- DL manuals

- Napoleon

- Indoor Fireplace

- BHD4N

- Installation And Operating Instructions Manual

Napoleon BHD4N Installation And Operating Instructions Manual

EN

W415-1285 / A / 11.03.14

FR

PG

69

$10.00

INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE.

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

NEVER LEAVE CHILDREN OR OTHER AT RISK INDIVIDUALS ALONE WITH THE APPLIANCE.

INSTALLATION AND

OPERATING INSTRUCTIONS

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 0G8 Canada /

103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone (705)721-1212 • Fax (705)722-6031 • www.napoleonfi replaces.com • ask@napoleonproducts.com

1.36D

CERTIFIED FOR CANADA AND UNITED STATES USING ANSI/CSA METHODS.

SAFETY INFORMATION

!

WARNING

- Do not store or use gasoline or other fl ammable

vapors and liquids in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS:

•

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use

any phone in your building.

•

Immediately call your gas supplier from a

neighbour’s phone. Follow the gas supplier’s

instructions.

•

If you cannot reach your gas supplier, call the

fi re department.

- Installation and service must be performed by a

qualifi ed installer, service agency or the supplier.

This appliance may be installed in an aftermarket,

permanently located, manufactured home (USA

only) or mobile home, where not prohibited by

local codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is

not convertible for use with other gases, unless a

certifi ed kit is used.

If the information in these instructions

are not followed exactly, a fi re or

explosion may result causing property

damage, personal injury or loss of life.

HOT GLASS WILL CAUSE

BURNS.

DO NOT TOUCH GLASS UNTIL

COOLED.

NEVER ALLOW CHILDREN TO

TOUCH GLASS.

!

WARNING

A barrier designed to reduce the risk of burns from the

hot viewing glass is provided with the appliance and

shall be installed.

C E R T I F I E D

Decorative Product: Not for use as a heating appliance.

BARRIER

CONFORMS TO AMERICAN NATIONAL STANDARDS: ANSI Z21.50, CERTIFIED TO CANADIAN CSA 2.22 FOR VENTED GAS FIREPLACES.

BHD4ST ILLUSTRA

TED

SAFETY BARRIER

BHD4N

NATURAL GAS

BHD4P

PROPANE

Summary of BHD4N

Page 1

En w415-1285 / a / 11.03.14 fr pg 69 $10.00 installer: leave this manual with the appliance. Consumer: retain this manual for future reference. Never leave children or other at risk individuals alone with the appliance. Installation and operating instructions wolf steel ltd., 24 napoleon rd., barrie...

Page 2: Table of Contents

W415-1285 / a / 11.03.14 2 en table of contents 1.0 installation overview 3 2.0 introduction 4 2.1 dimensions 5 2.2 general instructions 6 2.3 general information 7 2.4 rating plate / lighting instruction location 8 3.0 venting 9 3.1 venting lengths and components 10 3.2 typical vent installations 1...

Page 3: 1.0 Installation Overview

W415-1285 / a / 11.03.14 3 en note: changes, other than editorial, are denoted by a vertical line in the margin. 1.0 installation overview bhd4p ill ustrated combustible material venting, see “venting” section rating plate, see “rating plate information” section door, see “door removal/ installation...

Page 4: 2.0 Introduction

W415-1285 / a / 11.03.14 4 en 2.0 introduction 3.2c ! Warning • this appliance is hot when operated and can cause severe burns if contacted. • any changes or alterations to this appliance or its controls can be dangerous and is prohibited. • do not operate appliance before reading and understanding ...

Page 5

W415-1285 / a / 11.03.14 5 en bhd4st illustrated bhd4p illustrated 38 1/4" 841mm 34 3/16" 868mm 43 1/4" 1099mm 8" 203mm 5" 127mm 12 13/16" 325mm 25 1/8" 638mm right side left side right side left side 7 9/16" 192mm electrical inlet 7 9/16" 192mm gas inlet 2 1/16" 53mm 34 3/16" 868mm 45" 1143mm 38 1/...

