26

Page 22 laars heating systems figure 18. Hydronicpiping—multipleboilers,zoningwithcirculators.

Page 27

Page 23 n eo t herm boilers and water heaters figure 19. Hydronicpiping—multipleboilerswithindirectdhwtankpipedfromsystemloop.

Page 28

Page 24 laars heating systems figure 20. Hydronicpiping—multipleboilers,reversereturn,multi-tempzones,zoningwithcirculators.

Page 29

Page 25 n eo t herm boilers and water heaters figure 21. Hydronicpiping—heatingzoneswithindirectdhwtankpipedwithzonepumps the indirect dhw tank is piped directly off of the boiler. The boiler pump must shut down during dhw operation..

Page 30

Page 26 laars heating systems figure 22. Hydronicpiping,multipleboilerswithindirectdhwoffofoneboiler the boiler pump must shut down during dhw operation..

Page 31

Page 27 n eo t herm boilers and water heaters not be warranted. If the water in use exceeds the conditions recommended, a water softener or other device should be installed to improve water quality. 6b.2 piping requirements water piping should be supported by suitable hangers and floor stands. Do no...

Page 32

Page 28 laars heating systems factory pumps or other pumps are installed, the piping should be installed such that the pump supplies flow to the heater it is attached to only. The factory pumps are sized for 30 feet and 6 elbows of total pipe length, so the heater should be placed within 15 feet of ...

Page 33

Page 29 n eo t herm boilers and water heaters figure 24. Dhwpiping,oneheater,twoverticaltanks notes: 1. Optional cwmu & recirc. Line location. 2. Locate ntv dhw sensor or remote aquastat well in lower 1/3 of tank. 3. Back flow preventer may be required - check local codes. 4. Thermal expansion tank ...

Page 34

Page 30 laars heating systems figure 25. Dhwpiping,twoheaters,oneverticaltank figure 26. Dhwpiping,twoheaters,twoverticaltanks notes: 1. Optional cwmu & recirc. Line location. 2. Locate ntv dhw sensor or remote aquastat well in lower 1/3 of tank. 3. Back flow preventer may be required - check local ...

Page 35

Page 31 n eo t herm boilers and water heaters section 7 - installation and wiring 7.1installationwarnings 7.2 mainpowerconnections connect a 15a fused, 120-volt supply to the main power switch. (the hot leg is connected directly to the switch.) the neutral leg is connected directly to the white wire...

Page 36

Page 32 laars heating systems water heater sizes volts phase amps 199-500 120 single 2* no pump 199 120 single 7* with pump 285-500 120 single 8* with pump 600-850 see pump rating plate fla no pump (must be less than 7.4 fla) * minimum 15a circuit required boiler pump connections ratings sizes volts...

Page 37

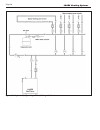

Page 33 n eo t herm boilers and water heaters figure 30. Ladderdiagram connections for external control - connect the 4-20ma signal from an external control or building automation system to terminal block 7 (tb7) in the control panel. The connections are labeled remote analog input. When making the ...

Page 38

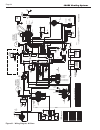

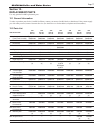

Page 34 laars heating systems figure 31. Wiringdiagram,allsizes bo ile r pu m p gn d bl k w h g n co m 2 24vac 24v co m 1 2 3 4 5 6 7 8 to tb4 -1 to tb3 -1 co m 1 bl /g n y/ g n pressur e switch br o r/ w h br or/wh n c c o m mb 1 mb 2 ec o m b a v d c b gn d the rm o- fu se o pt io na l swit ch use...

Page 39

Page 35 n eo t herm boilers and water heaters figure 32. Neotherm with touch screen touch screen section 8 navigating the touch screen 8.1 the touch screen the touch screen is located front and center on the neotherm and allows you to navigate into all of the functionality and control that is availa...

Page 40

Page 36 laars heating systems screen menu icons there are several icons at the top of the touch screen menus (and most of the other screens) that will help you move around the system: home upper left-hand corner return to home page camera upper left-hand corner screen-shot of current menu as a jpg f...

Page 41

Page 37 n eo t herm boilers and water heaters surface of the screen.) each time you press a key, the system will respond with a beep. If you are entering a password, an asterisk (*) will appear for each character you enter. The beeps and asterisks will help you enter the correct number of characters...

Page 42

Page 38 laars heating systems menu 7. Safetyparameterconfirmation 5. For each group, check the list carefully. Press yes if all of the parameters in the group have been entered correctly. For each group, you are given 30 seconds to select yes/no. A count-down timer is shown at the bottom of the scre...

