- DL manuals

- Nautilus

- Exercise Bike

- E626

- Service Manual

Nautilus E626 Service Manual

1

Nautilus

®

U624/U626 (Model Year 2014)

Upright Bikes Service Manual

8008323.040115.A

Service Manual

Important Safety Instructions

2

Safety Warning Labels and Serial Number

3

Reading the Product Specification Label

3

Specifications

3

Maintenance 4

Leveling the Machne

5

Moving the Machine

5

Troubleshooting 6

Console Service Mode

8

Maintenance Parts Exploded View

10

Replacement Procedure Skill Level

12

Mechanical Procedures

13

Belt Tension Adjustment

13

Set the Brake Tension (Calibration)

16

Part Replacement

19

Console

19

Pedals

21

Crank Arms – U626

23

Transport Wheels, Front Endcaps and Footpads

27

Shrouds

29

Handlebar Assembly

34

Console Mast

37

Data Cable in the Mast

41

Brake Assembly

44

Servo Motor

46

Drive Belt and Flywheel Assembly

50

Belt Tensioner Assembly (Idler Assembly)

53

Drive Pulley Assembly (Crank Assembly) – U624

55

RPM Sensor (Speed Sensor)

58

Power Inlet

60

Table of Contents

Nautilus, Inc., www.NautilusInc.com - Customer Service: technics@nautilus.com | 18225 NE Riverside Parkway, Portland, OR 97230 USA | © 2014 Nautilus, Inc. | ® indicates trademarks

registered in the United States. These marks may be registered in other nations or otherwise protected by common law. Polar

®

and Bluetooth

®

are registered trademarks of their

respective owners.

ORIGINAL DOCUMENT - ENGLISH VERSION ONLY

Summary of E626

Page 1

1 nautilus ® u624/u626 (model year 2014) upright bikes service manual 8008323.040115.A service manual important safety instructions 2 safety warning labels and serial number 3 reading the product specification label 3 specifications 3 maintenance 4 leveling the machne 5 moving the machine 5 troubles...

Page 2

2 important safety instructions and general troubleshooting information for the nautilus ® u624/u626 bikes 8008329.040115.A service procedures important safety instructions this icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and unde...

Page 3: Metric

3 safety warning labels and serial numbers specifications reading the product specification decal the manufacture date on the product specification decal is a date code: yy/ww (year/week). 8004287 revisions eco revision rev description approved date title. Part no. Rev. Sheet 1 of 1 scale: 1:1 do no...

Page 4

4 maintenance read all maintenance instructions fully before you start any repair work. In some conditions, an assistant is necessary to do the necessary tasks. ! Equipment must be regularly examined for damage and repairs. The owner is responsible to make sure that regular maintenance is done. Worn...

Page 5

5 moving the bike to move the upright bike, carefully tilt the handlebars toward you while pushing the front of the bike downward. Push the bike to the desired location. Notice: be careful when you move the bike. Abrupt motions can affect the computer operation. Leveling your bike levelers are found...

Page 6

6 troubleshooting condition/problem things to check solution no display/partial display/ unit will not turn on check electrical (wall) outlet make sure unit is plugged into a functioning wall outlet. Check connection on console connection should be secure and undamaged. Replace adapter or connection...

Page 7

7 condition/problem things to check solution console shuts off (enters sleep mode) while in use check electrical (wall) outlet make sure unit is plugged into a functioning wall outlet. Check connection on console connection should be secure and undamaged. Replace adapter or connection at unit if eit...

Page 8

8 console service mode – x624 / x626 series (my14) consoles the console setup mode lets you input the date and time, set the units of measurement to either english or metric, change the machine type, control the sound settings ( on/ off), or see maintenance statistics (total run hours – for service ...

Page 9

9 2. All leds off 1 second 3. Sequence segments 1 at a time – on 1 second, off 1 second press any key to exit test h. Run lcd test – drives 3x5 and 1x5 lcd displays with the following patterns: 1. All segments on 2. All segments off 3. Set individual segments one at a time until all segments are ill...

Page 10

10 maintenance parts exploded view your machine may differ. Use only as a guide. U624 a b c c d e f g h i j j a k l j m n o p q r s t u v w x d aa bb cc z y dd ee ff ff a console l hr cable w flywheel b console mast m chr sensors x brake assembly c pedals n seat y rpm sensor d crank arms o seat post...

