- DL manuals

- Main

- Boiler

- Combi 25 Eco Elite

- Installation & Service Instructions Manual

Main Combi 25 Eco Elite Installation & Service Instructions Manual

Summary of Combi 25 Eco Elite

Page 1

© baxi heating uk ltd 2014 installation & service instructions combi eco elite range these instructions include the benchmark commissioning checklist and should be left with the user for safe keeping..

Page 2

2 © baxi heating uk ltd 2014 natural gas main combi 25 eco elite g.C.N o 47 467 08 main combi 30 eco elite g.C.N o 47 467 09 building regulations and the benchmark commissioning checklist building regulations (england & wales) require notification of the installation of a heating appliance to the re...

Page 3

3 installer notification guidelines © baxi heating uk ltd 2014 choose building regulations notification route contact your relevant local authority building control (labc) who will arrange an inspection or contact a government approved inspector labc will record the data and will issue a certificate...

Page 4

4 legislation © baxi heating uk ltd 2014 codes of practice - refer to the most recent version important - installation, commissioning, service & repair this appliance must be installed in accordance with the manufacturer’s instructions and the regulations in force. Read the instructions fully before...

Page 5

5 safe manual handling © baxi heating uk ltd 2014 general the following advice should be adhered to, from when first handling the boiler to the final stages of installation, and also during maintenance. Most injuries as a result of inappropriate handling and lifting are to the back, but all other pa...

Page 6

6 © baxi heating uk ltd 2014 contents 1.0 introduction 7 2.0 general layout 8 3.0 appliance operation 9 4.0 technical data 10 5.0 dimensions and fixings 11 6.0 system details 12 7.0 site requirements 15 8.0 flue options 20 9.0 plume displacement 25 10.0 installation 29 11.0 commissioning 34 12.0 com...

Page 7

7 1.0 introduction © baxi heating uk ltd 2014 1.1 description 1. The main combi eco elite is a fully automatic gas fired wall mounted condensing combination boiler. It is room sealed and fan assisted, and will serve central heating and mains fed domestic hot water. 2. The boiler is set to give a max...

Page 8

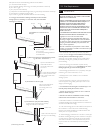

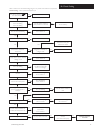

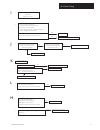

8 2.0 general layout © baxi heating uk ltd 2014 2.1 layout 1. Expansion vessel 2. Automatic air vent 3. Dhw plate heat exchanger 4. Circulation pump 5. Drain off point 6. Pressure relief valve 7. Selector switch 8. Central heating system pressure gauge 9. Pcb 10. Control box 11. 3-way valve assembly...

Page 9

9 3.0 appliance operation © baxi heating uk ltd 2014 3.1 central heating mode (fig. 2) 1. With a demand for heating, the pump circulates water through the primary circuit. 2. Once main burner ignites the fan speed controls the gas rate to maintain the heating temperature measured by the temperature ...

Page 10

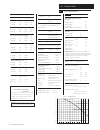

10 4.0 technical data © baxi heating uk ltd 2014 4.1 combi 25 & 30 eco elite flue terminal diameter 100mm dimensions projection 125mm outercase dimensions casing height - 780mm overall height inc flue elbow - 965mm casing width - 450mm casing depth - 345mm weights packaged boiler carton 54.7 kg inst...

Page 11

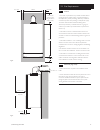

11 5.0 dimensions and fixings © baxi heating uk ltd 2014 dimensions a 780mm b 345mm c 450mm d 116mm Ø min. F 145mm g 132mm 210mm (80/125) h 225mm domestic hot water outlet (15mm) cold water inlet (15mm) heating return (22mm) heating flow (22mm) pressure relief valve (15mm) gas inlet (22mm) 65 mm 65 ...

Page 12

12 6.0 system details © baxi heating uk ltd 2014 6.1 information 1. The main combi eco elite condensing combination boiler is a ‘water byelaws scheme - approved product’. To comply with the water byelaws your attention is drawn to the following installation requirements and notes (irn). A) irn 001 -...

