Installation and operation instructions document 1204e h2319100e installation and operation instructions for low temperature pennant ™ hydronic boiler model pnch water heater model pncv for your safety: this product must be installed and serviced by a professional service technician, qualified in ho...

Laars heating systems page 2 section 1. General information 1.1 introduction ...................................................... 3 1.2 model identification .......................................... 4 1.3 warranty .......................................................... 4 1.4 dimensions ..........

Low temperature pennant page 3 section 1. General information using this manual – because the pennant boilers and pennant water heaters are identical appliances, with the exception of materials of manufacture, labels and ultimate use application, this manual provides information for the proper insta...

Laars heating systems page 4 all installations must be made in accordance with: 1) in the u.S., the " national fuel gas code "ansi z223.1/nfpa54, latest edition and all applicable local codes as required by the authorities having jurisdiction (ahj), or 2) in canada, the "natural gas and propane inst...

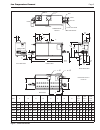

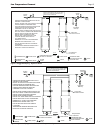

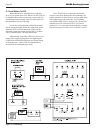

Low temperature pennant page 5 13.7 35 b c w* v* a 12.4 31 h 20.24 514 front view rear view w* v* top view flow switch inlet outlet 3 way actuator temperature switch prv f (w) 2 5 left side view pump pump g (v) 19.7 50 41.5 105 35.3 89 29.3 74 7.75 20 13.8 35 13.7 35 right side view d c w* b v* e di...

Laars heating systems page 6 above grade such that blockage of the terminal from accumulated debris or precipitation is prevented. The dimensions and requirements that are shown in table 1 should be met when choosing the locations for the appliance. 1.6 locating pump-mounted water heater with respec...

Low temperature pennant page 7 section 2. Venting and combustion air warning for indoor installations, as an additional measure of safety, laars strongly recommends installation of suitable carbon monoxide detectors in the vicinity of this appliance and in any adjacent occupied spaces. Avertissement...

Laars heating systems page 8 linear run. Subtract 10 allowable linear feet (3.0m) for every additional elbow used (see table 2 ). When fewer than 3 elbows are used, the maximum linear pipe length allowed is still 50 feet (15.2m). The connection for the intake air pipe is on the filter box. Pennant a...

Low temperature pennant page 9 avertissement le fonctionnement d’appareils connectés à un évent commun bouché peut provoquer de sérieuses blessures corporelles ou la mort. Des dispositifs de sécurité doivent être mis en place pour empêcher que les appareils soient utilisés avec un évent commun bouch...

Laars heating systems page 10 u.S. Installations (see note 1) canadian installations (see note 2) a= clearance above grade, veranda, porch, 12 inches (30 cm) 12 inches (30 cm) deck, or balcony b= clearance to window or door that may direct vent only: 12 inches (30 cm) be opened other than direct ven...

Low temperature pennant page 11 3 feet (0.9m) horizontally from the combustion air terminal, and locate the vent terminal at least 1 foot (0.3m) above the combustion air terminal. Warning the outdoor vent terminal gets hot. Unit must be installed in such a way as to reduce the risk of burns from con...

Laars heating systems page 12 design or venting system. (d) manufacturer requirements – gas equipment venting system not provided. When the manufacturer of a product approved side wall horizontally vented gas fueled equipment does not provide the parts for venting the fuel gases, but identifies “spe...

Low temperature pennant page 13 conforms with the national fuel gas code, ansi z223.1/nfpa 54 and/or csa b149.1, natural gas and propane installation codes. When resizing any portion of the common venting system, the common venting system should be resized to approach the minimum size as determined ...

Laars heating systems page 14 section 3. Gas supply and piping 3.1 gas supply and piping gas piping should be supported by suitable hangers or floor stands, not by the appliance. The pennant’s gas train allows the user to pipe the gas from either the right side or the left side of the unit. As shipp...

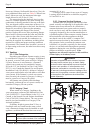

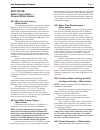

Low temperature pennant page 15 figure 4. Suggested piping - hydronic boiler. Thermometer sensor temperature globe valve check valve legend w/ fast fill bypass pressure reducing valve with air scoop and auto air vent expansion tank 3-way valve cold water make-up valve valve purge pump additional req...

