- 1 - i i n n s s t t a a l l l l a a t t i i o o n n c c o o u u r r s s e e l l a a w w n n m m o o w w e e r r r r o o b b o o t t introduction & features.................................................................................................................................. 2 start-up /...

- 2 - introduction & features remember that : maximum coverage 400 sq.M. However, it is a good idea to not exaggerate and bear in mind that gardens that are more complicated reduce the square meters covered by the robot. Maximum slope limit of 27° the robot can mow this maximum slope limit. Remember...

- 3 - start-up / installation getting started recharge the robot first, recharge the robot. It will come in handy at the end of installation for checking the correct functioning of the lawn mower. Fix the garden before starting the robot, the customer must be instructed on how to fix up the lawn. Th...

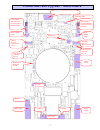

- 4 - the figure below shows a correct installation. Turning off the cutting blade. The robot turns off the cutting blade due to the following reasons - tall grass or slow motor speed. - a handle was touched. - the robot exceeded a 30° slope - the inclination of the robot has changed too quickly. - ...

- 5 - user interface (led) the keyboard consists of only two keys, an on/off key and a key to start and stop the robot. The led always shows the status of the robot. The leds relating to the batteries show their charge level when the robot is running and when it is in pause. Two leds must be checked...

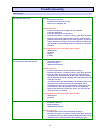

- 6 - if the robot breaks down, the led (on) will flash indicating the reason for the malfunctioning. As shown in the table below. When a robot stops, the first thing to understand is the condition of the “on” led and the “pause” led attention !!! : when the robot is switched on if all the leds are ...

- 7 - connections and upgrade - motherboard operating led grass sensors the cable must be connected to start from pin.1 grass sensors the cable must be connected to start from pin.1 on key. Pin 3-4 activates the robot start key pin 3-4 starts the robot reset key (-) battery (+) battery (f1) 20ah (f2...

- 8 - connection curb drop off and grass detectors.

- 14 - troubleshooting list of errors the robot does not turn on. Reasons - internal fuses are burnt - problems connected to the on key - batteries are completely flat solutions and checks - connect the robot to the recharger for a few minutes - check the inside fuses - check the charging level of t...

- 15 - assembling the body in reverse with the on key positioned in the start connector. (for safety purposes, run the test without the blade). If the robot turns on and off when the “start” key is pressed, then this means that the key is working and the failure should be in the motherboard. Has the...

- 16 - the robot does not turn correctly after doing a u-turn and makes too many turns, which affect the normal functioning of the robot. Nb. The robot cannot control the direction and therefore it is normal that it continues to turn. Reasons - loose belt - wheel motor with worn brushes - wheel moto...

- 17 - - on the battery there must be the label “li-type a” or “li-type b” with a version come out later than “2009-04-16” - clean the blade and grass residuals - clean and check the recharging knobs as well as the impedance of the recharging knobs as showed in the picture - recharge the robot all n...

- 18 - mechanical assembly operations assembly operations motherboard connections wheel motors make sure the motherboard is connected correctly. The red cable of the motor must be facing upwards. - once connected, check the correct functioning by turning on the robot and pressing the “start” key. Th...

- 19 - cutting motor pay attention to the cables above the motor. An incorrect connection causes an incorrect rotation of the cutting motor. Respect the colours of the wires and the placement as shown in the figure..

- 20 - revision and winter service revision for updating the robot each time the robot is repaired, it is recommended to: - update the robot version using the robot programmer. - check the impedance (ohm) of the recharging knobs and the cable. It must be lower than 1-2 ohm. Maybe we must install a c...