- DL manuals

- Labrie

- Automobile

- automizer

- Maintenance Manual

Labrie automizer Maintenance Manual

Summary of automizer

Page 1

A utomizer tm m aintenance m anual.

Page 3: Utomizer

A utomizer ™ m aintenance manual.

Page 4: Liability

Liability labrie enviroquip group assumes no liability for any incidental, consequential, or other liability that might result from the use of the information contained in this document. All risks and damages, incidental or otherwise, arising from the use or misuse of the information contained herei...

Page 5: Table of Contents

Liability ........................................................................................ Ii table of contents ....................................................................... Iii introduction ................................................................................ 1 about th...

Page 6

Iv table of contents preparing packer for removal - std. Units (method a) .............................................................................................. 30 removing the packer panel - std. Units (method a) .................................................................................

Page 7

Table of contents v adjusting chute proximity switch gaps (co-mingle vehicles) .............................................................................. 94 adjusting chute proximity switches (co-mingle vehicles) ......................................................................................

Page 8

Vi table of contents electrical system ..................................................................... 159 how the electrical system works .......................................................................................................................................... 159 electrical s...

Page 9

Table of contents vii valve with crusher panel section (standard arm) ................................................................................................... 231 valve with crusher panel section (heavy-duty arm) ...............................................................................

Page 10

Viii table of contents.

Page 11: Introduction

1 introduction about this manual this manual is designed to help qualified maintenance personnel repair, service and maintain the a utomizer ™. What you will find in this manual this manual outlines maintenance procedures related to the lifting arm, body and packer components. Topics not included in...

Page 12: Introducing The A

2 introduction for pneumatic and hydraulic schematics, refer to the schematics provided with your a utomizer ™ unit. N ote : a number of system schematics are included in this manual. About the illustrations in this manual because labrie enviroquip group is constantly updating its products, illustra...

Page 13: Key Features

Introduction 3 figure 1-1 monitor n ote : maintenance personnel as well as in-the-field technicians who encounter any problems with the multiplexed system should refer to the multiplex diagnostic manual (part# 153143) for troubleshooting information and guidelines. Key features the a utomizer ™, wit...

Page 14: A Word About Safety

4 introduction a word about safety with your safety in mind, we would like to remind you that only qualified personnel should service the hydraulic, electrical, and pneumatic systems on your side loader. In addition, they should also be fully knowledgeable of the operation of this unit. Please read ...

Page 15: To Contact Labrie

Introduction 5 to contact labrie plus in the u.S. Address: 1981 w. Snell road oshkosh, wi 54904 toll free: 1-800-231-2771 telephone: 1-920-233-2770 general fax: 1-920-232-2496 sales fax: 1-920-232-2498 parts and warranty: during business hours, 7:00 am to 7:00 pm central standard time technical supp...

Page 16

6 introduction.

Page 17: Safety

2 safety it is mandatory to read the entire operator’s manual before performing any maintenance task on this vehicle. Conventions basic safety notions the following safety notions are related to the use of the a utomizer ™. It is important to point out that the safe use of the vehicle remains the us...

Page 18: Responsibilities

8 safety responsibilities safety is everybody’s responsibility. Both the employer and employees must play their part to ensure safe working conditions in, on, and around the truck and to promote and enforce safe work practices and procedures to prevent injuries and incidents as well as property/equi...

Page 19: Employee Responsibilities

Safety 9 employee responsibilities it is the responsibility of the employee: to enforce all safety measures to meet the requirements set by the employer. to operate the a utomizer ™ only after having received instructions and training. to immediately report any damage or malfunction to the veh...

Page 20: General Precautions

10 safety do not use the body safety prop to prop a loaded body. Only qualified personnel should service the hydraulic, electrical, and pneumatic systems of this vehicle. They should also be knowledgeable about the operation of the vehicle. General precautions read and make sure that you fully u...

Page 21: Welding

Safety 11 report any doubts that you might have and any equipment safety service requirements regarding this vehicle to a supervisor. when removing nylon locknuts, always replace them by new ones. for any work (including cleaning and inspection) that has to be done between the body and the cha...

Page 22: Danger!

12 safety anytime a loaded vehicle is brought inside a garage, fire extinguishers shall be close at hand. The employer must also inform employees of an appropriate place to unload the body near the maintenance facility (preferably away from traffic, surface drains, and ditches). Locking out and tagg...

Page 23: Prior to Start Up

Safety 13 figure 2-2 master switch 7. Put an “o ff s ervice ” tag on the driver’s wheel and on the front windshield. 8. Use safety props to block any system that could move by gravity (open tailgate, raised body, etc.). 9. Drain all air tanks. 10. Verify and inspect any security device and/or mechan...

Page 24: Warning!

14 safety n ote : the hydraulic tank model may vary according to the options installed on the vehicle. 3. Once the engine is started, wait for air pressure to build up to at least 70 psi. Figure 2-4 air pressure indicator i mportant : do not operate or move the vehicle until air pressure has reached...

Page 25: Shutting Down The Vehicle

Safety 15 shutting down the vehicle if the vehicle has to be stored for an extended period of time, follow the chassis manufacturer shutdown and maintenance requirements. Also: 1. Park the vehicle on a hard, level surface and apply the parking brake. 2. Make sure that all moving parts are in their h...

Page 26

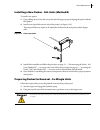

16 safety figure 2-7 body safety prop to set the body safety prop: 1. Make sure that there is enough clearance above the body to raise it safely. 2. Start the engine. 3. With the body up switch on the in-cab control panel, raise the body until the safety prop is free to tilt under it. 4. Release the...

Page 27: Danger!

Safety 17 putting the body safety prop back in place to put the body safety prop back in place: 1. Make sure that there is enough clearance above the body to raise it safely. 2. Start the engine. 3. With the body up switch on the in-cab control panel, raise the body until the safety prop can move fr...

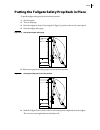

Page 28: Danger!

18 safety figure 2-10 safety pin (in storage position, left; in locking position, right) 3. Start the engine. 4. Turn on the pump. 5. With the tailgate up switch on the in-cab control panel, raise the tailgate about 3 feet (enough to raise the safety prop). 6. Pull the safety prop upward and set it ...

Page 29

Safety 19 putting the tailgate safety prop back in place to put the tailgate safety prop back in its home position: 1. Start the engine. 2. Turn on the pump. 3. Raise the tailgate by about 3 feet using the tailgate up switch on the in-cab control panel. 4. Raise the tailgate safety prop. Figure 2-12...

Page 30

20 safety 7. Put the safety pin back in place..

Page 31: General

3 general maintenance cleanliness cleanliness is part of safety. As such: clean all vehicle lights, warning lights and safety stickers so that you and the vehicle surroundings are safe at all times. clean the contact surface between the body and the chassis. Labrie enviroquip group recommends cl...

Page 32: Utomizer

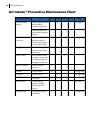

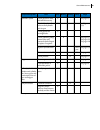

22 general maintenance a utomizer ™ preventive maintenance chart component/system task daily weekly monthly yearly page limit/proximity switches proper adjustment of all limit/proximity switches is imperative x see page 78 check and clean area around limit/proximity switches x packer and accessories...

Page 33

General maintenance 23 hydraulic system check oil level in tank, and refill if necessary x see page 137 check if the shut-off valve on the hydraulic tank is open x see figure 5-35 check ground for overnight leaks x check cylinders, pump, control valve and system for leaks. Repair or replace if requi...

Page 34: Hopper

24 general maintenance hopper the area behind the packer must be cleaned out every day. The packer will not work properly if waste accumulates in this area; it could cause severe damage to the packer and other related parts. Cleaning the hopper consists of 3 steps: preparing the hopper for clean-u...

Page 35

General maintenance 25 cleaning up the hopper (standard units) n ote : packer must be fully extended before applying the following procedure (see preparing the hopper for clean-up on page 24). Once the hopper has been prepared for clean-up: 1. Open the clean-out traps on each side of the hopper (see...

Page 36: Caution!

26 general maintenance 3 c. Grab the panel handle and pull the panel towards you. Figure 3-5 floating panel 4. With a scraper or pressurised water, remove all accumulated dirt behind the packer, under the cylinder brackets, and inside side rails (see figure 3-7). 5. Remove debris through the clean-o...

