- DL manuals

- Lancer

- Washer

- 810 LX

- User Manual

Lancer 810 LX User Manual

Summary of 810 LX

Page 1

810 lx / 815lx user manual.

Page 2

Original instructions.

Page 3

Nu_810-815_lx_ang_1306 3 precautions to be taken before use users must be trained before using the washer. The staff that use or repair this washer must have followed a complete training referring its use and maintenance. This training must include the selection and understanding of the washing cycl...

Page 5

Summary nu_810-815_lx_ang_1306 5 summary chapter 1 introduction ............................................... 9 1. Copyright – liability 10 2. Manufacturer 10 3. 810 lx / 815 lx range 10 4. User manual 11 chapter 2 before you start ..................................... 13 1. Safety advices 14 1.1 ...

Page 6

Summary nu_810-815_lx_ang_1306 6 6.1 some examples 21 6.2 fitting the baskets 23 chapter 3 washing cycle launching ...................... 25 1. Description and basic functions of keypad 26 2. Launching of a cycle 27 2.1 switching on 27 2.2 cycles 27 2.3 launching the cycle 29 2.4 information availab...

Page 7

Summary nu_810-815_lx_ang_1306 7 8. Table of factory-programmed cycles - 815lx – supply voltage 120v mono / 60hz 49 9. User cycle programming table 50 chapter 4 traceability ............................................... 51 1. External printer (option) 52 2. The pro kit (option) 53 chapter 5 mainte...

Page 8

Summary nu_810-815_lx_ang_1306 8 2. Warnings 63 2.1 lack of products 63 2.2 hot chamber 63 2.3 full basin 63 2.4 maintenance reminder 64 2.5 preventative maintenance required 64 3. Fault alarms 65 3.1 fault n°1 probe fault. 65 3.2 fault n°2 emptying fault. 65 3.3 fault n°3 heating excess. 66 3.4 fau...

Page 9

Chapter 1 introduction nu_810-815_lx_ang_1306 9 chapter 1 introduction you have in your possession a getinge lancer washer. Its good working and your entire satisfaction depend on the attention you pay when reading this guide. You will find here some advices about the use, the loading and the mainte...

Page 10

Chapter 1 introduction nu_810-815_lx_ang_1306 10 1. Copyright – liability all rights reserved. Getinge lancer pays close attention to all technical developments and continuously seeks to improve its products and services in order to provide an adequate response to the needs of its clients. Getinge l...

Page 11

Chapter 1 introduction nu_810-815_lx_ang_1306 11 4.User manual the present manual is destined to facilitate the operations of use, handle, maintenance and repair. This only concerns the operations to be done by an owner of code user. Before using your washer and in order to obtain the best service r...

Page 13

Chapter 2 before you start nu_810-815_lx_ang_1306 13 chapter 2 before you start after having installed rightly your washer, following the installation manual, you can begin to familiarize with this one. You will find in this chapter all the information of indispensable knowledge to assure the good w...

Page 14

Chapter 2 before you start nu_810-815_lx_ang_1306 14 1.Safety advices this apparatus, dedicated to an industrial use, has been developed to wash and dry glassware, labware in the chemistry, microbiology, quality control and analytical laboratories … this washer must be used under the normal conditio...

Page 15

Chapter 2 before you start nu_810-815_lx_ang_1306 15 safety glasses obligatory safety gloves obligatory risk for operator depends on the products (detergents and acids) used inside the machine and on the nature of deposit on washing items. Wearing safety glasses and gloves must not be sufficient in ...

Page 16

Chapter 2 before you start nu_810-815_lx_ang_1306 16 2.Opening the washer’s door pull the handle and lower the door to the horizontal position. At start of cycle, door is automatically locked. If a “cycle alarm” occurs, unlock the door by pressing on button then open the door. At end of cycle, wait ...

Page 17

Chapter 2 before you start nu_810-815_lx_ang_1306 17 4.Washing products the programs preestablished with this washer have been validated with the getinge lancer washing products. 4.1 washing products categories non-foaming detergent using the correct non-foaming detergent is required for proper clea...

Page 18

Chapter 2 before you start nu_810-815_lx_ang_1306 18 4.3 instructions to respect in case of changing the product formula before changing to a different type or brand of cleaning chemical (acid or detergent) it is necessary to rinse the plumbing circuitry of the machine. Install the new chemical(s) p...