Page 11

11 u626 j j a l a b c c d e f g h i k m n o p q r s t u v dd ee w d bb z y j x aa cc ff ff a console l hr cable w flywheel b console mast m chr sensors x brake assembly c pedals n seat y rpm sensor d crank arms o seat post w/ slider z speed sensor magnet e left shroud p adjustment knob aa servo moto...

Page 12

12 replacement procedure skill level level i : low - very little mechanical knowledge or exposure. Level ii : intermediate - some experience with mechanical procedures level iii : advanced - knowledgeable about mechanical procedures wa r n i n g at t e n t i o n d a n g e r immediate action required...

Page 14

14 note: your machine may not match the image. For reference only. 1. Remove the top shroud, left shroud and right shroud from the main unit. Refer to the “replace the shrouds” procedure. 2. To test the drive belt tension: • push the drive belt downward at the midpoint (m) between the pulleys and me...

Page 15

15 6. Reassembly is the reverse procedure. Notice: be sure not to crimp any cables. U624/r624 bikes— to reinstall the pedals, carefully align the threads and hand tighten to prevent cross-threading. Then tighten fully with pedal wrench. Note: the left pedal is reverse-threaded. Orientation is based ...

Page 16

16 set the brake tension (calibration) on the nautilus ® u624/u626 (model year 2014) bikes skill level: iii 8008331.040115.A replacement procedure notice: this document provides instructions for the calibration of the brake tension on the nautilus ® u624 and u626 upright bikes. If you need assistanc...

Page 17

17 note: your machine may not match the image. For reference only. 1. Disconnect and reconnect the ac adapter from the wall outlet to turn the power off and on. 2. Push quickstart and verify that the console shows that the default resistance level is 4. Disconnect all power and allow to sit for 5 mi...

Page 18

18 7. To adjust the brake tension, loosen the 2 hex head bolts (c) and move the servo motor assembly (d) until the closest point on the brake magnet (a) is within 3.0 mm (1/8”) of the flywheel (b). Tighten the bolts. Note: if the cardboard is not 3mm (1/8”) thick, you can use the pages of a paperbac...

Page 20

20 to reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the power cord from the wall outlet and the machine and wait 5 minutes before cleaning, maintaining or repairing the machine. Place the power cord in a secure location. Note: your machine may not match th...

Page 21

21 replace the pedals on the nautilus ® u624/u626 and r624/r626 (model year 2014) bikes skill level: i 8008333.040115.A replacement procedure notice: this document provides instructions for the replacement of the pedals on the nautilus ® u624 and u626 upright bikes, and r624 and r626 recumbent bikes...

Page 22

22 note: your machine may not match the image. For reference only. 1. Loosen and remove the old pedals. Discard the old pedals. Note: the left pedal is reverse-threaded. Orientation is based from a seated position on the bike. The left pedal has an “l”, the right pedal an “r”. 2. Install the new ped...

Page 23

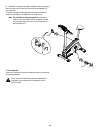

23 replace the crank arms on the nautilus ® u626/r626 (model year 2014) bikes skill level: ii 8008334.040115.A replacement procedure notice: this document provides instructions for the replacement of the crank arms on the nautilus ® u626 upright bike and r626 recumbent bike. If you need assistance, ...

Page 24

24 note: your machine may not match the image. For reference only. 1. Loosen and remove the old pedals. Set them safely aside for reassembly. Note: the left pedal is reverse-threaded. Orientation is based from a seated position on the bike. The left pedal has an “l”, the right pedal an “r”. 2. Using...

Page 25

25 4. Thread the crank puller into the crank arm (b). When the crank puller is in the correct position, only 1-2 threads on the outer portion (cp2) of the crank puller should show. Note: be sure the end of the bolt (cp1) of the crank puller is flush with the nut (cp2) as shown, before use. 5. Using ...

Page 26

26 (l) (r) 6. Installation is the reverse procedure. Installation does not require the use of the crank puller. Be sure the crank arms are connected at 180° from each other. To reinstall the pedals, carefully align the threads and hand tighten to prevent cross-threading. Then tighten fully with peda...

Page 27

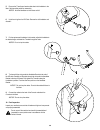

27 replace the transport wheels, endcaps and footpads on the nautilus ® u/r/e 624/626 (model year 2014) bikes and elllipticals skill level: ii 8008335.040115.A replacement procedure notice: this document provides instructions for the replacement of the transport wheels, front endcaps and footpads on...

