- DL manuals

- Lancer

- Ice Maker

- Flavor Select 30

- Installation And Service Manual

Lancer Flavor Select 30 Installation And Service Manual

LANCER CORP

6655 Lancer Blvd.

San Antonio, Texas 78219

To order parts, call

Customer Service: 800-729-1500

Warranty/Technical Support: 800-729-1550

Email: custserv@lancercorp.com

www.lancercorp.com

Manual PN: 28-0558/04

JULY 2008

Flavor Select 30 (FS30)

Ice Beverage Dispenser

Installation and Service Manual

PN: 28-0558/04

ISO 9001:2000 Quality System Certified

“Lancer” is the registered trademark of Lancer © 2013 by Lancer, all rights reserved.

Summary of Flavor Select 30

Page 1

Lancer corp 6655 lancer blvd. San antonio, texas 78219 to order parts, call customer service: 800-729-1500 warranty/technical support: 800-729-1550 email: custserv@lancercorp.Com www.Lancercorp.Com manual pn: 28-0558/04 july 2008 flavor select 30 (fs30) ice beverage dispenser installation and servic...

Page 2

About this manual the installation, and relocation if necessary, must be carried out by qualified personnel with up-to-date safety and hy- giene knowledge and practical experience, in accordance with current regulations. Please read carefully the guidelines and warnings contained herein as they are ...

Page 3

About the fs30 the fs30 is designed using the highest quality materials and state-of-the-art technology providing our customers with consistent quality and a unique drink experience. Fs30 specifications 30” (762 mm) 38 13/16” (986 mm) without lid 23” (584 mm) 30 1/2” (775 mm) 7 1/2” (190 mm) 10” (25...

Page 4

Pre-installation checklist before getting started each unit is tested under operating conditions and is thoroughly inspected before shipment. At the time of shipment, the carrier accepts responsibility for the unit. Upon receiv- ing the unit, carefully inspect the carton for visible damage. If damag...

Page 5

Warning/advertencia/avertissement ! The dispenser is for indoor use only. This appliance is intended for use in commercial applications such as res- taurants, stores or similar. This unit is not a toy. It should not be used by children or infirm persons without supervi- sion. This appliance is not i...

Page 6

Electrical warning/advertencia eléctrica/ avertissement Électrique f check the dispenser serial number plate for correct electrical requirements of unit. Do not plug into a wall electri- cal outlet unless the current shown on the serial number plate agrees with local current available. Follow all lo...

Page 7

Water notice/advertencia de suministro de agua/avertissement d’alimentation de l’eau ! Provide an adequate potable water supply. Water pipe connections and fixtures directly connected to a potable water supply must be sized, installed, and maintained according to federal, state, and local laws. The ...

Page 8

1. Installation before getting started each unit is tested under operating conditions and is thoroughly inspected before shipment. At the time of shipment, the carrier accepts responsibility for the unit. Upon receiving the unit, carefully inspect the carton for visible damage. If damage exists, hav...

Page 9

1.2 drain spider - continued if the drain spider is not in place, proceed with the following steps: a. Remove agitator clip and pin from agitator bar (fig 2). B. Remove agitator bar from the hub. C. Remove ice shroud by lifting the side opposite the auger and rotating out from beneath the auger. D. ...

Page 10

1.4 installing an icemaker ! Warning when installing an icemaker on the dispenser, use a bin thermostat to control the ice level (see below). This will pre- vent damage to the dispensing mechanism. The bracket for mounting a thermostat is located in the ice bin. During the automatic agita- tion cycl...

Page 11

! Caution failure to disconnect the motor power supply will damage the carbonator motor, the pump and void the warranty. ! Caution do not connect to a hot water or soft water source. This causes excessive foaming. ! PrecauciÓn si no desconecta la alimentaciÓn elÉctrica del motor podrÍan daÑarse la b...

Page 12

1.7 installation overview figure 6. Fs30-1 12 flavor select (fs) 22 ice beverage dispenser.

Page 13

Figure 7. Fs30-2 13 installation and operation manual pn 28-0580/03.

Page 14

1.8 connecting co2 a. Provide a regulated co2 supply to the dispenser through a 3/8 inch supply line. The maximum pressure is 80 psi (5.5 bar). ! Caution excessive co2 pressure can damage components. F grounding warning the dispenser must be properly electrically grounded to avoid serious injury or ...

