- DL manuals

- Navien

- Water Heater

- NCB-150E

- Service Manual

Navien NCB-150E Service Manual

Getting Service

If your boiler requires service, you have several options for getting service:

●

Contact Technical Support at 1-800-519-8794 or on the website: www.navienamerica.com.

For warranty service, always contact Technical Support first.

●

Contact the technician or professional who installed your boiler.

●

Contact a licensed professional for the affected system (for example, a plumber or electrician).

When you contact Technical Support, please have the following information at hand:

●

Model number

●

Serial number

●

Date purchased

●

Installation location and type

●

Error code, if any appears on the front panel display.

Navien, Inc.

800.519.8794 www.Navien.com

20 Goodyear lrvine, CA 92618

Service Manual

NCB-E Condensing Combi Boiler

T H E L E A D E R I N C O N D E N S I N G T E C H N O L O G Y

Version: 1.4 (Oct 26, 2015)

Summary of NCB-150E

Page 1

Getting service if your boiler requires service, you have several options for getting service: ● contact technical support at 1-800-519-8794 or on the website: www.Navienamerica.Com. For warranty service, always contact technical support first. ● contact the technician or professional who installed ...

Page 2

Warning if the information in these instructions is not followed exactly, a fire or explosion may result, causing property damage, personal injury, or death. Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance. What to do if you smell gas...

Page 4: Revisions

Revisions 3 version description of changes date 1.00 first issue october/27/2013 1.10 cascade information addition january/03/2014 1.20 e001 information addition, e205 information revision june/12/2014 1.30 afue change november/24/2014 1.40 ncb-150e,180e,210e and 240e model added september/30/2015 1...

Page 5: Contents

Version 1.4 4 ncb-e service manual 1. Safety information 10 1.1 safety definitions 10 1.2 safety symbols 10 1.3 symbols used in the instructions 10 1.4 safety precautions 10 2. Product information 14 2.1 product information 14 2.2 components 15 3. Technical data 17 3.1 general specifications 17 3.2 ...

Page 6

Contents 5 6. Replacement of parts 134 6.1 replacement procedure 134 6.2 components replacement instructions 134 6.2.1 pcb 134 6.2.2 fuse 135 6.2.3 fan motor (combustion air) 135 6.2.4 flame rod 136 6.2.5 ignition transformer 137 6.2.6 aps 137 6.2.7 main gas valve 138 6.2.8 condensate trap 139 6.2.9...

Page 7

Version 1.4 6 ncb-e service manual requirements for the state of massachusetts this appliance must be installed by a licensed plumber or gas fitter in accordance with the massachusetts plumbing and fuel gas code 248 cmr sections 2.00 and 5.00. Important: in the state of massachusetts (248 cmr 4.00 &...

Page 8: Navien Warranty

7 warranty exclusions navien’s limited warranty shall be void in the event of an occurrence of any of the following: ● improper installation, failure to install in strict compliance with the installation manual procedures, installed by a non-licensed installer, and installation in violation of appli...

Page 9

Version 1.4 8 ncb-e service manual ● installation at any location outside the united states and canada. ● removal or alteration of the rating plate. Rating plate, *plaque signalétique combination boiler * chaudière combinaison navien, inc. 20 goodyear, irvine, ca 92618 tel: 1-800-519-8794 direct ven...

Page 10

9 abbreviation definition ncb-e general name of ncb-180e, ncb-210e, and ncb-240e ng natural gas lp propane gas ap air pressure aps air pressure sensor dhw domestic hot water fm fan motor garc gas air ratio control gpm gallons per minute mgv main gas valve rpm revolutions per minute pcb printed circu...

Page 11: 1. Safety Information

Version 1.4 10 ncb-e service manual 1.1 safety definitions the following safety symbols are used in this manual. Read and follow all safety instructions in this manual precisely to avoid unsafe operating conditions, fire, explosion, property damage, personal injury, or death. 1.2 safety symbols dang...

Page 12

Safety information 11 danger hot burn hot water temperature setting ● water temperatures at or above 125°f (52°c) can cause severe burns instantly or death from scalds. ● households with small children, disabled, or elderly persons may require 120 °f (49°c) or lower temperature setting to prevent co...

Page 13

Version 1.4 12 ncb-e service manual warning gas type and ac voltage this boiler is configured for natural gas from the factory. If conversion to propane gas is required, the conversion kit supplied with the boiler must be used. ● be sure to use 120 vac, 60 hz, minimum 2 a current. Using abnormally h...

Page 14

Safety information 13 caution ● do not attempt to repair or replace any part of the boiler, unless it is specifically recommended in this manual. For all other service, contact an authorized technician or licensed professional. Improper adjustments, alterations, service, or maintenance may lead to p...

Page 15: 2. Product Information

Version 1.4 14 ncb-e service manual 2.1 product information navien features the ncb-e series gas boiler with a built-in circulation pump and air vent. This appliance is fully modulating and provides central heating and domestic hot water. Depending on the heat capacity, each model is divided into th...

Page 16

Product information 15 2.2 components the following diagram shows the key components of the boiler. Component assembly diagrams and particular parts lists are included in the appendixes. Intake air exhaust flue duct igniter & flame rod condensate trap auto feeder (make-up water) power switch air fil...

Page 17

Version 1.4 16 ncb-e service manual pressure relief valve adapter fan & motor dual venturi high limit switch air pipe gas pipe aps air vent circulation pump 3-way valve space heating supply space heating return ignition transformer premix burner primary heat exchanger secondary heat exchanger pressu...

Page 18: 3. Technical Data

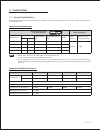

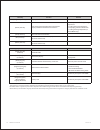

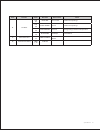

Technical data 17 3.1 general specifications the following table lists the specifications for the boiler. Additional specifications about water, gas, electric, and air supplies (venting) appear in the installation section. Space heating specifications navien combination boiler space heating ratings ...

