- DL manuals

- Labrie

- Automobile

- automizer

- Operator's Manual

Labrie automizer Operator's Manual

Summary of automizer

Page 1

A utomizer tm r ecycler o perator m anual.

Page 2: Utomizer

A utomizer tm r ecycler o perator manual.

Page 3: Liability

Liability labrie environmental group assumes no liabilty for any incidental, consequential, or other liability that might result from the use of the information contained in this document. All risks and damages, incidental or otherwise, arising from the use or misuse of the information contained her...

Page 4: Table of Contents

A utomizertm recycler ....................................................................................................................................................................... I o perator manual ..............................................................................................

Page 5: Operating The A

Iv table of contents pack push button (green) ..................................................................................................................................................... 38 return push button (yellow) ............................................................................

Page 6: Introduction

1 introduction the purpose of this manual is to introduce operators to the operational procedures for the a utomizer tm r ecycler . For information regarding maintenance procedures, refer to the maintenance manual for the a utomizer tm r ecycler . Introducing the a utomizer tm r ecycler the a utomiz...

Page 7: To Contact Labrie Plus

2 introduction to contact labrie plus address: 175 route du pont st-nicolas, qc g7a 2t3 toll-free: 1-877-831-8250 telephone: 1-418-831-8250 service fax: 1-418-831-1673 parts fax: 1-418-831-7561 mailing address: 175 route du pont st-nicolas, qc g7a 2t3 parts, service and warranty: (during business ho...

Page 8: Safety

2 safety safety is always of prime importance when operating any type of equipment. All operators working with the a utomizer tm r ecycler must be aware of the safety practices and features detailed in this section. Conventions basic safety notions the following safety notions are related to the use...

Page 9: Responsibilities

4 safety responsibilities safety is everybody’s responsibility. Both employer and employee must play their part to ensure the safety of the operator, the vehicle, and its immediate surroundings. Employer responsibilities it is the responsibility of the employer: to ensure that the a utomizer tm r ...

Page 10: Employee Responsibilities

Safety 5 employee responsibilities it is the responsibility of the employee: to enforce all safety measures to meet the requirements established by the employer. to operate the a utomizer tm r ecycler only after having received instruction and training. to perform routine daily unit inspection...

Page 11: General Precautions

6 safety do not back up the vehicle when the body is raised. do not drive with the tailgate fully open unless it is to unload refuse at the landfill. do not use the body safety prop to prop a loaded body. General precautions it is the employer’s responsibility to ensure that only qualified emp...

Page 12: Warning!

Safety 7 do not get into the hopper compartment or try to repair anything behind the packer when it is moving or when the hydraulic pump is still running. Personnel authorized to get into the hopper must first lock out and tag out the vehicle, as required by the employer. For more information, see...

Page 13: Fire

8 safety fire the employer must inform and train all personnel on the measures that must be taken in case of a vehicle and/or loaded body catching fire. Anytime a loaded vehicle is brought inside a garage, fire extinguishers shall be close at hand. The employer must also inform employees of an appro...

Page 14

Safety 9 47282 47286 47304 47308 32491 47314 47350 47352.

Page 15

10 safety 47422 47554 47562 47564 32490 79781.

Page 16

Safety 11 32492 32493 32494 32495 32496 32497 32499.

Page 17

12 safety 121349 84186 47466 47465 47463 47464.

Page 18

Safety 13 47461 84469 47525 32479 84037.

Page 19

14 safety 79848 84467 47358.

Page 20: Labels On Tailgate

Safety 15 labels on tailgate 32307 47266 47268 84458 79835.

Page 21: Labels On Cab Console

16 safety labels on cab console 43862 43874 43878 43888 43880 43876 43934 47451.

Page 22: Labels Inside Cab

Safety 17 labels inside cab 43798 43794 47284 47440 47276 43790 84273 43816.

Page 23

18 safety 84020 84114 47467 84404 43854 79822 79855.

Page 24

Safety 19 79843 84188 104539 84024 79840

Page 25: Safety Features

20 safety safety features back up alarm the back up alarm sounds when the truck is in reverse, the tailgate is opening or the hopper bucket is moving. Body safety prop safety props ensure that heavy body parts will not move inadvertently. Setting the body safety prop the body safety prop ensures tha...

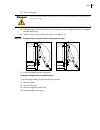

Page 26: Tailgate Safety Prop

Safety 21 4. Release the safety prop using the safety prop handle and position it adequately. Figure 2-2 safety prop handle 5. Lower the body until it rests on the safety prop. 6. Lock out and tag out the vehicle (see locking out and taging out the vehicle on page 27). You can now work safely undern...

