- DL manuals

- Laars

- Boiler

- Pennant PNCH

- Installation And Operation Instructions Manual

Laars Pennant PNCH Installation And Operation Instructions Manual

Installation and Operation Instructions

Document 1176F

H2214400F

Installation and Operation

Instructions for

Pennant

™

Hydronic Boiler

Model PNCH

Water Heater

Model PNCV

Sizes 500-2000

U.S. Reg. 2,765,423

WARNING

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or loss of life.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the fire department.

Installation and service must be performed by

a qualified installer, service agency, or gas

supplier.

AVERTISSEMENT

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion ou

pour éviter tout dommage matériel, toute

blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inflammables dans

le voisinage de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous

servir des téléphones dansle bâtiment où vous

vous trouvez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions du

fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualifié ou

par le fournisseur de gaz.

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in hot water boiler installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in flue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty. For indoor installations, as an additional

measure of safety, Laars strongly recommends installation of suitable Carbon Monoxide detectors in the

vicinity of this appliance and in any adjacent occupied spaces.

Summary of Pennant PNCH

Page 1

Installation and operation instructions document 1176f h2214400f installation and operation instructions for pennant ™ hydronic boiler model pnch water heater model pncv sizes 500-2000 u.S. Reg. 2,765,423 warning if the information in this manual is not followed exactly, a fire or explosion may resu...

Page 2

Laars heating systems page 2 section 1. General information 1.1 introduction ..................................................... 4 1.2 model identification ......................................... 4 1.3 warranty ......................................................... 5 1.4 dimensions .............

Page 3

Pennant (500-2000) page 3 section 6. Operating instructions 6.1 sequence of operation ................................. 36 6.2 filling the boiler system ............................... 36 6.3 programming the temperature control ......... 37 6.3.1 system piping ..........................................

Page 4

Laars heating systems page 4 section 1. General information using this manual – because the pennant boilers and pennant water heaters are identical appliances, with the exception of materials of manufacture, labels and ultimate use application, this manual provides information for the proper install...

Page 5

Pennant (500-2000) page 5 model character designation 1-3 model series designation p n c = pennant 4 usage h = hydronic v = volume water 5-8 size 0 5 0 0 = 500,000 btu/h input 0 7 5 0 = 750,000 btu/h input 1 0 0 0 = 999,000 btu/h input 1 2 5 0 = 1,250,000 btu/h input 1 5 0 0 = 1,500,000 btu/h input ...

Page 6

Laars heating systems page 6 figure 1. Dimensional data. Shipping weight size lbs. Kg 500 425 193 750 505 229 1000 615 279 1250 675 306 1500 760 345 1750 825 375 2000 955 434 *add 55 lbs. (25kg) for pump- mounted units. Air vent horiz. A b c d e f g h conn. Conn. Vent size in cm in cm in cm in cm in...

Page 7

Pennant (500-2000) page 7 1.6 locating pump-mounted water heater with respect to storage tank(s) for best results, a pump-mounted pennant water heater should be located within 15 feet (4.6m) of the storage tank(s). The pump is sized for 30 feet (9.1m) of piping. If the appliance must be installed wi...

Page 8

Laars heating systems page 8 figure 2. Combustion air and vent through roof. Each opening* size square inches square cm 500 125 807 750 188 1213 1000 250 1613 1250 313 2020 1500 375 2420 1750 438 2826 2000 500 3226 *net free area in square inches / square cm area indicated is for one of two openings...

Page 9

Pennant (500-2000) page 9 length allowed is 50 feet (15.2m). Three elbows have been calculated into the 50-foot (15.2m) linear run. Subtract 10 allowable linear feet (3.0m) for every additional elbow used (see table 2). When fewer than 3 elbows are used, the maximum linear pipe length allowed is sti...

Page 10

Laars heating systems page 10 u.S. Installations (see note 1) canadian installations (see note 2) a = clearance above grade, veranda, porch, 12 inches (30 cm) 12 inches (30 cm) deck, or balcony b = clearance to window or door that may be 4 feet (1.2 m) below or to side of opening; 36 inches (91 cm) ...

Page 11

Pennant (500-2000) page 11 spaces containing combustion appliances. If assistance is required in determining how a blocked vent safety system should be connected to a laars product, please call applications engineering at the rochester phone number listed on back cover of this manual. Refer to the i...

Page 12

Laars heating systems page 12 2.3.3 vertical vent terminal when the unit is vented through the roof, the vent must extend at least 3 feet (0.9m) above the point at which it penetrates the roof. It must extend at least 2 feet (0.6m) higher than any portion of a building within a horizontal distance o...