Page 19

Version 1.4 18 ncb-e service manual general specifications item ncb-150e ncb-180e ncb-210e ncb-240e dimensions 17 in (w) x 28 in (h) x 12 in (d) weight 66 lbs (30 kg) 74 lbs (34 kg) 84 lbs (38 kg) 84 lbs (38 kg) installation type indoor wall-hung venting type forced draft direct vent ignition electr...

Page 20

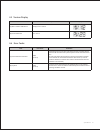

Technical data 19 3.2 dimensions the following diagrams show the dimensions of the boiler and the table lists the supply connections. 27.4" (695m m ) 28.8 ” ( 731m m ) supply connections description diameter a pressure relief valve adapter 3 / 4 in b air intake 2 in c exhaust gas vent 2 in d space h...

Page 21: 4. System Details

Version 1.4 20 ncb-e service manual 4.1 setting the dip switches caution do not remove the front cover unless the power to the boiler is turned off or disconnected. Failure to do so may result in electric shock. The boiler has two dip switch locations: on the main circuit board (pcb) and on the fron...

Page 22

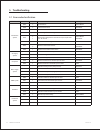

System details 21 setting the front panel dip switches 1 2 3 4 5 6 7 8 9 10 1 2 on on 2 on ng lp 2 on ● set of dip switches 1 (set of 10) the dip sw 1 on the front panel configures the temperature unit, well pump, and high altitude settings. Sw1 no. Application setting remarks 1 reserve 2 temperatur...

Page 23

Version 1.4 22 ncb-e service manual to measure the inlet gas pressure: 1. Shut off the manual gas valve on the gas supply line. Gas valve opened closed 2. Open a hot water faucet. The boiler should turn on and the gas in the gas supply line will be purged. 3. Leave the faucet on until the boiler shu...

Page 24

System details 23 note for ncb series, remove the boiler front cover by loosening the 4 phillips head screws securing it to the case. 5. Loosen the screws indicated in the figure below and connect a manometer to the pressure port. Reset the manometer to zero before use. Digital pressure manometer 6....

Page 25

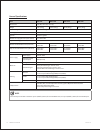

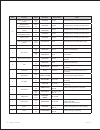

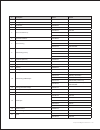

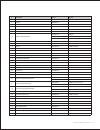

Version 1.4 24 ncb-e service manual 4.2.1 gas pipe sizing tables (referenced from 2012 national fuel gas code) these tables are for reference only. Please consult the gas pipe manufacturer for actual pipe capacities. Maximum natural gas delivery capacity in cubic feet (ft 3 ) per hour (0.60 specific...

Page 26

System details 25 maximum liquefied propane delivery capacity in thousands of btu/h (0.5” wc pressure drop) pipe size length (including fittings) 10' (3m) 20' (6m) 30' (9m) 40' (12m) 50' (15m) 60' (18m) 80' (24m) 100' (30m) 125' (38m) 150' (45m) 175' (53m) 200' (60m) 250' (76m) 1/2" 291 200 160 137 ...

Page 27

Version 1.4 26 ncb-e service manual procedure: 1. Turn off both gas and water supply to the boiler. 2. Unclasp the 3 buckles that fix the cover to the boiler, and then remove the cover by lifting it and pulling it outward. See figure 1 for illustration of the front cover on the unit. 1 1 2 3 figure ...

Page 28

System details 27 8. With the internal components exposed, locate the gas inlet pipe and the gas valve in the middle of the unit, as shown in figure 2. Gas valve gas inlet pipe figure 2. Ncb-e series internal components 9. Use a phillips screwdriver to remove the two screws at location a - the conne...

Page 29

Version 1.4 28 ncb-e service manual o-ring gas orifice packing figure 5. Exploded view of gas pipe assembly danger see figure 5. Inspect the o-ring between the gas valve and gas valve inlet adapter whenever they are disassembled. The o-ring must be in good condition and must be installed. Failure to...

Page 30

System details 29 12. Remove the gas orifice, ensure that the packing is properly seated inside the port, and then install the new gas orifice for use with lp gas. Ensure that the orifice is properly seated on the packing inside the port before proceeding to the next step. Packing 13. Replace the ga...

Page 31

Version 1.4 30 ncb-e service manual d. Fully open several hot water fixtures and set the boiler to operate at 2-stage d. Max mode. Measure the co 2 value at high fire. If the co 2 values do not match table 2 at high fire, do not adjust the gas valve. Check for the proper gas orifice. Danger improper...

Page 32

System details 31 c. Fully open a hot water fixture and set the boiler to operate at 1-stage min mode (refer to table 2). Measure the offset value at low fire and compare it to the values in table 3. If the offset value is out of range, the gas valve set screw will need to be adjusted. If adjustment...

Page 33

Version 1.4 32 ncb-e service manual 4.4 the front panel the front panel allows you to adjust the water temperature and view the operating status or error codes. Remove the protective sheet from the front panel before using it. 4.4.1 icons and digital display the icons and digital display on the fron...

Page 34

System details 33 4.4.2 buttons using the buttons on the front panel, you can turn on or off the boiler, monitor the current operation status, and set the values required for the boiler’s operation, such as space heating and dhw supply temperatures. Refer to the following table for detailed informat...

Page 35

Version 1.4 34 ncb-e service manual short key function remark [diagnostic] short key display of information for service [mode] short key sets heating temperature/hot water temperature displays/confirms information for customers converts () in order of setting heating temperature => setting hot water...

Page 36

System details 35 * when the power is first applied, please turn the panel segments and icons on for 3 seconds (in order to check lcd defect) * the firmware version of panel will be displayed for 2 seconds after 3 seconds from power application note if the air purge is operating, the segment repeats...