Page 37: Caution!

General maintenance 27 7 b. Pull the spring-loaded latch to the right and turn the latch handle a quarter of a turn clockwise to release the spring so that the latch can return to its original position. Cleaning up the hopper (co-mingle units) n ote : packer must be fully extended before applying th...

Page 38: Packer

28 general maintenance • cylinder pins • hoses, pipes, connections and cylinders (for leaks, etc.) • bolts (for tightness) • hopper floor and sidewalls (for excessive wear) figure 3-8 inside the hopper area 2. After inspection, on standard units, put the floating panel back in place (see figure 3-5)...

Page 39: Inspecting The Packer

General maintenance 29 preparing the packer for inspection to prepare the packer for inspection: 1. Start the engine and engage the hydraulic pump. 2. Fully extend the packer (see figure 3-1), then push the red emergency s top button (see figure 3-2) to stop the packer in this position. 3. Lock out ...

Page 40: Danger!

30 general maintenance 4. Check out for leaks on hydraulic hoses and tubes. Tighten leaking connections and/or replace defective hoses. 5. Verify cylinder rods: 5 a. Make sure that cylinder rod ends are clear of debris. 5 b. Make sure that cylinder rods have no scratches that may cause the cylinder ...

Page 41: Danger!

General maintenance 31 3. Extend the packer panel to within 12 inches of the end of the stroke. N ote : to extend (or retract) the packer over a short distance, push the green (or yellow) button and then push the red emergency button immediately. Repeat the process until the packer has reached the d...

Page 42

32 general maintenance figure 3-12 removing pins and hoses the cylinder pin top plate has 2 threaded holes to be used as a puller by inserting two ½ nc bolts. Removing the packer panel - std. Units (method a) n ote : there are 2 methods for preparing and removing the packer panel from a standard a u...

Page 43: Danger!

General maintenance 33 preparing packer for removal - std. Units (method b) n ote : there are 2 methods for preparing and removing the packer panel from a standard a utomizer ™ vehicle (method a [taking packer out through the rear of the body] and method b [taking packer out through the hopper]). If...

Page 44

34 general maintenance figure 3-13 side rail shields 2. Remove both side rails (see figure 3-14 and figure 3-15). Figure 3-14 right-side rail figure 3-15 left-side rail bolts to be removed (7) bolts to be removed (7).

Page 45: Danger!

General maintenance 35 3. Start the engine and engage the hydraulic pump. 4. Extend the packer to about 12 inches before the end of the stroke (see figure 3-16). Figure 3-16 packer at about 12 inches from end of stroke 5. Turn off the hydraulic pump and the engine. Disconnecting the packer - std. Un...

Page 46

36 general maintenance figure 3-18 removing pins and hoses the cylinder pin top plate has 2 threaded holes to be used as a puller by inserting two ½ nc bolts. 5. Start the engine and engage the hydraulic pump. 6. Retract both hydraulic cylinders. 7. Turn off the hydraulic pump and the engine. Removi...

Page 47: Danger!

General maintenance 37 installing a new packer - std. Units (method b) to install a new packer: 1. Using a lifting device, lower the new packer into the hopper, properly aligning the packer with the floor guides. 2. Install a new wiper blade on each side of the packer (see figure 3-19). These wiper ...

Page 48: Danger!

38 general maintenance 3. Fully retract the packer by pressing the yellow button on the packer control station. 4. Rotate the chute so that its upper edge is in the middle of the hopper or at its highest position. 5. Turn off the hydraulic pump and the engine. 6. Lock out and tag out the vehicle (se...

Page 49

General maintenance 39 figure 3-21 hopper deflector & chute stopper assembly figure 3-22 chute front support 1 g. Remove all bolts holding the chute shaft cover in place (see figure 3-23). 1 h. Take off the chute shaft cover. Deflector chute stopper ass..

Page 50

40 general maintenance figure 3-23 chute shaft cover 1 i. Remove the chute cylinder rod-end pin (see figure 3-24). Figure 3-24 chute cylinder 1 j. Unscrew the 2 bolts on the front shaft bracket to release the front end of the chute shaft (see figure 3-24). 1 k. Unscrew the 2 bolts on the rear shaft ...

Page 51

General maintenance 41 figure 3-25 chute shaft figure 3-26 rear chute shaft bracket 1 l. Carefully lift the chute out of the hopper. 2. Remove all bolts that secure the hopper divider guard in place (see figure 3-27). 3. Take off the hopper divider guard. Figure 3-27 hopper divider guard 4. Remove a...

Page 52

42 general maintenance figure 3-28 hopper divider 6. Remove both side rail shields (see figure 3-13). 6 bolts are to be removed to take off the right-hand side rail shield. 5 bolts are to be removed to take off the left-hand side rail shield. 7. Remove both side rails (see figure 3-14 and figure 3-1...

Page 53: Danger!

General maintenance 43 to do so: 1. Remove all packer roller assemblies from the follower panels (see figure 3-18). 2. Fold the follower panels over the packer (see figure 3-33). 3. Weld the follower panels to the packer. 4. Attach the packer to a lifting device (fork lift, etc.) and lift it out of ...

Page 54: Packer Cylinders

44 general maintenance figure 3-30 left side rail 8. Reinstall both side rail shields by putting all the bolts back in place (see figure 3-13). 9. Reinstall the hopper divider (see figure 3-31) with an appropriate lifting device. Figure 3-31 hopper divider 10. Reinstall the hopper divider guard (see...

Page 55: Accessing Packer Cylinders

General maintenance 45 accessing packer cylinders to access the packer cylinders: 1. Start the engine and engage the hydraulic pump. 2. Using the joystick, extend the automated arm to get a better access to the hopper area. 3. Fully extend the packer. 4. Disengage the pump and stop the engine. 5. Lo...

Page 56

46 general maintenance figure 3-32 removing rear cylinder pins 14. Remove the roller assemblies on the follower panels (see follower panel roller assemblies on page 65). 15. Fold the follower panels over the packer (see figure 3-33). Figure 3-33 folded follower panels cylinder pins access cover roll...

Page 57: Caution!

General maintenance 47 removing faulty packer cylinder to remove the faulty packer cylinder: 1. Carry out the preceding procedure (see accessing packer cylinders on page 45). 2. Ensure the hydraulic pump is disengaged and the engine is stopped. 3. Ensure the truck is locked out and tagged out proper...

Page 58: Sliding Shoes

48 general maintenance figure 3-35 bolts securing piston side of cylinder i mportant : protect the proximity switch during removal of the cylinder. 7. Remove the proximity switch target and save it for the new cylinder. 8. Replace the faulty cylinder with a new one. If covered by warranty, contact l...

Page 59: Testing For Excessive Wear

General maintenance 49 figure 3-36 sliding shoe testing for excessive wear to test for excessive wear: 1. Lock out and tag out the vehicle (see locking out and tagging out the vehicle on page 12). 2. With a pry bar, try to move the packer vertically (up and down motion) and horizontally (side to sid...

Page 60: Danger!

50 general maintenance figure 3-37 welds to be removed 7. From the cab, start the engine, engage the hydraulic pump and extend the packer to about 18 inches before the end of the stroke. Figure 3-38 packer at about 18 inches from end of stroke n ote : to extend (or retract) the packer over a short d...

Page 61

General maintenance 51 10. Remove all 3 bolts retaining each sliding shoe (see figure 3-39). Figure 3-39 retaining bolts 11. Tack weld a piece of steel tubing to the floor rail and to the front of both sliding shoes. Figure 3-40 tack welding 12. Start the engine, engage the hydraulic pump, and press...

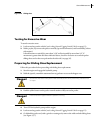

Page 62: Replacing Sliding Shoes

52 general maintenance replacing sliding shoes mechanics must first follow the preceding procedure (preparing for sliding shoe replacement on page 49) before continuing with the procedure below. To replace the worn-out sliding shoes, proceed this way: n ote : this procedure includes removing and rep...

Page 63: Danger!

General maintenance 53 reconnect cylinders to the packer. To do so, reverse the procedure entitled “disconnecting the packer - std. Units (method b)” on page 35. Then go to step 19. Figure 3-43 packer sitting on floor guide 10. Install the new sliding shoes on the packer. 11. Weld a tube on both flo...

Page 64: Danger!