Page 13

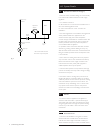

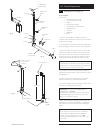

13 6.0 system details © baxi heating uk ltd 2014 6.5 system filling and pressurising (fig. 4) 1. A filling point connection on the central heating return pipework must be provided to facilitate initial filling and pressurising and also any subsequent water loss replacement/refilling. 2. A filling lo...

Page 14

14 6.0 system details © baxi heating uk ltd 2014 boiler other tap outlets expansion vessel* to hot taps check valve* pressure reducer valve* stop tap fig. 7 6.8 domestic hot water circuit (fig. 7) 1. All dhw circuits, connections, fittings, etc. Should be fully in accordance with relevant standards ...

Page 15

15 7.0 site requirements © baxi heating uk ltd 2014 7.1 location 1. The boiler may be fitted to any suitable wall with the flue passing through an outside wall or roof and discharging to atmosphere in a position permitting satisfactory removal of combustion products and providing an adequate air sup...

Page 16

16 7.0 site requirement © baxi heating uk ltd 2014 7.3 ventilation of compartments 1. Where the appliance is installed in a cupboard or compartment, no air vents are required. 2. Bs 5440: part 2 refers to room sealed appliances installed in compartments. The appliance will run sufficiently cool with...

Page 17

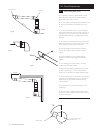

17 © baxi heating uk ltd 2014 7.0 site requirements 7.7 condensate drain failure to install the condensate discharge pipework correctly will affect the reliable operation of the boiler. Careful consideration must be given to the possibility of the pipework being subject to freezing conditions and ap...

Page 18

© baxi heating uk ltd 2014 7.0 site requirements 7.7 condensate drain (cont.) 12. A boiler discharge pump is available, ‘multifit’ part no. 720648301. This pump will dispose of both condensate & high temperature water from the relief valve. It has a maximum head of 5 metres. Follow the instructions ...

Page 19

19 7.0 site requirements © baxi heating uk ltd 2014 7.8 flue (figs. 17 & 18) note: due to the nature of the boiler a plume of water vapour will be discharged from the flue. This should be taken into account when siting the flue terminal. 1. The following guidelines indicate the general requirements ...

Page 20

20 8.0 flue options © baxi heating uk ltd 2014 8.1 horizontal flue systems 1. The standard flue is suitable only for horizontal termination applications. 2. Maximum permissible equivalent flue lengths are:- (60/100) (80/125) horizontal concentric 10 metres 20 metres 3. Any additional “in line” bends...

Page 21

21 8.0 flue options © baxi heating uk ltd 2014 vertical flues vertical flues (twin pipe) (ii) (i) (ii) (i) 8.2 twin & vertical flue systems 1. Maximum permissible equivalent flue lengths are:- (60/100) (80/125) vertical concentric 10 metres 20 metres twin pipe 20 metres 3. Any additional “in line” b...

Page 22

22 8.0 flue options © baxi heating uk ltd 2014 a b k,k1 r d c n u,w s l h j m e g f p 8.3 flue accessories a2 a3 a4 y,z key accessory size code no flue group a concentric flue system 100mm diameter a3 telescopic internal flue kit 315-500mm 5119654 a2 telescopic flue (incl elbow) 5118069 a horizontal...

Page 23

23 8.0 flue options © baxi heating uk ltd 2014 8.4 twin flue duct adaptor 1. The kit allows connection of a twin flue system to the boiler adaptor. 8.5 twin flue connection 1. Engage the twin flue duct adaptor in the boiler adaptor, making sure that it is pushed down as far as possible. 2. Ensure th...

Page 24

24 8.0 flue options © baxi heating uk ltd 2014 fig. 19 100mm 685mm 8.6 for roof terminals 1. In the case of a pitched roof 25 - 50 degrees, position the lead tile to replace/flash over existing roof tiling. Make an aperture in the roof suitable for the lower tube of the roof terminal and ensure the ...