Page 27: Danger!

22 safety figure 2-3 tailgate safety prop setting the tailgate safety prop to set the tailgate safety prop: 1. Make sure that the body is empty. 2. Remove the tailgate-locking mechanism safety pin. Figure 2-4 safety pin 3. Start the engine. Danger! The safety prop shall be set each time the tailgate...

Page 28: Danger!

Safety 23 4. Turn on the pump. 5. With the tailgate control lever in the cab control panel, raise the tailgate about 3 feet (enough to raise the safety prop). 6. Pull the safety prop upward and set it down (see figure 2-5). Figure 2-5 pulling the safety prop upward (left) and setting it down (right)...

Page 29: Camera System

24 safety figure 2-6 raising the tailgate safety prop 5. Release your grip on the safety prop to set it in its home position. Figure 2-7 setting the safety prop in its home position 6. With the tailgate control lever on the cab control panel, completely close the tailgate. The tailgate open light in...

Page 30: Tailgate Lock Valve

Safety 25 refer to the camera manufacturer manual provided with this vehicle for more information. Figure 2-8 camera inside the hopper figure 2-9 camera on the tailgate tailgate lock valve this lock valve ensures that the tailgate will not open during the packing cycle. It is located under the rear ...

Page 31: Prior to Start Up

26 safety prior to start up before starting the vehicle: 1. Make sure that no system will engage and/or start to operate as you start the engine. 1 a. Turn off all electrical components. 1 b. Disengage the hydraulic pump. Figure 2-10 hydraulic pump o n /o ff switch and indicator light 2. Make sure t...

Page 32: Cleanliness

Safety 27 figure 2-11 suction line mounted valve (steel tank) cleanliness cleanliness is part of safety. Ensure that the equipment works properly by removing any compacted garbage in the packer area after each body unloading. Clean all the lights and safety stickers so you and the surrounding pedest...

Page 33

28 safety figure 2-13 parking brake sign 2. Make sure that the body is completely unloaded. 3. Switch off the hydraulic pump. 4. Turn off the engine, remove the key from the ignition, store it in a safe and controlled area (preferably on yourself), and tape over the ignition switch. 5. Turn off and ...

Page 34: Shutting Down The Vehicle

Safety 29 shutting down the vehicle if the vehicle has to be stored for an extended period of time, follow the chassis manufacturer shutdown and maintenance requirements. Also: 1. Park the vehicle on a hard and level surface, and apply the parking brake. 2. Make sure that all moving parts are in the...

Page 35

30 safety.

Page 36: Controls and

3 controls and indicators the a utomizer tm r ecycler has a series of controls and indicators that allow easier operation of the different functions that come with the vehicle. These controls and indicators are mainly located on the cab console and on the dashboard. Cab console the cab console is lo...

Page 37

32 controls and indicators n ote : do not close the main valve on the hydraulic tank even if the pto switch is turned off. The pump is always turning whatever the engine’s rpm. It is very important not to let the pump run dry or without oil. Otherwise, the pump will be seriously damaged or even dest...

Page 38: Tailgate Control Switch

Controls and indicators 33 tailgate control switch the tailgate control switch is a 3-position switch that allows the operator to control the tailgate. Figure 3-2 t ailgate control switch when the tailgate is unlocked, the tailgate unlocked or body raised warning lamp goes on and a buzzer sounds. Fi...

Page 39: Hoist Control

34 controls and indicators hoist control the body raise control switch (see figure 3-4) is located on the cab console. This 3-position switch allows the operator to control the body. When the body is raised, the tailgate unlocked or body raised warning lamp (see figure 3-3) goes on and a buzzer soun...

Page 40: Cab Dashboard

Controls and indicators 35 cab dashboard the following is a description of the controls and buttons found on the dashboard. Parking brake the parking brake must be used every time the a utomizer tm r ecycler is stopped on idle position other than the regular traffic stops. Figure 3-6 parking brake w...

Page 41: Flashing Light Switch

36 controls and indicators flashing light switch this switch activates and deactivates the flashing lights. shift the switch up to turn on the flashing lights. shift the switch down to turn off the flashing lights. Figure 3-8 flashing light switch hopper light switch this switch activates and de...

Page 42: Strobe Light Switch

Controls and indicators 37 strobe light switch this switch activates and deactivates the strobe light mounted on the tailgate. shift the switch up to turn on the strobe light. shift the switch down to turn off the strobe light. Figure 3-10 strobe light switch (left); strobe light (right) i mport...

