- DL manuals

- Navien

- Boiler

- NHB-055

- Service Manual

Navien NHB-055 Service Manual - Revisions

Summary of NHB-055

Page 1

Warning if the information in these instructions is not followed exactly, a fire or explosion may result, causing property damage, personal injury, or death. Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance. What to do if you smell gas...

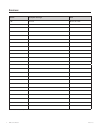

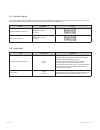

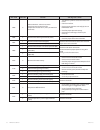

Page 2: Revisions

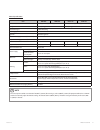

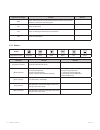

2 nhb service manual version 1.0 version description of changes date 1.00 first issue march / 26 / 2015 1.0 reviewed by : paek ji ho, revisions.

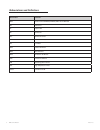

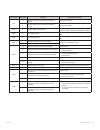

Page 3: Contents

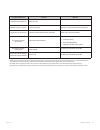

Nhb service manual 3 version 1.0 contents 1. Safety information 9 1.1 safety definitions 9 1.2 safety symbols 9 1.3 symbols used in the instructions 9 1.4 safety precautions 9 2. Product information 13 2.1 product information items 13 2.2 components 14 3. Technical data 16 3.1 general specifications...

Page 4

4 nhb service manual version 1.0 7. Components diagram and part list 133 7.1 case assembly 133 7.2 heat exchanger and waterway assembly 135 7.3 combustion parts assembly 138 8. Inspection and maintenance schedule 141 8.1 annual servicing 141 8.2 maintenance report 141 8.3 maintenance schedules 141 8...

Page 5

Nhb service manual 5 version 1.0 requirements for the state of massachusetts this appliance must be installed by a licensed plumber or gas fitter in accordance with the massachusetts plumbing and fuel gas code 248 cmr sections 2.00 and 5.00. Important: in the state of massachusetts (248 cmr 4.00 & 5...

Page 6: Navien Warranty

6 nhb service manual version 1.0 warranty exclusions navien’s limited warranty shall be void in the event of an occurrence of any of the following: ● improper installation, failure to install in strict compliance with the installation manual procedures, installed by a non-licensed installer, and ins...

Page 7

Nhb service manual 7 version 1.0 ● operating the boiler at water temperatures outside the factory calibrated temperature limits and/or exceeding the maximum setting of the high limit control. ● operating the boiler when it is not supplied with potable water at all times. ● subjecting the heat exchan...

Page 8

8 nhb service manual version 1.0 abbreviations and definitions abbreviation definition nhb general name of nhb-055, nhb-080, nhb-110 and nhb-150 ng natural gas lp propane gas ap air pressure aps air pressure sensor dhw domestic hot water fm fan motor gpm gallons per minute mgv main gas valve rpm rev...

Page 9: 1. Safety Information

Nhb service manual 9 version 1.0 1.3 symbols used in the instructions important warns of a risk of damage and environmental pollution note indicates additional information that is important but not related to personal injury or property damage. 1.4 safety precautions danger flammable materials keep ...

Page 10

10 nhb service manual version 1.0 danger if you smell gas: ● do not try to light any appliance. ● do not touch any electrical switches or use landline phones. ● from a neighbor’s phone, call your gas provider and follow their instructions. ● if you cannot reach your gas provider, call the fire depar...

Page 11

Nhb service manual 11 version 1.0 danger installation requirements ● installation conditions may affect how the boiler is serviced. Read all related information in the “installation manual”. ● the boilers must be installed according to all local and state codes or, in the absence of local and state ...

Page 12

12 nhb service manual version 1.0 warning ● shut off the gas supply if the boiler is damaged. Have your installer or plumber show you the location of the gas shut off valve and demonstrate how to close the valve. If the boiler is damaged as a result of overheating, fire, flood, or any other reason, ...