Page 25

25 9.0 plume displacement © baxi heating uk ltd 2014 9.1 plume displacement kit (fig. 23) kit no 5118638 content of kit 1 0.9m 60/100 concentric flue 1 1m 60 dia exhaust flue pipe 1 adaptor 2 60 dia support brackets 1 93° elbow/plume outlet assembly 1 flexible flue trim 3 “o” rings 1 ‘jubilee clip 1...

Page 26

26 9.0 plume displacement © baxi heating uk ltd 2014 concentric 60/100 flue 60Ø exhaust x y fig. 26 2 0 2 4 6 8 10 12 14 60 Ø exhaust (metr es) x concentric 60/100 flue (metres) y 0 16 1 3 4 6 5 7 9 8 25 30 fig. 27 2 0 2 4 6 8 10 12 14 60 Ø exhaust (metr es) x concentric 60/100 flue (metres) y 0 16 ...

Page 27

27 9.0 plume displacement © baxi heating uk ltd 2014 min. 2 metres fig. 28 50mm flue trim position of ‘jubilee’ clip screw fig. 33 30mm 30mm fig. 30 fig. 32 fig. 29 fig. 31 adaptor spigot 9.3 general fitting notes 1. Cut a hole in the external wall which the concentric flue assembly will pass throug...

Page 28

28 9.0 plume displacement © baxi heating uk ltd 2014 9.3 general fitting notes (cont.) 15. For aesthetic purposes it is permissible to route the 60Ø exhaust in an enclosed box, but the air inlet and plume outlet must remain in free air. 16. It is also possible to separate the plume outlet from the 9...

Page 29

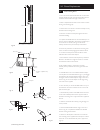

29 10.0 installation © baxi heating uk ltd 2014 10.1 unpacking & initial preparation the gas supply, gas type and pressure must be checked for suitability before connection (see section 7.4). 1. Remove staples, open flaps and remove cardboard sheet. Remove the polystyrene side pieces and literature....

Page 30

30 10.0 installation © baxi heating uk ltd 2014 10.3 fitting the boiler 1. Lift the boiler using the lifting points as shown by the shaded areas (fig. 43) the boiler should be lifted by two people. Engage the slots at the top rear of the boiler on the wall plate (fig. 43) (see safe manual handling p...

Page 31

31 10.0 installation © baxi heating uk ltd 2014 10.6 fitting the flue horizontal flue 1. The standard flue is suitable for lengths between 100mm minimum and 685mm maximum, as measured from the edge of the flue elbow outlet to the joint between the terminal and air duct (fig. 45). 2. Locate the flue ...

Page 32

32 10.0 installation © baxi heating uk ltd 2014 10.6 fitting the flue (cont) 6. The inner flue duct support bracket may be in the waste portion of the flue. In this case retrieve the bracket before discarding the waste. 7. Take the inner flue support bracket (if not already fitted) and engage it ove...

Page 33

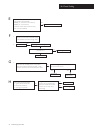

33 10.0 installation © baxi heating uk ltd 2014 fig. 56 fig. 55 cable clamp facia panel terminal block cover b br bk bk g/y 1 n l 2 n n l room ‘stat fused spur 230v fig. 57 b br bk bk g/y 1 n l frost thermostat external clock 2 n n l room ‘stat fused spur 230v 230v note: the 230v switched signal for...

Page 34

34 11.0 commissioning © baxi heating uk ltd 2014 11.1 commissioning the boiler 1. Reference should be made to bs:en 12828 & 14336 when commissioning the boiler. 2. At the time of commissioning, complete all relevant sections of the benchmark checklist at the rear of this publications. 3. Open the ma...

Page 35

35 11.0 commissioning © baxi heating uk ltd 2014 set boiler to maximum rate (see 11.1.11) allow the combustion to stabilise. Do not insert probe to avoid ‘flooding’ the analyser. Perform flue integrity combustion check insert the analyser probe into the air inlet test point, allowing the reading to ...