Page 37

Version 1.4 36 ncb-e service manual item description display method 3. Level1 error occurs level 1 error occurrence status when the current supply water temperature is 120°f and its water pressure is 12.3psi, the image below repeats at 5 seconds intervals. (celsius specification) error icon flashes ...

Page 38

System details 37 4.4.6 adjusting the space heating temperature the boiler is set to 140°f (60°c) by default. To adjust the space heating water temperature: 1. Press the mode button once. The space heating icon turns on. Mode 2. Press the + (up) or – (down) buttons until the desired temperature appe...

Page 39

Version 1.4 38 ncb-e service manual 3. Press + (up) or – (down) buttons until the desired temperature appears on the display. Mode 4. You can adjust the temperature while the display is flashing. Once the display stops flashing, the temperature setting is stored. Temperature range adjusting the wate...

Page 40

System details 39 4.4.8 viewing basic information (for homeowner) to view information about the boiler, press the [mode] button three times. “info” will appear in the display. Press the [+] or [–] buttons to switch between the information types. Item description display (a) space heating supply wate...

Page 41

Version 1.4 40 ncb-e service manual item description display (e) flow rate display of the current flow rate minimum display unit (0.2 gal/min or l/min) using sensor gpm flow rate display ex) 10.2gpm (f) outdoor air temperature (with optional outdoor temperature sensor only) display of current outdoo...

Page 42

System details 41 note ● while in the first digit indicates the history of the error with 0 being the most recent. The remaining 3 digits indicate the error code. If there is no error history, a “0” will be displayed. ● passed time display: the time between the currently displayed error and the just...

Page 43

Version 1.4 42 ncb-e service manual 4.4.10 information display (for servicer) 1. At the , press the [diagnostic] button once for 5 seconds to access the service information display. 2. Whenever the [+] / [-] button is pressed, the information data items are increased/decreased and displayed. 3. The ...

Page 44

System details 43 item description display (e) flow rate display of the current flow rate minimum display unit (0.2 gal/min or l/min) using sensor gpm flow rate display ex) 10.2gpm (f) outdoor air temperature (with optional outdoor temperature sensor only) display of current outdoor temperature outd...

Page 45

Version 1.4 44 ncb-e service manual item description display (j) heat capacity display of current heat capacity % range: 50-100% default : 100% % heat capacity display in percentage ex) 100%, (k) flame state display of flame detection current ad value flame on : below 70 flame off : over 175 display...

Page 46

System details 45 item description display (p) exhaust gas temperature current exhaust gas temperature display exhaust gas temperature display for celsius (°c) mode with sensor, ex) 60°c exhaust gas temperature display for fahrenheit (°f) mode with sensor, ex) 120°f exhaust gas temperature display w...

Page 47

Version 1.4 46 ncb-e service manual item description display (s) altitude setting information display of current altitude level setting 0-2,000ft 2,000-5,400ft 5,400-7,700ft 7,700-10,100ft (t) current units in cascade system. Display of current number of cascade unit. Cascade off cascade on (u)casca...

Page 48

System details 47 4.4.11 special parameter mode you can modify parameter settings for boiler operations, such as the space heating and dhw temperature ranges, in different operating conditions. Follow the instructions below to access the special parameter mode and change the available settings. Caut...

Page 49

Version 1.4 48 ncb-e service manual caution ● if you enter an incorrect password 10 times or make no input 5 minutes, the boiler will return to the normal mode. ● to return to the previous mode, press the reset button. ● the factory default password is “1234” ● if you make no adjustment for 10 secon...

Page 50

System details 49 item description display (c) lowest outdoor temperature setting this mode is used to configure the lowest outdoor temperature. The boiler will operate at the high end of the supply or return set-point range at this outdoor temperature. Outdoor low temperature setting range setting ...

Page 51

Version 1.4 50 ncb-e service manual item description display (f) space heating max heat capacity this menu is used to configure the desired space heating capacity. When the boiler operates in the normal mode, the space heating capacity is limited to the set value (%) setting range default 50-100% 10...

Page 52

System details 51 item description display (l) ch burning off differential during space heating, the boiler turns off the burner when the space heating supply temperature meets or exceeds the burner-off temperature. Setting range default 2 - 54°f(1 - 30°c) 0°f(0°c) for celsius (°c) mode; ex) at 0°c ...

Page 53

Version 1.4 52 ncb-e service manual item description display (p) return absolute max set-point this menu may be used to make changes to the maximum return temperature range the return control mode is in use. When configuring the custom mode in the outdoor reset control mode, the return temperature c...

Page 54

System details 53 item description display (t) cascade protocol setting this menu may be used to set the communication protocol for the cascade system. Set the parameter values according to the type of slave units installed in the cascade system. All the slave units are npe water heaters. Slave unit...

Page 55

Version 1.4 54 ncb-e service manual item description display (*) password change mode this menu may be used to set a new password to access the parameter setting menu. To set a new password: 1. Move to [*.Psc] and press the “mode” button. The current password is displayed, with the first digit flash...

Page 56

System details 55 component test performed display method fan gradually increase / decrease the speed of the fan motor starting from 0 rpm to full speed and back down to 0 rpm the current aps value and the current rpm value are repeatedly displayed at intervals of 2 seconds. Pump cycles the pump 10 ...

Page 57

Version 1.4 56 ncb-e service manual (3) operation conditions settings 1. While in , press the [+] / [-] button and then press the [mode] button once when “3. Opr” is displayed on the front panel. 2. Whenever the [+] / [-] button is pressed, it increases / decreases the operation condition and flashe...

Page 58

System details 57 4.4.13 cascade protocol settings you can connect one ncb-e boiler with up to 15 navien water heaters, using the ready-link communication cables. Select the ncb-e series combination boiler in the cascade system as the master unit, and then connect the water heaters to it as slave un...

