- DL manuals

- Nanni

- Engine

- N2.14

- Instruction Manual

Nanni N2.14 Instruction Manual

Summary of N2.14

Page 1

Instruction manual marine diesel engine n3.21 13122011-d mu_n3.21_970313240_eng.

Page 2

2 engine specifications n3.21 cycle 4 strokes, diesel max. Power - kw (hp)* 15,4 (21) number of cylinders / arrangement 3 in line displacement (cm3) 719 fuel timing before tdc (°) 20 to 22 compression rate 23:1 aspiration atmospheric bore x stroke (mm) 67 x 68 maximum rpm speed at full throttle (rpm...

Page 3

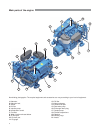

3 1. Alternator 2. Alternator belt 3. Starter 4. Air fi lter 5. Injection pump 6. Acceleration control 7. Fuel fi lter 8. Water injection exhaust elbow 9. Oil fi ller port 10. Oil drain port 11. Oil gauge 12. Oil fi lter 13. Heat exchanger 14. Coolant fi ller port 15. Sea-water pump 16. Exchanger dr...

Page 4

4 oil level i warning !: the oil checks must always be performed with the engine stopped and cold. Be careful, these fl uids are fl ammable. Do not smoke in the vicinity of these fl uids and do not allow for any sparks or fl ame in the vicinity. A. Oil gauge b. Oil fi ller port engine casing oil: re...

Page 5

Inspection and adjustment of the levels bleeding the fuel system the fuel system is self-priming but it needs to be manually bled when the fi lter is changed, after it runs out of fuel or after work on the system if it has run dry or it has been emptied. • open the fuel valve • place a container ben...

Page 6

Inspection and adjustment of the levels 6 alternator belt i warning !: perform this operation with the engine stopped. A. Alternator b. Alternator belt regularly check the tensions of the alternator belt. Tension the belt between the pulleys in accordance with the tension or defl ection given in the...

Page 7

Inspection and adjustment of the levels coolant level i warning !: when fi lling the cooling system, the coolant level must be checked after 10 minutes of use since the system purges itself automatically. Top up if necessary. A. Coolant plug b. Expansion tank turn the fi ller plug up to its fi rst s...

Page 8

8 8 i warning! : your engine must be installed by an authorised shipyard or a qualifi ed nanni industries representative in accordance with the on board assembly instructions. However, you can check some important points on the installation of the engine. However, your installation can be different ...

Page 9

9 installation inspection fuel supply system the fuel tank of the engine must be placed as possible at the same level or slightly higher than the engine. The return pipe must be placed under the mini level of the fuel tank. The max height between the fuel pump and the mini level of the tank is indic...

Page 10

10 10 the instrument panel provides you with important information on the engine when it is in operation. Regularly check this information when the engine is running. 2 ranges of instruments panels are available. Only the position and / or appearance of the instruments and / or the icons vary depend...

Page 11

11 eco3 eco4 a3 a4 b3 b4 c3 c4 stop on / stop start rpm x 100 10 0 40 30 20 5 35 15 25 stop on / stop start rpm x 100 10 0 40 30 20 5 35 15 25 °c 40 60 80 100 120 °f 105 180 220 250 stop on / stop start rpm x 100 10 0 40 30 20 5 35 15 25 bar 0 1 2 3 4 5 0 20 40 60 80 psi °c 40 60 80 100 120 °f 105 1...

Page 12: Nanni Industries S.A.S.

Nanni industries s.A.S. 11, avenue mariott e - zone industrielle bp 107- 33260 la teste france tel : + 33 (0)5 56 22 30 60 fax : +33 (0)5 56 22 30 79 e-mail : contact@nannidiesel.Com © 2009 - nanni industries sas the images, text and information contained in this document are based on the product’s ...