54 general maintenance 24. Tack weld both floor guides to the floor. Figure 3-44 tack weld on both sides of the floor guide 25. Start the truck and engage the hydraulic pump. 26. Retract the packer completely. 27. Turn off the hydraulic pump and the engine. 28. Lock out and tag out the vehicle (see ...

Page 65: Floor Guides

General maintenance 55 finishing up replacing sliding shoes and floor guides apply the following procedure to finish up replacing the sliding shoes and floor guides: 1. Run the packer a few times. 1 a. If the packer is binding, apply some primer paint on the floor guide to find out where the rubbing...

Page 66: Upper Wear Pads

56 general maintenance upper wear pads when the packer moves vertically by more than 3 ⁄ 16” (checked with a pry bar), the upper wear pads must be replaced. Figure 3-47 adjustment screws and upper wear pad preparing for upper wear pad replacement make sure you go through the following steps: 1. Star...

Page 67

General maintenance 57 figure 3-48 side rail shields 6. Remove both side rails (see figure 3-49 and figure 3-50). Figure 3-49 right-side rail figure 3-50 left-side rail bolts to be removed (7) bolts to be removed (7).

Page 68: Danger!

58 general maintenance 7. Start the engine and engage the hydraulic pump. 8. Extend the packer to about 12 inches before the end of the stroke (see figure 3-51). Figure 3-51 packer at about 12 inches from end of stroke n ote : to extend (or retract) the packer over a short distance, push the green (...

Page 69

General maintenance 59 figure 3-52 wear pad 2. Use the adjustment screws (see figure 3-53) to adjust the wear pads in order to maximize stability and smooth motion of the packer. Turn the adjustment screws clockwise/counter-clockwise to lower/raise the wear pad until the desired tightening or loosen...

Page 70: Lower Wear Pad

60 general maintenance lower wear pad removing lower wear pad - standard units to remove the lower wear pad on a standard unit, apply the following procedure: 1. Start the engine and engage the hydraulic pump. 2. Using the joystick, extend the automated arm to get better access to the hopper area. 3...

Page 71: Warning!

General maintenance 61 6 b. Open the panel mid-way. 6 c. Secure the panel with a sling or cable. 6 d. Remove the 2 pivots at the base of the floating panel (see figure 3-55). Figure 3-55 pivots 6 e. Lift the floating panel out of the hopper using an appropriate lifting device. 7. Remove the retainin...

Page 72: Danger!

62 general maintenance figure 3-56 retaining screws holding lower wear pad 8. Replace the old wear pad with a new one and put back all the retaining screws. 9. Reinstall the floating panel. Use steps 6a.) to 6e.) in reverse order of disassembly. 10. After closing back the floating panel, turn the la...

Page 73

General maintenance 63 8. Remove the hopper divider guard (see figure 3-27). 9. Take the floating panel out of the hopper with an appropriate lifting device. To do so: 9 a. Remove the 4 bolts that secure the floating panel to the front hopper posts (2 on each side). Figure 3-57 floating panel 9 b. P...

Page 74: Warning!

64 general maintenance figure 3-58 floating panel 9 c. Secure the panel with a sling or cable. 9 d. Remove the 2 pivots at the base of the floating panel (see figure 3-58). 9 e. Lift the floating panel out of the hopper using an appropriate lifting device. 10. Remove the retaining screws holding the...

Page 75: Replacing Packer Wipers

General maintenance 65 replacing packer wipers to replace the packer wipers, do the following: 1. Proceed with the preparation of the hopper and the correct positioning of the packer (see preparing for upper wear pad replacement on page 56). 2. Remove the old packer wipers and replace with new ones....

Page 76

66 general maintenance figure 3-60 removing all 4 bolts 4 b. Remove the roller assembly and replace it with a new one. 4 c. Put back all 4 bolts in their respective holes before tightening them up. 5. Remove the right-hand side bottom roller and replace it by repeating step 4. 6. Run full cycle to c...

Page 77: Rollers

General maintenance 67 rollers if the roller itself has to be replaced because of wear, apply the following procedure: 1. Once the roller has been removed from the follower panel (see follower panel roller assemblies on page 65), remove the external snap ring. Figure 3-61 removing external snap ring...

Page 78: Body Hoist Cylinder

68 general maintenance body hoist cylinder because it is frequently used, the body hoist cylinder needs to be inspected to ensure proper operation at all times. Figure 3-63 body hoist cylinder inspecting body hoist cylinder the body hoist cylinder should be visually inspected every week as part of r...

Page 79: Danger!

General maintenance 69 5. Check the gland on each cylinder section. If the gap between the gland and the tube is wider than 1 ⁄ 8 inch, you must call labrieplus immediately. Should the gap between the tube and the gland be wider than 1 inch, you must stop using the vehicle immediately and repair the...

Page 80: Danger!

70 general maintenance replacing body hoist cylinder to replace the body hoist cylinder: 1. Lock out and tag out the vehicle (see locking out and tagging out the vehicle on page 12). 2. Disconnect the hydraulic hose and fitting. Figure 3-67 hydraulic fitting 3. Take off the 2 cylinder base pillow bl...

Page 81

General maintenance 71 figure 3-69 pillow blocks 5. Using a lifting device, lift the body just enough to be able to tilt the safety prop under the body. The cylinder will remain in place. I mportant : ensure that the cylinder remains in vertical position while lifting the body. 6. Install the safety...

Page 82: Tailgate Seals and Hinges

72 general maintenance figure 3-70 securing cylinder to support the pillow blocks that are attached to the cylinder must be correctly positioned to allow insertion of the bolts through the support threaded holes (see figure 3-70). 13. Put back the 4 bolts and tighten them up to properly secure the c...

Page 83

General maintenance 73 figure 3-72 rubber seal.

Page 84: Chute (Co-Mingle Vehicles)

74 general maintenance chute (co-mingle vehicles) a mobile chute, located in the middle of the hopper, diverts waste on either side of the hopper. It is controlled from the cab via two push-buttons on top of the joystick. The chute must be inspected and lubricated on a daily basis. Inspecting the ch...

Page 85: Adjusting Chute Cylinder

General maintenance 75 8. Start the engine and engage the hydraulic pump. 9. Move the chute towards the right side of the hopper. 10. Disengage the hydraulic pump and stop the engine. 11. Lock out and tag out the vehicle (see locking out and tagging out the vehicle on page 12). 12. Inspect the rubbe...

Page 86

76 general maintenance figure 3-76 cylinder head and locknut 8. Turn the cylinder head clockwise or counterclockwise depending on the adjustment required. Turning it clockwise reduces the length of the cylinder rod, and turning it counterclockwise extends the rod. Make only half a turn at a time. 9....

Page 87: Proximity and Limit Switches

General maintenance 77 proximity and limit switches proximity and limit switches act as remote electrical on/off switches and must be adjusted properly. Figure 3-77 and figure 3-78 show where the proximity/limit switches are located on the truck. Figure 3-77 switches on the street side of the body f...

Page 88: Limit Switch Adjustment

78 general maintenance limit switch adjustment to adjust the limit switch: 1. Loosen the limit switch nut. 2. Move the lever arm to the approximate position where the switch is to be triggered. 3. Tighten up the nut. 4. To fine tune the adjustment, loosen the nut slightly. 5. With a flathead screwdr...

Page 89: Danger!

General maintenance 79 the proximity switch light should turn on when the target is detected; if not, repeat the adjustment procedure. Adjusting packer extend proximity switch packer proximity switches were adjusted at the factory for optimal packer operation. If the area behind the packer is not pr...

Page 90: Important

80 general maintenance if the packer stops before or after reaching the fully extended position, adjust the switch as follows: to adjust the packer extend proximity switch: 1. Start the engine and engage the hydraulic pump. 2. Push the green button on the packer control station to extend the packer ...

Page 91: Danger!

General maintenance 81 ideally, there should be a gap of approximately 3/16 inch between the proximity switch and the plate. If this is not the case, apply the following procedure: to adjust the gap between the proximity switch and the plate: 1. On the proximity switch, loosen the nuts located on ea...

Page 92: Important

82 general maintenance figure 3-82 packer retract proximity switch to verify that the switch needs adjusting, empty all refuse from the body, start a pack cycle and observe the home position of the packer when it completes its cycle. If the packer stops before reaching the home position or if the pa...