Page 59

Version 1.4 58 ncb-e service manual 4.4.15 cascade set-up procedure for np/nr series models to configure the nr/np series water heaters for a cascade system, follow the instructions below: 1. Press the sw3 and sw4 (service switches on the main pcb) simultaneously for more than 3 seconds on the np/nr...

Page 60

System details 59 4.5 version display item description display (a) main controller f/w version displays for 3 seconds (b) panel f/w version ex > ver 1.2 4.6 error codes item error code conditions (a) panel communication error e782 (level 1) automatically releases the error code when the main control...

Page 61

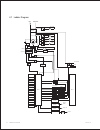

Version 1.4 60 ncb-e service manual 4.7 ladder diagram hot neutral venturi relay 1 relay 2 relay 3 relay pwm fan speed control 24v output 220v flame rod dc15v dc24v dc12v dc5v mcu 1 h.T.L wd-pss driving circuit relay 3 mgv1 mgv2 relay 1 relay 2 relay 4 relay 5 communication interface uart communicat...

Page 62

System details 61 4.8 electrical diagnostic point & wiring diagram color c ode b o r w y bk br gy : blue : or ange : r ed : w hit e : y ello w : black : br own : gr een/y ello w if an y of the or ig inal wir es as supplied the boiler must be replac ed , they must be r eplac ed their equiv alen t. Fm...

Page 63

Version 1.4 62 ncb-e service manual point function cn no. Wire color normal value check a dhw inlet temperature sensor cn13 1-2 blue-blue dc 0-5v voltage changes according to temperature. Heating return temperature sensor cn13 3-4 blue-blue dc 0-5v voltage changes according to temperature. Dhw outle...

Page 64

System details 63 point function cn no. Wire color normal value check m fan motor cn8 4-7 black-red dc 127-184v confirm steady voltage. Cn8 2-4 black-yellow dc 15v confirm steady voltage. Cn8 3-4 black-orange dc 0-7.5v voltage changes relative to fan operation. Cn8 1-4 black-white 0-6500rpm check pu...

Page 65

Version 1.4 64 ncb-e service manual 4.9 key components description 4.9.1 pcb part check point function to control each component and also to check the overall performance of the unit. Failure event malfunctioning pcb. Effects a component may not operate within the unit and could produce an error cod...

Page 66

System details 65 4.9.2 high limit switch part check point function 1. Overheat prevention switch. 2. If the unit detects extremely high temperatures, it will automatically trip and shut down the unit. 3. Excessively high water temperatures (more than 230 °f or 110 °c) in heat exchanger will activat...

Page 67

Version 1.4 66 ncb-e service manual 4.9.3 thermistor part check point function measure hot water, cold water, space heating outlet and inlet temperatures in the boiler. Failure event unable to properly measure water temperature within the boiler. Effects 1. If any of the thermistors fail, an error c...

Page 68

System details 67 4.9.4 fan motor part check point function provides combustion air into the burner and purges exhaust flue gas. Maintains the gas input with a long vent run, the fan operates with aps for ideal combustion. Failure event 1. Fan speed failure: the fan rpm is around 0 rpm. 2. The fan a...

Page 69

Version 1.4 68 ncb-e service manual 4.9.5 flame rod assembly part check point function to ignite gas by repeatedly discharging a high voltage spark to the main burner until gas ignites. Failure event 1. Unable to ignite during the ignition process. 2. Produces multiple unsuccessful attempts to ignit...

Page 70

System details 69 4.9.6 ignition transformer part check point function to ignite gas by repeatedly discharging a high voltage spark to the main burner until gas ignites. Failure event 1. Unable to ignite during the ignition process. 2. Produces multiple unsuccessful attempts to ignite. Effects 1. Th...

Page 71

Version 1.4 70 ncb-e service manual 4.9.7 aps part check point function detects the air pressure in the combustion system. Failure event 1. Combustion noise occurs. 2. Imperfect and/or abnormal flame occurs. 3. Occurs when aps does not detect proper voltage. Effects 1. The boiler is not operating. 2...

Page 72

System details 71 4.9.8 main gas valve part check point function 1. To control the amount of gas supplied to the burner based on fan speed. 2. When the unit experiences abnormal combustion, it shuts off the gas valve automatically and prevents unsafe situations. Failure event unable to open/close ef...

Page 73

Version 1.4 72 ncb-e service manual 4.9.9 burner part check point function 1. Pre-mix system reduces emissions and increase efficiency. 2. The burner facilitates the air/gas mixture necessary to produce the proper heat during combustion. Failure event 1. Unable to initialize/sustain combustion. 2. D...

Page 74

System details 73 4.9.10 flow sensor part check point function to detect water flow in gpm (gallons per minute) for steady hot water temperatures. Failure event 1. Unable to detect or measure water flow rate. 2. Damage to and/or water leakage from the water flow sensor. Effects 1. Ignition sequence ...

Page 75

Version 1.4 74 ncb-e service manual 4.9.11 primary heat exchanger part check point function 1. Main part for heat transfer from the burner. 2. There are multiple paths of water pipes on the heat exchanger surface as well as inside the combustion chamber which minimizes the heat loss. Failure event 1...

Page 76

System details 75 4.9.12 secondary heat exchanger part check point function 1. Main part for heat transfer from the burner. 2. There are multiple paths of water pipes on the heat exchanger as well as inside the combustion chamber which minimizes heat loss. Failure event 1. Water and/or exhaust gas l...

Page 77

Version 1.4 76 ncb-e service manual 4.9.13 dhw heat exchanger part check point function water heated in the primary/secondary heat exchanger is circulated to the plate heat exchanger, where the heat of heating water and tap water are exchanged so that hot water is available failure event 1. Water le...

