- DL manuals

- MacDon

- Tractor

- M150

- Operator's Manual

MacDon M150 Operator's Manual

Summary of M150

Page 1

M150 & m200 self-propelled windrower operator’s manual revision c part #169017 $25.

Page 2

This manual contains instructions for “safety”, “operation”, and “maintenance/service” for your new macdon model m150 and m200 self-propelled windrower. California proposition 65 warning diesel engine exhaust and some of its constituents are known to the state of california to cause cancer, birth de...

Page 3: 1 Introduction

Form 169017 / 169087 / 169095 1 revision c 1 introduction this instructional manual contains information on the macdon model m150 and m200 self-propelled windrowers that are designed to cut and lay in windrows, a wide variety of grain, hay and specialty crops. Windrowing allows starting the harvest ...

Page 4

Table of contents form 169017 / 169087 / 169095 2 revision c section/title page 1 introduction ...............................................................................................................................1 2 safety ......................................................................

Page 5

Table of contents form 169017 / 169087 / 169095 3 revision c 6.2 symbol definitions ......................................................................................................... 51 6.2.1 engine functions .......................................................................................

Page 6

Table of contents form 169017 / 169087 / 169095 4 revision c 7.7.5 park brake ................................................................................................................................. 130 7.7.6 hvac system .........................................................................

Page 7

Table of contents form 169017 / 169087 / 169095 5 revision c 8.7 cab air ................................................................................................................................ 218 8.8 operator’s station ..........................................................................

Page 8: 2 Safety

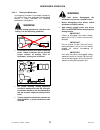

Safety form 169017 / 169087 / 169095 6 revision c 2 safety 2.1 safety alert symbol this safety alert symbol indicates important safety messages in this manual and on safety signs on the machine. This symbol means: attention! Become alert! Your safety is involved! Carefully read and follow the safety...

Page 9

Safety form 169017 / 169087 / 169095 7 revision c safety sign locations (continued) lift linkages #163561 front of platform #134070 (horizontal format), and on oil reservoir under hood (both sides) #44944 (vertical format) below door handle #32744 in cab #32744 behind door on sill - lh side only #16...

Page 10

Safety form 169017 / 169087 / 169095 8 revision c safety sign locations (continued) in cab #109868 in cab #109844 behind door on sill #109843 front of platform #110989 in cab #160422 bel0w door handle #32744.

Page 11

Safety form 169017 / 169087 / 169095 9 revision c safety sign locations (continued) on frame #42130 on fan shroud #134068 on frame #110986.

Page 12

Safety form 169017 / 169087 / 169095 10 revision c safety sign locations (continued) on drink cooler #160429 inside frame #32743 on frame #110986 on lift linkage #163562.

Page 13

Safety form 169017 / 169087 / 169095 11 revision c 2.4 general safety caution the following are general farm safety precautions that should be part of your operating procedure for all types of machinery. Protect yourself. • when assembling, operating and servicing machinery, wear all the protective ...

Page 14

Safety form 169017 / 169087 / 169095 12 revision c • do not modify the machine. Unauthorized modifications may impair the function and/or safety and affect machine life. • stop engine and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an id...

Page 15: 3 Definitions

Specifications form 169017 / 169087 / 169095 13 revision c 3 definitions term definition api american petroleum institute astm american society of testing and materials cab-forward windrower operation with the operator and cab facing in the direction of travel cdm cab display module dwa double windr...

Page 16: 4 Specifications

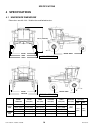

Specifications form 169017 / 169087 / 169095 14 revision c 4 specifications 4.1 windrower dimensions dimensions are with 18.4 - 26 drive tires and forked casters. Wheel position tread inch (mm) hubs inch (mm) casters inch (mm) tires inch (mm) shipping inch (mm) wheel base inch (mm) cab fwd eng fwd d...

Page 17

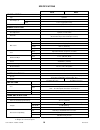

Specifications form 169017 / 169087 / 169095 15 revision c 4.2 specifications m150 m200 engine type cummins qsb -130 4 cyl. Turbo cat c6.6 6 cyl. Turbo displacement 275 cu.In. (4.5 l) 403 cu.In. (6.6 l) power rated 130 hp (97 kw) @ 2200 rpm 213 hp (159 kw) @ 2200 rpm peak 140 hp (104 kw) @ 2000 rpm ...

Page 18

Specifications form 169017 / 169087 / 169095 16 revision c m150 m200 header lift/tilt type hydraulic gear pumps (2) displacement 0.84 cu.In. (13.8 cc) flow 11.5 u.S. Gpm (46.5 l/min) system pressure (relief / max) 2500 psi (17.24 mpa) header flotation primary adjustment manual, external, draw-bolt w...

Page 19: 5 Operator’S Station

Operator’s station form 169017 / 169087 / 169095 17 revision c 5 operator’s station the operator’s station is designed for operating the windrower in a cab-forward mode (working mode), or in an engine-forward mode (transport mode). The operator station, which includes the seat, console, and steering...

Page 20

Operator’s station form 169017 / 169087 / 169095 18 revision c 5.2 operator presence the operator presence system is a safety feature that is designed to deactivate or alarm selected systems when the operator is not seated at the operator’s station. These systems include: • header drive • engine and...

Page 21

Operator’s station form 169017 / 169087 / 169095 19 revision c 5.4 training seat a wall mounted fold-up training seat, complete with seat belt, is provided for use as described below. • to lower seat, lift latch (a), and lower seat (b). • for storage, lift seat (b), and secure with latch (a). Warnin...

Page 22

Operator’s station form 169017 / 169087 / 169095 20 revision c 5.7 lights the field and transport light switches are located on a panel in the cab headliner. Refer to illustrations on following pages for location of lights. The lighting is dependent upon the position of the operator’s station (i.E. ...

Page 23

Operator’s station form 169017 / 169087 / 169095 21 revision c 5.7.2 engine-forward lighting - road the following lights are on / functional when the switch is in the road position. The hazard lights must be activated with the switch on the cdm when driving on the road. 5.7.3 cab-forward lighting - ...

Page 24

Operator’s station form 169017 / 169087 / 169095 22 revision c 5.7.4 beacon lighting - export (n.A. Optional) the beacon lights are functional when the ignition and the beacon switches are on. The beacons must be used when driving on the road. 5.7.5 slow moving vehicle (smv) signs the slow moving ve...

Page 25

Operator’s station form 169017 / 169087 / 169095 23 revision c 5.8 windshield wipers the windshield wiper controls are located in the cab headliner. The illustration above designates the controls as in the cab-forward mode. 5.9 rear view mirrors two adjustable outside mounted mirrors provide rear vi...

Page 26

Operator’s station form 169017 / 169087 / 169095 24 revision c 5.10.3 controls important to distribute the oil throughout the system, perform the following steps whenever the machine is first started after storage for more than one week: a. Turn blower switch to the first position. Turn temperature ...

Page 27

Operator’s station form 169017 / 169087 / 169095 25 revision c 5.12 operator amenities manual storage case cigarette lighter utility tray under armrest utility tray ashtray / cupholder auxiliary power auxiliary power ground switched battery cooler.

Page 28

Operator’s station form 169017 / 169087 / 169095 26 revision c 5.13 radios 5.13.1 am/fm radio a radio is available as optional equipment from your macdon dealer, and a space (a) is provided in the cab headliner to accommodate the installation. Two pre-wired speakers (b) have been factory installed i...

Page 29

Operator’s station form 169017 / 169087 / 169095 27 revision c 5.15 engine controls/gauges all engine controls and gauges are conveniently located on the operator’s console. Refer to the following illustration for the location and a description of each. Throttle controls engine rpm. Full - push leve...