Page 13: 2. Product Information

Nhb service manual 13 version 1.0 2.1 product information items navien features the nhb series gas boiler. This appliance is fully modulating and provides central heating. Depending on the heat capacity, each model is divided into four types; 055, 080, 110 and 150. Model maximum space heating input ...

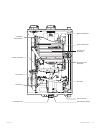

Page 14

14 nhb service manual version 1.0 2.2 components the following diagram shows the key components of the boiler. Component assembly diagrams and particular parts lists are included in the appendixes. Intake air air filter front panel pcb power switch aps lwco flue duct air vent connection exhaust spac...

Page 15

Nhb service manual 15 version 1.0 metal fiber premix buener mixing gas guide fan & motor dual venturi condensate trap ignition teansformer igniter & flame rod primary heat exchanger secondary heat exchanger gas valve gas connection space heating return.

Page 16: 3. Technical Data

16 nhb service manual version 1.0 3.1 general specifications the following table lists the specifications for the boiler. Additional specifications about water, gas, electric, and air supplies (venting) appear in the installation section. Space heating specifications navien condensing boiler space h...

Page 17

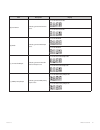

Nhb service manual 17 version 1.0 general specifications item nhb-055 nhb-080 nhb-110 nhb-150 dimensions 17in. (w) x 12in. (d) x 24in. (h) 17in. (w) x 13in. (d) x 24in. (h) weight 73 lbs. (33 kg) 80 lbs. (36 kg) installation type indoor wall-hung venting type forced draft direct vent ignition electr...

Page 18

18 nhb service manual version 1.0 3.2 dimensions the following diagrams show the dimensions of the boiler and the table lists the supply connections. 23.6" (600 m m ) supply connections description diameter a air intake 2 in b exhaust gas vent 2 in c air vent connection 3 / 4 in d rubber grommet 1 i...

Page 19: 4. System Details

Nhb service manual 19 version 1.0 set of pcb dip switch 1 (6 switch unit) the dip sw 1 on the circuit board configures the operation status and model / capacity settings. Off on ex) dip switch on / off switch function setting 1 & 2 operation status normal operation 1-off, 2-off 2-stage max 1-on, 2-o...

Page 20

20 nhb service manual version 1.0 set of pcb dip switch 2 (8 switch unit) the dip sw 2 on the circuit board configures the temperature control modes, country, and enables or disables the space heating thermostat. 1 2 3 4 5 6 on 1 2 3 4 5 6 7 8 on switch function setting 1 & 2 space heating temperatu...

Page 21

Nhb service manual 21 version 1.0 set of front panel dip switch 2 (2 switch unit) the dip sw 2 on the front panel configures settings for the type of gas. Before changing the settings, lift the rubber cover to access the front panel dip switches. 2 on ng lp 2 on 1 2 3 4 5 6 7 8 9 10 1 2 on on switch...

Page 22

22 nhb service manual version 1.0 2. Turn on the boiler. On the front panel, press and hold the diagnostics button for over5 seconds until “1.Par” is displayed. Mode 3. Press the + (up) button two times to change the display to “3.Opr”. 4. Press the mode button once to access the operation mode menu...

Page 23

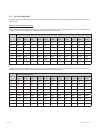

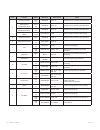

Nhb service manual 23 version 1.0 4.2.1 gas pipe sizing tables the following tables are referenced from 2012 national fuel gas code for reference only. Please consult the gas pipe manufacturer for actual pipe capacities. Maximum natural gas delivery capacity in cubic feet (ft 3 ) per hour (0.60 spec...

Page 24

24 nhb service manual version 1.0 maximum liquefied propane delivery capacity in thousands of btu / h (0.5” wc pressure drop) pipe size length (including fittings) 10 ft. (3 m) 20 ft. (6 m) 30 ft. (9 m) 40 ft. (12 m) 50 ft. (15 m) 60 ft. (18 m) 70ft. (21m) 80ft. (24m) 90ft. (27m) 100ft. (30m) 125ft....