Page 78

System details 77 4.9.14 circulation pump part check point function 1. Pump operates when using internal or external hot water circulation. 2. Internal circulation will minimize the effect of temperature fluctuations and external circulation delivers hot water to fixtures quickly resulting in water ...

Page 79

Version 1.4 78 ncb-e service manual 4.9.15 3-way valve part check point function diverts the water from the space heating system to the dhw plate heat exchanger and back based on input from dhw flow sensor and pcb. Failure event 1. No hot water in space heating mode. 2. No domestic hot water in dhw ...

Page 80

System details 79 4.9.16 water pressure sensor part check point function they are suitable for analyzing water pressure ratios in heating. Failure event unable to detect or measure to change water pressure effects water filling system does not operate automatically error code e351, e352, e353 diagno...

Page 81

Version 1.4 80 ncb-e service manual 4.9.17 auto feeder valve part check point function detect low and high water pressure using the electronic water pressure sensor if water pressure is low, water filling system operates automatically failure event 1. Water filling system does not operate automatica...

Page 82

System details 81 4.9.18 dual venturi part check point function to conrol the amount of mixed gas supplied with tdr of 10:1. It uses synchronous motor to control the amount of mixed gas by stage 1 and 2. Failure event 1. Blade not closing 2. Blade not opening effects 1. Frequent on/off due to excess...

Page 83: 5. Troubleshooting

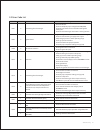

Version 1.4 82 ncb-e service manual 5.1 error code classification classification error code error level function self-diagnostic/action combustion system e003 3 ignition failure manual reset e004 2 false flame detection auto reset e012 3 flame loss manual reset e016 3 overheating of heat exchanger m...

Page 84

Troubleshooting 83 5.2 error code list error code sub code function self-diagnostic/action e001 0 overheating of heat exchanger ● clean the strainer ● check the pump for proper voltage from pcb(120ac) ● check for proper flow rate and circulation through the heating line. ● check the heat exchanger; ...

Page 85

Version 1.4 84 ncb-e service manual error code sub code function self-diagnostic/action e109 0 abnormal fan motor activity ● check and clean the intake air filter. ● verify proper voltage from pcb. ● check and clean the fan motor. E110 1 exhaust blockage (checking the fan) ● check the intake/exhaust...

Page 86

Troubleshooting 85 error code sub code function self-diagnostic/action e615 0 abnormal input data from high limit switch of heat exchanger ● check the htl and connection. ● check the pcb. 1 abnormal input data from exhaust sensor ● check the exhaust sensor wiring connection ● check the exhaust senso...

Page 87

Version 1.4 86 ncb-e service manual 5.1.1 001error error occurrence conditions and check items error description e001 overheating of heat exchanger 1. In order to prevent boiler in the heat exchanger, if the space heating water temperature is higher than 212 °f(100 °c), e001 will be displayed on the...

Page 88

Troubleshooting 87 check method failure mode cause check method abnormal circulation defective circulation pump when check the circulation pump, the circulation pump and fan run continuously in the error condition, in the status not occurred error, set pcb dip s/w #1 on and. 1. Check power supply to...

Page 89

Version 1.4 88 ncb-e service manual failure mode cause check method other trouble capacity setting sudden increase of temperature due to pcb dip s/w model setting error or max setting. Capacity dip s/w no. 5 6 150,000 btu (180) off off 175,000 btu (210) on off 199,000 btu (240) off on 120,000 btu (1...

Page 90

Troubleshooting 89 5.2.2 003error error occurrence conditions and check items error description e003 ignition failure in the case of an ignition failure, the boiler will attempt ignition 10 times. If no flame is detected, the system displays the error message 003e (manually cleared) on the front pan...

Page 91

Version 1.4 90 ncb-e service manual scenario2 check the flame rod power off the unit check connector check that gas valve is open or check lp supply check the voltage between #1 and #2 of cn 16: 22-24 vdc check the voltage between #1 and #3 of con 4: 22-24 vdc (see page 18 for wiring diagram) in cas...

Page 92

Troubleshooting 91 check method failure mode cause check method ignition failure gas supply error 1. Check if the main gas valve is open. 2. Check the gas supply pressure. ● ng: 3.5” - 10.5” w.C, lp: 8” – 13.5” w.C ● lp pressure drop occurs frequently in the winter. 3. Check the flexible pipe diamet...

Page 93

Version 1.4 92 ncb-e service manual failure mode cause check method ignition failure bracket igniter flame red ignite gap distance : 3.5-4.5mm (1/8”) no spark from electrode when no spark is made from the electrode at ignition: ● remove the electrode and check if there is a crack on the insulator. ●...

Page 94

Troubleshooting 93 failure mode cause check method ignition failure main gas valve 1. Check the primary/secondary power supply to the main gas valve. ● check, with a multi-meter, between the red-yellow and white-red wires to verify that the input power is dc 22-24v 2. Replace the pcb if power is not...

Page 95

Version 1.4 94 ncb-e service manual failure mode cause check method repeated ignition-out flame sensing error 1. Check the location of the flame, if there is any deformation or foreign substance, repair or replace the part. 2. Check the flame rod wire for proper connection and/or damage. 3. Check th...

Page 96

Troubleshooting 95 failure mode cause check method flame loss and noise occurs at ignition check if there are any blockages in the gas orifice plate. Ignition failure will occur if the gas orifices are clogged. ● remove the gas inlet pipe and check the orifice plate. Improper air intake air supply r...

Page 97

Version 1.4 96 ncb-e service manual check method failure mode cause check method flame before/after combustion leakage from main gas valve replace the gas flame if flame occurs before combustion or if there is remaining flame after combustion is stopped. Error before/after combustion discharge of el...

Page 98

Troubleshooting 97 5.2.4 012error error occurrence conditions and check items error description e012 flame loss if the system detects loss of flame during combustion, the system stops supplying fuel, attempts to restart, counts the incidents of flame loss, and if the incident occurs 20 times consecu...

