Magnum 6500 Owner's Manual

MAGNUM 6500

®

/ 7500

®

CORN/WOOD PELLET FURNACE

THIS APPLIANCE HAS BEEN TESTED AND APPROVED TO CSA B 366.1-M91-CAN/USA & UL 391-99

WARNING: THIS INSTRUCTION MANUAL MUST BE SAVED FOR FUTURE REFERENCE

PLEASE READ THIS ENTIRE MANUAL BEFORE INSTALLATION AND USE OF THIS CORN/WOOD PELLET

BURNING FURNACE. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN PROPERTY

DAMAGE, BODILY INJURY OR EVEN DEATH.

REFER TO ADDITIONAL MARKINGS ON APPLIANCE FOR ADDITIONAL INSTRUCTIONS

IMPORTANT: Always contact your local dealer/installer with questions before contacting the factory.

When you call have your serial number, purchase date, who installed the unit and a list of questions.

This appliance must be installed by a HVAC licensed/trained factory approved installer

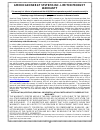

AMERICAN ENERGY SYSTEMS, INC. GRANTS NO WARRANTY, IMPLIED OR STATED, FOR THE

INSTALLATION OR MAINTENANCE OF THE STOVE AND ASSUMES NO RESPONSIBILITY FOR ANY

CONSEQUENTIAL DAMAGE(S).

Disclaimer Notice: No guarantee is made regarding the heating capacity of this unit. The actual area that this unit will heat depends on

factors such as fuel quality, fuel moisture, installation configuration, venting and fresh air configuration, operational practices, conditions of

the building, heat loss, type of construction, amount and type of insulation, type of air movement, and the location of the Furnace.

AMERICAN ENERGY SYSTEMS, INC. -150 Michigan Street SE - HUTCHINSON, MINNESOTA 55350

Web Site:

www.magnumheat.com

Rev. date 11/01/11

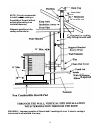

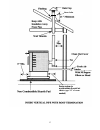

When installing your Magnum 6500/7500 Corn/Wood Pellet Furnace, particular attention needs to be

made in regards to fire protection. If the unit is not properly installed, a house fire may result. For your

safety, follow the installation and operation instructions provided, and if a question arises contact local

building or fire officials about restrictions and installation requirements in your area.

Read the operations and fuel section of this manual before plugging in your unit.

Always unplug the unit before attempting any service work.

Do not connect the unit to a chimney flue already serving another appliance.

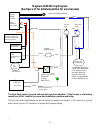

When installing the chimney pipe to the unit, it is important to remember that the unit operates on a

negative pressure and the chimney on a positive pressure. All chimney connections, elbows and fittings

must be airtight. (proper venting practices must be followed. Consult with a venting professional)

Ashes must be disposed of in a metal container with a tight fitting lid. Do not let ashes build up in ashpan.

All minimum clearances to combustibles must be followed. Ductwork clearances must be maintained.

The Magnum 6500/7500 Corn/Wood Pellet Furnace is tested for operation with 14% or less moisture

corn or with wood pellets with an ash content of no more than 3%. It is recommended that Corn with

11-12% moisture or wood pellets with an ash content of 1% or less be used for efficient operation of

this unit. Corn over 12% moisture has a lower BTU value and will be hard to burn on the lower

settings. Fuel over 12% moisture will dramatically reduce the heating ability of this appliance.

It is important to use fuel that is clean, dry and consistent. Make sure that your supplier is giving you

the same fuel each time that you purchase. It is recommended that you purchase your entire heating season

supply of fuel at one time so that the fuel will be the same.

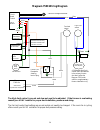

A voltage surge protector or ground fault outlet is required for this unit. The warranty on the

circuit board will be voided if proper surge protection is not installed before operating this unit

Proper voltage, polarity and grounding must be assured for appliance to operate correctly. Consult

with your electrician before operating this appliance to assure electrical is proper.

OWNER’S MANUAL

Installation – Operation – Maintenance Instructions