Page 93

General maintenance 83 figure 3-83 packer retracted about 1 inch from end-of-stroke 3. When the packer reaches the correct position, push the red emergency s top button. 4. Locate the packer retract proximity switch on the front right-hand side body corner (see figure 3-82). 5. Loosen both bolts (se...

Page 94: Danger!

84 general maintenance figure 3-84 proximity switch adjusting body-raised limit switch a limit switch located on the vehicle chassis near the body hoist cylinder activates the backup alarm and a warning buzzer, and turns on a warning light inside the cab as soon as the body is raised to a certain he...

Page 95: Warning!

General maintenance 85 this safety feature is provided to warn people around that the vehicle is in the process of being unloaded and to remind the operator that the body is still raised. To adjust the body raised limit switch: 1. Loosen the limit switch nut. 2. Move the body to the approximate posi...

Page 96

86 general maintenance figure 3-86 location of tailgate unlocked proximity switch figure 3-87 proximity switch support assembly to adjust the tailgate unlocked proximity switch: 1. Loosen the nuts on each side of the proximity switch bracket (see figure 3-88). Figure 3-88 proximity switch 2. Adjust ...

Page 97

General maintenance 87 4. Open the tailgate using the tailgate u p switch on the in-cab control panel and listen if the warning buzzer and backup alarm start sounding after you press the switch. 5. Repeat the procedure if need be. Adjusting tailgate fully open proximity switch (optional) the tailgat...

Page 98: Warning

88 general maintenance figure 3-90 hopper door proximity switch this switch is located on the lower side door frame. To verify that the switch needs adjusting, open the side access door by approximately 2 inches (5 cm) and try to operate any hydraulic function. No hydraulic function should be workin...

Page 99

General maintenance 89 figure 3-91 crusher panel up limit switch this switch is located behind the crusher panel itself. N ote : the crusher panel has to be lowered to access this limit switch. To adjust the crusher panel up limit switch: 1. Lower the crusher panel using the crusher panel down switc...

Page 100

90 general maintenance adjusting arm stowed limit switches (2) the arm stowed limit switches illuminate the arm out warning lights in the dashboard when the operator extends the arm or closes the gripper. If these limit switches are misaligned, the warning lights on the dashboard may continue to fla...

Page 101: Danger!

General maintenance 91 3 c. Tighten back up the nut. 4. Slightly close the gripper or extend the arm out (about 1 inch). The arm out warning lights should start flashing. 5. Repeat the procedure until the limit switches are properly adjusted. Adjusting arm mid-height limit switches (2) the two arm m...

Page 102

92 general maintenance the arm mid-height limit switches are located on the front side of the arm. These limit switches do not really need any adjustment other than the target itself. If they ever need adjustment, adjust the target so that the limit switch levers come in contact with the target when...

Page 103: Danger!

General maintenance 93 2. Raise the tailgate about 3 feet (enough to move the safety prop freely). 3. Pull the safety prop upward and set it down (see figure 2-11). 4. Lower the tailgate onto the safety prop. 5. Remove the fork-mounted pin below the threaded rod (see figure 3-93). Take the cotter pi...

Page 104

94 general maintenance adjusting chute proximity switch gaps (co-mingle vehicles) to ensure that a chute proximity switch is working properly, there must be a 3 ⁄ 16inch gap between the switch and the target that passes in front of it. To adjust the gap: 1. Move the chute to the right: 1 a. Start t...

Page 105

General maintenance 95 adjusting chute proximity switches (co-mingle vehicles) chute movement has to be stopped at the correct position to prevent garbage from falling between the chute and the hopper wall. This task is carried out by two proximity switches located near the chute cylinder. One proxi...

Page 106: Fuel Filter Replacement

96 general maintenance figure 3-96 left-hand side proximity switch 7. Move the proximity switch laterally and perform tests until the chute stops at a position that will prevent garbage from falling between the chute and the hopper wall. In the cab, make sure that the corresponding indicator lights ...

Page 107

General maintenance 97 4. After installing the fuel filter, move back the pipe to its original place. 5. Clip the pipe on the collars. I mportant : to prevent air from getting into the system, make sure the fuel filter that you install is full of fuel. Fuel filter.

Page 108: Painting and Finishing

98 general maintenance painting and finishing type of surface finishing and painting finishing recommended: surface preparation grit blasting (#50) or sandblasting (#80) for a 1.4 to 2.4-mil deep profile. primary coat: dupont black urethane primer #373p27678 to get a minimum thickness of 2 mils ...

Page 109: Lubrication

4 lubrication to help the various systems of your truck run smoothly and extend the life time of the many critical parts that affect performance, there is one thing that you must do and that is: lubricate, lubricate and lubricate! Insufficient lubrication is a major cause of component failure on all...

Page 110: Engine Oil

100 lubrication any hydraulic oil that possesses such properties may be used in the a utomizer ™. For northern regions, a hydraulic oil specific to these regions is strongly recommended. I mportant : it is the customer’s responsibility to use oil that is appropriate to the climate. Engine oil refer ...

Page 111: Taking An Oil Sample

Lubrication 101 figure 4-1 oil sample coupler 7. Remove the cap from the sample coupler and clean the coupler with a clean rag. 8. Push on the coupler spring ball (see figure 4-2) using a small tip to purge oil before taking a sample. The residual pressure in the system will push the oil out of the ...

Page 112

102 lubrication 2. Remove the protective cap from the probe. Figure 4-4 probe cap and tip 3. Install the probe on the coupler to fill the sample bottle. Use an ema coupler with m16 × 2.0 threads. Figure 4-5 installing probe on coupler 4. Fill the bottle to the level mark (the pump must be engaged to...

Page 113

Lubrication 103 5. Once the sample is taken, remove the probe from the coupler and pull out the probe to remove it from the bottle (see figure 4-7). Figure 4-7 pulling out probe from bottle 6. Put the seal cover over the bottle cap. Figure 4-8 sealing bottle 7. Fill in the identification form (stick...

Page 114

104 lubrication figure 4-10 lube charts on vehicle right-hand side.

Page 115

Lubrication 105 figure 4-11 a utomizer ™ lubrication charts.

Page 116

106 lubrication.

Page 117: Caution!

Lubrication 107 greasing crusher panel (optional) to properly maintain the crusher panel: 1. Grease the crusher panel cylinder heads by using the grease fittings. 2. Grease the crusher panel bushings. 3. Grease the grease fittings on the lower tube rings (see figure 4-13). Figure 4-12 grease areas c...

Page 118: Tailgate and Body Hinges

108 lubrication figure 4-13 grease fittings on lower tube rings tailgate and body hinges inspecting body-chassis hinges the body-chassis hinges should be lubricated monthly. Also, check for cracks or corrosion. Any crack must be reported, and repaired by qualified personnel. If necessary, contact la...

Page 119: Caution!

Lubrication 109 figure 4-15 body hinge (view from behind the rear mudguard) lubricating tailgate-locking mechanism and hinges it is important to lubricate the tailgate-locking mechanism and tailgate hinges and cylinders with multipurpose grease (see recommended lubricants on page 99) as per the lubr...

Page 120

110 lubrication figure 4-16 tailgate-locking mechanism figure 4-17 cylinder retaining ring figure 4-18 tailgate hinges (on standard and co-mingle units) locking mechanism tailgate locking pin safety pin grease fitting cylinder retaining ring grease fitting tailgate hinge grease fitting.

Page 121

Lubrication 111 figure 4-19 tailgate hooks (on co-mingle units only) figure 4-20 tailgate hinges (on co-mingle units only) grease fittings grease fittings.

Page 122

112 lubrication hopper door lubrication points hopper door latch hopper door hinges hopper door latch.

Page 123

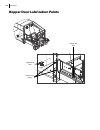

Lubrication 113 packer lubrication points (1) remote grease fittings for rear cylinder pins roller grease fitting.

Page 124

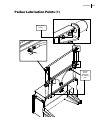

114 lubrication packer lubrication points (2) grease fitting (lh side front cylinder pin).

Page 125

Lubrication 115 chute lubrication points (co-mingle vehicles) pump drive shaft “u” joint grease fittings.

Page 126: Sump Box Hinges

116 lubrication sump box hinges grease fittings.

Page 127: Hydraulic System

5 hydraulic system as with all hydraulic systems, it may be necessary to periodically check and adjust the pressure relief settings. It may be that a major hydraulic component has been changed, that the vehicle is not performing in terms of payload, or that the vehicle has recently been put into ser...