Page 99

Version 1.4 98 ncb-e service manual check method fault possible causes check method flame loss and noise occurs after ignition low gas supply pressure 1. Check if a gas valve is opened or not. 2. Check the gas supply pressure. ● ng: 3.5” - 10.5” w.C, lp: 8” - 13.5” w.C ● lp pressure drop occurs freq...

Page 100

Troubleshooting 99 fault possible causes check method flame rod (electrode) replace the electrode or clean the fire detecting electrode. ● cause: due to the properties of the electrode, the oxide film is created due to long-term exposure to the high temperature; therefore, errors may be caused in de...

Page 101

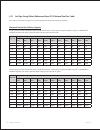

Version 1.4 100 ncb-e service manual fault possible causes check method flame loss and noise occurs after ignition digital pressure manometer check the offset values for low fire model gas type offset ncb-150e ng -0.04 in ±0.01 in lp -0.03 in ±0.01 in ncb-180e ng -0.04 in ± 0.01 in lp -0.03 in ± 0.0...

Page 102

Troubleshooting 101 5.2.5 016error error occurrence conditions and check items error description e016 bimetal overheated if the overheat controller on the heat exchanger is initiated during combustion/standby of the boiler, the system displays the 016e (manually cleared) message on the front panel. ...

Page 103

Version 1.4 102 ncb-e service manual check method fault possible causes check method defective safety device defective overheat controller check if the contact point of the overheat controller is defective. ● use a multi-meter to see if the resistance is normal (0.3Ω) or abnormal (∞). Overheat contr...

Page 104

Troubleshooting 103 5.2.6 030error error occurrence conditions and check items error description e030 exhaust gas temperature error if the overheat controller on the top of the exhaust duct is initiated, the system displays the heat exchanger bimetal overheat message 030e (cleared manually) on the f...

Page 105

Version 1.4 104 ncb-e service manual check method fault possible causes check method heat exchanger overheated damaged or clogged heat exchanger 1. The error occurs due to high exhaust gas temperature caused by a damaged or clogged heat exchanger. 2. Flush the heat exchanger to remove scale deposits...

Page 106

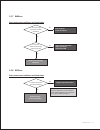

Troubleshooting 105 5.2.7 046error error occurrence conditions and check items is heat exchanger thermistor normally operating? Is resistance within normal range? (refer to page 66) replace heat exchanger thermistor. Check connector ( #3 and #4 of cn 13) 1 step: flushing, clean filter 2 step: try to...

Page 107

Version 1.4 106 ncb-e service manual 5.2.9 060error error occurrence conditions and check items error description e060 dual venturi error this error message is displayed on the front panel if the wiring is disconnected or the dual venturi malfunctions. The boiler switches into lock-out, and performs...

Page 108

Troubleshooting 107 check method fault possible causes check method dual venturi action error defective dual venturi cable or harness 1. Disconnect all cables from the dual venturi. 2. Using a multi-meter, test the dual venturi electrical wiring. Dual venturi not operating 1. Turn off the power to t...

Page 109

Version 1.4 108 ncb-e service manual 5.2.10 109error error occurrence conditions and check items error description e109 fan motor rpm error the system checks the rpm signal after the fan starts to run, and displays the error message 109e (cleared manually) in the following cases: 1. If the rpm remai...

Page 110

Troubleshooting 109 check method fault possible causes check method fan action error no fan operation 1. Check the power supply to the blower. ● black + red, approx. Dc 127-184 v 2. Replace the pcb if voltages are abnormal. (when replacing the pcb, turn off the unit and then wait for at least 10 sec...

Page 111

Version 1.4 110 ncb-e service manual 5.2.11 110error error occurrence conditions and check items error description e110 air pressure error the system senses the air volume and the rpm signal, and displays 110e on the front panel in the following cases: 1. When the initial fan auto-adjust is not perf...

Page 112

Troubleshooting 111 check method fault possible causes check method 110e exhaust blockage abnormal flow of intake air supply / exhaust 1. If 110e occurs intermittently during ignition or combustion, compare the standard rpm with the current rpm at min / max combustion (dip switch 1-1&1-2). If the cu...

Page 113

Version 1.4 112 ncb-e service manual 5.2.12 205error error conditions and check items error description e205 heat exchanger output temperature sensor open if an error (open: 14°f (-10°c) or lower) in the heat exchanger input temperature sensor is detected, the system displays the 421e error on the f...

Page 114

Troubleshooting 113 check method fault possible causes check method defective sensor defective temperature sensor connector check if the temperature sensor is open and if the connector is connected properly. Temperature sensor check the resistance of the temperature sensor. (defective if it is 30kΩ ...

Page 115

Version 1.4 114 ncb-e service manual 5.2.13 218error error conditions and check items error description e218 heat exchanger input temperature sensor open if an error (open: 14°f (-10°c) or lower) in the heat exchanger input temperature sensor is detected, the system displays the 421e error on the fr...

Page 116

Troubleshooting 115 check method fault possible causes check method defective sensor defective temperature sensor connector check if the temperature sensor is open and if the connector is connected properly. Temperature sensor check the resistance of the temperature sensor. (defective if it is 30kΩ ...

Page 117

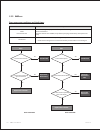

Version 1.4 116 ncb-e service manual 5.2.14 351error error conditions and check items error description e351 abnormal auto feeder valve if the water pressure sensor senses low water level as the heating pipe pressure is low, the system stops operation of the boiler, and refills water automatically. ...

Page 118

Troubleshooting 117 check method fault possible causes check method water is not refilled cold water valve is closed or frozen turn on cold water tap and check if the valve works or is frozen. Water supply defective auto feeder valve 1. Check the auto feeder valve filter if water is not refilled. 2....