Page 43

Page 39 n eo t herm boilers and water heaters 8.5configuringparameters in this section, we will give you a quick explanation of how to change parameters on the controller. 1. From the home page screen (menu 11), press the icon for the controller. Menu 11. Homepagescreen 2. The status summary page fo...

Page 44

Page 40 laars heating systems 8.6settingthedateandtimeonthe systemdisplay the display includes an internal clock, which keeps track of the date and time. This setting is important, because log entries for lockouts and alerts include time listings. If the date and time setting for the boiler is not c...

Page 45

Page 41 n eo t herm boilers and water heaters 8.7 configurationsub-menus(all) menu 18. Home screen to navigate to the configuration menu screen, first touch the controller icon on the home screen to access the status summary screen, menu 19. Statussummaryscreen from the status summary screen, touch ...

Page 46

Page 42 laars heating systems 8.7.4 dhw-domestichotwater configuration dhw - domestic hot water is used to configure the dhw temperature parameters for water heaters (ntv) and for indirect water heaters that are used with boiler (nth) systems. 8.7.5 warmweathershutdown configuration from this sub-me...

Page 47

Page 43 n eo t herm boilers and water heaters the system pump connections are located on terminal block 5 (tb5) in the control panel. The system pump contacts are rated for 120vac, 7.4 amps. To use the contacts, power must be supplied on one terminal with the other terminal wired to the pump or a re...

Page 48

Page 44 laars heating systems 8.7.13 frost protection frost protection will assist in keeping the neotherm from freezing when the unit is not able to fire, but is still able to run the pumps. The frost overrun time can be changed on this screen. 8.7.14systemconfiguration the installer can set the co...

Page 49

Page 45 n eo t herm boilers and water heaters figure 35. Lead/lagoperation,2boilers. Low demand - the first boiler in sequence fires at less than 65% first boiler second boiler demand increases - once the first boiler reaches 65%, the second boiler switches on, and both modulate together between 20%...

Page 50

Page 46 laars heating systems figure 37. Lead/lagoperation,3ormoreboilers low demand - the first boiler in sequence fires at less than 65% 1 2 3 4 demand increases - once the first boiler reaches 65%, the second boiler switches on, and both modulate together between 29% and 65% demand increases - on...

Page 51

Page 47 n eo t herm boilers and water heaters menu 23. Configurationmenu, scroll down and select ‘lead lag slave configuration’. In the lead lage slave sub-menu, identify each unit (including the lead/lag master) as a slave by turning on “slave enable.” 8.7.17lead/lagslaveconfiguration menu 21. Home...

Page 52

Page 48 laars heating systems 8.7.18leadlagmasterconfiguration then set up the master controller by going to the lead lag master boiler and opening up the lead lag master configuration in that boilers configuration menu. Select master enable select ok and then back out to the main menu. Wiring conne...

Page 53

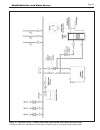

Page 49 n eo t herm boilers and water heaters figure 39. Basconnnectionstoasingleboiler 8.8 connectionstoa buildingautomationsystem neotherm boilers can be controlled and monitored through the included modbus ports. The modbus wiring must be completed according to the diagrams shown below. If altern...

Page 54

Page 50 laars heating systems 8.10.1–combustionsetupprocedure in this section, we will explain how to set up the gas valve so the boiler will run efficiently at both the high fire and low fire conditions. Required tools: screwdrivers, torx bits, allen wrench set, combustion analyzer warning improper...

Page 55

Page 51 n eo t herm boilers and water heaters auto at the end of the test. Manual in run - the manual in run control will only set the fan speed when the control has proven flame and the unit has entered the run mode. Manual in run and standby - using this setting, the manual control will set the fa...

Page 56

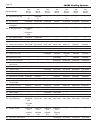

Page 52 laars heating systems 500 399 gas type high fire, co 2 low fire, co 2 diffrntl pressure ( incheswc) natural 8.8 to 9.8% 0.5% lower than 3.6” to 3.9” propane 9.8 to 10.2% high fire setting table16. (residential,sizes150-285mbtu) co 2 rangeanddifferentialpressure gas type high fire, co 2 low f...

Page 57

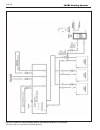

Page 53 n eo t herm boilers and water heaters 600 750,850 inlet gas pressure high fire co 2 adjustment (under cap) gas pressure tap low fire co 2 adjustment outlet gas pressure inlet gas pressure low fire co 2 adjustment high fire co 2 adjustment (under cap) outlet gas pressure gas pressure tap outl...