Page 28

28 note: your machine may not match the image. For reference only. 1. Place a static object (like a book or box) under the front stabilizer (c). The static object should not be compressible. 2. Using a short #2 phillips screwdriver, loosen and remove the screws (a1) from the footpad (a), and set the...

Page 29

29 replace the shrouds on the nautilus ® u624/u626 (model year 2014) bikes skill level: ii 8008336.040115.A replacement procedure notice: this document provides instructions for the replacement of the shrouds on the nautilus ® u624 and u626 upright bikes. If you need assistance, please contact your ...

Page 30

30 note: your machine may not match the image. For reference only. 1. Remove the seat post and the seat adjustment knob (a). Set them safely aside for reassembly. 2. Your machine has one of these crank configurations. Please use the im- ages to select your configuration: 3. Using a wrench and socket...

Page 31

31 6. Loosen and remove the pedals. Set them safely aside for reassembly. Note: the left pedal is reverse-threaded. Orientation is based from a seated position on the bike. The left pedal has an “l”, the right pedal an “r”. 7. Twist the crank cover (p) toward the front of the machine to disengage th...

Page 32

32 11. Using a #2 phillips screwdriver, remove the 6 screws (indicated) that secure the left shroud. Remove the bottom screws first, and then the top screws. Slowly remove the left shroud. Note: find the power inlet (e) in the left shroud. Disconnect the power inlet cable (e1) from the wiring harnes...

Page 33

33 12. Using a #2 phillips screwdriver, remove the 3 screws that secure the right shroud. Remove the bottom screws first, and then the top screw. Slowly remove the right shroud. 13. Installation is the reverse procedure. Put the left shroud in postion first to align the screws for the right shroud. ...

Page 34

34 replace the handlebar assembly on the nautilus ® u624/u626 (model year 2014) bikes skill level: ii 8008337.040115.A replacement procedure notice: this document provides instructions for the replacement of the handlebar assembly on the nautilus ® u624 and u626 upright bikes. If you need assistance...

Page 35

35 note: your machine may not match the image. For reference only. 1. Remove screws that attach console to the mast. Carefully lift the console off the mast. 2. Disconnect the data cable and heart rate cable from the back of the console. Set the console and screws safely aside for reassembly. Note: ...

Page 36

36 5. Remove the t-handle and washers that attach the handlebar to the mast. Set them safely aside for reassembly. Notice: hold the handlebar so that it does not fall. 6. Untie the string from the hr cable. Remove the old handlebar and discard it. 7. Put the replacement handlebar in the bracket, adj...

Page 37

37 replace the console mast on the nautilus ® u624/u626 (model year 2014) bikes skill level: ii 8008338.0401115.A replacement procedure notice: this document provides instructions for the replacement of the console mast on the nautilus ® u624 and u626 upright bikes. If you need assistance, please co...

Page 38

38 note: your machine may not match the image. For reference only. 1. Remove screws that attach console to the mast. Carefully lift the console off the mast. 2. Disconnect the data cable and heart rate cable from the back of the console. Set the console and screws safely aside for reassembly. Note: ...

Page 39

39 5. Remove the t-handle and washers that attach the handlebar to the mast. Set them safely aside for reassembly. Notice: hold the handlebar so that it does not fall. 6. Remove the handlebar and set it safely aside for reassembly. 7. Remove the mast gasket. 8. Remove the hardware (indicated) from t...

Page 40

40 10. Put the handlebar in the bracket, adjust the handlebar to the desired angle, and install the t-handle through the holes and washers. Notice: do not crimp the cables. 11. Use the pull cable in the handlebar bracket to route the hr cable through the slot under the handlebar bracket to the top o...

Page 41

41 replace the data cable in console mast on the nautilus ® u624/u626 (model year 2014) bikes skill level: ii 8008339.040115.A replacement procedure notice: this document provides instructions for the replacement of the data cable in the console mast on the nautilus ® u624 and u626 upright bikes. If...

Page 42

42 note: your machine may not match the image. For reference only. 1. Remove screws that attach console to the mast. Carefully lift the console off the mast. 2. Disconnect the data cable and heart rate cable from the back of the console. Set the console and screws safely aside for reassembly. Note: ...