Page 6: Warning

W415-1285 / a / 11.03.14 6 en 2.2 general instructions 4.1b this gas appliance should be installed and serviced by a qualified installer to conform with local codes. Installation practices vary from region to region and it is important to know the specifi cs that apply to your area, for example in m...

Page 7: 67.9%

W415-1285 / a / 11.03.14 7 en 2.3 general information when the appliance is installed at elevations above 4,500 ft (1372m), and in the absence of specifi c recommendations from the local authority having jurisdiction, the certifi ed high altitude input rating shall be reduced at the rate of 4% for e...

Page 8: Warning

W415-1285 / a / 11.03.14 8 en 2.4 rating plate / lighting instruction location w385-1936 c e r t i f i e d bchd4n bchd4p &(57,),('81'(5+202/2*8(6(/21/(61250(6$16,=e&6$e9(17('*$6),5(3/$&()2 vented gas fireplace. Approved for bedroom, bathroom and bed-sitting room installation. Suitable for mobile ho...

Page 9: 3.0 Venting

W415-1285 / a / 11.03.14 9 en 3.0 venting 7.2c this appliance uses a 5” (127mm) exhaust / 8” (203.2mm) air intake vent pipe system. Refer to the section applicable to your installation. For safe and proper operation of the appliance follow the venting instruction exactly. Deviation from the minimum ...

Page 10

W415-1285 / a / 11.03.14 10 en use only wolf steel, simpson dura-vent, selkirk direct temp, american metal amerivent or metal-fab venting components. Minimum and maximum vent lengths, for both horizontal and vertical installations, and air terminal locations for either system are set out in this man...

Page 11

W415-1285 / a / 11.03.14 11 en 3.2 typical vent installations when venting, the horizontal run must be kept to a maximum of 20 feet (6m). If a 20 foot (6m) horizontal run is required, the appliance must have a minimum vertical rise off the appliance of 57" (1448mm). On all horizontal vent runs, ensu...

Page 12

W415-1285 / a / 11.03.14 12 en 3.3 special vent installations 3.3.1 periscope termination use the periscope kit to locate the air termination above grade. The periscope must be installed so that when fi nal grading is completed, the bottom air slot is located a minimum of 12” (304.8mm) above grade. ...

Page 13

W415-1285 / a / 11.03.14 13 en 3.4 vent terminal clearances installations canada u.S.A. A 12” (305mm) 12” (305mm) clearance above grade, veranda porch, deck or balcony. B 12” (305mm) Δ 9” (229mm) Δ clearance to windows or doors that open. C 12” (305mm)* 12” (305mm) * clearance to permanently closed ...

Page 14

W415-1285 / a / 11.03.14 14 en 3.5 vent application flow chart 13.1a top exit horizontal termination vertical termination vertical rise is equal to or greater than the horizontal run vertical rise is less than horizontal run vertical rise is equal to or greater than the horizontal run vertical rise ...

Page 15

W415-1285 / a / 11.03.14 15 en 3.8 horizontal termination 16.5a simple venting confi guration (only one 45° and 90° elbow) (h t ) t ) for vent confi gurations requiring more than one 45° elbow and 90° elbow, the following formulas apply: formula 1: h t t formula 2: h t + v t example: v 1 = 8 ft (2.4...

Page 16

W415-1285 / a / 11.03.14 16 en 16.5_2a simple venting confi guration (only one 45° and 90° elbow) (h t ) > (v t ) for vent confi gurations requiring more than one 45° elbow and 90° elbow, the following formulas apply: formula 1: h t t formula 2: h t + v t example: v 1 = 4 ft (1.2m) v 2 = 1.5 ft (0.5...

Page 17

W415-1285 / a / 11.03.14 17 en 3.9 vertical termination (h t ) t ) simple venting configurations. See graph to determine the required vertical rise v t for the required horizontal run h t . Required vertical rise in feet (meters) v t horizontal vent run plus offset in feet (meters) h t for vent conf...