Page 25

Nhb service manual 25 version 1.0 4.3 gas conversion nhb series boilers are configured for natural gas at the factory. If conversion to propane gas is required, use the conversion kit supplied with the boiler. Warning this conversion kit shall be installed by a qualified service agency* in accordanc...

Page 26

26 nhb service manual version 1.0 6. Loosen the three screws indicated below in figure 2 and 3. Figure 2. Nhb isometric view 7. Remove the pcb assembly. Figure 3. Nhb series pcb 8. With the internal components exposed, locate the gas inlet pipe and the gas valve in the middle of the unit, as shown i...

Page 27

Nhb service manual 27 version 1.0 11. Once the gas orifice is exposed, remove the two screws that hold the part in place. Remove the gas orifice from its housing and prepare the new gas orifice for the lp conversion for installation. Remove two 2 screws here figure 6. Access to gas orifice in fan as...

Page 28

28 nhb service manual version 1.0 14. Place the pcb assembly back on to the boiler and tighten the three screws. 15. Check the labels carefully and then connect all the wires. 16. Set the front panel dip switch to change the gas type. For lp, set dip switch 2 #2 to on. For ng, set dip switch 2 #2 to...

Page 29

Nhb service manual 29 version 1.0 c. Activate multiple zones and set the boiler to operate at 1-stage min mode. Measure the co 2 value at low fire (refer to “4.1.1 pcb dip switches” on page 19 and "(3) operation conditions settings" on page 59). If the co 2 value is not within 0.5% of the value list...

Page 30

30 nhb service manual version 1.0 c. Activate multiple zones and set the boiler to operate at 1-stage min mode (refer to "(3) operation conditions settings" on page 59). Measure the offset value at low fire and compare it to the values in table 3. If the offset value is out of range, the gas valve s...

Page 31

Nhb service manual 31 version 1.0 4.4 the front panel the front panel allows you to adjust the temperature and view the operating status or error codes. Remove the protective sheet from the front panel before using it. 4.4.1 lcd display display (icon) function remarks displays heating icon upon heat...

Page 32

32 nhb service manual version 1.0 segment status display function remarks wait shown while waiting for a response from the main controller when the boiler performs an error test or error history load rst shown on error reset clr shown on deleting the error history and parameters. Init shown on facto...

Page 33

Nhb service manual 33 version 1.0 long key combination function remarks [power] long key (300msec) power on / off [mode] long key (2 seconds) error history display must be in normal mode or error display mode [reset] long key (5 seconds) individual deletion of error history / tech data works only at...

Page 34

34 nhb service manual version 1.0 4.4.3 turning the boiler on or off to turn the boiler on or off, press the [power] button for 0.3 seconds. Mode if the unit is experiencing an error the error code will continue to display on the front panel even if the unit is turned off. Item description display p...

Page 35

Nhb service manual 35 version 1.0 9. Entering is available via . Item description display 1. Normal status normal operating mode with power on when the current supply water temperature is 120°f and the water pressure is 12.3psi, the image below repeats at 5 second intervals (fahrenheit specification...

Page 36

36 nhb service manual version 1.0 4.4.5 error display and reset 1. When an error higher than level 2 occurs (the boiler may stop operation or only has basic functions), the boiler enters directly at or . 2. When an error occurs at other panel modes, only the error icon flashes and it enters after te...

Page 37

Nhb service manual 37 version 1.0 note ● the outdoor reset control will take precedence over this temperature setting. ● in case of outdoor reset sensor malfunction, the boiler will operate at this set temperature. ● take note of the original heating temperature in case you want to restore it to the...

Page 38

38 nhb service manual version 1.0 4.4.8 viewing basic information (for homeowner) to view information about the boiler, press the [mode] button three times. “info” will appear in the display. Press the [+] or [–] buttons to switch between the information types. Item description display (a) space hea...

Page 39

Nhb service manual 39 version 1.0 item description display (i) space heating water pressure display of current water pressure in case of using water pressure sensor, turn-on of psi icon, indication of water pressure at segment. Ex )12.3 psi psi (j) dhw priority time indicating dhw priority use time ...