Page 13

Pennant (500-2000) page 13 distance from gas meter or last stage regulator size and gas type 0-100' 0-31m 100-200' 31-61m 200-300' 61-91m 500 natural 1-1/2" 3.8cm 2" 5.1cm 2" 5.1cm 500 propane 1" 2.5cm 1-1/2" 3.8cm 1-1/2" 3.8cm 750 natural 2" 5.1cm 2" 5.1cm 2-1/2" 6.4cm 750 propane 1-1/2" 3.8cm 1-1/...

Page 14

Laars heating systems page 14 20°f 25°f 30°f 35°f size flow h/l flow h/l flow h/l flow h/l gpm feet gpm feet gpm feet gpm feet 500 43 1.7 34 1.1 28 0.9 24 0.7 750 64 3.3 51 2.3 43 1.7 36 1.2 1000 85 5.0 68 3.6 57 3.1 49 2.2 1250 106 8.1 85 6.1 71 4.7 61 3.4 1500 128 10.0 102 7.2 85 5.5 73 4.2 1750 n...

Page 15

Pennant (500-2000) page 15 primary/secondary manditory for all variable flow systems install air vents at high points in system piping & sizing of expansion tank per tank manufacturer's instructions dimension "c" (common piping) to be four pipe diameters, max. (no elbows or valves) boiler circuit pi...

Page 16

Laars heating systems page 16 primary/secondary manditory for all variable flow systems install air vents at high points in system piping & sizing of expansion tank per tank manufacturer's instructions dimension "c" (common piping) to be four pipe diameters, max. (no elbows or valves) boiler circuit...

Page 17

Pennant (500-2000) page 17 figure 6. Hydronic piping — one boiler, multi-temperature system. Primary/secondary manditory for all variable flow systems install air vents at high points in system piping & sizing of expansion tank per tank manufacturer's instructions dimension "c" (common piping) to be...

Page 18

Laars heating systems page 18 legend check valve thermometer temperature sensor globe valve expansion tank with air scoop and auto air vent 3-way valve valve caution: this drawing shows suggested piping configuration and valving, check with local codes and ordinances for additional requirements. Pre...

Page 19

Pennant (500-2000) page 19 legend check valve thermometer temperature sensor globe valve expansion tank with air scoop and auto air vent 3-way valve valve pressure reducing valve w/ fast fill bypass purge valve pump caution: this drawing shows suggested piping configuration and valving, check with l...

Page 20

Laars heating systems page 20 section 4b. Water connections — pennant water heater 4b.1 water system piping — water heater hot water piping should be supported by suitable hangers or floor stands. Do not support piping with this appliance. Due to expansion and contraction of copper pipe, considerati...

Page 21

Pennant (500-2000) page 21 figure 9. Water heater piping — one heater, one tank. Notes: 6. Caution: pump sizing must be based upon water hardness at job site 1. Optional cwmu & recirc. Line location. 2. Locate pennant dhw sensor or remote aquastat well in lower 1/3 of tank. 3. Back flow preventer ma...

Page 22

Laars heating systems page 22 figure 10. Water heater piping — multiple heaters, one tank. Figure 11. Water heater piping — one heater, multiple tanks..

Page 23

Pennant (500-2000) page 23 gpm ft temp rise °f lpm m temp rise °c size s n h s n h s n h s n h s n h s n h 500 45 68 90 1.8 2.3 3.5 19 13 9 170 257 341 0.5 0.7 1.1 10 7 5 750 45 68 90 2.1 3.0 6.0 28 19 14 170 257 341 0.6 0.9 1.8 16 10 8 1000 45 68 90 2.3 3.6 6.1 38 25 19 170 257 341 0.6 1.1 1.9 21 1...

Page 24

Laars heating systems page 24 single circuit connections pump heater only w/o pump with pump 500 15 20 15 750 15 20 15 1000 20 25 15 1250 25 30 15 1500 25 30 15 1750 25 — 15 2000 25 — 20 table 10. Electrical data. Figure 13. Removing jumpers. Section 5. Electrical connections warning the appliance m...

Page 25

Pennant (500-2000) page 25 figure 14. Field wiring panel figure 15. External control connection wiring. The suggested piping diagrams, and connected to the “s c2” and “sup s” terminals. See section 6.3 for “mode” definitions and figures 22 to 24 for field wiring schematics. Outdoor reset sensor: the...

Page 26

Laars heating systems page 26 5.3 external staging control wiring warning improper field wiring may result in fire or explosion which can cause property damage, severe injury, or death. Make only wiring connections which are in accordance with the installation and operation manual. Avertissement un ...

Page 27

Pennant (500-2000) page 27 figure 16. Pennant 500 - 750 ladder diagram..

Page 28

Laars heating systems page 28 figure 17. Pennant 1000 ladder diagram..

Page 29

Pennant (500-2000) page 29 figure 18. Pennant 1250 - 2000 ladder diagram..