Page 128

118 hydraulic system clean the strainer inside the hydraulic tank after the first 50 hours of use, and once a year afterwards (see cleaning the strainer on page 153). hydraulic oil must be replaced at least once a year, or when contaminated (see emptying the hydraulic tank on page 152). N ote : ...

Page 129

Hydraulic system 119 when the dual vane pump is turned on, the transmission electronic control unit ( ecu ) starts monitoring vehicle and engine speed, and allows the vane pump to engage (or not). If the vehicle is going faster than 15 mph (25 km/h) or if engine speed exceeds 900 rpm, the vane pump ...

Page 130: Directional Control Valve

120 hydraulic system directional control valve a utomizer ™ vehicles are equipped with a directional control valve (see figure 5-2), as part of the body vane pump, that powers all body functions (tailgate, body hoist, and packer). Figure 5-2 directional control valve • tailgate: 4 ways, 3 positions ...

Page 131: Proportional Valve

Hydraulic system 121 proportional valve a utomizer ™ vehicles are equipped with a proportional valve (see figure 5-3), as part of the arm vane pump, that powers all arm functions (gripper [open/close], lifting arm [extend/retract, up/down], chute [left/right], crusher panel [up/down], etc.) and othe...

Page 132: Inspecting The Pump

122 hydraulic system inspecting the pump the hydraulic pump is powered by the vehicle engine through a drive shaft. The pump should be visually inspected every working day. N ote : on some units, the pump is directly installed on a pto with no drive shaft between them. Figure 5-4 pump when inspectin...

Page 133: Replacing The Hydraulic Pump

Hydraulic system 123 replacing the hydraulic pump occasionally, circumstances such as a broken pump drive shaft, a leaking or noisy pump or a lack of hydraulic pressure or oil flow may necessitate the replacement of the pump. Before proceeding with the replacement of the pump, determine the type of ...

Page 134

124 hydraulic system 8. Remove the dump valve. N ote : the dump valve is usually, but not necessarily, located atop the pump. N ote : always reinstall the dump valve and its components (shims, block assembly) as they were before uninstallation. Make sure you do not invert them. 9. Remove the suction...

Page 135

Hydraulic system 125 13 b. Remove all 4 retaining bolts that hold the mounting cap in place. N ote : you may leave two retaining bolts partially unscrewed to facilitate rotation with a metallic bar. 13 c. Rotate the mounting cap accordingly..

Page 136

126 hydraulic system rotation can be done by turning the mounting cap clockwise or counter-clockwise with your hands or by using a metallic bar as illustrated in the above picture. N ote : make sure pump does not come apart. N ote : the cartridge will rotate with the housing. I mportant : do not pul...

Page 137

Hydraulic system 127 13 g. Remove all 7 retaining bolts that hold the front cap in place. N ote : you may leave two retaining bolts partially unscrewed to facilitate rotation with a metallic bar. 13 h. Rotate the front cap accordingly. Rotation can be done by turning the front cap clockwise or count...

Page 138

128 hydraulic system i mportant : be sure not to pull on the front cap. Otherwise, the dowel pin may leave its position in the housing. N ote : the cartridge will rotate with the housing. 13 i. Put all 7 bolts back in place. 13 j. Check if the shaft rotates freely. 13 k. Tighten up all bolts to the ...

Page 139: Caution!

Hydraulic system 129 figure 5-7 depth of hole to be drilled 14 c. Reinstall the drive shaft. 14 d. Place the yoke on the shaft as illustrated on page 135. The yoke must be fully engaged on the shaft with both holes aligned (one hole over the other). 14 e. Apply loctite 243 (medium strength) to bolt ...

Page 140: Caution!

130 hydraulic system 4. Loosen the breather cap on the hydraulic tank to depressurize the tank. If tank is of the pressurized type. 5. Disconnect the electric coil on the dump valve, if equipped. 6. Place a pan under the pump to catch dripping oil and unscrew all hydraulic hoses (4) that are attache...

Page 141

Hydraulic system 131 if need be, disconnect the drive shaft from the pump and save it for the replacement pump. 12. Install the new pump. Before attempting to install the new pump, it is very important to check the porting configuration of that pump; the ports on the replacement pump must be positio...

Page 142: Caution!

132 hydraulic system 18. Prime the new pump (see priming a new pump on page 136). N ote : labrie enviroquip group strongly recommends you change the filter element and the hydraulic oil as well as clean the hydraulic tank after installation of a new pump (see replacing filter elements on page 154 an...

Page 143

Hydraulic system 133 figure 5-10 suction block 9. Attach the pump to a suitable lifting device and remove all 5/8” bolts that hold the pump to the pto extension shaft. 10. Remove the pump. 11. Install the new pump using a suitable lifting device. Before attempting to install the new pump, it is very...

Page 144: Caution!

134 hydraulic system 12. Connect the pump to the pto extension shaft. Align the splines on the pto to those on the pump for ease of connection. Figure 5-11 splines on pump 13. Put all 5/8” bolts back in to secure the pump to the shaft. 14. Go through steps 8 to 5 inclusively to reinstall the various...

Page 145

Hydraulic system 135 installing a yoke locking bolt n ote : it is important to perform this procedure after a pump replacement or a pump drive shaft replacement. To install a yoke locking bolt, do the following: 1. Locate the hole on the yoke and the hole on the drive shaft (see illustration below)....

Page 146: Priming A New Pump

136 hydraulic system figure 5-12 steel wire on yoke n ote : use the following parts: qub00700 (bolt) and 154503 (steel wire). Priming a new pump to prevent cavitation or air in the hydraulic system after installing a new pump or even when flushing the hydraulic system, make sure to prime the pump be...

Page 147: Caution!

Hydraulic system 137 7. Start the engine. You can slowly raise the engine rpm only after 5 minutes. When you raise the rpm, always make sure that the pump does not make excessive noise. 8. Before putting the vehicle back in service, recalibrate the system pressures. Inspecting the hydraulic tank ver...

Page 148

138 hydraulic system figure 5-15 steel hydraulic tank n ote : the illustration above shows the model of hydraulic oil tank most often installed on our trucks. However, other models exist and your truck may be equipped with one of these. Filter suction breather cap oil temp./level gauge access panel ...

Page 149

Hydraulic system 139 adjusting pressure and relief valves a 0–4000 psi pressure gauge as well as a set of ball-end hex keys are required to adjust pressure and relief valves (see figure 5-16). Figure 5-16 pressure gauge and ball-end hex key adjusting vane pump relief valves (if equipped) the body an...

Page 150

140 hydraulic system figure 5-17 relief valve on pump figure 5-18 relief valve on chassis to adjust the body vane pump relief valve: 1. Lock out and tag out the vehicle (see locking out and tagging out the vehicle on page 12). 2. Install the 0–4000 psi pressure gauge on the quick-connect fitting loc...

Page 151

Hydraulic system 141 6. Adjust the body vane pump relief valve according to the pressure chart (see table 1). 7. Once the body vane pump relief valve is adjusted, back out the main relief. I mportant : when the body and arm vane pump relief valves are adjusted to the proper pressure, adjust the reli...

Page 152

142 hydraulic system figure 5-20 relief valve using a ½” allen key, turn the adjustment screw clockwise to increase pressure or counter- clockwise to reduce pressure. Use a 1½” key to screw/unscrew the locknut. 6. Reconnect the packer extend proximity switch. Adjusting the body relief valve (electro...

Page 153

Hydraulic system 143 8. Remove the pressure gauge from the inlet cover and install it on the maximum pilot pressure port (see d on figure 5-21). 9. Disconnect the packer extend proximity switch. Activate the packer extend until it reaches the end of stroke. 10. Adjust pilot pressure to 550 psi (± 50...

Page 154: Warning!

144 hydraulic system refer to the hydraulic pressure table to adjust each function of the lifting arm. Before performing the procedure, make sure that all function levers and their adjustment screws have been properly identified on the valve. N ote : a helper may be needed when adjusting arm pressur...

Page 155: Warning!

Hydraulic system 145 figure 5-23 main relief valve adjustment screw adjusting chute pressure (co-mingle vehicles) to calibrate the working pressure of the chute: 1. Secure the arm working area using safety tape or barricades. 2. Start the engine and engage the hydraulic system (pump switch on). 3. A...

