- DL manuals

- Magnum

- Scrubber

- 24'' CYLINDRICAL

- Operating Instructions Manual

Magnum 24'' CYLINDRICAL Operating Instructions Manual

M

AGNUM

Operating Instructions (EN)

MODELS:

26'' DISK

28'' DISK

30'' DISK

34’’ DISK

24’’ CYLINDRICAL

27’’ CYLINDRICAL

30’’ CYLINDRICAL

34’’ CYLINDRICAL

28'' EDGE

32'' EDGE

www.rpscorporation.com

www.factorycat.com

VERSION 13.0530

www.tomcatequip.com

M

AGNUM

-OP-EN

©

2013 RPS Corporation

Read these Instructions before

using the machine.

Read these Safety Messages

before using the machine.

Summary of 24'' CYLINDRICAL

Page 1

M agnum operating instructions (en) models: 26'' disk 28'' disk 30'' disk 34’’ disk 24’’ cylindrical 27’’ cylindrical 30’’ cylindrical 34’’ cylindrical 28'' edge 32'' edge www.Rpscorporation.Com www.Factorycat.Com version 13.0530 www.Tomcatequip.Com m agnum -op-en © 2013 rps corporation read these i...

Page 2

- 2 - m agnum -op-en introduction this manual is furnished with each new machine. This manual will allow the operator to get the best performance out of your rps manufactured scrubber-drier, sweeper, burnisher, or orbital scrubber. Read this manual thoroughly before operating or servicing the machin...

Page 3

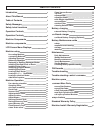

M agnum -op-en - 3 - table of contents introduction 2 about this manual 2 table of contents 3 safety messages 4 safety label locations 6 operation controls 7 operation controls 8 machine components 9 machine components 10 lcd screen menu displays: 11 machine setup 12 un-crating machine: 12 connectin...

Page 4: Danger

- 4 - m agnum -op-en safety messages 9ouwillseefourkindsofsafetyremindersinthismanual danger $!.'%2indicatesahazardoussituationwhichifnot avoided, will result in death or serious injury. Warning 7!2.).'indicatesapotentiallyhazardoussituation which, if not avoided, could result in death or serious in...

Page 5: Warning

M agnum -op-en - 5 - warning the batteries in this machine produce hazardous voltage which can cause electrical shock, burns and/ orelectrocution!Lwaysdisconnect"atteriesbefore servicing this machine. Warning 7henclimbingordescendingrampsalwaysdrive machine forward. To avoid overturning the machine,...

Page 6: Danger

- 6 - m agnum -op-en safety label locations read and obey all safety labels on your m agnum &loor3crubber)fyouhavequestionsabouttheselabelsaskyour supervisor. These images indicate where on the m agnum safety labels are located. If ever the labels become illegible, worn off, or torn, promptly report...

Page 7

M agnum -op-en - 7 - operation controls 1. Spray jet [blue] (optional): !Ctivates7ater0umpforremote3pray7and 2. “on-board” soap system [gray] (optional): dispenses soap directly to the scrubdeck level 3. Econ toggle switch [green] (optional): reduces power to give machine a longer run time 4. Key sw...

Page 8

- 8 - m agnum -op-en operation controls 1. Emergency shut off switch (optional): shuts off the machine in case of an emergency f 2. Hour meter: (ourmetertoindicatecompletetime machine has been on 3. Recharge cycle meter: shows the amount of charges on a machine 4. Manager solution lockout (optional)...

Page 9

M agnum -op-en - 9 - machine components 1. Traction drive: propels machine forward/backward 2. Solution flow valve: #ontrolssolutionmowrate 3. Solution filter: &ilterswatersolutionpriortoscrub - bing 4. Drive button: depress to drive forward - release to stop (this starts and stops the drive motor) ...

Page 10

- 10 - m agnum -op-en machine components 1. Control panel: machine controls and access to electrical components 2. “on-board” battery charger: recharges batteries 3. Squeegee blade: 2ecoversdirtywaterfromthemoortoberecoveredby6acuum (ose 4. Vacuum hose: creates vacuum for squeegee (note: keep free a...