Page 43: Pack Push Button (Green)

38 controls and indicators pack push button (green) the packer start cycle button activates the packer for one complete cycle. A complete cycle takes about 2 minutes. Figure 3-12 pack push button return push button (yellow) the packer retract button will retract the packer at the beginning of its st...

Page 44: Speed-Up Control Switch

Controls and indicators 39 speed-up control switch in auto-neutral mode, this switch enables the engine to run at a predetermined rpm. Figure 3-14 speed-up switch multi-cycle control switch this function allows the packer to cycle a preset number of cycles (from 2 to 8, 3 being the standard) by pres...

Page 45

40 controls and indicators packer control station (on body) the a utomizer tm r ecycler has another packer control station. This one is located on the body near the crusher panel levers and has the same functions than those of the in-cab packer control station (see packer control station (inside cab...

Page 46: Crusher Panel Levers

Controls and indicators 41 crusher panel levers the a utomizer tm r ecycler has two levers that control both crusher panels. These levers are located on the body near the place where the swivel arm is fixed to the body. The left-hand lever controls the front crusher panel while the right-hand lever ...

Page 47

42 controls and indicators.

Page 48: Operating The

4 operating the a utomizer tm r ecycler the different methods, procedures and necessary actions to operate the a utomizer tm r ecycler are presented in this section. Before operating the a utomizer tm r ecycler , the operator must be completely familiar with all safety procedures, and the location, ...

Page 49: Visual Inspection

44 operating the a utomizer tm r ecycler visual inspection before starting the vehicle, the operator must perform a visual inspection of the truck. Ensure the engine is not running and the parking brake is set. ensure the cleanliness of lamps, safety labels, camera lenses, mirrors, windows, and th...

Page 50: Danger!

Operating the a utomizer tm r ecycler 45 body inspection procedure: 1. Activate the packer for a full cycle. 2. Check the hopper bucket operation. 3. Check if the tailgate safety pins are in place. Put them in place to lock the tailgate properly. 4. As you walk along the side of the truck, clean all...

Page 51

46 operating the a utomizer tm r ecycler apply the following inspection procedure: 1. Make sure to park the vehicle on a safe and level ground. 2. Ensure that the parking brake is applied and the vehicle is tagged out for maintenance purposes (see locking out and taging out the vehicle on page 27). ...

Page 52

Operating the a utomizer tm r ecycler 47 figure 4-3 bucket torque tube scraper figure 4-4 crusher panels 10. Fully raise the bucket. 11. Fold the swivel arm. Bucket torque tube scraper crusher panels.

Page 53: Inspection Sheet

48 operating the a utomizer tm r ecycler inspection sheet the following is an example of an inspection sheet. The operator must follow the inspection sheet provided by his employer. If the employer doesn’t have any, ask for his permission before using this example. Vehicle condition report date: ___...

Page 54: Planning Your Route

Operating the a utomizer tm r ecycler 49 loading, packing and unloading planning your route it is important to plan your route in order to be efficient. Planning your route will shorten your collection time and prevent from being caught in a traffic jam. Remember that the a utomizer tm r ecycler was...

Page 55: Emergency Actions

50 operating the a utomizer tm r ecycler 2. Check the emergency red button. 3. Press the yellow button to ensure the packer is completely retracted. 4. Check around the packer for any obstruction preventing it from moving freely. 5. Check fuses and breakers in the console. 6. Report your findings to...

Page 56: Standard Unloading Procedure

Operating the a utomizer tm r ecycler 51 standard unloading procedure once you have finished your route, make sure the hopper bucket is fully raised, the swivel arm is folded and locked alongside the body, and the crusher panels are lowered. Keep some recycling materials not packed in front of the p...

Page 57: Unloading Corrective Actions

52 operating the a utomizer tm r ecycler 12. Perform the end-of-the-day inspection. . Unloading corrective actions as you are unloading the body, some recycling materials may fall or be blown away between the chassis and the body. Apply the following procedure for the remaining recyclables stuck on ...

Page 58: Unloading Emergency Actions

Operating the a utomizer tm r ecycler 53 6. Once finished, slightly raise the body and put the safety prop back to its vertical position. 7. Lock the safety prop. 8. Lower the body onto the chassis before moving the vehicle. Unloading emergency actions if the truck starts to sink on one side as you ...