Page 40

40 nhb service manual version 1.0 4.4.9 error occurrence history display 1. At the or , press the [info] button for over 2 seconds to access the error history mode. The most recent error will be displayed first. 2. When the [+] / [-] button is pressed, the error history can be searched. A total of 1...

Page 41

Nhb service manual 41 version 1.0 4.4.10 information display (for servicer) 1. At the , press the [diagnostic] button once to access the service information display. 2. Press [+] or [-] to navigate through the user parameters. 3. Item of current service information data is indicated as an alphabetic...

Page 42

42 nhb service manual version 1.0 item description display (g) outdoor reset curve display of heat load (1~7) 1: finned tube baseboard 2: fan coil 3: cast iron baseboard 4: low mass radiant 5: high mass radiant 6: radiator 7: custom (set by installer) if finned tube baseboard is set; if outdoor rese...

Page 43

Nhb service manual 43 version 1.0 item description display (o) current aps display of current aps voltage value display of the aps value as voltage up to the first decimal place, ex) 3.2v; (p) exhaust gas temperature display of current exhaust gas temperature exhaust gas temperature display for cels...

Page 44

44 nhb service manual version 1.0 item description display (s) altitude setting information display of current altitude level setting 0~2,000ft 2,000~5,400ft 5,400~7,700ft 7,700~10,100ft (v) space heating system supply water temperature display of the current system space heating outgoing water temp...

Page 45

Nhb service manual 45 version 1.0 item description display (y) temperature for exhaust gas 2. Indicating current exhaust gas 2 temperature. For celsius (°c) mode; ex) at 30°c for fahrenheit (°f) mode; ex) 100°f (z) ch demand indicating current heating demand. In case of ch demand off in case of dhw ...

Page 46

46 nhb service manual version 1.0 item description display (3) dhw set temperature. Indicating current dhw set temperature. For celsius (°c) mode; ex) at 60°c for fahrenheit (°f) mode; ex) 120°f (4) boiler pump indicating current boiler pump status. In case of boiler pump off. In case of boiler pump...

Page 47

Nhb service manual 47 version 1.0 item description display (8) dual venturi indicating current dual venturi status. In case of dual venturi off. In case of dual venturi on. (9) lwco indicating current lwco input status. In case of lwco off. In case of lwco on. ( ▷ ) air handler output indicating cur...

Page 48

48 nhb service manual version 1.0 4.4.11 special parameter mode you can modify parameter settings for boiler operations, in different operating conditions. Follow the instructions below to access the special parameter mode and change the available settings. Caution parameters must be set by a qualif...

Page 49

Nhb service manual 49 version 1.0 (1) parameter setting mode 1. When [+] / [-] buttons are operated at and if 1 par item is indicated at the segment, at one time pressing of [mode] button, then it is entered into . 2. After entering into, ‘pass’ is indicated and if [mode] button is pressed to input ...

Page 50

50 nhb service manual version 1.0 caution ● if you enter an incorrect password 10 times or make no input 5 minutes, the boiler will return to the normal mode. ● to return to the previous mode, press the reset button. ● the factory default password is “1234” ● if you make no adjustment for 10 seconds...

Page 51

Nhb service manual 51 version 1.0 item description display (c) lowest outdoor temperature setting this mode is used to configure the heat load type to be used with the outdoor reset control mode the boiler will operate at the high end of the supply or return set-point range at this outdoor temperatu...

Page 52

52 nhb service manual version 1.0 item description display (f) space heating max heat capacity this menu is used to configure the desired space heating capacity. When the boiler operates in the normal mode, the space heating capacity is limited to the set value (%) setting range default ( [heating m...

Page 53

Nhb service manual 53 version 1.0 item description display (l) space heating burner off differential during space heating, the boiler turns off the burner when the space heating supply temperature meets or exceeds the burner-off temperature. Setting range default 2 ~ 54°f(1 ~ 30°c) 4°f(2°c) for cels...