Page 58

Page 54 laars heating systems 14. Prime the condensate trap with water. (this is not required for nth 600, 750, and 850 units.) 15. Refer to local codes and the make-up water valve manufacturer’s instructions as to whether the make-up water valve should be left open or closed. 16. After placing the ...

Page 59

Page 55 n eo t herm boilers and water heaters label and turn on the gas and electrical power to the appliance. 4. The neotherm unit will begin the start sequence. The blower and pump will energize for the pre-purge period, then the ignition sequence will start. After all safety devices have been ver...

Page 60

Page 56 laars heating systems section 10 maintenance warning disconnect all power to the appliance before attempting any service. Contact with electricity can result in severe injury or death. 10.1systemmaintenance do this once a year, unless otherwise noted. 1. Lubricate the system water-circulatin...

Page 61

Page 57 n eo t herm boilers and water heaters factory for proper trouble shooting practices prior to replacing the control. If control replacement is required, turn off all power to the appliance and shut off all manual gas valves to the appliance. Remove the front door to the appliance and the plas...

Page 62

Page 58 laars heating systems caution the ignitor and sensor may be hot, and can cause burns or injury. Transformerwithintegralcircuitbreaker the appliance has a 24vac transformer with integral 4 amp circuit breaker installed to supply the control voltage required for the appliance. The transformer ...

Page 63

Page 59 n eo t herm boilers and water heaters 12. Place the appliance in operation according to the instructions in section 10. Check all gas connections for leaks. Confirm that all fasteners are tight. Optionalgaspressureswitches the high and low gas pressure switches are 24v manual reset switches ...

Page 64

Page 60 laars heating systems section 11 troubleshooting 11.1 lockouts, holds, and alerts the control system on the neotherm responds to three kinds of trouble indications: • lockout: a “lockout” is caused by a serious problem that might involve a safety issue. Once the controller enters a lockout, ...

Page 65

Page 61 n eo t herm boilers and water heaters 3. Press the long yellow alert or yellow lockout bar (the long bar will be a long grey ‘history’ bar if not currently in alert or lockout). Menu 3. Ok, lockouts, alerts, or silence. Choose which history list you would like to see. Ok: brings you back to ...

Page 66

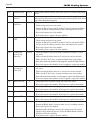

Page 62 laars heating systems 11.2 troubleshooting table this table includes a listing of the fault codes that may be displayed. Some of these can be corrected by changing a parameter, while other conditions are more complicated, and will require a service technician. The fi rst column lists the code...

Page 67

Page 63 n eo t herm boilers and water heaters 13 internal fault: pii (pre-ignition interlock) shorted to ilk (interlock) h or l internal fault 1. Reset module 2. If fault repeats, replace module. 15 internal fault: safety relay test failed due to feedback on l internal fault 1. Reset module 2. If fa...

Page 68

Page 64 laars heating systems 27 internal fault: flame rod shorted to ground detected h internal fault 1. Reset module 2. If fault repeats, replace module. 28 internal fault: a/d linearity test fails h internal fault 1. Reset module 2. If fault repeats, replace module. 29 internal fault: flame bias ...

Page 69

Page 65 n eo t herm boilers and water heaters 62 fan speed not proved h will not be a lockout fault. Hold only. 63 lci (limit control input) off h 1. Check wiring and correct any faults. 2. Check interlocks connected to the lci to assure proper function. 3. Reset and sequence the module; monitor the...

Page 70

Page 66 laars heating systems 94 header sensor fault h 1. Check wiring and correct any possible errors. 2. Replace the header sensor. 3. If previous steps are correct and fault persists, replace the module. 95 stack sensor fault h 1. Check wiring and correct any possible errors. 2. Replace the stack...

Page 71

Page 67 n eo t herm boilers and water heaters 109 ignition failed l 1. Check main valve wiring and operation - correct any errors. 2. Check the fuel supply. 3. Check fuel pressure and repeat turndown tests. 4. Check ignition transformer electrode, fl ame detector, fl ame detector siting or fl ame rod p...

Page 72

Page 68 laars heating systems 149 flame detected h or l holds if fl ame detected during safe start check up to flame establishing period. 150 flame not detected h sequence returns to standby and restarts sequence at the beginning of purge after the hf switch opens if fl ame detected during safe start ...

Page 73

Page 69 n eo t herm boilers and water heaters 165 block intake off l 1. Check wiring and correct any errors. 2. Inspect the block intake switch to make sure it is working correctly. 3. Reset and sequence the module. 4. During standby and purge, measure the voltage across the switch. Supply voltage s...