Page 43

43 5. Tie the length of string to the end (a) of the data cable at the base of the mast. Hold the other end of the data cable (b) and carefully pull it out of the mast so that the string extends through the length of the mast. Untie the string from the old data cable and discard the old cable. Notic...

Page 44

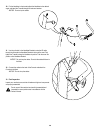

44 replace the brake assembly on the nautilus ® u624/u626 (model year 2014) bikes skill level: iii 8008340.040115.A replacement procedure notice: this document provides instructions for the replacement of the brake assembly on the nautilus ® u624 and u626 upright bikes. If you need assistance, pleas...

Page 45

45 note: your machine may not match the image. For reference only. 1. Carefully remove the shrouds. Refer to the “replace the shrouds” procedure. 2. Insert 2.5” x 10” cardboard between the brake magnet (a) and the flywheel (b), and tape the cardboard to the brake magnet. Note: be sure the cardboard ...

Page 46

46 replace the servo motor on the nautilus ® u624/u626 (model year 2014) bikes skill level: iii 8008341.040115.A replacement procedure notice: this document provides instructions for the replacement of the servo motor on the nautilus ® u624 and u626 upright bikes. If you need assistance, please cont...

Page 47

47 notice: it is necessary to remove the shrouds for this procedure. Refer to the “replace the shrouds” procedure. It may be necessary to adjust the brake tension at the end of this procedure. Refer to the “set the brake tension” procedure. Note: your machine may not match the image. For reference o...

Page 48

48 5. Observe the cable routing. Disconnect the speed sensor cable (d) and power inlet cable (e) from the wiring harness (f). 6. Tie the length of string to the end of the lower console cable (g) at the top of the mast mount. Pull the cable and string down through the hole (h) at the base of the mas...

Page 49

49 13. Reinstall the mast, console, mast gasket and top shroud. (refer to the “replace the shrouds” procedure.) turn the power on. Machine is on. Current is active. There is risk of electrical shock. 14. Use the console to set the resistance to the highest level. Unplug the machine. Disconnect all p...

Page 51

51 notice: it is necessary to remove the shrouds for this procedure. Refer to the “replace the shrouds” procedure. It is necessary to adjust the drive belt tension at the end of this procedure. Refer to the “belt tension adjustment” procedure note: your machine may not match the image. For reference...

Page 52

52 3. Using needlenose pliers, carefully release the spring (e1) on the belt tensioner (e). 4. To remove the hardware from the flywheel (c), use the 15 mm open end wrench to hold the nut (f) on one side steady and remove the nut on the opposite side with the 15 mm socket and wrench. Set the hardware...

Page 54

54 notice: it is necessary to remove the shrouds for this procedure. Refer to the “replace the shrouds” procedure. It is necessary to adjust the drive belt tension at the end of this procedure. Refer to the “belt tension adjustment” procedure note: your machine may not match the image. For reference...

Page 56

56 note: your machine may not match the image. For reference only. 1. Carefully remove the shrouds. Refer to the “replace the shrouds” procedure in this manual. 2. Slowly turn the drive pulley (a) backward and carefully ease the drive belt (b) off the drive pulley to the outside. Be sure to keep fin...

Page 57

57 5. Carefully pull the pulley shaft assembly (h) until it works out of the frame and releases the washer (j), bumper (k), bearings (l) and bearing brackets (m). 6. Installation is the reverse procedure. Notice: do not overtighten the crank hardware as this can damage the bearings. Use these torque...

Page 59

59 notice: it is necessary to remove the shrouds for this procedure. Refer to the “replace the shrouds” procedure. Note: your machine may not match the image. For reference only. 1. Carefully remove the shrouds. Refer to the “replace the shrouds” procedure in this manual. 2. Observe the cable routin...

Page 61

61 notice: it is necessary to remove the shrouds for this procedure. Refer to the “replace the shrouds” procedure. Note: your machine may not match the image. For reference only. 1. Carefully remove the left shroud. Refer to the “replace the shrouds” procedure in this manual. 2. Carefully disconnect...

Page 62

62 c 3. Loosen and remove the thin nut from the power inlet (c) on the outside of the shroud. 4. Pull the power inlet plug (c) out of the hole toward the inside of the shroud. Discard the old power inlet assembly. 5. Installation is the reverse procedure. Notice: do not crimp any cables. Be sure the...