Page 119

Version 1.4 118 ncb-e service manual 5.2.15 352error error conditions and check items error description e352 high water pressure upon receiving a signal from the water pressure sensor, the system displays the error(e352) on front panel. High water level error if the water level of 56.6 psi or higher...

Page 120

Troubleshooting 119 5.2.16 353error error conditions and check items error description e353 abnormal water pressure sensor if an error (under 0.3v or over 2.8v) in the water pressure sensor is detected continuously for 3 seconds, the system displays the error message e353 on the front panel. If this...

Page 121

Version 1.4 120 ncb-e service manual 5.2.17 407error error conditions and check items error description e407 hot water outlet thermistor open or short if an error (open: 14°f (-10°c) or lower) in the dhw outlet elbow input temperature sensor is detected, the system displays the 407e error on the fro...

Page 122

Troubleshooting 121 check method fault possible causes check method defective sensor defective temperature sensor connector check if the temperature sensor is open and if the connector is connected properly. Temperature sensor check the resistance of the temperature sensor. (defective if it is 30kΩ ...

Page 123

Version 1.4 122 ncb-e service manual 5.2.18 421error error conditions and check items error description e421 cold water inlet thermistor open or short if an error (open: 14°f (-10°c) or lower) in the dhw outlet elbow input temperature sensor is detected, the system displays the 421e error on the fro...

Page 124

Troubleshooting 123 check method fault possible causes check method defective sensor defective temperature sensor connector check if the temperature sensor is open and if the connector is connected properly. Temperature sensor check the resistance of the temperature sensor. (defective if it is 30kΩ ...

Page 125

Version 1.4 124 ncb-e service manual 5.2.19 439error error occurrence conditions and check items error description e439 flow sensor error as one or more units are operating in the cascade system, if no flow is detected during dhw using, the system considers it as a defective flow sensor. The system ...

Page 126

Troubleshooting 125 fault possible causes check method boiler not working defective flow sensor 1. Check the current flow displayed on the front panel. ● if the flow sensor is defective, the displayed flow value is 0.0 while water flows from the hot water tap. ● remove the flow sensor and blow into ...

Page 127

Version 1.4 126 ncb-e service manual 5.2.20 515error error occurrence conditions and check items error description e515 error if an error occurs in the internal circuit of the pcb (e.G., resistance, transistor or relay fault), the system displays 515e (cleared manually) on the pcb. Check items 1. De...

Page 128

Troubleshooting 127 5.2.21 517error error occurrence conditions and check items are the dip s/w on the pcb properly set? Change the dip s/w to the proper settings reset the unit yes no 5.2.22 594error error occurrence conditions and check items error description e594 error if the communication is ab...

Page 129

Version 1.4 128 ncb-e service manual 5.2.24 740error error conditions and check items error description e740 abnormal outdoor sensor if an error (under 2.2kΩ or over 122.2kΩ) in the outdoor sensor is detected continuously for 3 seconds, the system displays the error message e740 on the front panel. ...

Page 130

Troubleshooting 129 5.2.25 777error error conditions and check items is the factory jumper installed properly on cn24? Is the lwco installed properly? Is the output voltage normal on cn25? (ac 24v) is proper power being supplied to the lwco? Replace the main pcb check lwco check the factory installe...

Page 131

Version 1.4 130 ncb-e service manual 5.2.26 782error error occurrence conditions and check items reconnect panel to the pcb 1. Step: reset the unit. 2. Step: if problem persists, replace the pcb and front panel. Yes is the wiring from the front panel properly connected to the pcb? No.

Page 132

Troubleshooting 131 5.3 troubleshooting guide by symptom 5.3.1 noise error type cause check method vibration noise defective installation incorrect mounting to the wall or in an improper location. ● check for improper installation and reinstall the unit if necessary. Fan vibration noise vibration ca...

Page 133

Version 1.4 132 ncb-e service manual 5.3.2 water temperature issue error type cause check method boiler is not operating properly. Front panel power off hot water does not run if the front panel is switched off. Defective flow sensor the boiler does not work due to the defective flow sensor. ● the f...

Page 134

Troubleshooting 133 5.3.3 circuit breaker operation error type cause check method circuit breaker trips power supply the circuit breaker trips immediately as soon as the power cord is plugged in the receptacle. Check the sheath of power cord, or if there is short-circuit. Check the components in ord...

Page 135: 6. Replacement of Parts

Version 1.4 134 ncb-e service manual 6.1 replacement procedure caution 1. When performing maintenance and/or servicing the boiler, always turn off the electric power, gas and water shut-off valve. Wait for the boiler to become cool. Be careful to avoid injury to your fingers on sharp edges. 2. Drain...

Page 136

Replacement of parts 135 6.2.3 fan motor (combustion air) 1. Turn off the gas supply to the unit. 2. Disconnect the unit from the power supply. 3. Turn off the water supply to the unit. 4. Remove the mounting screw from the fan assembly as shown in figure 4 below. 5. Remove the fan assembly bracket ...

Page 137

Version 1.4 136 ncb-e service manual 5. Remove the 2 screws from the flame rod as shown in figure 7 below. Figure 7 6. Remove the flame rod wiring connector. Figure 8 7. Remove the flame rod from the burner assembly and replace with the new part. 8. Reconnect the 2 ignition transformer insulated cab...

Page 138

Replacement of parts 137 11. Turn on water supply, power supply, and gas supply to the unit. Note verify that the ignition transformer insulated cables are firmly connected to the flame rod. 6.2.6 aps 1. Turn off the gas supply to the unit. 2. Disconnect the unit from the power supply. 3. Turn off t...

Page 139

Version 1.4 138 ncb-e service manual 7. Disconnect wiring connector from the front panel. Figure 13 8. Disconnect all wiring connectors from the pcb remove the 3 screws from bottom pcb bracket and upper pcb bracket. 9. Remove the 2 screws and disconnect the wiring connector at the gas valve. Figure ...