Page 30

Operator’s station form 169017 / 169087 / 169095 28 revision c 5.16 windrower controls auto-steer engagement switch engages auto-steer system (if compatible system is installed). Engage - click to engage. Disengage - turn steering wheel to disengage. Hazard warning lights activates signals on windro...

Page 31

Operator’s station form 169017 / 169087 / 169095 29 revision c 5.17 header controls all header controls are conveniently located on the operator’s console, and on the gsl handle. Note some controls are optional equipment, and may not be present in your unit. Some controls may be installed, but will ...

Page 32

Operator’s station form 169017 / 169087 / 169095 30 revision c 5.17.3 ground speed lever (gsl) header switches the gsl (a) contains switches for the following header functions that are most often adjusted while in operation to suit changing crop conditions. All are momentary type switches. A decal t...

Page 33

Operator’s station form 169017 / 169087 / 169095 31 revision c 5.17.3.3 header position switches press and hold switch at location shown to move header. Release switch at desired position. Note refer to the specific header section in this instructional manual for detailed switch operating modes. 5.1...

Page 34

Operator’s station form 169017 / 169087 / 169095 32 revision c 5.17.4 console header switches the operator’s console contains switches for the following header functions. 5.17.4.1 deck shift / float preset switch • draper header with deck shift option controls deck shifting for double windrowing opt...

Page 35

Operator’s station form 169017 / 169087 / 169095 33 revision c 5.18 cab display module (cdm) 5.18.1 engine and windrower functions 5.18.2 header functions float switch - header right side changes header float push + to increase / push - to decrease remembers setting with deck shift option if activat...

Page 36

Operator’s station form 169017 / 169087 / 169095 34 revision c 5.18.3 operating screens the m150 and m200 windrower cab display module (cdm), and the windrower control module (wcm) provide information on several functions for the engine, header, and windrower. The information displayed in various op...

Page 37

Operator’s station form 169017 / 169087 / 169095 35 revision c cab - forward / engine running / header disengaged (scroll through display with cdm switch or gsl switch) display (lower or upper line) description #####.# engine hrs total engine operating time. #####.# header hrs total header operating...

Page 38

Operator’s station form 169017 / 169087 / 169095 36 revision c cab - forward / engine running / header engaged auger header (scroll through display with cdm switch or gsl switch) display (lower or upper line) description #####.# engine hrs total engine operating time. #####.# header hrs total header...

Page 39

Operator’s station form 169017 / 169087 / 169095 37 revision c cab - forward / engine running / header engaged draper header / index switch off (scroll through display with cdm switch or gsl switch) display (lower or upper line) description #####.# engine hrs total engine operating time. #####.# hea...

Page 40

Operator’s station form 169017 / 169087 / 169095 38 revision c cab - forward / engine running / header engaged draper header / index switch on (scroll through display with cdm switch or gsl switch) display (lower or upper line) description #####.# engine hrs total engine operating time. #####.# head...

Page 41

Operator’s station form 169017 / 169087 / 169095 39 revision c cab - forward / engine running / header engaged rotary header (scroll through display with cdm switch or gsl switch) display (lower or upper line) description #####.# engine hrs total engine operating time. #####.# header hrs total heade...

Page 42

Operator’s station form 169017 / 169087 / 169095 40 revision c miscellaneous operational information display (upper line) description indicates left turn when is pressed on cdm. See note 1. ■ right turn > indicates left turn when is pressed on cdm. See note 2. ■ hazard ■ indicates hazard warning lig...

Page 43

Operator’s station form 169017 / 169087 / 169095 41 revision c 5.18.4 cab display module (cdm) warnings/alarms the cdm displays warnings and sounds alarms to notify the operator of abnormal windrower status at startup when the ignition is turned on, and at engine operating speeds above 500 rpm. 5.18...

Page 44

Operator’s station form 169017 / 169087 / 169095 42 revision c 5.18.4.2 display warnings display warnings and alarms display flas h ing alarm tone description brake off engine running, brake solenoid not activated. Brake on 9 short beep with each flash. Gsl out of n-detent but interlock switch remai...

Page 45

Operator’s station form 169017 / 169087 / 169095 43 revision c display warnings and alarms (continued) display flas h ing alarm tone description in park 9 one short beep. Gsl in n-detent, steering wheel centered, and brakes are engaged. Knife speed overload 9 short beep with each flash until conditi...

Page 46

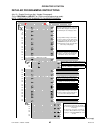

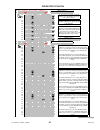

Operator’s station form 169017 / 169087 / 169095 44 revision c 5.18.5 cab display module (cdm) programming the monitoring system requires programming for each header, and the header must be attached to the windrower so that the cdm recognizes the type of header. Programming the system may be accompl...

Page 47

t...

Page 48

n o / y e s v i e w c o n t r o l l o c k s ? L1 c x x ...

Page 49

e s p a n o l l1 c x ...

Page 50

e x i t c a l ? N o / y e s t o c a l i b r a...

Page 51

n o / y e s s...

Page 52

Operator’s station form 169017 / 169087 / 169095 50 revision c 5.18.6 setting guidelines 5.18.6.1 pressure settings windrower model header model application/system suggested overload warning setting psi (kpa) windrower pressure comp setting psi (kpa) m150 d60 and a40d reel / draper pressure 3000 (20...

Page 53: 6 Operation

Windrower operation form 169017 / 169087 / 169095 51 revision c 6 operation 6.1 owner/operator responsibilities caution • it is your responsibility to read and understand this manual completely before operating the windrower. Contact your dealer if an instruction is not clear to you. • follow all sa...

Page 54

Windrower operation form 169017 / 169087 / 169095 52 revision c windrower operating symbols (cont’d) air conditioning fresh air recirculate blower 6.2.3 header functions program header tilt up header index header down return to cut header up conveyor/auger speed header tilt down float left increase ...

Page 55

Windrower operation form 169017 / 169087 / 169095 53 revision c 6.3 windrower operation 6.3.1 operational safety follow these safety precautions: caution • wear close fitting clothing and protective shoes with slip resistant soles. • remove foreign objects from the machine and surrounding area. • as...

Page 56

Windrower operation form 169017 / 169087 / 169095 54 revision c 6.3.3 pre-season check a. Perform the following safety checks at the beginning of each operating season: caution • review the operator’s manual to refresh your memory on safety and operating recommendations. • review all safety signs an...

Page 57

Windrower operation form 169017 / 169087 / 169095 55 revision c 6.3.5 engine operation 6.3.5.1 starting danger • avoid possible injury or death from a runaway machine. • this machine has safety devices which allow the engine to start only when the ground speed lever is in n-detent, the steering whee...

Page 58

Windrower operation form 169017 / 169087 / 169095 56 revision c g. Normal start - engine temperature above 60°f (16°c): 1. Set throttle (d) to start position (e) - fully back. Important the machine gauges and instruments provide important information about machine operation and condition. Familiariz...

Page 59

Windrower operation form 169017 / 169087 / 169095 57 revision c warning if starter engages with steering wheel unlocked, ground speed lever out of neutral, or header clutch engaged, do not start engine. See your windrower dealer. 6.3.5.2 engine warm-up allow engine to run with throttle lever (d) at ...

Page 60

Windrower operation form 169017 / 169087 / 169095 58 revision c note fill fuel tank daily, preferably at the end of the day's operation to help prevent condensation in the tank. Tank capacity is 97 u.S. Gallons (378 l). Important do not fill tank completely as space is required for expansion. A fill...

Page 61

Windrower operation form 169017 / 169087 / 169095 59 revision c 6.3.6 driving the windrower warning before starting engine, securely fasten your seat belt and ensure trainer’s seat belt is fastened if occupied. The seat belt can help ensure your safety if it is used and maintained. Warning • avoid d...