Page 18

W415-1285 / a / 11.03.14 18 en (h t ) > (v t ) simple venting configurations. See graph to determine the required vertical rise v t for the required horizontal run h t . Required vertical rise in feet (meters) v t horizontal vent run plus offset in feet (meters)h t the shaded area within the lines r...

Page 19: 4.0 Installation

W415-1285 / a / 11.03.14 19 en 4.0 installation 4.1 wall and ceiling protection ! Warning do not fill the space between the vent pipe and enclosure with any type of material. Do not pack insulation or combustibles between ceiling firestops. Always maintain specified clearances around venting and fir...

Page 20: Warning

W415-1285 / a / 11.03.14 20 en this application occurs when venting through an exterior wall. Having determined the correct height for the air terminal location, cut and frame a hole in the exterior wall as illustrated to accommodate the fi restop assembly. Dry fi t the fi restop assembly before pro...

Page 21: Warning

W415-1285 / a / 11.03.14 21 en 4.2 using flexible vent components for safe and proper operation of the appliance, follow the venting instructions exactly. All inner fl ex pipe and outer fl ex pipe joints may be sealed using high temperature sealant w573-0002 (not supplied) or the high temperature se...

Page 22

W415-1285 / a / 11.03.14 22 en 4.2.1 horizontal air terminal installation a. Stretch the inner fl ex pipe to the required length taking into account the additional length needed for the fi nished wall surface. Apply a heavy bead of the high temperature sealant w573-0007 mill pac (not supplied) to th...

Page 23: Warning

W415-1285 / a / 11.03.14 23 en a. Fasten the roof support to the roof using the screws provided. The roof support is optional. In this case the venting is to be adequately supported using either an alternate method suitable to the authority having jurisdiction or the optional roof support. B. Stretc...

Page 24: Warning

W415-1285 / a / 11.03.14 24 en 4.3 gas installation this appliance is also certifi ed to be installed as an oem (original equipment manufacturer) installation in a manufactured home (u.S. Only) or mobile home and must be installed in accordance with the manufacturer’s instructions and the manufactur...

Page 25

W415-1285 / a / 11.03.14 25 en a. Remove the screen and door from the appliance, see "side screen removal / door removal" section. B. Remove media and media tray from the applaince, see "cradle burner removal" section. C. Unscrew the 2 screws that hold the access panel to the fi rebox. D. Remove the...

Page 26: Warning

W415-1285 / a / 11.03.14 26 en maintain these minimum clearances to combustibles from appliance and vent surfaces: combustible appliance framing: - 1/4" (6.4mm) to the sides of appliance - 8 1/4" (210mm) to the top of appliance combustible appliance fi nishing: - 0" (0mm) above the appliance opening...

Page 27

W415-1285 / a / 11.03.14 27 en 45 1/2" [1156mm] 46 1/2" [1181mm] a 46 1/2" [1181mm] a b 5.1 framing 5.1.1 see-thru framing (bhd4st) 5.1.2 peninsula framing (bhd4p) a: min 22 5/8" (575mm) max 24 1/8" (613mm) note: all framing dimensions are based on the fi nishing material supports position. Framing ...

Page 28

W415-1285 / a / 11.03.14 28 en * within the appliance enclosure a minimum 3” (76mm) clearance between the top of the vent pipe and combustible materials is required. All other clearances within the enclosure, including where the vent pipe exits the enclosure are subject to 2” (51mm)to the sides and ...

Page 29: Warning

W415-1285 / a / 11.03.14 29 en ! Warning joint compound where required joint compounds such as durabond 90 and tapes that are resilient to heat and cracking should be used when taping and mudding seams. Setting tiles and grouting we recommend you use tiles with a dry butt joint to be installed using...

Page 30

W415-1285 / a / 11.03.14 30 en 5.3.1 finishing support adjustment depending on the fi nishing material we have allowed from 0" (0mm) to 3/4" (19mm) of adjustment after the 1/2" (13mm) combustible board has been installed. Loosen the 8 screws on each fi nishing support. Adjust the fi nishing support ...