Page 36

36 11.0 commissioning © baxi heating uk ltd 2014 11.3 check the operational (working) gas inlet pressure 1. Ensure that all controls are calling for heat, and the selector switch is in the central heating and hot water position ( ). The current boiler temperature is shown on the display. 2. It is ne...

Page 37

37 12.0 completion © baxi heating uk ltd 2014 12.1 completion 1. Instruct the user in the operation of the boiler and system including the integral timer, explaining the operational sequence. 2. Set the central heating and hot water temperature control knobs to the requirements of the user. 3. Caref...

Page 38

38 13.0 servicing © baxi heating uk ltd 2014 case front panel fig. 69 facia panel securing screws fig. 70 inner door panel fig. 71 condensate trap sump 13 .1 annual servicing 1. For reasons of safety and economy, it is recommended that the boiler is serviced annually. Servicing must be performed by ...

Page 39

39 13.0 servicing © baxi heating uk ltd 2014 13.2 annual servicing - inspection (cont) 6. Undo the nut on the gas pipe at the gas/air inlet (fig. 72) and the gas valve. Remove the pipe, taking care not to lose the sealing washers. Also remove the injector. 7. Disconnect the electrode lead caps, remo...

Page 40

40 14.0 changing components © baxi heating uk ltd 2014 important: when changing components ensure that both the gas and electrical supplies to the boiler are isolated before any work is started. When the component has been changed turn the selector switch fully anticlockwise against the spring press...

Page 41

41 14.0 changing components © baxi heating uk ltd 2014 14.3 fan 1. Undo the nut on the gas pipe at the gas/air inlet (fig. 79) and the gas valve. Remove the pipe, taking care not to lose the sealing washers. Also remove the injector. 2. Disconnect the electrode lead caps, remove the strain relief cl...

Page 42

42 14.0 changing components © baxi heating uk ltd 2014 14.5 burner (fig. 82) 1. Undo the nut on the gas pipe at the gas/air inlet and the gas valve. Remove the pipe, taking care not to lose the sealing washers. Also remove the injector. 2. Disconnect the electrode lead caps, remove the strain relief...

Page 43

43 14.0 changing components © baxi heating uk ltd 2014 14.7 safety thermostat (fig. 65) 1. Pull the plug off the thermostat. 2. Remove the screws securing the thermostat to the mounting plate on the flow pipe. 3. Reassemble in reverse order, ensuring that the plug is pushed fully on. 14.8 central he...

Page 44

44 14.0 changing components © baxi heating uk ltd 2014 14.11 heat exchanger automatic air vent (fig. 86 ) 1. Drain the boiler primary circuit and unscrew the automatic air vent from the pump body. 2. Examine the ‘o’ ring seal, replacing if necessary, and fit it to the new automatic air vent. 3. Reas...

Page 45

45 14.0 changing components © baxi heating uk ltd 2014 14.15 pressure gauge (figs. 90 & 91) 1. Drain the boiler primary circuit and undo the nut on the pressure gauge capillary. 2. Undo the screws securing the gauge retaining bracket. 3. Remove the bracket and gauge assembly. Depress the barbs on th...

Page 46

46 14.0 changing components © baxi heating uk ltd 2014 14.18 plate heat exchanger (fig. 94) 1. Drain the boiler primary circuit and remove the gas valve as described in section 14.22. 2. While supporting the heat exchanger undo the screws securing it to the brass manifolds. 3. Withdraw the heat exch...

Page 47

47 14.0 changing components © baxi heating uk ltd 2014 14.20 p.C.B. (figs. 97 & 98) 1. Note the settings of the temperature control knobs, rotate them fully anticlockwise and carefully pull them off the drive pins. 2. Completely undo the screws securing the control box cover and release the cover re...

Page 48

48 14.0 changing components © baxi heating uk ltd 2014 14.22 gas valve (fig. 99) important: after replacing the valve the co 2 must be checked and adjusted as detailed in section 15.0 setting the gas valve. Only change the valve if a suitable calibrated combustion analyser is available, operated by ...