Page 54

54 nhb service manual version 1.0 item description display (p) return absolute max set-point this menu may be used to make changes to the maximum return temperature range the return control mode is in use. When configuring the custom mode in the outdoor reset control mode, the return temperature cha...

Page 55

Nhb service manual 55 version 1.0 item description display (w) setting of dhw mode – boiler pump setting of boiler pump on / off at dhw mode setting range default on / off off in case of boiler pump off in case of boiler pump on (x) setting of dhw mode – system pump setting of system pump on / off a...

Page 56

56 nhb service manual version 1.0 item description display (3) space heating min heat capacity displaying space heat min heat capacity. Setting range default space heating min capacity ~ [space heating max capacity – 20%] minimum heat performance available of model space heating min capacity is 12% ...

Page 57

Nhb service manual 57 version 1.0 (2) error checking mode 1. While in , press the [+] / [-] button and then press the [mode] button once. “2.Tst” is displayed on the front panel. 2. After accessing , make sure that the boiler is not operating (stop flow) 3. Increase / decrease and change the compone...

Page 58

58 nhb service manual version 1.0 component test performed display method fan gradually increase / decrease the speed of the fan motor starting from 0 rpm to full speed and back down to 0 rpm the current aps value and the current rpm value are repeatedly displayed at intervals of 2 seconds. Boiler p...

Page 59

Nhb service manual 59 version 1.0 (3) operation conditions settings 1. While in , press the [+] / [-] button and then press the [mode] button once when “3. Opr” is displayed on the front panel. 2. Whenever the [+] / [-] button is pressed, it increases / decreases the operation condition and flashes ...

Page 60

60 nhb service manual version 1.0 4.4.12 resetting the boiler (factory reset) if an error message appears, you can try resetting the boiler to resolve the problem. To reset the boiler, press the reset button. Mode if resetting the boiler does not solve the problem, refer to the troubleshooting secti...

Page 61

Nhb service manual 61 version 1.0 4.5 version display press the [diagnostic] button for more than 10 seconds at will display the main controller firmware version for 3 seconds, display the panel firmware version for 3 seconds and return the system to . Item description display (a) main controller f ...

Page 62

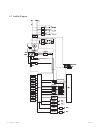

62 nhb service manual version 1.0 4.7 ladder diagram.

Page 63

Nhb service manual 63 version 1.0 4.8 electrical diagnostic point & wiring diagram color c ode b o r w y bk br gy : blue : or ange : r ed : w hit e : y ello w : black : br own : gr een/y ello w if an y of the or ig inal wir es as supplied the boiler must be replac ed , they must be r eplac ed their ...

Page 64

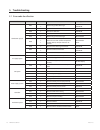

64 nhb service manual version 1.0 point function cn no. Wire color normal value check a exhaust thermistor cn13 1-2 blue-blue dc 0~5v voltage changes according to temperature. Heating return temperature sensor cn13 5-6 blue-blue dc 0~5v voltage changes according to temperature. Heating supply temper...

Page 65

Nhb service manual 65 version 1.0 4.9 key components description 4.9.1 pcb part check point function controls each component and monitors the overall performance of the unit. Failure event malfunctioning pcb. Effects a component may not operate within the unit and could produce an error code. In mos...

Page 66

66 nhb service manual version 1.0 4.9.2 high limit switch part check point function 1. Overheat prevention switch. 2. If the unit detects extremely high temperatures, it will automatically trip and shut down the unit. 3. Excessively high water temperatures (more than 230 °f or 110 °c) in heat exchan...

Page 67

Nhb service manual 67 version 1.0 4.9.3 thermistor part check point function measure hot water, cold water, space heating outlet and inlet temperatures in the boiler. Failure event unable to properly measure water temperature within the boiler. Effects 1. If any of the thermistors fail, an error cod...

Page 68

68 nhb service manual version 1.0 4.9.4 fan motor part check point function provides combustion air into the burner and purges exhaust flue gas. Maintains the gas input with a long vent run, the fan operates with aps for ideal combustion. Failure event 1. Fan speed failure: the fan rpm is around 0 r...