Page 156: Danger!

146 hydraulic system figure 5-24 control levers 4. Take a reading of the maximum pressure at this point. 5. With the proper hex key, tighten or loosen the work port relief valve screw so as to adjust the chute pressure to 1200 psi. Adjusting pressure on 96-gallon grippers the section of the proporti...

Page 157

Hydraulic system 147 4. Make sure that all hoses are tight and not leaking. 5. Connect a pressure gauge (0–4000 psi) to the quick-connect coupler on the proportional valve (see figure 5-25). Figure 5-25 installing the pressure gauge 6. Put the transmission in neutral, start the engine and engage the...

Page 158

148 hydraulic system 3. Set the switch on the control panel to high pressure and move the manual levers back and forth to release any residual pressure. 4. Make sure that all hoses are tight and not leaking. 5. Connect a pressure gauge (0–4000 psi) to the quick-connect coupler on the proportional va...

Page 159

Hydraulic system 149 figure 5-28 relief adjustment screws adjusting low pressure on 300-gallon grippers to adjust low pressure on 300-gallon gripper built-in valves: 1. Lock out and tag out the vehicle (see locking out and tagging out the vehicle on page 12). 2. Secure the area around the path of th...

Page 160

150 hydraulic system figure 5-29 external relief valve adjustment screw external relief valve adjustment screw.

Page 161: Pressurizing The Tank System

Hydraulic system 151 figure 5-30 pressure adjustment values pressurizing the tank system n ote : for chassis-mounted tanks only. No pressurization is needed for behind-the-cab mounted tanks; gravity is enough to cause the oil to flow. Cavitation inside the pump generates excessive wear and noise. To...

Page 162: Emptying The Hydraulic Tank

152 hydraulic system figure 5-31 5-psi relief valve and breather cap figure 5-32 pressure gauge and regulator emptying the hydraulic tank to empty the hydraulic tank: 1. Prepare the vehicle accordingly: 1 a. Apply the parking brake 1 b. Start the engine 1 c. Engage the hydraulic pump 1 d. Retract al...

Page 163: Cleaning The Strainer

Hydraulic system 153 1 g. Stop the engine 2. Lock out and tag out the vehicle (see locking out and tagging out the vehicle on page 12). 3. Clean around the filler cap and remove it. 4. Place a clean container (minimum capacity: 60 gallons) under the drain plug. 5. Remove the drain plug under the tan...

Page 164: Replacing Filter Elements

154 hydraulic system figure 5-33 strainer assembly on steel tank replacing filter elements i mportant : to protect new components of the hydraulic system, the return filter element must be changed after the first 50 hours of operation of the vehicle. Change the element twice a year afterwards (see a...

Page 165

Hydraulic system 155 figure 5-34 filter restriction indicator (steel tank) to replace the hydraulic filter: 1. Lock out and tag out the vehicle (see locking out and tagging out the vehicle on page 12). 2. Prepare a pan or a bucket to collect the oil that will come out of the filter housing (two gall...

Page 166: Replacing Hydraulic Oil

156 hydraulic system figure 5-36 filter element 5. Reinstall the filter head cover. Replacing hydraulic oil to do so: 1. Empty the hydraulic tank (see emptying the hydraulic tank on page 152). 2. Clean the strainer (if necessary) (see cleaning the strainer on page 153). 3. With a clean dry cloth, re...

Page 167: Caution!

Hydraulic system 157 7. Reinstall the filler cap and fully open the ball valve. 8. Prime the pump (see priming a new pump on page 136). 9. Start the engine. Inspecting hydraulic cylinders you must inspect all hydraulic cylinders at least once a month. When you do so: 1. Make sure that the ball valve...

Page 168

158 hydraulic system 2. Pull on the red emergency s top button. 3. Start the engine and engage the hydraulic pump. 4. Fully extend the packer cylinders, then disengage the hydraulic pump. 5. Disconnect the packer extend proximity switch. This prevents the packer from returning to its initial positio...

Page 169: Electrical System

6 electrical system this chapter is divided into two sections. The first section describes how the electrical components work and the second section describes how to adjust and repair the electrical components. How the electrical system works the electrical system includes the following components: ...

Page 170

160 electrical system the control box is centrally mounted in the cab. It includes push buttons, toggle switches, and warning lamps. Autocar acx has an integrated control panel in the dashboard. Some units also have auxiliary controls located under the curbside seat. Other units also have external c...

Page 171: Fuses and Circuit Breakers

Electrical system 161 adjusting and repairing electrical components the required electrical system adjustments include: circuit breakers and fuses adjusting limit and proximity switches packer fully retracted proximity switch packer fully extended proximity switch hopper door proximity swi...

Page 172: Important

162 electrical system circuit breakers there is a button on the circuit breaker of the relay box located inside the cab. Pushing this button resets the breaker. N ote : consult the oem manual for information on equipment not manufactured by labrie enviroquip group. The following table provides a des...

Page 173: Pneumatic System

7 pneumatic system the air (pneumatic) system is crucial for efficient brake and body operation. N ote : before searching for parts, identify the type of cab of your unit (cab over or conventional). The mounting of some components for the body depends on the type of cab configuration. The main hydra...

Page 174

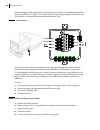

164 pneumatic system when the tailgate or body switch on the control panel is activated, the corresponding solenoid valve in the air control box (see figure 7-2) sends air to the corresponding air actuator on the main valve. This results in a movement of the hydraulic spool inside the valve. Figure ...

Page 175

Pneumatic system 165 figure 7-3 air filter to bleed the water trap, do the following: 1. Lock out and tag out the vehicle (see locking out and tagging out the vehicle on page 12). 2. Using a rag, unscrew the drain cocks. This will bleed all the water from the water trap and the air filter bowl locat...

Page 176

166 pneumatic system figure 7-5 drain valve i mportant : pay particular attention to the dryer cartridge. On this type of equipment, the compressor works all the time (frequent use of the brake system). As a result, lots of moisture is injected into the air system. For more information, see air drye...

Page 177

Pneumatic system 167 introducing the packer air system the hydraulic valve, which controls some of the hydraulic functions, is equipped with air actuators. The packer air actuator pushes back and forth on the hydraulic spool of the valve, resulting in a movement of the packer (extension or retractio...

Page 178: Air Dryer

168 pneumatic system air dryer units are equipped with an air dryer and/or alcohol evaporator. These devices are used to reduce water in the air system, preventing corrosion or freezing of the air components in cold weather. Maintenance on the air dryer and/or alcohol evaporator is covered in the ch...

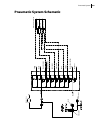

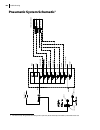

Page 179: Pneumatic System Schematic

Pneumatic system 169 pneumatic system schematic hy draul ic m a in v a lv e pr im ar y ta n k 65 ps i su ppl y c h u te loc k (op ti on ) ta il g a te o pen ta il g a te c los e r e turn pa c k bo dy lo w e r bo dy r a is e sp a r e o u t sp a r e sp ar e s p are in tai lg at e pack er bo dy li ft i...

Page 180

170 pneumatic system.

Page 181: Troubleshooting

8 troubleshooting this chapter contains information to help you narrow down and/or solve problems that might occur with your a utomizer ™. Procedures throughout this chapter require that the people performing troubleshooting tasks have basic knowledge in electrical, hydraulic and pneumatic systems. ...

Page 182

172 troubleshooting figure 8-1 digital multimeter or vom (volt-ohm-milliammeter) n ote : the ammeter must support at least 10 amps. Figure 8-2 jumper wire with alligator clips figure 8-3 two oil pressure gauges (0–4000 psi) 0–4000 psi pressure gauge (part# hyf00910) female quick coupler (part# hyf10...

Page 183

Troubleshooting 173 figure 8-4 ball-end hex wrench (metric and sae ).

Page 184: Troubleshooting Guide

174 troubleshooting troubleshooting guide this troubleshooting guide will help identify the most commonly seen problems on the a utomizer ™. The table below will also provide the possible cause of the problem and give solutions to resolve that problem. For further information regarding customized op...

Page 185

Troubleshooting 175 not the proper grade of oil empty oil and refill with anti- foaming oil. See recommended lubricants on page 99 and emptying the hydraulic tank on page 152. Cavitation, excessive noise or vibration of the pump. Ball valve on hydraulic tank fully open the ball valve on the hydrauli...