Page 31

W415-1285 / a / 11.03.14 31 en 5.4 non-combustible facing material door top of appliance 4” (101.6mm) 6” (152.4mm) 2” (50.8mm) 0” (0mm) 5” (127mm) 3”(76.2mm) b b warning: non-combustible facing material must not project more than 4” (101.6mm) from the face of the door (all four sides). If greater pr...

Page 32

W415-1285 / a / 11.03.14 32 en appliance recess or alcove area note: recesses or alcoves above the appliance can be made as deep as desired provided the minimum clearances to combustibles are maintained. Non-combustible material can be used, provided the minimum clearances to combustible materials a...

Page 33: Warning

W415-1285 / a / 11.03.14 33 en combustible mantel clearance can vary according to the mantel depth. Use the graph to help evaluate the clearance needed. ! Warning risk of fire, maintain all specified air space clearances to combustibles. Failure to comply with these instructions may cause a fire or ...

Page 34: 6.0 Finishing

W415-1285 / a / 11.03.14 34 en 6.0 finishing ! Warning risk of fire! Never obstruct the front opening of the appliance. The front of the appliance must be finished with any non-combustible materials such as brick, marble, granite, etc., provided that these materials do not go below the specified dim...

Page 35

W415-1285 / a / 11.03.14 35 en 6.2 end safety screen removal / installation (bhd4p only) a. Remove the 4 securing screws from the top and bottom of the end screen retainer, refer to figure 1. B. Pull the screen forward and out from the unit, refer to figure 2. Fig. 1 note: a side screen must be remo...

Page 36: Warning

W415-1285 / a / 11.03.14 36 en ! Warning glass may be hot, do not touch glass until cooled. The door latches are part of a safety system and must be properly engaged. Do not operate the appliance with latches disengaged. Facing and/or finishing materials must not interfere with air flow through air ...

Page 37

W415-1285 / a / 11.03.14 37 en panel cover control panel cover 6.4 control panel removal a. Remove screen, see "side screen removal" section. B. Remove the panel cover using the two fi ner holes, lift it up and away from the appliance, as shown below. C. Remove the control panel cover by lifting it ...

Page 38

W415-1285 / a / 11.03.14 38 en 6.6 hearth pad installation note: the individual hearth pads can be easily identifi ed by the numbers cast on the underside of each pad. Note: the pilot is located on the right end in these instructions. A. Remove the main doors from the appliance, refer to the "door r...

Page 39: Warning

W415-1285 / a / 11.03.14 39 en ! Warning failure to position the logs in accordance with these diagrams or failure to use only logs specifically approved with this appliance may result in property damage or personal injury. Logs must be placed in their exact location in the appliance. Do not modify ...

Page 40

W415-1285 / a / 11.03.14 40 en 8. Place log #7 onto the pin located in log #6 and onto the pin in log #5, as shown in figure 7. 9. Place log #8 on the hearth pad and let it rest against the notch in the side of log #7, as shown in figure 8. Hint: the best view of log #8 is shown in the left side vie...

Page 41: Warning

W415-1285 / a / 11.03.14 41 en 6.8 glass media installation 74.2b evenly spread the glass media onto the media tray, ensuring no glass media falls into the pilot opening. If this happens, insert a clean bag into your vacuum cleaner and vacuum out the glass media. Replacement glass can be purchased f...

Page 42: Warning

W415-1285 / a / 11.03.14 42 en logo 1/2” (13mm) 1/2” (13mm) it is necessary to hard wire this appliance. Permanently framing the appliance with an enclosure, requires the appliance junction box to be hard wired. This appliance must be electrically connected and grounded in accordance with local code...

Page 43

W415-1285 / a / 11.03.14 43 en a. In case of a power outage locate your battery housing (located in the control compartment). B. Install the 4 "aa" batteries, if not already installed. C. Connect the battery housing to the battery connector located in the control compartment of the appliance (refer ...

Page 44: Warning

W415-1285 / a / 11.03.14 44 en 7.4 wiring diagram 69.7 ! Warning do not wire 110 volts to the valve or wall switch. On / off switch acs/ipi switch battery housing (supplied in manual baggie) ground dfc valve orange green ground eyelet on / off ipi / cpi disconnect these connections to the on/off swi...