Page 69

Nhb service manual 69 version 1.0 4.9.5 flame rod assembly part check point function continuously discharges a high voltage spark to the main burner until gas ignites. Failure event 1. Unable to ignite during the ignition process. 2. Produces multiple unsuccessful attempts to ignite. Effects 1. The ...

Page 70

70 nhb service manual version 1.0 4.9.6 ignition transformer part check point function continuously provides a high voltage to flame rod until gas ignites. Failure event 1. Unable to ignite during the ignition process. 2. Produces multiple unsuccessful attempts to ignite. Effects 1. The unit cannot ...

Page 71

Nhb service manual 71 version 1.0 4.9.7 aps part check point function detects the air pressure in the combustion system. Failure event 1. Combustion noise occurs. 2. Imperfect and/or abnormal flame occurs. 3. Occurs when aps does not detect proper voltage. Effects 1. The boiler is not operating. 2. ...

Page 72

72 nhb service manual version 1.0 4.9.8 main gas valve part check point function 1. To control the amount of gas supplied to the burner based on fan speed. 2. When the unit experiences abnormal combustion, it shuts off the gas valve automatically and prevents unsafe situations. Failure event unable ...

Page 73

Nhb service manual 73 version 1.0 4.9.9 burner part check point function 1. Pre-mix system reduces emissions and increase efficiency. 2. The burner facilitates the air/gas mixture necessary to produce the proper heat during combustion. Failure event 1. Unable to initialize/sustain combustion. 2. Dus...

Page 74

74 nhb service manual version 1.0 4.9.10 primary heat exchanger part check point function 1. Main part for heat transfer from the burner. 2. There are multiple paths of water pipes on the heat exchanger surface as well as inside the combustion chamber which minimizes the heat loss. Failure event 1. ...

Page 75

Nhb service manual 75 version 1.0 4.9.11 secondary heat exchanger part check point function 1. Main part for heat transfer from the burner. 2. There are multiple paths of water pipes on the heat exchanger as well as inside the combustion chamber which minimizes heat loss. Failure event 1. Water and/...

Page 76

76 nhb service manual version 1.0 4.9.12 water pressure sensor part check point function detects water pressure in the heating system. Failure event unable to detect or measure to change in water pressure. Effects water filling system does not operate automatically error code e302, e352, e353 diagno...

Page 77

Nhb service manual 77 version 1.0 4.9.13 dual venturi part check point function controls the amount of mixed gas to modulate heating input. It uses synchronous motor to control the amount of mixed gas by stage 1 and 2. Failure event 1. Blade not closing 2. Blade not opening effects 1. Frequent on / ...

Page 78: 5. Troubleshooting

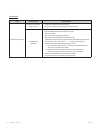

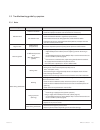

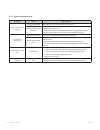

78 nhb service manual version 1.0 5.1 error code classification classification error code error level function self-diagnostic / action combustion system e001 3 2 overheating of heat exchanger manual reset auto reset e003 3 ignition failure manual reset e004 2 false flame detection auto reset e012 3...

Page 79

Nhb service manual 79 version 1.0 5.2 error code classification error code sub code function self-diagnostic / action e001 1 overheating of heat exchanger 1. Clean the strainer. 2. Check the pump for proper voltage from pcb(120vac) 3. Check for proper flow rate and circulation(external) through the ...

Page 80

80 nhb service manual version 1.0 error code sub code function self-diagnostic / action e030 0 exhaust overheat : exhaust limit switch shuts down the unit when the flue temperature exceeds 230 °f (110 °c) for more than 10 minutes. 1. Turn off the system for at least 30 minutes then restart. 2. Clean...

Page 81

Nhb service manual 81 version 1.0 error code sub code function self-diagnostic / action e279 1 abnormal operation: system return thermistor (open) check the thermistor. 2 abnormal operation: system return thermistor (short) check the thermistor. E291 0 supply / return inversion limit check if the su...