Page 30

Laars heating systems page 30 figure 19. Pennant 500 - 1000 wiring schematic..

Page 31

Pennant (500-2000) page 31 figure 20. Pennant 1250 - 1500 wiring schematic..

Page 32

Laars heating systems page 32 figure 21. Pennant 1750 - 2000 wiring schematic..

Page 33

Pennant (500-2000) page 33 figure 22. Field wiring. Note: positions of field wiring terminals may vary , but terminal designations are as indicated..

Page 34

Laars heating systems page 34 figure 23. Field wiring for modes 1 - 5. Note: positions of field wiring terminals may vary , but terminal designations are as indicated. Tst a t tst a t - - - - - - - - - - - - - - 1c 1n o 2 c 2 n o 3c 3n o set d c om d h t d ht out 4c 4 n o in s s c1 out s o d s s c 2...

Page 35

Pennant (500-2000) page 35 figure 24. Field wiring for mode 6. 1c 1no 2c 2no 3c 3no 4c 4no 4c 3c 4no 3no 2c 1c 2no 1no 4 s tage boiler using 4 control output s 4 s tage boiler using 2 c ontrol o utput s jumper jumper 4c 3c 4no 3no 2c 1c 2no 1no 4 s tage boiler u sing 3 c ontrol output s jumper jumpe...

Page 36

Laars heating systems page 36 section 6. Operating instructions 6.1 sequence of operation a call for heat can be initiated either automatically (auto mode) under thermostatic control by the pennant temperature control, or by an external contact closure (manual mode). In auto mode, the pennant burner...

Page 37

Pennant (500-2000) page 37 11. Shut down the entire system and vent all radiation units and high points in the system piping, as described in step 4. 12. Close make-up water valve and check strainer in pressure reducing valve for sediment or debris from the make-up water line. Reopen make-up water v...

Page 38

Laars heating systems page 38 application mode system setting sensors used • parallel piping (non- primary/secondary) hydronic system 1 • none • dhw with or without a tank aquastat • primary/secondary hydronic system 2 • laars system (preferred by laars) sensor (shipped • no outdoor reset with each ...

Page 39

Pennant (500-2000) page 39 figure 27. Temperature control target temperature graph. Time selected after the heat demand in the system is satisfied. This setting also affects the 24vac output on the “pmp” “pmp” terminals (see section 5.2). These terminals can power a contactor for a larger system pum...

Page 40

Laars heating systems page 40 example 2 hydronic primary/secondary (mode 2) programming. Mode 2 is used in primary-secondary piping hydronic systems without outdoor reset. Mode 5 adds outdoor reset. Step 1: install the additional sensor in the primary loop (see figure 4), and wired to the “sc2” and ...

Page 41

Pennant (500-2000) page 41 caution if the tank temperature control is set too high, a potential for hot water scalding may exist. Mode 2: primary secondary piping. Install a “supply sensor” in the primary loop using the laars part number r2014800 sensor (included with every pennant unit). Connect th...

Page 42

Laars heating systems page 42 figure 28. Temperature control interstage differential. 6.4 advanced topics for most installations, section 6.3 provides all the information required to set up the pennant boiler, and this section should be skipped. Continue setup in section 6.5. This section provides d...

Page 43

Pennant (500-2000) page 43 figure 29. Temperature control min & max. Next stage. After the minimum time delay between stages has expired, the control examines the control error to determine when the next stage is to fire. The control error is determined using pid logic. Proportional compares the act...

Page 44

Laars heating systems page 44 figure 30. Temperature control outdoor start graph. Pump operation is continuous. Also, during outdoor reset, with the pump delay set to on , the pump continues to run even during warm weather shut down. 6.4.7 setpoint operation when either mode 1 or 2 is selected, the ...

Page 45

Pennant (500-2000) page 45 figure 31. Typical gas train configuration. Figure 32. Typical control panel. The boiler zones when the outdoor air is as cold as the outdr dsgn temperature. Warm weather shut down (wwsd wwsd wwsd wwsd wwsd) – when the outdoor air temperature rises above the wwsd setting, ...

Page 46

Laars heating systems page 46 6.4.10 external boiler operation when mode 6 is selected, the control allows for an external control to operate the pennant’s stages. In this mode, the control operates the pump in order to provide purging and exercising. The staging operation is provided by an external...

Page 47

Pennant (500-2000) page 47 appliance. The ignition sequence will start again and the burner will start. The appliance will return to its previous mode of operation. Note: sizes 1000–2000 have two ignition controls and two ignitors, which work independently of one another. If the ignition control for...

Page 48

Laars heating systems page 48 section 7. Maintenance 7.1 system maintenance 1. Lubricate the system water-circulating pump, if required, per the instructions on the pump. 2. If a strainer is employed in a pressure reducing valve or the piping, clean it every six months. 3. Inspect the venting system...