Page 11

M agnum -op-en - 11 - lcd screen menu displays: ** use green menu selection button on control panel to change screens ** 1. Battery level indicator - indicates the energy level remaining in the batteries (shown on all menu displays) 2. Scrubdeck down pressure gauge - sets the down pressure on the br...

Page 12: Notice

- 12 - m agnum -op-en machine setup un-crating machine: carefully check the crate for any signs of damage and that the batteries are in the unit. To un-crate the machine, remove banding strips from around the crate. Take off the top and sides and dispose properly. Remove brackets from machine wheels...

Page 13: Notice

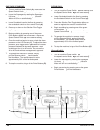

M agnum -op-en - 13 - adjusting squeegee: 1. Turning adjustment knob (a) clockwise ) (tightening) will ) lower tips and raise the center of the squeegee (see below) . 2. This squeegee is adjusted too far back and will not pick up on the corners (see below) . Note: tips off of the floor. 3. This squee...

Page 14

- 14 - m agnum -op-en installing disk pad driver or brush: 1. Turn on machine power. 2. Raise the scrubdeck by depressing the brush switch to the up and off position and turn the machine f power back off 2emove+ey f f 3. )fthemachineisequippedwith*awsremovepin (a) and undo latch (b) onfrontof*awstoo...

Page 15: Caution

M agnum -op-en - 15 - installing cylindrical brush: 1. Turn on machine power. 2. Raise the scrubdeck by depressing the brush switch to the up and off position and turn machine power f backoff2emove+ey caution disconnect the batteries. 3. Remove side access door on each side of the scrub- deck by dep...

Page 16: Notice

- 16 - m agnum -op-en installing edge pads: 1. Turn on machine power. 2. Raise the scrubdeck by depressing the brush switch tothe50and off position and turn machine power f back off. 3. Select the correct pads that best meet your cleaning application. Consult your local dealer for assistance. 4. 2em...

Page 17: Notice

M agnum -op-en - 17 - leveling p ro p olish disk decks: notice !Ll3crubdecksshouldbelevelattimeofmachine delivery. If machine scrubdeck is not level - contact your servicing dealer. 1. $rivemachinetoamatlevelsurfaceandturnmachine off. 2. Ensure that scrubdeck is in full upright position. 3. 4urnonma...

Page 18

- 18 - m agnum -op-en side broom system: 1. 9ourmachinemaycomeequippedwiththe optional side broom system (see below) . 2. &lip3ide"roomswitch (yellow toggle on the left side of the control panel) to engage broom. ) 3. To adjust the side broom height, turn adjustment screws (a) clockwise to raise and...

Page 19: Notice

M agnum -op-en - 19 - machine operation pre-cleaning checklist: read and understand the safety messages section on pages 3 and 4 before operating the machine. 1. #heck"attery#ondition'augeonthe#ontrol0anel make sure batteries are fully charged before using. 2. Check the condition of the pads or brus...

Page 20

- 20 - m agnum -op-en one pass scrubbing: 1. Turn on machine power switch (a) , make sure the 3peed#ontrol+nob (b) is at a lower setting. ) 2. Lower the squeegee by rotating the squeegee lift lever (c) all the way to the right ) (vacuum motor will turn on automatically) . 3. ,ower3crubdeckheadtothem...

Page 21: Notice

M agnum -op-en - 21 - adjust solution flow: 1. 0ush50 onthe3olution&low4oggle (a) to ) increasethesolutionmowandpush$/7. Onthe toggletodecreasesolutionmow (see below) . Adjust curtains: 1. &or*awcurtainsrelease*awlatch (b) and remove ) *aw0in (c) onthefrontofthe*awstoopenthem ) (see below) . 2. Loos...

Page 22: Notice

- 22 - m agnum -op-en open recovery lid: 1. Release both latches (a) on recovery ) tank lid (see below) . 2. Rotate lid fully open. Flush recovery tank: 1. Rinse the recovery tank after every use (b) . This will prevent heavy build-up on the bottom of the tank, foul odors as well as cloggingofthe$ra...