Page 186

176 troubleshooting faulty hydraulic line perform a circuit analysis using the main hydraulic schematics (see main hydraulic schematic (1) on page 185). Stuck hydraulic spool inside valve make sure that no spool inside the directional valve is stuck in a position that could send the hydraulic flow t...

Page 187

Troubleshooting 177 emergency s top buttons (red) make sure all emergency stop buttons are pulled out. Hydraulics see adjusting pressure and relief valves on page 139. Faulty harness between packer module and control station defective packer module hopper door open close the hopper door. Packer does...

Page 188: Pump

178 troubleshooting pump the pump is operated by a control switch located on the control panel. When it is engaged, the switch turns green. Three conditions must be met for the pump to engage and the switch to turn green: air pressure must be at approximately 70 psi engine speed must be lower th...

Page 189: Packer Air System

Troubleshooting 179 figure 8-5 plug to loosen i mportant : do not activate any hydraulic function during system bleeding. 6. When the noise stops, tighten the pipe/hose fitting. 7. Cycle the packer to ensure that there are no leaks and the pump is running smoothly. 8. Disconnect the gauge. Packer ai...

Page 190

180 troubleshooting 4. Inject compressed air on one side of the actuator to ensure that the spool moves freely inside the valve (the same process will have to be done for the other side of the actuator). • if the spool is not moving freely, lubricate or replace the air actuator. • if the spool is mo...

Page 191: Tailgate-Locking Mechanism

Troubleshooting 181 tailgate-locking mechanism n ote : refer to “main hydraulic schematic (1)” on page 185 and main hydraulic schematic (2) on page 186. The tailgate-locking mechanism is equipped with hydraulic safety components that prevent accidental unlocking of the tailgate during operation. One...

Page 192

182 troubleshooting figure 8-9 tailgate-locking mechanism.

Page 193

Troubleshooting 183 tailgate unlocking spontaneously if the tailgate seems to unlock by itself when using the packer, the “power bleed” inside the valve might not be working on the right side of the hydraulic cylinder. To fix this problem: 1. Apply all safety measu res to ensure safety around the ve...

Page 194: Pneumatic System Schematic

184 troubleshooting pneumatic system schematic 1 1. For reference only. The pneumatic schematic specific to your truck, based on the body serial number, is found in the truck’s cab. Hy draul ic m a in v a lv e pr im ar y ta n k 65 ps i su ppl y c h u te loc k (op ti on ) ta il g a te o pen ta il g a...

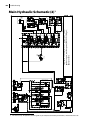

Page 195: Main Hydraulic Schematic (1)

Troubleshooting 185 main hydraulic schematic (1) 1 m at iÈr e / m at er ial : s e lo n s t a nda rd / a cco rding t o : pl at f o r m e / pl at f o r m co ncus p a r / de s ig n e d b y de s s innÉ p a r / dra f t b y da t e da t e 1 1 unit É s / unit s : p o ids / w e ig ht: no . RÉ f /re f no . F ...

Page 196: Main Hydraulic Schematic (2)

186 troubleshooting main hydraulic schematic (2) 1 m at iÈr e / m at er ial : s e lo n s t a nda rd / a cco rding t o : pl at f o r m e / pl at f o r m co ncus par / desi g n ed by d essi nnÉ par / draf t by dat e da t e 1 1 unit É s / unit s : p o ids / w e ig ht: no . RÉ f /re f no . F ini de s ur...

Page 197: Multiplexing

9 multiplexing as labrie enviroquip group vehicles become more and more efficient, they require more automation features and thus some programming. Currently, a utomizer ™ vehicles require programming of: labrie’s can bus-based multiplexed system the allison transmission parameters, and the cu...

Page 198: Main Page

188 multiplexing each time the operator turns the ignition key on, a complete bit test of the multiplex system is conducted. This test takes about 5 seconds to complete. N ote : a flashing green light on the monitor indicates that the display power is on. This light should be blinking steadily at 2 ...

Page 199

Multiplexing 189 figure 9-3 main page press the far right button to reset the counter display to zero. Time and date indicator (optional) a time and date indicator may be found on the upper left-hand side corner of the screen. The availability of this indicator is based on the chassis on which the b...

Page 200

190 multiplexing table 1 warning messages (cont’d) warning and caution messages solution arm up:chute bad pos. Place chute in correct position arm up:crusher not raised raise crusher panel arm:auxiliary deadman on release auxiliary deadman arm:body raised lower body arm:hopper door not close close h...

Page 201

Multiplexing 191 gripper open:arm too high lower arm high hydraulic oil temp. Turn off engine and refer to your maintenance personnel low hydraulic oil add hydraulic oil packer extend:air weigh signal unload body packer:already extended refer to maintenance personnel or labrieplus packer:already ret...

Page 202

192 multiplexing pump:bodylower switch on release bodylower switch prior to engaging pump pump:bodyraise switch on release bodyraiseswitch prior to engaging pump pump:crusherdown switch on release crusherdown switch prior to engaging pump pump:crusherup switch on release crusherup switch prior to en...

Page 203

Multiplexing 193 pump:packer extend switch on release packer extend switch prior to engaging pump pump:packer retract switch on release packer retract switch prior to engaging pump pump:pto not ok refer to maintenance personnel or labrieplus pump:rpm too high lower engine speed below 900 rpm pump:ta...

Page 204

194 multiplexing table 2 error messages (cont’d) error messages solution button pack 12 is disconnected refer to maintenance personnel or labrieplus button pack 13 is disconnected refer to maintenance personnel or labrieplus button pack 14 is disconnected refer to maintenance personnel or labrieplus...

Page 205: Main Menu

Multiplexing 195 should the system issue a warning or caution message, it will appear on the main page. For example, if the following caution message “pump not started: main air pressure” is issued by the system, it will appear on the main page of the monitor. An action that could be taken by the op...

Page 206

196 multiplexing when the main menu is displayed, you can have access to the following sections: multicycle i/o status program version pump usage (optional) time adjust (available according to chassis) displayed in the lower center of the screen is an indicator that monitors traffic on the...

Page 207

Multiplexing 197 figure 9-7 control panel to test the new settings: 1. On the control panel press the multicycle switch and the green start cycle button (figure 9-7). 2. Once the packer has completed its cycles and come to a stop, switch off the hydraulic pump and turn off the engine. The number of ...

Page 208

198 multiplexing figure 9-8 module i/o status page input status the input status page is accessible from the module i/o status page. After selecting the desired module and pressing “ok”, the input status page of the selected module is displayed (see figure 9-9). Figure 9-9 input status page the inpu...

Page 209

Multiplexing 199 press “esc” to return to the preceding page. Press the “output” button to display the output status page. Output status the output status page is accessible from the input status page (see figure 9-10). Figure 9-10 output status page the rectangles on this page are used to check the...

Page 210

200 multiplexing but before the force page is displayed, a warning message appears on the monitor screen (see figure 9-11). Figure 9-11 warning message this message stays on for 15 seconds. Then an “ok” prompt appears on the lower right-end corner of the screen. I mportant : it is very important to ...

Page 211

Multiplexing 201 as no input function can be forced to be active or inactive, the operator must press the “output” button to go to the following page (see figure 9-14). Figure 9-14 force page (output) the force page allows the operator to force a function to be overridden. This is useful to enable a...

Page 212

202 multiplexing the joystick page is accessible from the module i/o status page (see figure 9-8). From that page select “joystick” using up/down arrows and press “ok”. The joystick page opens (see figure 9-15). Figure 9-15 joystick page the joystick page allows the operator to check if all function...

Page 213

Multiplexing 203 the j1939 bus, which is used for the chassis equipment; and the canopen bus, which is used for the body. These 2 communication buses are completely independent of one another, except for some specific data that are transferred from the chassis j1939 bus to labrie’s multiplex sys...

Page 214: Warning Buzzer

204 multiplexing warning buzzer among the many buttons on the control panel you will find a warning buzzer (see figure 9-18). This buzzer sounds and a red light in its center flashes to warn the operator of any situation that might be hazardous. When this happens, the operator can look at the monito...

Page 215

Multiplexing 205 replacing the can bus-based multiplex joystick should the can bus-based multiplex joystick need to be replaced for any reason, it will have to be replaced with a new joystick of the same kind and same part number in order to insure continued proper operation of the multiplex system....