Page 19

Chapter 2 before you start nu_810-815_lx_ang_1306 19 5. External printer (option) 5.1 checking the printer before launching any cycle or reprinting the printout, check the quantity of paper of the printer roller. 5.2 choice of the suitable paper rolls it is recommended that a high quality thermal pa...

Page 20

Chapter 2 before you start nu_810-815_lx_ang_1306 20 5.7 note printing if the printer is connected to a battery pack and not an ac battery charger, it is imperative to control the operating mode (sleep mode / idle mode) of your printer prior to launch the printing. In the user menu, you can access t...

Page 21

Chapter 2 before you start nu_810-815_lx_ang_1306 21 6. Using of the accessories if the loadings to be handled are superior to 25 kg there is place to use a handling system. 6.1 some examples in order to wash items in "te" or "th" type baskets, place the baskets on the "ps" (basic rack) or "psb" (ba...

Page 22

Chapter 2 before you start nu_810-815_lx_ang_1306 22 in the case of washing items with small diameter openings such as volumetric flasks, it is very important that the flow rate of the injectors used must be lower than the flow capacity of the flasks to be washed in order to avoid a gradual filling ...

Page 23

Chapter 2 before you start nu_810-815_lx_ang_1306 23 6.2 fitting the baskets 1-2-3 basket wheels 4 pin a) pull the slide rails out of the chamber. B) remove the front pins. C) insert wheels 1 and 2 of the basket in the slide rails. D) fit the pins back in place between wheels 2 and 3. The choice of ...

Page 25

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 25 chapter 3 washing cycle launching this chapter has been made to enable to function your washer. You will get the launching procedure of a washing cycle and the manipulations to do at the start and the end of cycle..

Page 26

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 26 1.Description and basic functions of keypad legend : 1 start" button 2 enter button (for programming) / door unlock 3 washer power on/off button 4 button 3 / "-" function button 5 button 4 / "+" function button 6 liquid crystal display unit...

Page 27

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 27 2.Launching of a cycle before start, verify that the taps of entrance of water are opened. 2.1 switching on push the key . The display indicates the number of the last executed program and the type of washer. P r o g r a m n ° 0 4 l a n c e...

Page 28

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 28 programme 02: bacteriology, virology prewash with cold water with the detergent wash with hot water with the detergent. acid rinse with the neutralizant acid final rinse at 80° with demineralized water drying at 100° (only on 815l...

Page 29

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 29 2.3 launching the cycle after choosing the washing cycle number, push on button and one of the following screens will be displayed : a) the display indicates : - the selected cycle number, - the temperature in the chamber, - the current fun...

Page 30

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 30 2.4 information available during the wash cycle button display indication comment 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 temperature at bottom of chamber instantaneous temperature read by the probe located in bottom of chamber programmed temperatu...

Page 31

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 31 3.End of cycle 3.1 opening of the doors burn risk if the door is opened over 60°c. At the end of the cycle, let cool the supports, baskets, accesories and washed objects before handling them. If the chamber temperature is higher than 60°c, ...

Page 32

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 32 3.3 reprinting of the ticket for washers equipped with the printer (option), it is possible to print the ticket again in the following cases: - need of a second ticket - lack of paper (end of roll) - poor printout press the keys and 1 1 1 1...

Page 33

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 33 4.Access to user menu switch on the appliance by pressing . The display indicates the number of the last cycle performed. P r o g r a m n ° 0 1 l a n c e r x x x x l x press and hold button for 3 seconds to validate. A c c e s s c o d e - -...

Page 34

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 34 4.1 modifying the washing cycles it is not recommend to set wash programs at maximum values for time and temperature as this will result in reduced equipment life and increased maintenance frequency of equipment. If you wish to create a cus...

Page 35

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 35 choose water for prewash 1 phase: cold water mains or purified water select with //////////////// 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 ++++++++++++++++ and //////////////// 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 ---------------- buttons. Accept with bu...

Page 36

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 36 choose water for running water rinse 1 phase: cold water mains or purified water select with //////////////// 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 ++++++++++++++++ and //////////////// 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 ---------------- buttons. Ac...