Page 23: Caution

M agnum -op-en - 23 - tip tank: 1. &ullydrain3olution4ankandthe2ecovery4ank 2. Remove squeegee. 3. 5nlatch4ank,atch (a) on each side ) of the machine (see below) . Caution casters need to be swiveled back (b) as shown, other ) - wise machine will tip. 4. /pen*aws (see below) . 5. Tip tank back caref...

Page 24

- 24 - m agnum -op-en deck height adjustment: 1. To adjust deck height for brush clearance, loosen jam nut on adjustment bolt (a) , turn adjustment bolt clockwise to raise scrubdeck - counterclockwise to lower scrubdeck. Retighten jam nut (see below) . Vacuum motor: 1. The machine is equipped with a...

Page 25: Danger

M agnum -op-en - 25 - battery charging charger specifications s output voltage of 24 volts s output current of 18 amps max (optional) s )nputvoltageof6olts(z (220v/50 hz available) s !Utomaticshutoffcircuit s made for deep cycle batteries danger explosive hydrogen gas forms when batteries are chargin...

Page 26: Danger

- 26 - m agnum -op-en on-board charger charger specifications s output voltage of 24 volts s output current of 12 amps max s )nputvoltageof6olts(z (220v/50 hz available) s !Utomaticshutoffcircuit s made for deep cycle batteries danger explosive hydrogen gas forms when batteries are charging!Nopenmame...

Page 27: Danger

M agnum -op-en - 27 - battery maintenance guide safety: danger explosive hydrogen gas forms when batteries are charging!Nopenmameorsparkcancausethisgas to explode. Serious personal injury or property damage could occur. Only charge the batteries in this machine in a well ventilated area. Warning bef...

Page 28: Notice

- 28 - m agnum -op-en maintenance daily maintenance: 1. Remove the clean pads or brushes. Never use soiled pads when cleaning. Replace pads when they become packed with residue. 2. 2emoveandcleandebrisfromthemoatshutoffscreen and drain saver located inside the recovery tank. 3. $rainandrinse4ankstho...

Page 29

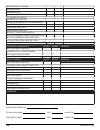

M agnum -op-en - 29 - pm records #534/-%2).&/2-!4)/. #534/-%2 %-!), !$$2%33 0(/.% #)49 34!4% zip #/.4!#4 -!#().%).&/2-!4)/. -/$%, 3%2)!, 7/2+/2$%2 (/52-%4%2+ey #(!33)3(/52-%4%2 (/52-%4%24raction 2%#(!2'%.5-"%2 (/52-%4%23crub )3/,!4/2(/52-%4%2 2%#(!2'%#/5.4%2 note: )solatorsneedtobereplacedon3crubber...

Page 30

- 30 - m agnum -op-en "253($%#+,)&43934%- "253(-/4/23 6!#55-37)4#( 6!#55--/4/20%2&/2-!.#% /&&"/!2$6!#37)4#( 315%%'%%,)&43934%- 315%%'%%!$*534-%.40)4#(!.$(%)'(4 315%%'%%",!$%3 $2!).(/3%!.$0,5' 3)$%"2//-/0%2!4)/. 302!9*%405-0(/3%./::,% "!44%29#(!2'%2#/..%#4)/.&5.#4)/. 0)4#(/&3#25"$%#+-534"%,%6%, 0)4#(...

Page 31

M agnum -op-en - 31 - trouble-shooting problem cause solution ./0/7%2./4().'/0%2!4%3 &!5,490/7%237)4#( #/.4!#4,/#!,3%26)#).'$%!,%2 "!44%2)%3.%%$#(!2').' 3%%#(!2').'"!44%2)%3 &!5,49"!44%2)%3 2%0,!#%"!44%29 ,//3%"!44%29#!",% 4)'(4%.,//3%#!",% -!).#)2#5)4"2%!+%242)00%$ 7!)4-).54%3&/2!54/2%3%4 $%4%2-).%...