Page 62

Windrower operation form 169017 / 169087 / 169095 60 revision c • avoid inclines, ditches and fences. • do not rapidly accelerate or decelerate when turning • reduce speed before turning, crossing slopes, or travelling over rough ground. • do not allow anyone to stand behind the machine while operat...

Page 63

Windrower operation form 169017 / 169087 / 169095 61 revision c 6.3.6.2 cab-forward operation warning do not drive windrower on road in cab- forward configuration, unless it is equipped with the proper lighting and markings for cab- forward road travel. A. Swivel operator’s seat to cab-forward posit...

Page 64

Windrower operation form 169017 / 169087 / 169095 62 revision c 6.3.6.2.1 reverse in cab-forward mode warning back up slowly. Steering is opposite to normal when reversing. Hold steering wheel at the bottom, and turn wheel in direction you want the rear (cab-forward) of the machine to travel. A. Mov...

Page 65

Windrower operation form 169017 / 169087 / 169095 63 revision c c. Set ground speed range switch (d) to h for road speed [0 - 23 mph (37 km/h)]. Cdm will display road gear at (e), and an alarm will briefly sound. D. Slowly push throttle (f) to full forward (operating speed). Cdm should display 2270 ...

Page 66

Windrower operation form 169017 / 169087 / 169095 64 revision c 6.3.6.4 spin turn hydrostatic steering gives the operator significantly more manoeuvrability than mechanical steering. To make a spin turn, refer to illustration and proceed as follows: caution be sure area is clear before making turns....

Page 67

Windrower operation form 169017 / 169087 / 169095 65 revision c 6.3.7 adjustable caster tread width the rear casters can be adjusted to a narrow tread width to allow loading and shipping without having to remove them. A narrow tread width also suits smaller headers by allowing more space to the uncu...

Page 68

Windrower operation form 169017 / 169087 / 169095 66 revision c 6.3.8 transporting 6.3.8.1 driving on road the m150 and m200 windrowers are designed to be driven on the road with the engine-forward to provide better visibility for the operator and improved stability for the machine. Refer to section...

Page 69

Windrower operation form 169017 / 169087 / 169095 67 revision c c. Push light switch to road position to activate lamps. Always use these lamps on roads to provide warning to other vehicles. Use high / low lights as required when other vehicles are approaching. Do not use field lamps on roads, as ot...

Page 70

Windrower operation form 169017 / 169087 / 169095 68 revision c 6.3.8.2 towing header with windrower warning harvest header with transport option • the windrower without the header must not be used to tow headers due to reduced traction, and possible loss of control, unless the weight box option is ...

Page 71

Windrower operation form 169017 / 169087 / 169095 69 revision c g. Remove pins (d) from lower end of lift linkages. Note pins (d) are also used to secure weight box to windrower linkage. H. Disconnect the center-link as follows: hydraulic link - m200 std, m150 option 1. Pull up on latch (e), and loc...

Page 72

Windrower operation form 169017 / 169087 / 169095 70 revision c j. Attach header transport hitch to header as follows: 1. Position end (a) of the aft section onto front wheel hook (b). 2. Push down until latch (c) captures the end (a). 3. Secure latch (c) with clevis pin (d). 4. Remove the l-pin fro...

Page 73

Windrower operation form 169017 / 169087 / 169095 71 revision c k. Make the electrical connections (j) at the header wheel, and at the joint (k). L. Attach weight box to windrower lift arm linkage as follows: important to prevent damage to the lift system when lowering header lift linkages without a...

Page 74

Windrower operation form 169017 / 169087 / 169095 72 revision c n. Activate header down switch in cab to lower lift arms until the lift arm “floats” up away from the linkage at the rear of the lift arm. O. Attach slow speed transport hitch to the weight box tongue with drawbar pin (secure using lync...

Page 75

Windrower operation form 169017 / 169087 / 169095 73 revision c 6.3.8.2.2 from transport mode to field operation danger stop engine and remove key from ignition before leaving operator's seat for any reason. A child or even a pet could engage an idling machine. A. Shut down engine and remove key fro...

Page 76

Windrower operation form 169017 / 169087 / 169095 74 revision c m. Move float pins from location (g) to disengage the float, and store pins at location (h). Important to prevent damage to the lift system when lowering header lift linkages without a header or weight box attached to windrower, ensure ...

Page 77

Windrower operation form 169017 / 169087 / 169095 75 revision c 6.3.8.3 towing the windrower in emergency situations, for example, towing out of a field or into a shop, windrower may be towed without a trailer, providing the following precautions are followed: warning a proper towing apparatus is cr...

Page 78

Windrower operation form 169017 / 169087 / 169095 76 revision c 6.3.8.4 final drives a. Disengage and engage final drives as follows: 1. Remove the two hex bolts (a) at center of drive wheel. 2. Remove cap (b), and flip over so that dished side faces in. The cap depresses a pin which disengages the ...

Page 79

Header - general form 169017 / 169087 / 169095 77 revision c 6.4 header operation the m150 and m200 windrowers are designed to use the macdon a series auger header, r series rotary header, and d series rigid draper header, with or without a hay conditioner. This section describes attachment and deta...

Page 80

Header - general form 169017 / 169087 / 169095 78 revision c 6.4.2 header flotation float is intended for cutting crops that require the cutterbar to be in contact with the ground. Optimum float is for the cutterbar to maintain contact with the ground with minimum bouncing and scooping or pushing so...

Page 81

Header - general form 169017 / 169087 / 169095 79 revision c danger stop engine, and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine. 6. Grasp the divider rod and lift. The force to lift should be as noted in the following ...

Page 82

Header - general form 169017 / 169087 / 169095 80 revision c 6.4.2.3 float options for draper headers without the deck shift option, auger headers, and rotary headers, the float can be pre-programmed for three types of windrowing conditions. For example: • position 1 - border • position 2 - normal •...

Page 83

Header - general form 169017 / 169087 / 169095 81 revision c 6.4.3 levelling the windrower linkages are factory set to provide the proper level for the header, and should not normally require adjustment. If the header is not level, perform the following checks prior to adjusting the leveling linkage...

Page 84

Header - general form 169017 / 169087 / 169095 82 revision c 6.4.4 header drive the headers are hydraulically driven, and controlled from the windrower with no mechanical drive shafts. Two hydraulic piston pumps on the windrower provide fluid power to the knife or discs, drapers or auger, reel, lift...

Page 85

Header - general form 169017 / 169087 / 169095 83 revision c 6.4.5 header angle header angle is defined as the angle between the ground and the drapers/cutterbar, and is adjustable to accommodate crop conditions and/or soil type. Refer to the appropriate header operator’s manual for range of adjustm...

Page 86

Header - general form 169017 / 169087 / 169095 84 revision c d. Periodically check the operation of the hook locking mechanism and ensure that it is working properly as follows: 1. If header is attached to windrower, disconnect center-link hook from header by pulling up on handle (a) to release the ...

Page 87

Header - general form 169017 / 169087 / 169095 85 revision c 6.4.6 cutting height the header is raised or lowered with the header up or header down switches on the gsl. The cdm indicates the header height by a reading on the display lower line between 00.0 and 10.0, with 00.0 being on the ground. Us...

Page 88

Header - general form 169017 / 169087 / 169095 86 revision c 2. If the header is below the pre-set height, press and hold the header up switch to raise the header. Release switch to stop header. Alarm will sound when header rises past the pre-set height. 3. If the header angle is changed, double-cli...

Page 89

Header - general form 169017 / 169087 / 169095 87 revision c 6.4.7 double windrowing the double windrow attachment (dwa) allows the combining of two windrows of conditioned material close together to be picked up by a forage chopper. This unit may be mounted on the macdon m150 and m200 windrowers. T...