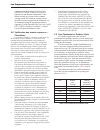

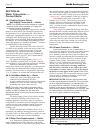

Laars heating systems page 16 size 20°f (11°c) 25°f (14°c) 30°f (17°c) 35°f (19°c) gpm lpm gpm lpm gpm lpm gpm lpm 500 43 161 34 129 26 107 24 92 750 64 241 51 193 43 161 36 138 1000 85 321 68 257 57 214 49 184 1250 106 401 85 322 71 269 61 231 1500 128 483 102 386 85 322 73 276 1750 n/r n/r 119 451...

Low temperature pennant page 17 section 4b. Water connections — pennant water heater 4b.1 water system piping — water heater hot water piping should be supported by suitable hangers or floor stands. Do not support piping with this appliance. Due to expansion and contraction of copper pipe, considera...

Laars heating systems page 18 figure 6. Suggested piping — one water heater, one tank. Table 9. Temperature rise — water heater. Size gpm water flow temperature rise °f lpm water flow temperature rise °c soft normal hard soft normal hard soft normal hard soft normal hard 500 45 68 90 19 13 9 170 257...

Low temperature pennant page 19 figure 7. Suggested piping — multiple water heaters, one tank. Figure 8. Suggested piping — one water heater, multiple tanks..

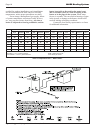

Laars heating systems page 20 figure 9. Suggested piping — multiple water heaters, multiple tanks. Section 5. Electrical connections warning the appliance must be electrically grounded in accordance with the requirements of the authority having jurisdiction or, in the absence of such requirements, w...

Low temperature pennant page 21 single two circuit size circuit heater pump 500 20 15 15 750 20 15 15 1000 (taco) 20 / (b&g) 30 20 15 1250 30 25 15 1500 30 25 15 1750 — 25 20 2000 — 25 20 table 10. Electrical data (amps). Figure 10. Removing jumpers. Single pole switches, including those of safety c...

Laars heating systems page 22 figure 11. Field wiring. 5.3 low water cut-off when this boiler is installed above radiation level, it is required that a low water cut-off (lwco) be installed unless this requirement is superceded by jurisdictional requirements. Specific instructions for the installati...

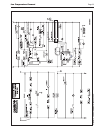

Low temperature pennant page 23 figure 12. Ladder diagram, sizes 500-1000..

Laars heating systems page 24 figure 13. Ladder diagram, sizes 1250-2000..

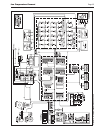

Low temperature pennant page 25 figure 14. W iring diagram, sizes 500-1000..

Laars heating systems page 26 figure 15. W iring diagram, sizes 1250-1500..

Low temperature pennant page 27 figure 16. W iring diagram, sizes 1750-2000..

Laars heating systems page 28 section 6. Operating instructions 6.1 filling the boiler system 1. Ensure the system is fully connected. Close all bleeding devices and open make-up water valve. Allow system to fill slowly. 2. If make-up water pump is employed, adjust pressure switch on pumping system ...

Low temperature pennant page 29 unless the flame sensor detects a flame, the gas valves will close and the ignition module will either attempt ignition again (up to three times) or will lockout (if the optional lockout ignition module is used). Note: at this point, if gas pressure is below the requi...

Laars heating systems page 30 oah – maximum setpoint this is the maximum allowable calculated setpoint, regardless of outdoor temperature. Default is 190°f. Range is 90°f to 210°f. Rc – reset ratio the ratio of air temperature movement to water temperature movement. Sets the slope of the reset curve...

Low temperature pennant page 31 necessary. The manifold gas pressure must be 2.5” w.C. (0.62kpa). 8. Complete the setup by checking the co 2 at the outlet of the unit. The co 2 should be 8% for natural gas, or 9.2% for propane. 9. After placing the appliance in operation, the burner safety shutoff d...