Page 140

Replacement of parts 139 18. Turn on water supply, power supply, and gas supply to the unit. 19. Verify the gas pressures to the unit with the values provided in this service manual. Note always replace the old o-rings and gaskets with new parts to ensure tight seals between connections. Ensure that...

Page 141

Version 1.4 140 ncb-e service manual 7. Detach the 3 wire connectors that connect the flow sensor to the pcb. Figure 22 8. Pull out the flow sensor. Figure 23 9. Replace with old flow sensor with the new part. 10. Reinstall the flow sensor into heat exchange and reattach the stainless clip. Ensure t...

Page 142

Replacement of parts 141 6. Carefully remove the pump. Figure 26 7. Remove the air vent. Figure 27 8. Replace with the new circulation pump (or air vent). 9. Place the new pump back into its original position and ensure that all connections are tightly sealed. 6.2.10 circulation pump 1. Turn off the...

Page 143

Version 1.4 142 ncb-e service manual note always use proper o-rings at the pump connection to ensure tight seals 6.2.11 3-way valve 1. Turn off the gas supply to the unit. 2. Turn off the 120v power supply to the unit. 3. Turn off the water supply to the unit. Drain all water from the appliance. 4. ...

Page 144

Replacement of parts 143 4. Remove the stainless pin from the space heating strainer body. Figure 33 5. Pull out the space heating strainer. Figure 34 6. Replace with new strainer filter. Figure 35 6.2.12 water pressure sensor 1. Turn off the gas supply to the unit. 2. Turn off the 120v power supply...

Page 145

Version 1.4 144 ncb-e service manual 5. Remove the domestic hot water outlet collar. Figure 21 6. Remove the two fasteners at the dhw exchanger. Figure 22 7. Replace with the new dhw exchanger. Figure 23 6.2.14 auto feeder valve 1. Turn off the gas supply to the unit. 2. Turn off the 120v power supp...

Page 146

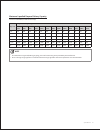

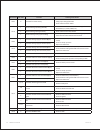

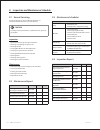

Components diagram and part list 145 7.1 case assembly 2 1 4 5 6 7 8 3 # description part # remark 1 intake air duct assembly 30008662b 2 exhaust pipe assembly 30008673a 3 case 20027375a ncb models 20033278a ncb-e models 4 intake air filter 20007667a ncb models 5 air pressure sensor 30010238a ncb mo...

Page 147

Version 1.4 146 ncb-e service manual 7.2 burner assembly 1 2 9 10 11 12 13 14 21 18 17 4 20 13 19 12 10 16 15 3 6 5 7 8.

Page 148

Components diagram and part list 147 # description part # remark 1 damper 30008825a 2 o-ring (g50) 20003019a 3 fan bracket 20022095a 4 siphon 30012280a 5 burner chamber ass'y 20030283a ncb-150e 30010353a ncb-180e 30008440a ncb-210e/240e 6 ignition transformer 30010455a 7 burner packing 20027105a ncb...

Page 149

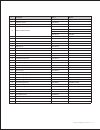

Version 1.4 148 ncb-e service manual 7.3 waterway assembly (ncb) a a 24 8 4 5 2 14 3 9 15 16 17 10 11 12 2 3 6 28 3 16 2 36 21 32 3 33 30 24 23 19 19 27 26 37 26 25 30 29 6 34 13 22 21 3 20 16 35 31 35 16 18 3 2 1 3 22 24 28 16 35 27 35 16 26 *before 2015.5.15 prduced units only. 38 # description pa...

Page 150

Components diagram and part list 149 # description part # remark 4 dhw outlet elbow 30012328a 5 packing 20006852a 6 thermistor 30008366a 7 dhw outlet adaptor 30003747a 8 dhw flow sensor 30012033b 9 o-ring (p14) 20006952a 10 dhw cold water adaptor 30010315a ncb-180 30010316a ncb-210 30010317a ncb-240...

Page 151

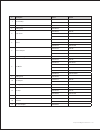

Version 1.4 150 ncb-e service manual 7.4 waterway assembly (ncb-e) a a 24 8 4 5 2 14 3 9 15 16 17 10 11 12 2 3 6 28 38 34 3 16 2 36 21 32 3 33 30 24 23 19 19 27 26 37 19 25 29 6 13 22 21 3 20 16 35 31 35 16 18 3 2 1 3 22 # description part # remark 1 dhw heat exchanger 30015581a ncb-150e 30008181a n...

Page 152

Components diagram and part list 151 # description part # remark 7 dhw outlet adaptor 30003747a 8 dhw flow sensor 30012033b 9 o-ring (p14) 20006952a 10 dhw cold water adaptor 30015582a ncb-150e 30010315a ncb-180e 30010316a ncb-210e 30010317a ncb-240e 11 o-ring (p20) 20017212a 12 dhw cold water filte...

Page 153

Version 1.4 152 ncb-e service manual 7.5 fan (gas) assembly 2 4 7 5 6 11 14 12 11 10 9 13 11 15 1 3 8.

Page 154

Components diagram and part list 153 # description part # remark 1 fan assembly 30015586a ncb-150 30008834a ncb-180/210/240 2 fan packing 20022744a 3 o-ring (g75) 20018079a 4 dual venturi 30015587a ncb-150 30010672a ncb-180 30008909a ncb-210/240 5 silence 20030064a ncb-150 20019142a ncb-180 20023829...

Page 155

Version 1.4 154 ncb-e service manual 8.1 annual servicing in order to maintain its safe and efficient operation, it is recommended that the boiler is serviced annually. Caution servicing must be performed by a qualified service agency or gas supplier inspection ● visual inspection for general signs ...

Page 156: Memo

Memo.

Page 157: Memo

Memo.