Page 59: Chassis Daily Cleaning

54 operating the a utomizer tm r ecycler 6. Clean all accumulated dirt under cylinder brackets and inside the side tracks using the hoe and pressurized water if necessary. Be careful with proximity switches to prevent misalignment. 7. Perform a visual inspection for leaks or wear in this area. 8. Ra...

Page 60: Operating The Hopper Bucket

Operating the a utomizer tm r ecycler 55 operating the hopper bucket the following sections will describe operational safety procedures and controls of the hopper bucket. Hydraulic power supply this vehicle has two (2) hydraulic hoses that supply the hydraulic power of the vehicle to fixed container...

Page 61: Crusher Panels

56 operating the a utomizer tm r ecycler figure 4-9 container crusher panels when a bridge of cardboard is forming over the packer (see figure 4-10), the packer might not be able to push material inside the body. Two (2) crusher panels can be used to break the load inside the hopper. After unloading...

Page 62

Operating the a utomizer tm r ecycler 57 figure 4-10 packer figure 4-11 crusher panels figure 4-12 crusher panel levers rear crusher panel front crusher panel front crusher panel lever rear crusher panel lever.

Page 63: Swivel Arm

58 operating the a utomizer tm r ecycler swivel arm along the left-hand side of the hopper is a retracted swivel arm on which a set of control levers is mounted. These levers (see figure 4-13) are used to operate both the container and the hopper bucket. The swivel arm is retractable to reduce the w...

Page 64: Warning!

Operating the a utomizer tm r ecycler 59 figure 4-15 position of the arm lock levers once the arm is released, pull it towards the front of the truck until it locks. Figure 4-16 position of the arm to close the swivel arm, just pull down the left-hand lock lever and push the arm to its home position...

Page 65: Warning Light and Safety

60 operating the a utomizer tm r ecycler warning light and safety on the dashboard, there is one (1) flashing red light (see figure 4-17) which indicates not to drive the vehicle if the hopper bucket is not completely raised. Figure 4-17 warning light also, ensure the following before moving the veh...

Page 66: Loading/unloading Procedure

Operating the a utomizer tm r ecycler 61 figure 4-18 hopper door proximity switch loading/unloading procedure to ensure safe operation of the hopper bucket at all times, apply the following step-by-step procedure: 1. Stop the vehicle along the container. Proper distance between the vehicle and the c...

Page 67: Warning!

62 operating the a utomizer tm r ecycler 3. Make sure the right-hand side hopper door is closed before loading recyclable materials into the hopper. 4. Unlock the swivel arm from its resting position along the hopper (see swivel arm on page 58). 5. Unfold the swivel arm towards the front of the vehi...

Page 68

Operating the a utomizer tm r ecycler 63 figure 4-21 unfold swivel arm and bucket down figure 4-22 hoses connected to container figure 4-23 lock lever n ote : always watch for clearance between the bucket and the container. Move vehicle if necessary..

Page 69

64 operating the a utomizer tm r ecycler figure 4-24 clearance required 8. Using the container control lever (see figure 4-25), load recyclable materials into the hopper bucket (see figure 4-26). Figure 4-25 container control lever.

Page 70: Warning!

Operating the a utomizer tm r ecycler 65 figure 4-26 loading the bucket n ote : if recyclables start to pile up in the hopper bucket, lower the container and raise the bucket a few feet off the ground to move the recyclables further back in the bucket. Lower the hopper bucket and continue unloading ...

Page 71

66 operating the a utomizer tm r ecycler figure 4-27 packer control station 12. Unlock the swivel arm, fold it until the proximity switch turns off, and release the residual pressure inside the hydraulic hoses by moving the container control lever back and forth (see figure 4-28). 13. Disconnect and...

Page 72: Warning!

Operating the a utomizer tm r ecycler 67 n ote : make sure to roll up hoses around fitting holder on the swivel arm after each use. This will prevent hydraulic hoses from falling when the vehicle is moving (see figure 4-29) figure 4-29 hydraulic hoses rolled up warning! Do not drive the vehicle if t...

Page 73

68 operating the a utomizer tm r ecycler.

Page 74

Our office in the u.S. Our office in canada 1981 w. Snell road 175 route du pont oshkosh, wi 54904 st-nicolas, qc g7a 2t3 toll free: 1-800-231-2771 toll free: 1-877-831-8250 telephone: 1-920-233-2770 telephone: 1-418-831-8250 general fax: 1-920-232-2496 service fax: 1-418-831-1673 sales fax: 1-920-2...