Page 82

82 nhb service manual version 1.0 error code sub code function self-diagnostic / action e777 0 abnormal operation: lwco(external device) 1. Check the lwco wiring connection 2. Ensure that the system water level is appropriate. 3. Add make-up water to the system if necessary. 4. Check for proper volt...

Page 83

Nhb service manual 83 version 1.0 5.2.1 001error error occurrence conditions and check items error description e001 overheating of heat exchanger 1. In order to prevent boiling in the heat exchanger, if the space heating water temperature is higher than 216°f(102°c), e001 will be displayed on the fr...

Page 84

84 nhb service manual version 1.0 check method failure mode cause check method abnormal circulation defective circulation pump(external) when check the circulation pump, the circulation pump and fan run continuously in the error condition, in the status not occurred error 1. Check power supply to th...

Page 85

Nhb service manual 85 version 1.0 5.2.2 003error error occurrence conditions and check items error description e003 ignition failure in the case of an ignition failure, the boiler will attempt ignition 10 times. If no flame is detected, the system displays the error message 003e (manually cleared) o...

Page 86

86 nhb service manual version 1.0 scenario2 is gas valve operating normally? Does the main gas valve have proper voltage? Is gas valve open? Check the flame rod power off the unit check that gas valve is open or check lp supply check connector check the voltage between the white-yellow of cn 16: 22-...

Page 87

Nhb service manual 87 version 1.0 check method failure mode cause check method ignition failure gas supply error 1. Check if the main gas valve is open. 2. Check the gas supply pressure. ● ng: 3.5” - 10.5” w.C, lp: 8” – 13.5” w.C ● lp pressure drop occurs frequently in the winter. 3. Check the flexi...

Page 88

88 nhb service manual version 1.0 failure mode cause check method ignition failure igniter flame rod bracket ignite gap distance : 3.5~4.5mm (1/8”) no spark from electrode when no spark is made from the electrode at ignition: ● remove the electrode and check if there is a crack on the insulator. ● a...

Page 89

Nhb service manual 89 version 1.0 failure mode cause check method ignition failure main gas valve 1. Check the primary/secondary power supply to the main gas valve. ● check, with a multi-meter, between the red-yellow and white-red wires to verify that the input power is dc 22-24v 2. Replace the pcb ...

Page 90

90 nhb service manual version 1.0 failure mode cause check method repeated ignition-out flame sensing error 1. Check the location of the flame, if there is any deformation or foreign substance, repair or replace the part. 2. Check the flame rod wire for proper connection and/or damage. 3. Check the ...

Page 91

Nhb service manual 91 version 1.0 5.2.3 004error error occurrence conditions and check items error description e004 false-flame detection 1. Pre ignition false-flame if a flame signal is detected continuously for 3 seconds before combustion (stand-by, pre- purge, pre-ignition), a false-flame error 0...

Page 92

92 nhb service manual version 1.0 5.2.4 012error error occurrence conditions and check items error description e012 flame loss if the system detects loss of flame during combustion, the system stops supplying fuel, attempts to restart, counts the incidents of flame loss, and if the incident occurs 2...

Page 93

Nhb service manual 93 version 1.0 check method fault possible causes check method flame loss and noise occurs after ignition low gas supply pressure 1. Check if a gas valve is opened or not. 2. Check the gas supply pressure. ● ng: 3.5” - 10.5” w.C, lp: 8” - 13.5” w.C ● lp pressure drop occurs freque...

Page 94

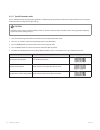

94 nhb service manual version 1.0 fault possible causes check method flame loss and noise occurs after ignition digital pressure manometer check the offset values for min fire model gas type offset nhb-055 ng -0.04 in ± 0.01 in lp -0.03 in ± 0.01 in nhb-080 ng -0.04 in ± 0.01 in lp -0.02 in ± 0.01 i...