Page 90

Header operation - d series form 169017 / 169087 / 169095 88 revision c 6.5 d series header operation 6.5.1 header attachment important to prevent damage to the lift system when lowering header lift linkages without a header or weight box attached to windrower, ensure that float engagement pin is in...

Page 91

Header operation - d series form 169017 / 169087 / 169095 89 revision c c. Start the engine, and activate header down button on the gsl to fully retract header lift cylinders. D. Slowly drive windrower forward so that boots (b) enter header legs (e). Continue to drive slowly forward until lift linka...

Page 92

Header operation - d series form 169017 / 169087 / 169095 90 revision c 3. Push down on rod end of link cylinder (k) until hook engages pin on header and is locked. 4. Check that center-link is locked onto header by pulling upward on rod end of cylinder. Hydraulic link with optional self- alignment ...

Page 93

Header operation - d series form 169017 / 169087 / 169095 91 revision c k. Remove pin from storage position (n) in linkage, and insert in hole (o) to engage float springs. Secure with hairpin. L. Disengage lift cylinder stops. Refer to section 6.4.1 header lift cylinder stops. M. Start engine, and a...

Page 94

Header operation - d series form 169017 / 169087 / 169095 92 revision c e. Remove pin from location (d) to disengage float springs, and insert in storage hole (e). Secure with lynch pin. Important to prevent damage to the lift system when lowering header lift linkages without a header or weight box ...

Page 95

Header operation - d series form 169017 / 169087 / 169095 93 revision c j. Disconnect center-link as follows: mechanical link - m150 1. Loosen nut (j), and rotate barrel (k), to relieve load on link. 2. Remove cotter pin on pin (l), and remove pin to disconnect from windrower. Reinstall pin in heade...

Page 96

Header operation - d series form 169017 / 169087 / 169095 94 revision c 6.5.3 header position refer to section 6.4 header operation for procedures for controlling header height, header tilt, and float. 6.5.4 reel fore-aft position the reel fore-aft position can be hydraulically adjusted with the opt...

Page 97

Header operation - d series form 169017 / 169087 / 169095 95 revision c note display will flash ##.## min reel (mph or kph) to prompt the operator to change the minimum set point, or increase ground speed if ground speed plus index is less than the minimum reel speed set point. B. Set reel index as ...

Page 98

Header operation - d series form 169017 / 169087 / 169095 96 revision c 6.5.6.2 reel only speed set the speed of the reel independently of ground speed as follows: caution check to be sure all bystanders have cleared the area. Note this procedure can also be used to change the reel speed “on the go”...

Page 99

Header operation - d series form 169017 / 169087 / 169095 97 revision c 6.5.7 draper speed draper speed affects the orientation of stalks in the windrow. Faster draper speeds tend to form herringbone or dovetail configurations. Refer to your header operator’s manual for guidelines on what speed to u...

Page 100

Header operation - d series form 169017 / 169087 / 169095 98 revision c example: windrower is operating at 8 mph with header index “on” and set at 1.5. Display shows; 9.5 1.5 drap indx where 9.5 (8+1.5) is the draper speed in mph, and 1.5 is the header index setting. Windrower speed drops to 7.5 mph...

Page 101

Header operation - d series form 169017 / 169087 / 169095 99 revision c 6.5.8 knife speed the ideal cutting speed of the knife should be such that a clean cut is achieved. Crop types and conditions usually influence the knife and forward speeds. The windrower control module (wcm) reads a code from t...

Page 102

Header operation - d series form 169017 / 169087 / 169095 100 revision c 6.5.9 deck shift (optional) the hydraulic deck shift option allows the operator to control deck position and draper rotation from the operator’s station. It enables crop delivery from left side, center, or right side of the hea...

Page 103

Header operation - a series form 169017 / 169087 / 169095 101 revision c 6.6 a series header operation 6.6.1 header attachment a. Remove hairpin from pin (a), and remove pin from left and right header boots (b) on header. Important to prevent damage to the lift system when lowering header lift linka...

Page 104

Header operation - a series form 169017 / 169087 / 169095 102 revision c d. Connect center-link as follows: mechanical link - m150 1. Loosen nut (f), and rotate barrel (g), to adjust length so that other end lines up with header bracket. 2. Install pin (h), and secure with cotter pins. 3. Adjust lin...

Page 105

Header operation - a series form 169017 / 169087 / 169095 103 revision c e. Raise the header fully with the header up switch on the gsl. Stop engine and remove key. Danger to avoid bodily injury from fall of raised header, always engage header lift cylinder stops when working on or around raised hea...

Page 106

Header operation - a series form 169017 / 169087 / 169095 104 revision c 6.6.2 header detachment a. Raise the header fully with the header up switch on the gsl. Stop engine and remove key. Danger to avoid bodily injury from fall of raised header, always engage header lift cylinder stops when working...

Page 107

Header operation - a series form 169017 / 169087 / 169095 105 revision c h. Disconnect center-link as follows: mechanical link - m150 1. Loosen nut (g), and rotate barrel (h) to relieve load on link. 2. Remove cotter pin on pin (j), and remove pin to disconnect from header. Reinstall pin in header. ...

Page 108

Header operation - a series form 169017 / 169087 / 169095 106 revision c 6.6.3 auger speed caution check to be sure all bystanders have cleared the area. 6.6.3.1 a40d headers on a40d double knife headers, the auger speed can be changed independently from the reel speed, with a switch on the cdm. Cha...

Page 109

Header operation - a series form 169017 / 169087 / 169095 107 revision c 6.6.4 reel speed 6.6.4.1 a40d header the a40 reel drive is hydraulically driven, and is independent of the auger and knife speeds. Important to prevent over-speeding the auger, initially set the speed of the reel and auger as f...

Page 110

Header operation - a series form 169017 / 169087 / 169095 108 revision c 6.6.5 knife speed the ideal cutting speed of the knife should be such that a clean cut is achieved. Crop types and conditions usually influence the knife and forward speeds. The windrower control module (wcm) reads a code from ...

Page 111

Header operation - r series form 169017 / 169087 / 169095 109 revision c 6.7 r series header operation 6.7.1 header attachment a. Remove hairpin from pin (a), and remove pin from on left and right header boots (b) on header. Important to prevent damage to the lift system when lowering header lift li...

Page 112

Header operation - r series form 169017 / 169087 / 169095 110 revision c d. Connect center-link as follows: mechanical link - m150 1. Loosen nut (f), and rotate barrel (g), to adjust length so that other end lines up with header bracket. 2. Install clevis pin (h), and secure with cotter pin. 3. Adju...

Page 113

Header operation - r series form 169017 / 169087 / 169095 111 revision c hydraulic link with optional self- alignment kit 1. Adjust the position of the center-link cylinder with the reel up and reel down switches, and header tilt switches on the gsl to position the hook above the header attachment p...

Page 114

Header operation - r series form 169017 / 169087 / 169095 112 revision c 6.7.2 header detachment a. Raise the header fully with the header up switch on the gsl. Stop engine, and remove key. Danger to avoid bodily injury from fall of raised header, always engage header lift cylinder stops when workin...

Page 115

Header operation - r series form 169017 / 169087 / 169095 113 revision c g. Disconnect center-link as follows: mechanical link - m150 1. Loosen nut (e), and rotate barrel (f), to relieve load on link. 2. Remove cotter pin on pin (g), and remove pin to disconnect from header. Reinstall pin in header....

Page 116

Header operation - r series form 169017 / 169087 / 169095 114 revision c 6.7.3 disc speed the header is allocated a code that the wcm reads when the header is first attached to the windrower, and the disc speed set-point automatically becomes the minimum disc speed for the header. The operator can t...

Page 117

Header operation - r series form 169017 / 169087 / 169095 115 revision c 6.7.4 converging drum assemblies - grass seed header the twin converging drum assemblies are designed specifically for grass seed and similar crops where conditioning is not a requirement. The hydraulically adjustable drum asse...