Laars heating systems page 32 section 7. Maintenance 7.1 system maintenance 1. Lubricate the system water-circulating pump, if required, per the instructions on the pump. 2. If a strainer is employed in a pressure reducing valve or the piping, clean it every six months. 3. Inspect the venting system...

Low temperature pennant page 33 7.2.2 filter the filter used in the pennant is washable. Since the filter is washable, it will only need replacement occasionally. If filter replacement is needed, it should only be replaced with a factory part. Inspect the air filter monthly, or more often in dirty e...

Laars heating systems page 34 ate for powering the gas valves. It also controls the blower’s pre-purge and post-purge. Pennant models 500 through 1000 have one ignition control. Models 1250 through 2000 have two ignition controls. To replace a control, shut off the 120-volt power to the appliance. R...

Low temperature pennant page 35 section 8. Trouble shooting 8.1 resolving lockouts there are many causes of lockouts. The three most common causes are: (1) inadequate gas supply, (2) poor combustion, (3) ignitor failure. 1. Inadequate gas supply: before proceeding, ensure that the gas supply has not...

Laars heating systems page 36 the setpoint of the boiler operating control. If the set points are correct and the system design, controls scheme, etc. Are fixed, the temperature differentials may be increased to reduce short cycling. If desired temperature response is not achievable without short cy...

Low temperature pennant page 37 item description size size size size size size size 500 750 1000 1250 1500 1750 2000 sheet metal components - see figure 19 1 panel, jacket, side left 5c3420 5c3420 5c3420 5c3420 5c3420 5c3420 5c3420 2 panel, jacket, side right 5c3521 5c3521 5c3521 5c3521 5c3521 5c352...

Laars heating systems page 38 bracket, chamber , front left 12c201 1 15c201 1 17c201 1 20c201 1 26 bracket, chamber , front right 12c2009 15c2009 17c2009 20c2009 27 divider , chamber , front 15c2010 20c2002 27a divider , upper , chamber , front 15c2005 15c2005 27b divider , lower , chamber , front 1...

Low temperature pennant page 39 41 heat exchanger , copper r2014901 r2014902 r2014903 r2026701 r2014904 r2026702 r2014905 heat exchanger , cupro-nickel r2027801 r2027802 r2027803 r2027804 r2027805 r2027806 r2027807 42 w ater barrier , inlet/outlet 20305101 20305101 20305101 20305101 20305101 2030510...

Laars heating systems page 40 66 ignition control, single trial e2107300 e2107300 e2107300 e2107300 e2107300 e2107300 e2107300 (1) (1) (2) (2) (2) (2) (2) igniltion control, three trial e2313900 e2313900 e2313900 e2313900 e2313900 e2313900 e2313900 (1) (1) (2) (2) (2) (2) (2) 67 diagnostic board e21...

Low temperature pennant page 41 (1) (1) (3) (1) (2) burner tray assembly , 4 burners, right, lp 10c6620 10c6620 10c6620 10c6620 (1) (1) (1) (2) burner tray assembly , 4 burners, left, lp 10c6520 10c6500 10c6520 10c6520 (2) (2) (2) (4) 78 valve, gas, combination v2017600 v2017600 v2017600 v2017600 v2...

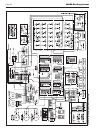

Laars heating systems page 42 figure 19. Sheet metal components. Detail “a” typical controller components detail "a" typical controller components.

Low temperature pennant page 43 figure 20. Internal components. 28 29 30 80 79 78 77 76 27/a/b 81 82 32 17 18b 21 19 20 18a 18 23 25 26 41 22 59 24 see enlargement (detail “a”) on next page 60 61 62 36/37 37b 39b 39a 37a 33 35a 33 34/35 35b 38/39 notes: model 2000 shown for reference. See enlargemen...

Laars heating systems page 44 detail “b” mounted pump heat exchanger components 42 55 56 57 44 58 44 45 47 54 49 52 50 51 42 43 46 84 83 figure 21. Detail of internal components. H2319100e customerserviceandproductsupport: 800.900.9276 • fax 800.559.1583 headquarters: 20 industrial way, rochester, n...