Page 49

49 15.0 setting the gas valve © baxi heating uk ltd 2014 15.1 setting the gas valve (co 2 check) important: the co 2 must be only be checked and adjusted to set the valve if a suitable calibrated combustion analyser is available, operated by a competent person - see section 13.1 1. The combustion (c...

Page 50

50 16.0 electrical © baxi heating uk ltd 2014 - brown - black - blue - white br bk b w - green - green / yellow - red g g/y r control pcb x2 x3 x9 x501 1 2 1 2 3 3 4 4 5 5 6 7 8 9 x1 1 2 dhw ntc sensor central heating ntc sensor fan gas valve overheat stat pump x400 x401 g g b b r r b b bk br b g b ...

Page 51

51 17.0 short parts list © baxi heating uk ltd 2014 short parts list key g.C. Description manufacturers no. No. Part no. 326 fan 5121447 426 motor 3 way valve 5132452 320 electrode assembly 5130293 422 gas valve 720301001 404 hall effect sensor 5114767 313 burner 5130292 419 water pressure switch 51...

Page 52

52 18.0 fault finding © baxi heating uk ltd 2014 note: when instructed to turn the selector to the reset position turn the selector switch fully anticlockwise against the spring pressure to the reset position and hold for 5 seconds to reset the boiler. 18.1 initial fault finding checks 1. Check that...

Page 53

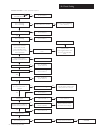

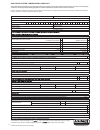

53 18.0 fault finding © baxi heating uk ltd 2014 refer to section 16.0 “illustrated wiring diagram” for position of terminals and components central heating - follow operational sequence (do turn selector switch to the display illuminates error 20, 28 or 50 flashing error 119 flashing burner lights ...

Page 54

54 18.0 fault finding © baxi heating uk ltd 2014 turn selector switch to the display illuminates error 20, 28 or 50 flashing error 119 flashing burner lights error 110 flashing error 133 flashing turn domestic hot water thermostat to maximum. Open dhw tap fully. Dhw hall effect sensor operated (red ...

Page 55

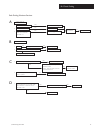

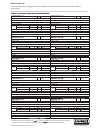

55 18.0 fault finding © baxi heating uk ltd 2014 fault finding solutions sections is there 230v at: is there 230v at: main terminals l and n check electrical supply 1. No main terminal fuse replace fuse replace pcb display illuminated 2. No pcb - x1 connector terminals 1,2 check wiring 3. No no a pu...

Page 56

56 18.0 fault finding © baxi heating uk ltd 2014 e20 or e50 - temperature sensors faulty. Cold resistance approximately 10kΩ @ 25° c (dhw and ch sensors) 20kΩ @ 25° c (flue sensor) (resistance reduces with increase in temp.) e28 - incorrect pcb fitted no e replace sensor or pcb (e28) gas at burner e...

Page 57

57 © baxi heating uk ltd 2014 18.0 fault finding check and correct if necessary 1. The mechanical set of the gas valve (co2 values - see instruction) 2. Flame sensing electrode and lead connections 3. Flame sensing electrode position flame current should be more than 0.5 μ a replace pcb replace pcb ...

Page 58

*all installations in england and wales must be to local authority building control (labc) either directly or through a competent persons scheme. A building regulations compliance will then be issued to the customer. Www.Centralheating.Co.Uk © heating and hotwater industry council (hhic) this commis...

Page 59

Www.Centralheating.Co.Uk it is recommended that your heating system is serviced regularly and that the appropriate service interval record is completed. Service provider before completing the appropriate service record below, please ensure you have carried out the service as described in the manufac...

Page 60

© baxi heating uk ltd 2014 comp n o 7210839 - 04 (3/14) main a trading division of baxi heating uk ltd (3879156) brooks house, coventry road, warwick. Cv34 4ll after sales service 0844 871 1570 technical enquiries 0844 871 1555 website www.Mainheating.Co.Uk e&oe all descriptions and illustrations pr...