Page 118: 7 Maintenance

Maintenance and servicing form 169017 / 169087 / 169095 116 revision c 7 maintenance and servicing the following instructions are provided to assist the operator in the use of the m150 and m200 windrower. Detailed maintenance, service, and parts information are contained in the service instruction m...

Page 119

Maintenance and servicing form 169017 / 169087 / 169095 117 revision c 7.3 maintenance specifications 7.3.1 recommended fuel, fluids and lubricants 7.3.1.1 fuel fuel spec sulphur (by weight) water & sediment (by vol.) cetane no. °c lubri city diesel grade no.2 astm d-975 0.5% max. 0.05% max. 40 min....

Page 120

Maintenance and servicing form 169017 / 169087 / 169095 118 revision c 7.3.2 recommended torques 7.3.2.1 bolts the tables shown give correct torque values for various bolts and capscrews. • tighten all bolts to the torques specified in chart unless otherwise noted throughout this manual • check tigh...

Page 121

Maintenance and servicing form 169017 / 169087 / 169095 119 revision c 7.3.2.2 hydraulic fittings 7.3.2.2.1 flare type a. Check flare and flare seat for defects that might cause leakage. B. Align tube with fitting before tightening. C. Lubricate connection and hand tighten swivel nut until snug. D. ...

Page 122

Maintenance and servicing form 169017 / 169087 / 169095 120 revision c 7.3.3 conversion chart quantity inch-pound units factor si units (metric) unit name abbr. Unit name abbr. Area acres acres x 0.4047 = hectares ha flow us gallons per minute gpm x 3.7854 = liters per minute l/min force pounds forc...

Page 123

Maintenance and servicing form 169017 / 169087 / 169095 121 revision c 7.4 engine compartment hood the engine hood has two open positions: • the lowest is for general maintenance such as checking and adding fluid, servicing the cooling box, etc. • the highest position accommodates full access to the...

Page 124

Maintenance and servicing form 169017 / 169087 / 169095 122 revision c 7.5 maintenance platforms swing away platform/stair units are provided on both sides of the windrower for access to the operator’s station and engine bay maintenance. 7.5.1 opening/closing platforms a. Push latch (a) down, and pu...

Page 125

Maintenance and servicing form 169017 / 169087 / 169095 123 revision c 4. At the same time, pull front (cab-forward) end of platform away from frame, while moving it towards the walking beam. Aft corner (e) of platform should project slightly into engine bay when optimum opening is reached. Caution ...

Page 126

Maintenance and servicing form 169017 / 169087 / 169095 124 revision c 7.6 lubricating the windrower warning to avoid personal injury, before servicing windrower or opening drive covers, follow procedures in section 7.1 preparation for servicing. Recommended lubricant lubricant spec description use ...

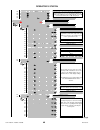

Page 127: 200

Maintenance and servicing form 169017 / 169087 / 169095 125 revision c lubrication points (continued) formed caster wheel bearing 1 place (both wheels) 200 top link - two fittings (both sides) high temp. Extreme pressure (ep2) performance with 1% max molybdenum disulphide (nlgi grade 2).Lithium base...

Page 128

Maintenance and servicing form 169017 / 169087 / 169095 126 revision c 7.7 operator’s station 7.7.1 seat belts keep the operator and trainer seat belts in good condition as follows: a. Keep sharp edges and items that can cause damage away from the belts. B. From time to time, check belts, buckles, r...

Page 129

Maintenance and servicing form 169017 / 169087 / 169095 127 revision c 7.7.3 gsl adjustments 7.7.3.1 gsl lateral movement the gsl should easily move into the n-detent by itself. Adjust the lateral pivot resistance as follows: danger stop engine and remove key from ignition before leaving operator’s ...

Page 130

Maintenance and servicing form 169017 / 169087 / 169095 128 revision c 7.7.4 steering adjustments 7.7.4.1 steering link pivots the following checks should be performed annually: danger stop engine and remove key from ignition before leaving operator's seat for any reason. A child or even a pet could...

Page 131

Maintenance and servicing form 169017 / 169087 / 169095 129 revision c 7.7.4.2 steering chain tension danger stop engine and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine. A. Check steering for binding or excessive play w...

Page 132

Maintenance and servicing form 169017 / 169087 / 169095 130 revision c 7.7.5 park brake the brake is applied when the interlock is fully engaged. To engage the interlock and hence the brake, the gsl must be in the n-detent position, and the steering wheel centered. 7.7.5.1 interlock switch danger st...

Page 133

Maintenance and servicing form 169017 / 169087 / 169095 131 revision c f. Position switch support (c) inside console, and push rubber nuts (d) into holes. G. Check operation of switch. H. Reinstall control panel (b) with five screws (a). C d b a.

Page 134

Maintenance and servicing form 169017 / 169087 / 169095 132 revision c 7.7.6 hvac system 7.7.6.1 fresh air intake filter the fresh air filter is located under the right cab- forward side platform, and should be serviced every 50 hours under normal conditions, and more frequently in severe conditions...

Page 135

Maintenance and servicing form 169017 / 169087 / 169095 133 revision c 7.7.6.2 return air cleaner the return air filter is located behind the operator’s seat on the cab wall, and should be serviced every 100 hours as follows: danger stop engine and remove key from ignition before leaving operator’s ...

Page 136

Maintenance and servicing form 169017 / 169087 / 169095 134 revision c b. Remove the eight screws (h) that attach the cover (j), and remove the cover. Warning to avoid cuts from evaporator fins, do not use bare hands to brush away clogs. C. Use a vacuum or compressed air to remove dirt from inside t...

Page 137

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 135 revision c 7.8 cummins engine (m150) caution • never operate engine in a closed building. Proper ventilation is required to avoid exhaust gas hazards. • keep the engine clean. Straw and chaff on a hot engine are a fire hazard....

Page 138

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 136 revision c e. Clean area around the plastic cap on access hole (b). Remove the cap. F. Insert the tool (c) into the flywheel housing until it engages the ring gear. G. Attach a 1/2 inch square drive ratchet or breaker bar and ...

Page 139

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 137 revision c g. Add oil as follows if level is below the low mark: one u.S. Qt. (1 litre) is will raise the level from low to high. Caution do not fill above the high mark. 1. Turn handle (a) on filler cap (b) counter clockwise ...

Page 140

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 138 revision c k. Tighten the filter an additional ½ to ¾ turn by hand. Important do not use a filter wrench to install the oil filter. Over-tightening can damage the gasket and filter. L. Install the oil pan drain plug (c). M. Re...

Page 141

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 139 revision c 7.8.5 air intake system important do not run engine with air cleaner disconnected or disassembled. Engine intake air (a) is drawn through a duct (b) from the cooling box that pre-cleans the air, and then through a d...

Page 142

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 140 revision c important do not remove the secondary filter element (k) unless it needs replacing. Do not attempt to clean the secondary (inner) element. 1. Hold a bright light inside element, and check carefully for holes. Discar...

Page 143

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 141 revision c o. Insert primary filter element (j) into canister over secondary element, and push into place, ensuring that element is firmly seated in canister. P. Position end cap (f) onto filter housing, with vacuator valve po...

Page 144

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 142 revision c 7.8.6 fuel system 7.8.6.1 fuel tank venting the fuel tank is vented by a hose that is connected to the filler tube. The hose is connected to a filter that should be changed annually. Change the filter as follows: da...

Page 145

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 143 revision c 7.8.6.2 fuel filters the m150 and m200 windrower fuel system is equipped with primary (c) and secondary (d) filters. Both filters are screw-on cartridge type, but the primary (c) filter is equipped with a separator ...