Page 37

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 37 if washer is equipped with neutralizing option, choose additive intake time : 0 to 6 mn 59s. 1 second will deliver approximately 5 ml of chemical. Note : the volume of water in the wash chamber is approximately 12 liters. Select the minutes...

Page 38

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 38 select the duration of the hot demin.* rinse : 0 to 30 mn 59 s. Select the minutes with //////////////// 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 ++++++++++++++++ and //////////////// 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 ---------------- buttons. Accept ...

Page 39

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 39 e n d o f m e n u the display unit returns to user menu. O p e r a t o r m e n u r e a d i n g p r o g r a m ..

Page 40

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 40 4.2 sequences reading of one washing cycle after accessing to user menu, you must choose reading program. With //////////////// 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 ++++++++++++++++ and //////////////// 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 ----------...

Page 41

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 41 4.3 dosing pump priming once enter user menu, you must choose “pump priming” sub-menu using buttons //////////////// 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 ++++++++++++++++ and //////////////// 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 ---------------- . O ...

Page 42

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 42 4.4 name choice of one washing cycle in addition to being identified by its number (01, 02, 03, etc.), each programmed cycle can be given a "name" (examples: chemistry, bacterio, instruments, anaesthetic). A maximum of 16 characters is avai...

Page 43

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 43 4.5 the choice of machine name after accessing to user menu, you must choose machine name with //////////////// 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 ++++++++++++++++ and //////////////// 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 ---------------- buttons t...

Page 44

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 44 4.6 reading of cycle faults after accessing to user menu, you must choose fault cycles with //////////////// 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 ++++++++++++++++ and //////////////// 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 ---------------- buttons to r...

Page 45

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 45 4.7 printer parameters (option) this menu allows to customize 2 heading lines and 3 foot lines on the ticket (if printer option). O p e r a t o r m e n u p r i n t e r p a r a m . Accept with button. H e a d 1 : e n t e t e d u t i c k e t ...

Page 46

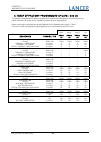

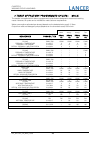

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 46 5.Table of factory-programmed cycles – 810 lx the washer is supplied with 4 factory-programmed cycles that are designed to meet most washing needs. However, all cycles can be modified to meet customer requirements. Water consumption estimat...

Page 47

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 47 6.Table of factory-programmed cycles – 810 lx – supply voltage 120v mono / 60hz the washer is supplied with 4 factory-programmed cycles that are designed to meet most washing needs. However, all cycles can be modified to meet customer requi...

Page 48

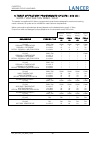

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 48 7.Table of factory-programmed cycles - 815lx the washer is supplied with 4 factory-programmed cycles that are designed to meet most washing needs. However, all cycles can be modified to meet customer requirements. Water consumption estimate...

Page 49

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 49 8.Table of factory-programmed cycles - 815lx – supply voltage 120v mono / 60hz the washer is supplied with 4 factory-programmed cycles that are designed to meet most washing needs. However, all cycles can be modified to meet customer requir...

Page 50

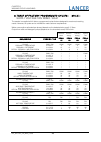

Chapter 3 washing cycle launching nu_810-815_lx_ang_1306 50 9.User cycle programming table the programs 11 to 14, 21 to 24, 31 to 34, 41 to 44 are free and can be programmed by yourself. Water consumption estimated per phase (depends on the baskets/racks used): 12 liters. Output from acid and deterg...

Page 51

Chapter 4 traceability nu_810-815_lx_ang_1306 51 chapter 4 traceability these last years, traceability has become a crucial issue. The matter is to control permanently the correct development of the washing cycle and to obtain its validation. Traceability enables the supervision of the correct perfo...

Page 52

Chapter 4 traceability nu_810-815_lx_ang_1306 52 1.External printer (option) its role: the lancer printer gives permanently the development of the washing. Also, it permits the stock of the information. Its results: at the end of the program, the results are registered and archived, whether on a pap...

Page 53

Chapter 4 traceability nu_810-815_lx_ang_1306 53 2.The pro kit (option) the washers are controlled by a programmable microprocessor. In order to obtain an independent verification of the washing process, an additional card is provided. The pro kit is a microprocessor independent from the controller ...