Page 32

- 32 - m agnum -op-en problem cause solution 0//27!4%22%#/6%2/.452.3 7)0%237/2. 2%0,!#%7)0%2-!4%2)!, 7)0%23#(!44%2 4)'(4%.0)6/40/).43 315%%'%%37).')3").$).' #/.4!#4,/#!,3%26)#).'$%!,%2 ).#/22%#4315%%'%%3):% #/.4!#4,/#!,3%26)#).'$%!,%2 4)2%3./)39 "%!2).'$29 '2%!3%"%!2).'3 &!5,49(5"3 #/.4!#4,/#!,3%26)...

Page 33

M agnum -op-en - 33 - trouble-shooting central command note: this machine is operated by a sophisticated electronic “controller” that has many fail safes within it. It self-analyzes problems and flashes a four-digit alpha-numeric code of what is wrong in the lcd window. -ostofthesecodesrequireatechni...

Page 34

- 34 - m agnum -op-en 5. 7700: vacuum motor circuit is open. 6. Throttle error: 9oupressedthefootpedalbeforeturning on the key. Turn off the key and try again, leaving foot off of the f pedal. 7. 2c00 and 2c01 error: low voltage warning. Voltage has dropped down below the minimum required to operate...

Page 35

M agnum -op-en - 35 - machine specs body construction/dimensions m agnum 4!.+-!4%2)!, 0/,9 7 ⁄ 7 16 ⁄ ⁄ '') (1.11 cm) #(!33)3#/.3425#4)/. 3 ⁄ 3 16 ⁄ ⁄ '' steel (.2 cm) &2/.47(%%,3 (2 × ) 12'' ¨ 3.5'' [(2 × ) 30.5 ¨ 8.9 cm] 2%!2#!34%23 (2 × ) 5'' ¨ 2'' [(2 × ) 12.7 × 5 cm] 3):%,¾7¾( 56'' ¨ 24'' ¨ 43'...

Page 36: Notice

- 36 - m agnum -op-en common wear parts round disk brushes: brushes model 26'' disk model 28'' disk model 30'' disk model 34'' disk super grit 13-421ss 14-421ss 15-421ss 17-421ss tough grit 13-421s 14-421s 15-421s 17-421s midi grit 13-421c 14-421c 15-421c 17-421c light grit 13-421ps 14-421ps 15-421p...

Page 37: Notice

M agnum -op-en - 37 - remover burnishing pad %$'% %$'% porko burnishing pad %$'% .! Velcro pad 300-4024 .! New style cylindrical brushes: &or-achine3erial'reater brushes model 24'' cylindrical model 27'' cylindrical model 30'' cylindrical model 34'' cylindrical 3uper'rit .! .! .! .! 4ough'rit 225-82...

Page 38

- 38 - m agnum -op-en soap choices traditional drums / totes wall-mounted supercon demo / rental quarts onboard auto dispensing !(&'%." %.!)%"! !',.

Page 39

M agnum -op-en - 39 - powercat p.O. Box 503 racine, wi 53404-0503 phone: 414-745-9337 fax: 262-632-1630 www.Powercatsolutions.Com distributed by: powercat, llc, 2008. An environmentally cleaner that works! It is a solvent free degreaser that works on oil, carbon, even rubber marks. Incorporates the ...

Page 40

- 40 - m agnum -op-en standard warranty policy rps corporation warrants its machines, parts and accessories to be free of manufacturer’s defects for the periods speci- ledbelow7arrantywillbegrantedatthesolediscretionof203#orporationandissubjecttolnalclaimandpartsreview by203#orporationanditsvendors4...

Page 41

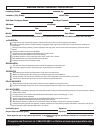

M agnum -op-en - 41 - machine install / warranty registration installing dealer: installed by: location: (city, state): install date: end-user company name: end-user contact: address: city/state: zip: phone: fax: email: model: serial #: hour meter: buyer’s representative has received instruction in ...

Page 43

© rps corporation 2013 1711 south street 2acine7) www.Rpscorporation.Com www.Factorycat.Com www.Tomcatequip.Com 4el53 tel. Int: (011) 262-681-3583 &ax.