Page 146

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 144 revision c d. Change secondary filter (d) as follows: 1. Clean around the filter head. 2. Place a container under the filter to catch spilled fluid. 3. Remove filter (d) with a filter wrench. 4. Clean gasket mating surface. Im...

Page 147

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 145 revision c g. Remove plug (l), to ensure tank is completely drained after fuel has stopped flowing from hose. H. Add some clean fuel to tank to flush out any remaining contaminants. I. Replace drain plug, and reattach hose (j)...

Page 148

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 146 revision c 7.8.6.5 system priming controlled venting of air is provided at the injection pump through the fuel drain manifold. Small amounts of air introduced by changing filters, or injection pump supply line will be vented a...

Page 149

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 147 revision c 7.8.7 engine cooling system the engine cooling system is designed to maintain the engine operating temperature within the specified operating range. Note antifreeze is essential in any climate. It broadens the opera...

Page 150

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 148 revision c 7.8.7.2 radiator cap caution to avoid personal injury from hot coolant, do not turn radiator cap until engine has cooled. A. Remove the radiator cap (c), and check as follows: 1. The radiator cap must fit tightly. N...

Page 151

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 149 revision c e. Place a drain pan [about 8 u.S. Gallons (30 litres)] under the engine and radiator. F. Remove the radiator cap, and open radiator drain valve (d) on the engine side of the radiator lower tank. Use a deflector or ...

Page 152

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 150 revision c 7.8.8 gearbox 7.8.8.1 lubricant level caution park on a flat, level surface, header on the ground and the ground speed lever in n- detent position. Danger stop engine and remove key from ignition before leaving oper...

Page 153

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 151 revision c 7.8.8.2 changing lubricant change gearbox lubricant after the first 50 hours, and then at 500 hours as follows: note the engine should be warm prior to changing the oil. A. Stop the engine, and remove the key. B. Pl...

Page 154

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 152 revision c 7.8.9 exhaust system caution to avoid burns, do not touch muffler when engine is running or before allowing sufficient cooling time after shut-down the exhaust system requires no regular maintenance. But it should b...

Page 155

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 153 revision c 7.8.10 belts danger stop engine and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine. 7.8.10.1 tension a. The alternator, water pump, and f...

Page 156

Maintenance and servicing - m150 engine form 169017 / 169087 / 169095 154 revision c c. Loosen compressor mounting hardware (b), and push compressor towards engine to release belt (a) tension. D. Remove belt (a). E. Insert the drive end of a ½ inch drive ratchet wrench into the belt tensioner (c). F...

Page 157

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 155 revision c 7.9 cat engine (m200) caution • never operate engine in a closed building. Proper ventilation is required to avoid exhaust gas hazards. • keep the engine clean. Straw and chaff on a hot engine are a fire hazard. • n...

Page 158

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 156 revision c 7.9.3 changing oil and oil filter note the engine should be warm prior to changing the oil. A. Stop the engine, and remove the key. B. Open engine compartment hood to lowest position. C. Place a drain pan of about 5...

Page 159

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 157 revision c 7.9.4 air intake system important do not run engine with air cleaner disconnected or disassembled. Engine intake air is drawn through a duct (a) from the cooling box that pre-cleans the air, and then through a dual ...

Page 160

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 158 revision c important do not remove the secondary filter element (j) unless it needs replacing. Do not attempt to clean the secondary (inner) element. 1. Hold a bright light inside primary element (h), and check carefully for h...

Page 161

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 159 revision c n. Insert primary filter element (h) into canister over secondary element, and push into place, ensuring that element is firmly seated in canister. O. Position end cap (f) onto filter housing with duct (c) pointing ...

Page 162

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 160 revision c d. Assemble hose clamps (b) to hose, and attach hose assembly to muffler and air filter. E. Ensure arrows on inlet side of check valve points up. F. Tighten clamps, and install plastic ties (a) to hold valve in corr...

Page 163

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 161 revision c 7.9.6 fuel system 7.9.6.1 fuel tank venting the fuel tank is vented by a hose that is connected to the filler tube. The hose is connected to a filter that should be changed annually. Change the filter as follows: da...

Page 164

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 162 revision c change both filters as follows every 500 hours of operation: danger stop engine and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine. A. Op...

Page 165

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 163 revision c e. Change secondary filter (d) as follows: 1. Thoroughly clean around the filter head (l). 2. Remove filter (d) with a filter wrench, and safely dispose of the filter. 3. Lubricate o-ring seal with clean engine oil....

Page 166

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 164 revision c 7.9.6.4 draining fuel tank draining the fuel tank is necessary to remove old or contaminated fuel. To drain the tank, refer to following illustrations and proceed as follows: danger stop engine and remove key from i...

Page 167

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 165 revision c g. Remove plug (d), to ensure tank is completely drained after fuel has stopped flowing from hose. H. Add some clean fuel to tank to flush out any remaining contaminants. I. Replace drain plug (d), and reattach hose...

Page 168

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 166 revision c 7.9.7 engine cooling system the engine cooling system is designed to maintain the engine operating temperature within the specified operating range. Note antifreeze is essential in any climate. It broadens the opera...

Page 169

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 167 revision c 7.9.7.2 radiator cap caution to avoid personal injury from hot coolant, do not turn radiator cap until engine has cooled. A. Remove the radiator cap (a) and check as follows: 1. The radiator cap must fit tightly. No...

Page 170

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 168 revision c e. Remove radiator cap. F. Place a drain pan [about 8 u.S. Gallons (30 litres)] under the engine and radiator. Caution to avoid personal injury from hot coolant, do not open valve until engine cools. G. Open radiato...

Page 171

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 169 revision c m. Stop engine, and drain water out before rust or sediment settles. See steps d. To i. N. Close radiator drain valve (b), and replace block drain plug (d). O. Fill system with a solution of clean water and a heavy ...

Page 172

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 170 revision c 7.9.8 gearbox 7.9.8.1 lubricant level caution park on a flat, level surface, header on the ground and the ground speed lever in n- detent position. Danger stop engine and remove key from ignition before leaving oper...

Page 173

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 171 revision c 7.9.8.2 changing lubricant change gearbox lubricant after the first 50 hours, and then at 500 hours as follows: note the engine should be warm prior to changing the oil. Danger stop engine and remove key from igniti...

Page 174

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 172 revision c 7.9.9 exhaust system caution to avoid burns, do not touch muffler when engine is running or before allowing sufficient cooling time after shut-down. The exhaust system requires no regular maintenance, but it should ...

Page 175

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 173 revision c 7.9.10 belts danger stop engine and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine. 7.9.10.1 tension a. The alternator, water pump, and f...

Page 176

Maintenance and servicing - m200 engine form 169017 / 169087 / 169095 174 revision c 7.9.10.3 fan belt replacement danger stop engine, and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine. A. Shutdown the engine, and open en...

Page 177

Maintenance and servicing form 169017 / 169087 / 169095 175 revision c 7.10 cooling box 7.10.1 cooling box screen the cooling box screen is equipped with an automatic cleaning device which "vacuums" the screen by means of two rotors. They only operate when the engine is running. The rotors are elect...

Page 178

Maintenance and servicing form 169017 / 169087 / 169095 176 revision c i. If necessary, adjust clearance as follows: 1. Loosen nut (b) on motor support (c). 2. Move support in or out until rotor is 0.08 - 0.24 in. (2 - 6 mm) from screen near the center. 3. Re-tighten nut (b). 4. Loosen the two motor...

Page 179

Maintenance and servicing form 169017 / 169087 / 169095 177 revision c 7.10.2 cooling box maintenance the radiator and oil cooler should be cleaned daily with compressed air, and more frequent cleaning may be necessary in severe conditions. The charge air cooler and air conditioning condenser may al...