Page 55

Chapter 5 maintenance of the washer nu_810-815_lx_ang_1306 55 chapter 5 maintenance of the washer this chapter describes the maintenance operations to assure the good working of your washer. Residues of products such as acetone, solvents, petroleum, petroleum derivatives, chromium sulphate, acid (su...

Page 56

Chapter 5 maintenance of the washer nu_810-815_lx_ang_1306 56 1.Filters 1.1 strainers filters check the cleanness of the strainer filters and clean them if needed. 1.2 chamber filters these two filters prevent the residues to enter the hydraulic circuit. A pump suction filter b chamber bottom filter...

Page 57

Chapter 5 maintenance of the washer nu_810-815_lx_ang_1306 57 3.External maintenance of the washer getinge lancer washers are entirely covered with panels (bodywork) in stainless steel aisi 304l. 3.1 cleaning method the periodic maintenance cleaning must be done with a cleaning product. Should the p...

Page 58

Chapter 5 maintenance of the washer nu_810-815_lx_ang_1306 58 4.Decontamination of the machine and parts 4.1 when to decontaminate the washer? Special care must be taken to protect users and maintenance personnel from coming in contact with the chemicals, temperatures, and hazardous materials that m...

Page 59

Chapter 5 maintenance of the washer nu_810-815_lx_ang_1306 59 5.Preventive maintenance getinge lancer’s technical assistance service recommends to all the users at least one annual preventive maintenance visit. The preventive maintenance reduces the risks of stops of the washer due to breakdowns and...

Page 60

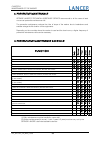

Chapter 5 maintenance of the washer nu_810-815_lx_ang_1306 60 7.Recommended spare parts 810 lx – 815 lx description new part # quantity/ machine door spring 12010003 2 door wheels 46020064 2 door sling 46040004 2 emptying pump 50 hz 23010047 1 emptying pump 60hz 23010070 pressurestat 28020066 1 auto...

Page 61

Chapter 6 problems nu_810-815_lx_ang_1306 61 chapter 6 problems in this chapter you will get all the problems that you might get on your washer. In a general way and whatever the noted anomaly, it is appropriate to stop the machine, to disconnect the power supply cable and to turn off the taps of wa...

Page 62

Chapter 6 problems nu_810-815_lx_ang_1306 62 1. Incidents 1.1 the detergent or neutralizing agent does not enter the washer the tube is blocked. the tank is empty. the pump hose is pinched. 1.2 the washer does not function it is not connected to the power supply. there is mains power. th...

Page 63

Chapter 6 problems nu_810-815_lx_ang_1306 63 2.Warnings 2.1 lack of products *only for washer with level float w a r n i n g l a c k o f c h e m i c . Incident: the following message is displayed if lack of chemical at start of cycle when you press the key. Action: check level of additive tanks, rep...

Page 64

Chapter 6 problems nu_810-815_lx_ang_1306 64 2.4 maintenance reminder m a i n t e n a n c e i n x x x h o u r s incident: after turning on the machine, the reminder of the upcoming preventative maintenance is shown on the display. Action: press the key to acknowledge the reminder. Schedule a prevent...

Page 65

Chapter 6 problems nu_810-815_lx_ang_1306 65 3.Fault alarms these alarms stop the operation of the washer. To clear the alarm mode, the washer must be switched off by pressing button. 3.1 fault n°1 probe fault. F a u l t n ° 0 1 p r o b e d e f e c t probe fault definition : the probe used to check ...

Page 66

Chapter 6 problems nu_810-815_lx_ang_1306 66 3.3 fault n°3 heating excess. F a u l t n ° 0 3 h e a t i n g e x c e s s heating excess definition : this message is displayed if the basin temperature exceeds the programmed temperature by 20°c. Corrective action : verify that the incoming water tempera...

Page 67

Chapter 6 problems nu_810-815_lx_ang_1306 67 3.5 fault n°5 no water. F a u l t n ° 0 5 n o w a t e r no water definition : the washer did not reach the required water level by the end of the normal filling time defined in the common times menu. Corrective action : check that the water inlet valves a...

Page 68

Pictures and drawings non contractua l. Getinge lancer reserves the righ t to make changes i n thi s manual.