Page 45: 8.0 Operating Instructions

W415-1285 / a / 11.03.14 45 en 8.0 operating instructions when lit for the fi rst time, the appliance will emit a slight odour for a few hours. This is a normal temporary condition caused by the “burn-in” of internal paints and lubricants used in the manufacturing process and will not occur again. S...

Page 46

W415-1285 / a / 11.03.14 46 en 8.3 anti condensation switch this appliance has the ability to switch from an electronic intermittent pilot ignition (ipi) to a standing pilot (acs) for cold climates. The heat generated by the standing pilot will improve the start up operation on colder climate days. ...

Page 47: 9.0 Adjustment

W415-1285 / a / 11.03.14 47 en this appliance has an air shutter that has been factory set open according to the chart below: regardless of venturi orientation, closing the air shutter will cause a more yellow flame, but can lead to carboning. Opening the air shutter will cause a more blue flame, bu...

Page 48

W415-1285 / a / 11.03.14 48 en 9.3 flame characteristics glass burner log burner cradle it’s important to periodically perform a visual check of the pilot and burner fl ames. Compare them to the illustration provided. If any fl ames appear abnormal call a service person. Flame must envelop upper 3/8...

Page 49: 10.0 Maintenance

W415-1285 / a / 11.03.14 49 en 10.0 maintenance caution: label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing. This appliance and its venting system should be inspected before use and at leas...

Page 50: Warning

W415-1285 / a / 11.03.14 50 en 10.1 annual maintenance 37.1c ! Warning the firebox becomes very hot during operation. Let the appliance cool completely or wear heat resistant gloves before conducting service. Never vacuum hot embers. Do not paint the pilot assembly. • this appliance will require mai...

Page 51: Warning

W415-1285 / a / 11.03.14 51 en 5.4 do not clean glass when hot! Do not use abrasive cleaners to clean glass. Buff lightly with a clean dry soft cloth to remove accumulated dust or fi ngerprints. Clean both sides of the glass after the fi rst 10 hours of operation with a recommended fi replace glass ...

Page 52

W415-1285 / a / 11.03.14 52 en 10.4 burner removal 10.4.1 log burner removal a. Remove the door(s) refer to the "door removal/installation" section for instructions. B. Vacuum the glass media out of the appliance. Ensure you insert a clean bag into your vacuum cleaner. C. Remove the 12 screws securi...

Page 53

W415-1285 / a / 11.03.14 53 en 10.4.4 shipping bracket removal a. Remove the door(s), refer to "door removal / installation" section for instructions. B. Cut the strap holding the glass and vent thimble in place. C. Remove the 2 screws holding the shipping bracket / vent shield in place, as shown. N...

Page 54

W415-1285 / a / 11.03.14 54 en a. Remove the screen and glass door. See "door / screen removal and installation" section. Remove the burners, see "burner removal" section. B. Remove the 12 screws holding the valve train in place. Note: a new gasket may be required when reinstalling the valve train a...

Page 55: 11.0 Replacements

W415-1285 / a / 11.03.14 55 en 11.0 replacements contact your dealer or the factory for questions concerning prices and policies on replacement parts. Normally all parts can be ordered through your authorized dealer / distributor. For warranty replacement parts, a photocopy of the original invoice w...

Page 56: 12.0 Bhd4P

W415-1285 / a / 11.03.14 56 en 13 17 10 19 18 21 20 22 11 12 16 15 18 22 16 15 safety screen safety screen safety screen 17 20 21 23 24 25 26 27 ref . No. P art number d escription 1 w010-3481 media bowl assembl y 2 w010-2997 media bowl trim 3 4 5 6 7 8 9 10 11 12 ref . No. P art number d escription...

Page 57: 13.0 Bhd4St

W415-1285 / a / 11.03.14 57 en 6 4 3 8 1 7 2 5 19 18 21 20 22 12 1 2 02.1 1 .14 bhd4st over view 53 4 5 6 7 8 9 10 11 12 13 items ma y not appear exactl y as illustra ted ref . No. P art number d escription 1 w010-3481 media bowl assembl y 2 w010-2997 media bowl trim 3 4 5 6 7 8 9 10 11 12 ref . No....