Page 49

Pennant (500-2000) page 49 and boilers ordered with low temperature controls. To replace the switch, shut off the 120-volt power to the appliance. Remove the cover from the switch to access the mounting screws. Remove the screws, and pull the switch off the control panel. Remove the capilliary and b...

Page 50

Laars heating systems page 50 6. Allow the heat exchanger to drain. Remove the front cover(s) by removing the rubber access strip(s) and the retaining screws. Remove the venting and remove the top, by removing the screws that attach the top to the side panels. Remove the side panels. Remove the fron...

Page 51

Pennant (500-2000) page 51 controller setup. Contact your laars representative to discuss possible remedies. 8.4 short cycling — water heater short cycling will generally occur only in combination space heating and water heating applications when the water heater is operating in the space-heating mo...

Page 52

Laars heating systems page 52 models (500 and 750), one 3-stage model (1000), and four 4-stage models (1250 to 2000). The 2-stage models have one ignition module, and the 3- and 4- stage models have two ignition modules capable of independent operation. A diagnostic panel, that includes test points,...

Page 53

Pennant (500-2000) page 53 table 12. Troubleshooting error codes..

Page 54

Laars heating systems page 54 item description size size size size size size size 500 750 1000 1250 1500 1750 2000 sheet met al components see figure 33 1 panel, jacket, side left 5c3420 5c3420 5c3420 5c3420 5c3420 5c3420 5c3420 2 panel, jacket, side right 5c3521 5c3521 5c3521 5c3521 5c3521 5c3521 5...

Page 55

Pennant (500-2000) page 55 internal component s see figures 35 and 34 17 base assembly 5c1020 7c1020 10c1020 12c1020 15c1020 17c1020 20c1020 18 chamber , front 5c2003 7c2003 10c2003 12c2003 15c2003 17c2003 20c2003 18a chamber , left side, front 5c2015 5c2015 5c2015 5c2015 5c2015 5c2015 5c2015 18b ch...

Page 56

Laars heating systems page 56 35b t ile, front, center t2016900 t2016900 t2016900 t2016900 (1) (1) (2) (2) 36 t ile, rear t2015700 (1) 37 t ile, rear , left side t2017500 t2016600 t2016600 t2016600 t2016600 t2016600 (1) (1) (1) (1) (1) (1) 3 7 a t ile, rear , right side t2016600 t2016600 t2018100 t2...

Page 57

Pennant (500-2000) page 57 item description size size size size size size size 500 750 1000 1250 1500 1750 2000 49 relief v alve, pnch, 75 psi a0063300 a0063600 a0063600 a0063600 a0063600 a0063600 a0002700 relief v alve, pncv , 125 psi ra0001200 ra0001200 ra0001200 ra0001200 a0064400 a0064400 a00664...

Page 58

Laars heating systems page 58 high limit, auto reset, pncv , 210f max. E2217700 e2217700 e2217700 e2217700 e2217700 e2217700 e2217700 71 high limit, manual reset, pnch re0015900 re0015900 re0015900 re0015900 re0015900 re0015900 re0015900 high limit, manual reset, pncv , 210f max. E2217800 e2217800 e...

Page 59

Pennant (500-2000) page 59 burner manifold assy , 4 burners, right, lp 10c6620 10c6620 10c6620 10c6620 (1) (1) (1) (2) burner manifold assy , 4 burners, lef t, lp 10c6520 10c6500 10c6520 10c6520 (2) (2) (2) (4) 78 v alve, gas, combination v2017600 v2017600 v2017600 v2017600 v2017600 v2017600 v201760...

Page 60

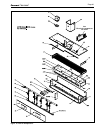

Laars heating systems page 60 figure 33. Sheet metal components. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 16 16b 16c 16d 16a base shown for reference note: model 2000 shown for reference. 5a.

Page 61

Pennant (500-2000) page 61 figure 34. Internal components. See electrical components for detail..

Page 62

Laars heating systems page 62 figure 35. Heat exchanger components. See pump chart below for pump numbers. Pennant hydronic size pump p/n 500 a2001700 750 a2001700 1000 a2001800 1250 a2001800 1500 a2001900 1750 a2001900 2000 a2109700 pennant water heater pump p/n size soft water normal water hard wa...

Page 63

Pennant (500-2000) page 63 figure 36. Electrical components..

Page 64

H2214400f ® 800.900.9276 • fax 800.559.1583 (customer service, service advisors & technical support) 20 industrial way, rochester, nh 03867 • 603.335.6300 • fax 603.335.3355 (applications engineering) 1869 sismet road, mississauga, ontario, canada l4w 1w8 • 905.238.0100 • fax 905.366.0130 www.Laars....