Lagler ELAN Operation, Maintenance, Safety Manual - 1. Introduction

ELAN 01.02.2013

English / Englisch

1. Introduction

You have purchased a high-quality product from LÄGLER

®

.

We wish you great success with your ELAN. This

machine was manufactured using the most modern

methods of production. All LÄGLER

®

products are subjected

to a thorough inspection before leaving the factory.

Please read these operating instructions carefully before

you start working with your ELAN for the first time.

These operating instructions include important information

on work safety and will give you answers to many

questions so that you can work with the machine safely

and without any problems. If you cannot find a specific

subject in this manual, please refer to your sanding

instructions manual or contact your local dealer. Your

local dealer is very familiar with the ELAN machine and

is a highly qualified expert trained by our company. Your

local dealer will provide you with the best possible advice

and support.

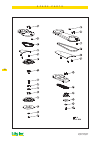

1.1 Features of the machine

In figure 1 (page 2), we have included the designations

of the most important components of the ELAN. Take

your time to become familiar with the machine.

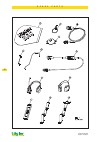

1.2 Description of the machine

The ELAN stair-sanding, edge-sanding and corner-san-

ding machine works with a sanding disc on which Velcro

sanding discs can be fastened. Traditional sanding discs

fastened with a tensioning screw can, of course, also be

used. The work zone is protected by the attachment. The

fan housing, on which the electric motor is mounted in

vertical position, is located on the attachment. A motor

power supply cable is used to connect the machine to

the power supply system. The motor switch with ON / OFF

is located on the right side in the handle piece. The

machine is moved by means of two steering wheels at

the rear side of the machine. The handles are located on

top of the motor. The suction union piece, to which the

dust bag clamp and the dust bag are attached, is located

underneath the handles.

The ELAN can only be used for dry processing operations.

Never use the ELAN for wet processing operations (life-

threatening risk)!

Contents

1.

Introduction

3

1 .1 Features of the machine

3

1 .2 Description of the machine

3

1 .3 Application

4

1 .4 Safety instructions

4

1 .5 Protective devices

5

2.

Technical data

5

3.

Getting started

7

3.1 Preparing the machine

7

3.2 Connecting the power supply cable

8

3.3 Starting the machine

8

3.4 Switching off the machine

8

4.

Working with the ELAN

9

4.1 General application tips

9

4.2 Replacing the sanding disc

10

4.3 Re-equipping the sanding plate support 11

4.4 Emptying the dust bag

12

5.

Storage

12

6.

Maintenance routines

13

6.1 Tightening the V-belt

13

6.2 Changing the V-belt

14

6.3 Renewing the attachment belt pulley

15

6.4 Renewing the carbon brushes

16

6.5 Checking the dust suction system

17

6.6 Replacing the steering wheels

17

6.7 Replacing the motor belt pulley

18

6.8 Cleaning the machine following

restoration tasks

18

6.9 Adjusting the steering wheels

19

7.

Regular checkup according to safety

regulations and VDE

20

8.

Troubleshooting

21

9.

Safety precautions

22

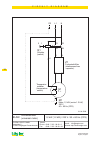

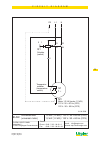

Circuit

diagram

24

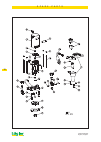

Spare parts

26

Service

passport

33

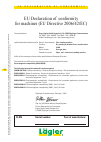

EU Declaration of conformity

34

3

I N T R O D U C T I O N