Page 15

! Agitation warning the bin agitation system will operate automatically. Do not place hands in the bin or the ice chute. ! Advertencia agitaciÓn el sistema funcionarÁ automÁticamente bin agitaciÓn. No da para arriba en la bandeja o la cascada de hielo. ! Agitation avertissement le systÈme fonctionne...

Page 16

2. Cleaning and sanitizing instructions general information a. The cleaning and sanitizing procedures provided pertain to the lancer equipment identified by this manual. If other equipment is being cleaned, follow the guide lines established by the manufacturer for that equipment. B. Lancer equipmen...

Page 17

Do disconnect water lines when cleaning and sanitizing syrup lines, to avoid contamination. Do not use strong bleaches or detergents; these can discolor and corrode various materials. Do use metal scrapers, sharp objects, steel wool, scouring pads, abrasives, or solvents on the dispenser. Do use hot...

Page 18

Remove the gasket which secures the shroud by pulling it out. Push the front section of the shroud back. Pull the shroud up and out. Remove the lower ice chute assembly. Remove the dispensing wheel shroud. Remove the lower ice chute assembly. G. White wheel shroud (pellet ice) g. Black wheel shroud ...

Page 19

2.5 cleaning and sanitizing beverage components - bag-in-box systems note: extended lengths of product lines may require more time to flush and rinse lines. A. Disconnect the syrup quick disconnect coupling from the syrup packages and connect the coupling to a bag valve removed from an empty bag-in-...

Page 20

3. How to operate and adjust the dispenser 3.1 normal operation a. Fill cup with desired amount of ice. B. Place cup under nozzle below desired brand. C. Select up to two desired bonus flavors from those available on the keypad, by pressing against the flavor label once. Selection indicator light wi...

Page 21

Menus and submenus 1. Bonus flavors a. Decide if the bonus flavors will be set to add an injected flavor to the brands or dispense carbonated water/plain water. B. Choose the valve number (1-4) by scrolling up and down arrows. C. Use the left and right arrows to shift to the top, middle, or bottom “...

Page 22

3.3 purging the carbonation system purge the carbonator tank whenever carbonation issues occur. A. Turn off co2 supply. B. Turn off power to the unit. Unplug the carbonator harness from the power supply. C. Open the relief valve until water is coming out. Close the relief valve, checking for any rem...

Page 23

3.6 carbonator pump modifications the electric, positive displacement rotary vane pump with 170 psi bypass should only be serviced by trained personnel. To achieve optimum carbonation, use filtered water with the pump. A. Turn off power to the dispenser. B. Remove drip tray and splash plate. C. Turn...

Page 24

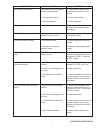

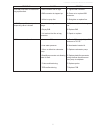

4. Troubleshooting trouble cause remedy 4.1 no product when switch is activated. (switch panel does not light up when activated.) a. Keyswitch is off, or keyswitch harness is disconnected. B. 9-in valve harness is disconnected. C. Defective switch assembly. D. No power to unit a. Turn keyswitch on a...

Page 25

Trouble cause remedy 4.7 valves do not operate. A. Keyswitch is off, or keyswitch harness is disconnected. B. Circuit breaker tripped. C. Unit not plugged in. A. Turn keyswitch and/or make sure keyswitch harness is con- nected. B. Reset circuit breaker. C. Plug in dispenser 4.8 water in ice bin a. C...

Page 26

Trouble cause remedy 4.14 insufficient syrup flow. A. Insufficient co2 pressure to bib pumps. B. Shutoff on mounting block not fully open. C. Foreign debris in syrup flow control. D. Defective bib pump. A. Adjust co2 pressure to 80 psi, 5.5 bar (min 70 psi, 4.8 bar) for bib pumps. B. Open shutoff fu...

Page 27

Trouble cause remedy 4.17 valve will not shut off. A. Debris in solenoid seat. B. Solenoid plunger sticking. A. Activate valve a few times to free debris. Remove the solenoid coil and plunger and clean out foreign material. B. Replace solenoid coil. 4.18 syrup only dispensed. No water, but co2 gas d...

Page 28

Trouble cause remedy 4.22 circuit breaker tripping. A. Valve wire harnesses shorted to itself or faucet plate. B. Controller pcb is bad. C. Secondary wire harness is shorted. D. Power supply is bad. A. Detect short by disconnecting valve harnesses from switch panel (2 25-pin harnesses and 2 9-pin ha...