Page 180

Maintenance and servicing form 169017 / 169087 / 169095 178 revision c h. Lift latch (m), and open access door (n) on the cooling box. I. Loosen wing-nuts (o), move retainers (p) and open access door (q) important fins on coolers can be very easily bent which may interfere with its function. Exercis...

Page 181

Maintenance and servicing form 169017 / 169087 / 169095 179 revision c 7.11 electrical system electrical schematics are attached at the back of this manual. 7.11.1 battery warning • gas given off by battery electrolyte is explosive. Keep all smoking materials, sparks and flames away from batteries. ...

Page 182

Maintenance and servicing form 169017 / 169087 / 169095 180 revision c 7.11.1.3 charging caution • ventilate the area where batteries are being charged. • do not charge a frozen battery. Warm to 60 °f (16°c) before charging. • do not connect or disconnect live circuits. To prevent sparks, turn off c...

Page 183

Maintenance and servicing form 169017 / 169087 / 169095 181 revision c c. Attach one end of battery cable to positive terminal (a) of booster battery, and other end to positive terminal (b) of windrower batteries. D. Attach second cable to negative terminal (c) of booster battery, and then to a good...

Page 184

Maintenance and servicing form 169017 / 169087 / 169095 182 revision c 7.11.1.6 replacing battery caution do not attempt to service battery unless you have the proper equipment and experience to perform the job. Have it done by a qualified dealer danger stop engine and remove key from ignition befor...

Page 185

Maintenance and servicing form 169017 / 169087 / 169095 183 revision c 7.11.1.7 preventing electrical system damage a. Carefully observe polarity when attaching booster battery. B. Do not short across battery or alternator terminals, or allow battery positive (+) cable or alternator wire to become g...

Page 186

Maintenance and servicing form 169017 / 169087 / 169095 184 revision c 7.11.2 headlights - engine-forward danger stop engine, and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine. Note header should be attached and raised to...

Page 187

Maintenance and servicing form 169017 / 169087 / 169095 185 revision c c. Pinch the wire retainer (e), and lift away from hooks. D. Remove bulb (f) from body. Important do not touch the glass of the halogen bulb as the oils or other chemicals from your skin will cause the bulb to fail prematurely. E...

Page 188

Maintenance and servicing form 169017 / 169087 / 169095 186 revision c 7.11.3 field lights - cab-forward danger stop engine and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine. 7.11.3.1 adjustment the field lights are best ...

Page 189

Maintenance and servicing form 169017 / 169087 / 169095 187 revision c important do not touch the glass of the halogen bulb as the oils or other chemicals from your skin will cause the bulb to fail prematurely. G. Match slots on new bulb (g) with lugs (j) in optical unit, and insert bulb into unit. ...

Page 190

Maintenance and servicing form 169017 / 169087 / 169095 188 revision c c. Remove light from receptacle. D. Pinch the wire retainer (l), and lift away from hooks. E. Remove bulb (m) from body, and pull wire from connector (n). Important do not touch the glass of the halogen bulb as the oils or other ...

Page 191

Maintenance and servicing form 169017 / 169087 / 169095 189 revision c 7.11.7 red tail lights (if installed) danger stop engine and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine. A. Shutdown engine, and remove the key. Tu...

Page 192

Maintenance and servicing form 169017 / 169087 / 169095 190 revision c d. Pull lamp out of socket. E. Disconnect harness from lamp. Important do not touch the glass of the halogen bulb, as the oils or other chemicals from your skin will cause the bulb to fail prematurely. F. Connect harness to new l...

Page 193

Maintenance and servicing form 169017 / 169087 / 169095 191 revision c 7.11.9 gauge light a. Shutdown engine, and remove the key. Turn off the lights. B. Remove the appropriate gauge access hole decal (a) behind the operator’s console. C. Remove nut (b) securing mounting bracket (c) to gauge inside ...

Page 194

Maintenance and servicing form 169017 / 169087 / 169095 192 revision c 7.11.13 circuit breakers and fuses danger stop engine and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine. The circuit breakers and fuses are located in...

Page 195

Maintenance and servicing form 169017 / 169087 / 169095 193 revision c 7.11.13.3 fuse box decal.

Page 196

Maintenance and servicing form 169017 / 169087 / 169095 194 revision c 7.11.13.4 main fuses - 125 amp the 125 amp main fuse holders are located on the frame, under the right cab-forward side platform, beside the battery. Access the fuses as follows: danger stop engine and remove key from ignition be...

Page 197

Maintenance and servicing form 169017 / 169087 / 169095 195 revision c 7.12 hydraulic system the m150 and m200 windrower hydraulic system provides oil for the windrower drive system, and header lift and drive systems. Warning • avoid high pressure fluids. Escaping fluid can penetrate the skin causin...

Page 198

Maintenance and servicing form 169017 / 169087 / 169095 196 revision c 7.12.2 changing hydraulic oil note change hydraulic oil every 2000 hours. A. Stop engine and remove key. B. Open engine compartment hood to highest position. C. Place a suitable container [at least 20 gal. Us (75 litres)] under d...

Page 199

Maintenance and servicing form 169017 / 169087 / 169095 197 revision c 7.12.5 header and reel hydraulics 7.12.5.1 pressure compensator valve the pressure compensator valve is pre-set to be sufficient for all header sizes and options. See table below. When the system operating pressure approaches the...

Page 200

Maintenance and servicing form 169017 / 169087 / 169095 198 revision c 7.12.5.3 header drop rate the header should lower gradually when the lower header switch is pressed. From full height to ground should take approximately 3.5 seconds. Adjust as follows: danger stop engine and remove key from igni...

Page 201

Maintenance and servicing form 169017 / 169087 / 169095 199 revision c 7.12.6 traction drive hydraulics 7.12.6.1 transmission oil pressure the windrower transmission consists of two variable displacement axial piston hydraulic pumps - one for each drive wheel. The pumps are driven through a gearbox ...

Page 202

Maintenance and servicing form 169017 / 169087 / 169095 200 revision c 3. Hold screw (d) with allen wrench (e), and loosen jam-nut (f). 4. Adjust screw as required. 5. Repeat checking and adjustment until relief pressure is correct, then tighten jam-nut (e) while holding screw (d). Replace cap (c). ...

Page 203

Maintenance and servicing form 169017 / 169087 / 169095 201 revision c 7.13 wheels and tires 7.13.1 drive wheels 7.13.1.1 tire inflation a. Visually check daily that tires have not lost pressure. Under-inflation of drive tires can cause sidewall cracks. Danger to avoid severe personal injury or deat...

Page 204

Maintenance and servicing form 169017 / 169087 / 169095 202 revision c 7.13.1.3 lubricant the drive wheel gearbox lubricant should be changed after the first 50 hours. Check the level every 200 hours or annually, and change lubricant every 1000 hours. The windrower should be on level ground when che...

Page 205

Maintenance and servicing form 169017 / 169087 / 169095 203 revision c 7.13.1.4 drive wheel removal/installation danger to avoid severe personal injury or death caused by machine runaway, shut off engine and remove key before performing any of the following checks and/or adjustments. A. Remove heade...

Page 206

Maintenance and servicing form 169017 / 169087 / 169095 204 revision c 7.13.2 caster wheels 7.13.2.1 tire inflation a. Visually check daily that tires have not lost pressure. Under-inflation of drive tires can cause side wall cracks. Danger to avoid severe personal injury or death caused by machine ...

Page 207

Maintenance and servicing form 169017 / 169087 / 169095 205 revision c 7.13.2.2 ballast requirements fluid ballasting of rear caster tires is recommended to provide adequate machine stability when using large headers on the windrower. Also, the stability of machine varies with different attachments,...

