- DL manuals

- Labnics Equipment

- Furnace

- LSCF-100A

- Instruction Manual

Labnics Equipment LSCF-100A Instruction Manual

Summary of LSCF-100A

Page 1

Instruction manual model : lhtf 100 series labnics equipment high temperature tube furnace please read this manual carefully before using the instrument.

Page 2: Table of Content

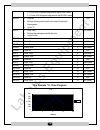

Table of content sr. No. Content page no. A. Introduction 1 b. Information related to safety 1 1. Unpacking & handling of the furnace 1 2. Electrical safety 2 3. Human health and environmental safety 3 c. General information 3 1. Technical details 3 2. Furnace components & related technical properti...

Page 3

A. Introduction this booklet includes our recommendations, hints and points of notice for you to have a safe and better service from this equipment. We kindly ask you to carefully read this manual and only then to operate the furnace. This insignia is used for the purpose of warning you against risk...

Page 4

2. Electrical safety 2.1 electrical connections due to safety none of the labnics furnaces that use over 16 amps have a plug while delivery. Main connection of furnace over 16 amps should be managed through a circuit breaker and according to electrical diagram supplied together with this manual. Ele...

Page 5

- 3 - 3. Human health and environmental safety 1. Do not operate this furnace while there is any live substance in it. 2. Do not operate this furnace with flammable, explosive, poisonous etc. Materials (hydrogen, lpg, acetylene, arsenic, tnt, gunpowder etc.) inside. Labnics does not accept any respo...

Page 6

- 4 - lstf-200e 1400°c 610 63kg 60x41x92cm 75x1000cm 5,50 +/-2°c 2 lstf-300a 1500°c 180 48kg 60x41x72cm 38x750cm 3,60 +/-2°c 3 lstf-300b 1500°c 250 51kg 60x41x72cm 50x750cm 3,10 +/-2°c 3 lstf-300c 1500°c 450 53kg 60x41x72cm 75x750cm 4,50 +/-2°c 3 lstf-300d 1500°c 610 68kg 60x41x92cm 75x1000cm 6,25 +...

Page 7

Pv sp 500 600 set out1 out2 at al1 al2 pro - 5 - 2.1.1 honeywell dc1010 almost all controllers employed have a short period of self test during which any interference is not possible . Please wait till this test is over . Honeywell dc 1010 a) general notes regarding application pv (process variable)...

Page 8

- 6 - b) honeywell dc1010 dc1010 controller does not feature any programming capacity but can be used to set a temperature only. The controller will reach predefined temperature and will dwell indefinitely. 2.1.2 honeywell udc2500 programming hints udc 2500 controller has 3 programming modes: sprate...

Page 9

- 7 - insignia related technical explanation r1 r1 relay led turns on when energized ( usual operational relay) r2 r2 relay led turns on when energized mn turns on when controller is in manual mode (normally off) sn turns on at increments of 1 secs when a program is running key : used to return to b...

Page 10

- 8 - this may cause significant chemical reactions to occurs eventually leading to affect the life of elements. Operator must remember that sic elements always prefer to have oxidizing atmospheres .This is due to the fact that a protective layer of silica glazing is built up to protect the elements...

Page 11

- 9 - 3. What is pid control? The simplest way of temperature control is on/off. On/off controlling supplies full power till a predetermined set point is reached and power is turned off after this threshold is reached, turning on again when temperature drops down. Temperature is never stable, only f...

Page 12

- 10 - user should take care of two major points, if especially the recrystallized tube size is larger than 60mms. • programming should be applied to manage controlled heating to set temperature and also controlled cooling is strongly recommended. Heat up rates of less than 8°c/min is strongly advis...

Page 13

- 11 - 5. Hints 5.1. Repairs & replacements a) change of tube always make sure that the reason for malfunctioning is due to element failure before disassembling the furnace o ceramic tube can be freely changed for tube furnaces over 1400 c where sic and mosi2 heating elements are used. Please use fo...

Page 14

- 12 - 5.2. Calibration depending on using frequency and application temperature, you may require a calibration of the thermocouple from time to time or even a change of the thermocouple. For k type thermocouples we advice a change for every year. For s or r type thermocouples the useful life can be...

Page 15

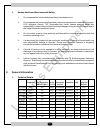

- 13 - 4. Thermocouple shows a low temperature 4.1 the thermocouple may have been shorted or may have been moved from its original place 4.2 thermocouple may be reverse connected 4.3 controller may be have a faulty configuration d. Operational properties 1. Electrical & other requirements phase volt...

Page 16

- 14 - to operate the furnace: 1. Turn on the green i/0 switch. This will open the controller panel but the furnace will not start heating. The purpose of this is to give time to operator to feed in programming data / set the required temperature etc. Without actually the heat up. 2. To start heatin...

Page 17

R1 r2 mn sn run stop heat switch power switch temp. Controller r1 r2 mn sn run stop r1 r2 mn sn run stop - 15 - r1 r2 mn sn run stop 2.1 the control panel (pc442) fig.1. General appereance of the control panel fig.2. General appereance of the temperature controller please note that there are two dif...

Page 18

R1 r2 mn sn run stop r1 r2 mn sn run stop r1 r2 mn sn run stop r1 r2 mn sn run stop r1 r2 mn sn run stop r1 r2 mn sn run stop r1 r2 mn sn run stop r1 r2 mn sn run stop r1 r2 mn sn run stop r1 r2 mn sn run stop - 16 - 1. If you require a delay time before the programme starts ,press “ ” key one by on...

Page 19

- 17 - 5. You will observe the actual temperature at upper display of the furnace and the program number and stage (segment) number at the lower display. 6. Program will start from the process value and carry on according the program data. 7. During the program is running, by pressing " " key one by...

Page 20

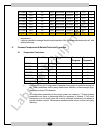

- 18 - 8. Now, please follow the steps that are shown at the table below. 9. Always define a cool down segment to room temperature at the end of the program. Otherwise, after the program has come to an end the furnace temperature will stabilize at the last segments temperature value until the power ...

Page 21

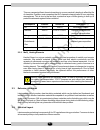

2. (°c/hr) if eu-h option is adjusted in the rpunit menu 3. (°c/min) if eu-m option is adjusted in the rpunit menu sg2sp • soak sp 2 300 • defines the set point which the furnace will heat up in this segment. • unit is °c sg2ti • soak time 2 1hr:30min • defines the waiting time at the set point • un...

Page 22: Service Report

Customer’s address : service report contact person / designation : tel.No.: fax no.: weekly off.: dept.: date nature of problem : observation & action taken : customer’s remarks : parts replaced : parts recommended / action required : yes service engineer’s name & signature requisition number : cust...

Page 23

Labnics equipment 43040 christy st., fremont, ca 94538 usa. Toll free : (877) 620 9992 tel. : (925) 271 4322 fax : (925) 886 0400 email : info@labnics.Com website : www.Labnics.Com.