Page 29

Trouble cause remedy 4.26 bib pump fails to restart after bag replacement. A. Bib connector not on tight. B. Bib connector is stopped up. C. Kinks in syrup line. A. Tighten bib connector. B. Clean out or replace bib connector. C. Straighten or replace line. 4.27 bib pump fails to stop when dispensin...

Page 30

5. Illustrations, parts listings and wiring diagrams 5.1 final assembly 1 2 3 4 9 8 7 5 11 12 6 10 18 17 16 13 14 15 19 20 21 24 23 22 25 26 27 29 30 32 31 33 34 28 30 flavor select (fs) 22 ice beverage dispenser.

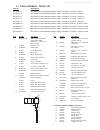

Page 31

5.1 final assembly - parts list part no. Description 85-14808-12 ibd, above counter multi brand series 14800, 115v/60hz, 8 brands / 12 flavors 85-14810-12 ibd, above counter multi brand series 14800, 115v/60hz, 10 brands / 12 flavors 85-14812-12 ibd, above counter multi brand series 14800, 115v/60hz...

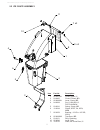

Page 32

5.2 ice chute assembly 10 11 4 6 5 3 2 1 7 x2 9 x2 8 item part no. Description 1 05-2257/01 chute, upper, ic 2 54-0406 chute, printed, ibd 3 05-0999/01 lever, chute, ibd 4 04-0268 scr, 6-19x.625 lg, plsti,hhsw/w 5 03-0241 spring, chute, ibd 6 12-0244 switch, spst, 5a, 250v, mdm 7 05-0359 bushing, .1...

Page 33

5.3 pellet ice assembly and parts listing use the components listed on this page with pellet ice only. 6 1 2 5 4 3 item part no. Description 1 05-2325/01 ice shroud, ic 2 23-1401/01 agitator assy, helical, ic 3 10-0762 pin, hex design, fs-16 4 03-0368 retainer, pin, agitator, ibd 5 82-3651 dispensin...

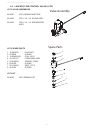

Page 34

5.4 lancer flow control valve (lfcv) lfcv valve assemblies 82-3820 lfcv, bonus injector 82-3823 lfcv, 3.0 - 4.5, syrup assy 82-3824 lfcv, 3.0 - 4.5, soda/water assy lfcv spare parts 1 10-0430/05 plug nut 2 02-0538 o-ring 3 12-0364/04-01 coil, lfcv 4 23-1301/01 core seal assy 5 03-0180/02 spring, cor...

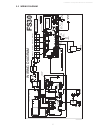

Page 35: Fs30

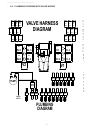

5.5 wiring diagram fs30 power suppl y 16v led communica tion lights note: flash when communica ting reprogramming (diagnostic) program reset run 1 2 3 4 reset able 24v secondar y primar y power rela y carbona tor pump carb cap agit at or 115v val ve board (diagnostic) board probe mdb sla ve low high...

Page 36: S1-1

5.6 plumbing diagram with valve wiring s1-1 s1- 2 s1- 3 s1- 4 is2- 3 is2- 2 is2- 1 is1- 1 is1- 2 is1- 3 is1-1 v1 s2-1 s2-2 s2- 3 s2- 4 v2 is2-3 is2-2 is2-1 s2-4 s2-3 s2-1 soda2 s2-2 water2 yel blk brn blk blu blk red blk blu wht v1 yel wht v1 red wht v1 yel blk red blk brn blk yel gry v a l v e m o ...

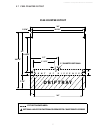

Page 37: Fs30 Counter Cutout

5.7 fs22 counter cutout 30” 28 1/8” 15/16” 30 1/2” 23” 18 5/8” 1 5/8” 7 1/2” 1 1/2” 3“ diameter optional 3“ 26” 15” 11 1/2” 2“ f r o n t o f d i s p e n s e r optional holes for fastening dispenser to counter with screws cut out dashed area fs30 counter cutout d r i p t r ay 37 installation and oper...

Page 38

Lancer to order parts, call customer service: 800-729-1500 warranty: 800-729-1550 email: custserv@lancercorp.Com www.Lancercorp.Com.