Page 208

Maintenance and servicing form 169017 / 169087 / 169095 206 revision c 7.13.2.3 wheel nut torque at first use, or when a wheel is removed, check caster wheel bolt torque as follows after 5 hours, and then at 200 hour intervals: note to avoid damage to wheel rims, do not over-tighten wheel nuts. Fork...

Page 209

Maintenance and servicing form 169017 / 169087 / 169095 207 revision c 7.13.2.5 formed caster wheel removal / installation danger to avoid severe personal injury or death caused by machine runaway, shut off engine and remove key before performing any of the following checks and/or adjustments. A. Re...

Page 210

Maintenance and servicing form 169017 / 169087 / 169095 208 revision c 7.14 maintenance schedule the maintenance schedule (see next page) specifies the periodic maintenance procedures and service intervals. Regular maintenance is the best insurance against early wear and untimely breakdowns. Followi...

Page 211

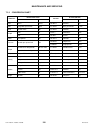

Maintenance and servicing form 169017 / 169087 / 169095 209 revision c 7.14.2 interval maintenance interval service first use refer to break-in inspections (previous page). Annually * 1. Change fuel tank vent line filter. 2. Check battery fluid level. 3. Check battery charge. 4. Check antifreeze con...

Page 212

Maintenance and servicing form 169017 / 169087 / 169095 210 revision c windrower serial number ____________________ combine this record with the record in the header operator’s manual. Refer to section 7 maintenance and servicing for details on each maintenance procedure. Copy this page to continue ...

Page 213

Maintenance and servicing form 169017 / 169087 / 169095 211 revision c action: 9 - check 6 - lubricate s - change - clean + - add ma in ten anc e reco r d hour meter reading date serviced by 500 hours s engine oil and filter (or annually) s fuel filters 9 engine valve tappet clearance (1 st ) (m200 ...

Page 214: 8 Troubleshooting

Troubleshooting * see your macdon dealer ** refer to windrower technical manual form 169017 / 169087 / 169095 212 revision c 8 troubleshooting 8.1 engine symptom problem solution section m150 m200 engine hard to start or will not start. Controls not in neutral. Move gsl to neutral. 6.3.5.1 move stee...

Page 215

Troubleshooting * see your macdon dealer ** refer to windrower technical manual form 169017 / 169087 / 169095 213 revision c symptom problem solution section m150 m200 engine runs irregularly or stalls frequently. Unsteady fuel supply. Change filter on fuel tank vent line. Replace clogged fuel filte...

Page 216

Troubleshooting * see your macdon dealer ** refer to windrower technical manual form 169017 / 169087 / 169095 214 revision c symptom problem solution section m150 m200 high fuel consumption. Improper type of fuel. Use proper fuel. 7.3.1.1 clogged or dirty air cleaner. Service air cleaner. 7.8.5.1 7....

Page 217

Troubleshooting * see your macdon dealer ** refer to windrower technical manual form 169017 / 169087 / 169095 215 revision c 8.2 electrical symptom problem solution section m150 m200 low voltage and/or battery will not charge. Defective battery. Have battery tested. 7.11.1 defective alternator belt....

Page 218

Troubleshooting * see your macdon dealer ** refer to windrower technical manual form 169017 / 169087 / 169095 216 revision c 8.4 header drive symptom problem solution section header drive not engaging. Header drive switch in cab not engaged. Engage switch. 5.17.1 appropriate solenoid not being energ...

Page 219

Troubleshooting * see your macdon dealer ** refer to windrower technical manual form 169017 / 169087 / 169095 217 revision c symptom problem solution section both wheels will not pull in forward or reverse (continued). Charge pressure relief valve misadjusted or damaged. Check the valve adjustment. ...

Page 220

Troubleshooting * see your macdon dealer ** refer to windrower technical manual form 169017 / 169087 / 169095 218 revision c symptom problem solution section steering wheel will not unlock. Transmission interlock cylinder not working. Contact macdon dealer. * steering is too stiff or too loose steer...

Page 221

Troubleshooting * see your macdon dealer ** refer to windrower technical manual form 169017 / 169087 / 169095 219 revision c symptom problem solution section m150 m200 air conditioning not cooling. (continued) expansion valve stuck in open or closed position. Broken refrigerant line. Leak in system....

Page 222

Troubleshooting * see your macdon dealer ** refer to windrower technical manual form 169017 / 169087 / 169095 220 revision c symptom problem solution section air conditioning cools intermittently. Compressor clutch slipping. Contact macdon dealer. * unit icing up due to: adjust thermostat. ** • ther...

Page 223: 9 Options / Attachments

Options / attachments form 169017 / 169087 / 169095 221 revision c 9 options / attachments 9.1 reel drive and lift plumbing reel drive and lift plumbing for draper headers on windrowers that are shipped from the factory in auger header configuration. Installation instructions are included. 9.2 windr...

Page 224

Options / attachments form 169017 / 169087 / 169095 222 model year - 2010 9.17 warning beacons roof mounted rotating warning beacons. Available with installation instructions for installation into pre-wired cab (including switch). The beacons are standard equipment for export windrowers, and optiona...

Page 225

Index form 169017 / 169087 / 169095 223 revision c air cleaner m150, m200 ....................................... 139, 157 air conditioning compressor protection ........................................ 24, 134 condenser......................................................... 133, 177 controls .......

Page 226

Index form 169017 / 169087 / 169095 224 model year - 2010 changing oil ...................................................... 137, 156 exhaust ............................................................. 152, 172 fan belt .............................................................. 153, 174 fuel ...

Page 227

Index form 169017 / 169087 / 169095 225 revision c radio ............................................................................... 26 rear view mirrors ........................................................... 23 reel position switch .............................................................

Page 228

M150 and m200 cdm / wcm fault codes form # 169017 / 169087 / 169095 226 revision c e 1 r a n g e n o t a l l o w e d high range activated while in cab forward (m150). E 2 r t c n o t a l l o w e d return to cut activated with the header off. E 3 s i g n a l s n o t a l l o w e d turn signals activat...

Page 229

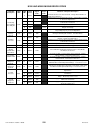

M150 and m200 engine error codes form 169017 / 169087 / 169095 227 revision c example: cdm displays the error code 110s 16f 28c step 1. 110s - s is spn column, then locate code 110 in that column . Step 2. 16f - f is the fmi column, then locate code 16 in that column. Step 3. 28c - c is occurrences,...

Page 230

M150 and m200 engine error codes form # 169017 / 169087 / 169095 228 revision c j1939 spn description j1939 spn j1939 fmi lamp color cummins engine code cat engine code cummins / caterpillar description engine oil pressure 100 1 red 415 360 oil pressure low - data valid but below normal operational ...

Page 231

M150 and m200 engine error codes form 169017 / 169087 / 169095 229 revision c j1939 spn description j1939 spn j1939 fmi lamp color cummins engine code cat engine code cummins / caterpillar description injector metering rail 1 pressure 157 0 red 449 fuel pressure high - data valid but above normal op...

Page 232

M150 and m200 engine error codes form # 169017 / 169087 / 169095 230 revision c j1939 spn description j1939 spn j1939 fmi lamp color cummins engine code cat engine code cummins / caterpillar description 14 red 292 auxiliary temperature sensor input # 1 circuit - special instructions accelerator peda...

Page 233

M150 and m200 engine error codes form 169017 / 169087 / 169095 231 revision c j1939 spn description j1939 spn j1939 fmi lamp color cummins engine code cat engine code cummins / caterpillar description 7 amber 1142 3 injector cylinder #3 - mechanical system not responding properly or out of adjustmen...

Page 234

M150 and m200 engine error codes form # 169017 / 169087 / 169095 232 revision c j1939 spn description j1939 spn j1939 fmi lamp color cummins engine code cat engine code cummins / caterpillar description 4 amber 2374 exhaust gas pressure sensor circuit - voltage below normal, or shorted to low source...