Page 216: Programmed Parameters

206 multiplexing figure 9-21 allison doc software if the ecu of your vehicle requires repair or replacement, or if it needs specific programming parameters, see programmed parameters below. Programmed parameters programming in the transmission ecu module affects engine speed, pto engagement and oper...

Page 217

Multiplexing 207 to tap into the ecu, labrie uses the following wires on the allison connector: table 6 allison wires to be enabled wires wire # (wtec iv) pack enable 117 input pto enable 143 output pto enable 130 output neutral indicator – pto 145 auto-neutral pack enable (if present) 142 table 7 i...

Page 218: Cummins Engine Parameters

208 multiplexing cummins engine parameters the following table contains the engine programming parameters specific to the a utomizer ™ units. Enter those parameters into cummins engine ecms. For more information, call labrieplus. Table 9 cummins engine parameters menu: features & parameters paramete...

Page 219: Lifting Arms

10 lifting arms to keep the arm in good working order and to reduce the amount of down time and the risk of accidents, a preventive maintenance program must be implemented and followed thoroughly. Maintenance personnel must be familiar with the operation of the arm, the safety around it and the main...

Page 220

210 lifting arms figure 10-1 mounting bolts figure 10-2 rollers and bearings figure 10-3 bolt locks bearings rollers.

Page 221

Lifting arms 211 figure 10-4 right hand™ gripper figure 10-5 hoses and connections 5. Check for loose nuts and bolts..

Page 222: Gripper Auto-Closing System

212 lifting arms figure 10-6 bolts 6. Check both arm stowed limit switches. For more information, see adjusting arm stowed limit switches (2) on page 90. 7. Lubricate arm moving parts as per the arm lubrication chart on page 228. 8. Lock out and tag out the vehicle (see locking out and tagging out t...

Page 223: Danger!

Lifting arms 213 figure 10-7 auto-closing limit switch (lower) and camera switching limit switch figure 10-8 gripper closed (left) and open (right) inspecting the auto-closing system to inspect the system: 1. Make sure that the vehicle is parked on safe, level ground. 2. Secure the area around the p...

Page 224: Danger!

214 lifting arms 4. Lower and fully open the gripper. 5. Close the gripper a few inches (to release the limit switch) and lift the gripper to see if it closes automatically. If the gripper does not close on its way up, refer to the following section. Adjusting the auto-closing system the gripper aut...

Page 225: Auto-Packing

Lifting arms 215 • if the gripper does not close while raising the arm, the limit switch is not properly adjusted. In that case, completely lower the gripper and adjust the limit switch so that it clicks as soon as the target is detected. 6. Perform a few up-and-down cycles of the gripper. Each time...

Page 226: Position

216 lifting arms right hand™ arm chain tension and gripper position proper chain tension is essential for smooth operation of the standard or hd right hand™ arm on a utomizer ™ vehicles. To adjust chain tension and gripper position: 1. Lower the gripper to its lowest position. 2. Measure between the...

Page 227

Lifting arms 217 3 c. Both arms should be in contact with the bumpers installed on the end of the rail. If badly worn, replace both bumpers. 3 d. Tighten both top adjustment nuts until you achieve the target measurement at the link arms. It is normal that the link arms are in contact with the bumper...

Page 228: Circuit

218 lifting arms figure 10-12 arm alignment (the location of the chain tension bolts is indicated by arrows) n ote : the above illustration shows a standard right-hand tm arm. Bleeding air out of the lifting arm hydraulic circuit when replacing a hydraulic cylinder, a holding valve, or when opening ...

Page 229

Lifting arms 219 gripper hydraulic circuit this subcircuit includes two cylinders (bore 1 ½ in., stroke between 5 and 7 in.) a holding valve and a flow divider valve. It controls the open/close motion of the gripper in order to grip containers. In/out hydraulic circuit this subcircuit includes two c...

Page 230: Lifting Arm Holding Valves

220 lifting arms 3. Using the joystick or the lever on the proportional valve, fully extend the rail cylinders of the arm. 4. As soon as a constant and uniform oil flow (without air bubbles) is leaking out, tighten the fitting. Keep the hydraulic function engaged until the fitting is tightened. 5. L...

Page 231

Lifting arms 221 to adjust the gripper holding valve pressure: 1. Apply all safety measures to ensure safety around the vehicle at all times. 2. Make sure that the parking brake is applied. 3. Locate the gripper holding valves (see figure 10-15 [standard arm], or figure 10-16 [hd arm]). 4. Connect a...

Page 232

222 lifting arms figure 10-15 96-gal gripper holding valve figure 10-16 cylinder-mounted holding valve (hd arm gripper) adjusting in/out holding valve pressure n ote : there is a holding valve mounted on the in/out cylinder (standard and hd). To adjust the in/out holding valve pressure: 1. Apply all...

Page 233

Lifting arms 223 3. Locate the holding valve on the in/out cylinder (see figure 10-18). 4. Connect a pressure gauge to the automated arm valve. Figure 10-17 quick coupler for pressure gauge 5. Start the engine and engage the hydraulic pump. 6. Using a lever on the valve, manually extend the right ha...

Page 234

224 lifting arms adjusting up/down holding valve pressure n ote : the up/down cylinder on a standard lifting arm has no holding valve on it. However, it has a pressure relief cartridge that provides stroke-end cushioning during extension of the cylinder. The up/down cylinder on a hd lifting arm is f...

Page 235

Lifting arms 225 figure 10-20 holding valve adjustment screw (up/down cylinder) - hd arm i mportant : cushioning cartridges on up/down cylinder (see figure 10-20) should be torqued to 28 ft-lb. Adjusting the arm vane pump relief valve usually, there is no arm vane pump relief valve on an a utomizer ...

Page 236: Adjusting Arm Speed

226 lifting arms adjusting arm speed n ote : no arm speed adjustment is required unless replacing the valve or one of its sections. Arm speed is controlled by the amount of hydraulic fluid (flow) that is being sent to the arm cylinder. The arm control valve spools can limit the flow of hydraulic oil...

Page 237

Lifting arms 227 2. Secure the area around the path of the arm with barrier tape or barricades. 3. Put the transmission in neutral, start the engine, and engage the hydraulic pump. 4. Clearly identify the stopper screw on the valve that relates to the proper function (boom extension/retraction, grip...

Page 238

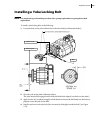

228 lifting arms lubrication charts and hydraulic schematics the following are examples of lubrication charts and hydraulic schematics for the r ight h and ™ lifting arm. Please note that these documents are for reference purposes only. The lubrication charts are based on a 40-hour a week truck oper...

Page 239

Lifting arms 229 figure 10-23 arm w/ 96-gallon gripper.

Page 240

230 lifting arms hydraulic schematic (standard arm) m at iÈr e / m at er ial : s e lo n s t a nda rd / a cco rding t o : pl at f o r m e / pl at f o r m co ncus par / desi g n ed by d essi nnÉ par / draf t by dat e da t e 1 1 unit É s / unit s : po id s / w ei g h t : no . RÉ f /re f no . F ini de s...

Page 241

Lifting arms 231 valve with crusher panel section (standard arm) m at iÈr e / m at er ial : s e l o n s t a nda rd / a cco rding t o : pl at f o r m e / pl at f o r m co ncus p a r / de s ig n e d b y de s s innÉ p a r / dra f t b y da t e da t e 1 1 unit É s / unit s : p o ids / w e ig ht: no . RÉ ...

Page 242

232 lifting arms valve with crusher panel section (heavy-duty arm) m at iÈr e / m at er ial : s e l o n s t a nda rd / a cco rding t o : pl at f o r m e / pl at f o r m co ncus p a r / de s ig n e d b y de s s innÉ p a r / dra f t b y da t e da t e 1 1 unit É s / unit s : p o ids / w e ig ht: no . R...

Page 243

Our office in the u.S. Our office in canada 1981 w. Snell road 175a route marie-victorin oshkosh, wi 54904 levis, qc g7a 2t3 toll free: 1-800-231-2771 toll free: 1-877-831-8250 telephone: 1-920-233-2770 telephone: 1-418-831-8250 general fax: 1-920-232-2496 service fax: 1-418-831-1673 sales fax: 1-92...