Page 74

Page 70 laars heating systems 192 invalid igniter on during setting l 1. Return to confi guration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If fault repeats, replace module. 193 invalid ignite failure delay setting l 1. Retur...

Page 75

Page 71 n eo t herm boilers and water heaters 203 invalid mfep (main flame establishing period) fl ame failure response setting l 1. Return to confi guration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If fault repeats, replace ...

Page 76

Page 72 laars heating systems 217 invalid run stabilization time setting l 1. Return to confi guration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If fault repeats, replace module. 218 invalid stack limit enable setting l 1. Re...

Page 77

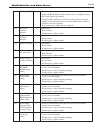

Page 73 n eo t herm boilers and water heaters 229 invalid modulation output setting l 1. Return to confi guration mode and recheck selected parameters, reverify and reset module. 2. If fault repeats, verify electrical grounding. 3. If fault repeats, replace module. 230 invalid ch (central heat) deman...

Page 78

Page 74 laars heating systems 11.3 diagnostic tests and input/ output indicators two kinds of screens are grouped together in this section: • detailed indications of the input and output signals • diagnostic tests of the pumps and burner modulation note that these functions apply to just one selecte...

Page 79

Page 75 n eo t herm boilers and water heaters 11.4 lead/lag slave diagnostics the control system includes a diagnostic screen that lists some information on the lead/lag slaves in the system. See menu 13 menu 13. Lead/lag diagnostics use the left- and right-arrows to see all of the columns in the di...

Page 80

Page 76 laars heating systems select one of the controllers listed on the right side of the screen. Press one of the buttons below the right column to see the snapshot. See menu 18. Menu 18. Typical control snapshot the show status button captures the current status of the i/o of the control only. S...

Page 81

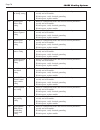

Page 77 n eo t herm boilers and water heaters 12.2partslist size size size size size size size item description nth 210 nth 285 nth 399 nth 500 nth 600 nth 750 nth 850 ntv 199 ntv 285 ntv 399 ntv 500 ntv 600 ntv 750 ntv 850 jacketcomponents–see figure 63 1 front panel assembly r60d3200 r60d3200 r60d...

Page 82

Page 78 laars heating systems size size size size size size size item description nth 210 nth 285 nth 399 nth 500 nth 600 nth 750 nth 850 ntv 199 ntv 285 ntv 399 ntv 500 ntv 600 ntv 750 ntv 850 28 heat exch. Rail clip — r50d1006 — — — — — (2) (2) (2) 30 pvc reducer rp2053000 rp2052900 rp2052800 50d4...

Page 83

Page 79 n eo t herm boilers and water heaters size size size size size size size item description nth 210 nth 285 nth 399 nth 500 nth 600 nth 750 nth 850 ntv 199 ntv 285 ntv 399 ntv 500 ntv 600 ntv 750 ntv 850 63 inlet water temp sensor re2320600 re2320600 re2320600 re2320600 re2320600 re2320600 re2...

Page 84

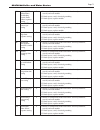

Page 80 laars heating systems partsillustration1. Jacketcomponents.

Page 85

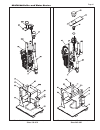

Page 81 n eo t herm boilers and water heaters partsillustration2. Internalcomponents, sizes 150–210 partsillustration3. Internalcomponents, sizes 285–600

Page 86

Page 82 laars heating systems partsillustration4. Internalcomponents,sizes750-850

Page 87

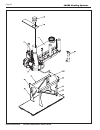

Page 83 n eo t herm boilers and water heaters partsillustration5. Gastraincomponents,sizes150-500 sizes 150-285.

Page 88

Page 84 laars heating systems partsillustration6. Gastraincomponents,sizes600-850

Page 89

Page 85 n eo t herm boilers and water heaters partsillustration7. Heatexchangercomponents 68a sizes 285 -.

Page 90

Page 86 laars heating systems partsillustration8. Electricalcomponents (front) battery ( cr2032 ) touchscreen (back).

Page 91

Page 87 n eo t herm boilers and water heaters notes:.

Page 92

H2374100a customer service and product support: 800.900.9276•fax800.559.1583 headquarters: 20industrialway,rochester,nh03867•603.335.6300•fax603.335.3355 1869 sismet road, mississauga, ontario, canada l4w 1w8 • 905.238.0100 • fax 905.366.0130 www.Laars.Com printed in u.S.A. © laars heating systems 1...