Page 58: 14.0 A

W415-1285 / a / 11.03.14 58 en 8 ldns decora tive sticks 9 glass media kit embers (v arious colours) 10 11 12 88 77 bhd4 accessories items ma y not appear exactl y as illustra t ed 6 4 5 3 2 6 1 4 5 gd826 ref . No. P art number d escription 1 w660-0104 receiver (gd826) 2 w660-0074 transmitter (gd826...

Page 59: 15.0

W415-1285 / a / 11.03.14 59 en 2 4 3 1 2 4 3 1 items ma y not appear exactl y as illustra t ed 02 06 14 bhd4 glass burner (w100-0160) ref . No. P art number d escription 1 w010-2954 burner assembl y 2 w080-1400 burner bracket (x2) 3 w290-0018 venturi gasket 4 w720-0005 venturi 1 w 0 1 0 -2 95 4 b u ...

Page 60: 16.0

W415-1285 / a / 11.03.14 60 en 2 4 3 5 2 4 3 5 items ma y not appear exactl y as illustra t ed bhd4 log / cradle burner (w100-0161) ref . No. P art number d escription 1 w010-2955 burner assembl y 2 w080-1244 burner bracket 3 w290-0018 venturi gasket ref . No. P art number d escription 4 w720-0005 v...

Page 61: 17.0

W415-1285 / a / 11.03.14 61 en 13 10 8 12 9 11 6 7 5 13 10 8 12 9 11 6 7 5 items ma y not appear exactl y as illustra t ed glass burner v a l ve train assembl y ref . No. P art number description 1 w432-0103 gas manifold 2 w456-0037 burner orifice #37 3 w290-0157 manifold gasket 4 w105-0001 bushing ...

Page 62: 18.0

W415-1285 / a / 11.03.14 62 en 6 7 6 7 items ma y not appear exactl y as illustra t ed 02 06 14 log burner v a l ve train assembl y ref . No. P art number d escription 1 w432-0103 gas manifold 2 w456-0037 burner orifice #37 3 w290-0157 manifold gasket 4 w105-0001 bushing 5 w190-0029 control board 6 ...

Page 63: 19.0 Troubleshooting

W415-1285 / a / 11.03.14 63 en 19.0 troubleshooting symptom problem test solution pilot will not light. Makes noise with no spark at pilot burner. Wiring. - verify the wire for the sensor and the wire for the ignitor are connected to the correct terminals (not reversed) on the module. Note: sensor h...

Page 64

W415-1285 / a / 11.03.14 64 en symptom problem test solution carbon is being deposited on glass, logs, rocks, media or combustion chamber surfaces. Air shutter has become blocked. - ensure air shutter opening is free of lint or other obstructions. Flame is impinging on the glass, logs, rocks, media ...

Page 65

W415-1285 / a / 11.03.14 65 en 42.7_3b symptom problem test solution white / grey fi lm forms. Sulphur from fuel is being deposited on glass, logs or combustion chamber surfaces. - clean the glass, see “care of glass” section - do not clean glass when hot. - if deposits are not cleaned off regularly...

Page 66: 20.0 Warranty

W415-1285 / a / 11.03.14 66 en napoleon® warrants its products against manufacturing defects to the original purchaser only. Registering your warranty is not necessary. Simply provide your proof of purchase along with the model and serial number to make a warranty claim. Napoleon® reserves the right...

Page 67: 21.0 Service

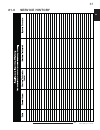

W415-1285 / a / 11.03.14 67 en 43.1 21.0 service history.

Page 68

Other napoleon ® products fireplace inserts • charcoal grills • gas fireplaces • waterfalls • wood stoves heating & cooling • electric fireplaces • outdoor fireplaces • gourmet grills fireplaces / heating & cooling call: 705-721-1212 • grills call: 705-726-4278 napoleonproducts.Com 24 napoleon road,...