Page 95

Nhb service manual 95 version 1.0 fault possible causes check method [location of assembly screw and ground bolt in heat exchanger] defected metal fiber 1. Check the presence of debris in the metal fiber. 2. Check the sagging of the metal fiber and then the gaps with the electrode. [gap between the ...

Page 96

96 nhb service manual version 1.0 5.2.5 016error error occurrence conditions and check items error description e016 bimetal overheated if the overheat controller on the heat exchanger is initiated during combustion/standby of the boiler, the system displays the 016e (manually cleared) message on the...

Page 97

Nhb service manual 97 version 1.0 check method fault possible causes check method defective safety device defective overheat controller check if the contact point of the overheat controller is defective. ● use a multi-meter to see if the resistance is normal (0.3Ω) or abnormal (∞). Overheat controll...

Page 98

98 nhb service manual version 1.0 5.2.6 030error error occurrence conditions and check items error description e030 exhaust gas temperature error if the temperature sensor on the top of the exhaust duct is initiated, the system displays the exhaust overheat message 030e (cleared manually) on the fro...

Page 99

Nhb service manual 99 version 1.0 check method fault possible causes check method heat exchanger overheated damaged or clogged heat exchanger 1. The error occurs due to high exhaust gas temperature caused by a damaged or clogged heat exchanger. 2. Flush the heat exchanger to remove scale deposits. 3...

Page 100

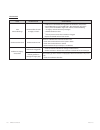

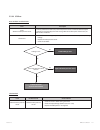

100 nhb service manual version 1.0 5.2.7 046error error occurrence conditions and check items is heat exchanger thermistor normally operating? Is resistance within normal range? (refer to page 67) replace heat exchanger thermistor. Check connector ( #7 and #8 of cn 13) 1 step: flushing, clean filter...

Page 101

Nhb service manual 101 version 1.0 5.2.9 060error error occurrence conditions and check items error description e060 dual venturi error this error message is displayed on the front panel if the wiring is disconnected or the dual venturi malfunctions. The boiler switches into lock-out, and performs p...

Page 102

102 nhb service manual version 1.0 check method fault possible causes check method dual venturi action error defective dual venturi cable or harness 1. Disconnect all cables from the dual venturi. 2. Using a multi-meter, test the dual venturi electrical wiring. Dual venturi not operating 1. Turn off...

Page 103

Nhb service manual 103 version 1.0 5.2.10 109error error occurrence conditions and check items error description e109 fan motor rpm error the system checks the rpm signal after the fan starts to run, and displays the error message 109e (cleared manually) in the following cases: 1. If the rpm remains...

Page 104

104 nhb service manual version 1.0 check method fault possible causes check method fan action error no fan operation 1. Check the power supply to the blower. ● black + red, approx. Dc 127~184 v 2. Replace the pcb if voltages are abnormal. (when replacing the pcb, turn off the unit and then wait for ...

Page 105

Nhb service manual 105 version 1.0 5.2.11 110error error occurrence conditions and check items error description e110 air pressure error the system senses the air volume and the rpm signal, and displays 110e on the front panel in the following cases: 1. When the initial fan auto-adjust is not perfor...

Page 106

106 nhb service manual version 1.0 check method fault possible causes check method 110e exhaust blockage abnormal flow of intake air supply / exhaust 1. If 110e occurs intermittently during ignition or combustion, compare the standard rpm with the current rpm at min / max combustion (dip switch 1-1&...

Page 107

Nhb service manual 107 version 1.0 5.2.12 205error error conditions and check items error description e205 heat exchanger output temperature sensor open if an error (open: 14°f (-10°c) or lower) in the heat exchanger input temperature sensor is detected, the system displays the 205e error on the fro...

Page 108

108 nhb service manual version 1.0 check method fault possible causes check method defective sensor defective temperature sensor connector check if the temperature sensor is open and if the connector is connected properly. Temperature sensor check the resistance of the temperature sensor. (defective...

Page 109

Nhb service manual 109 version 1.0 5.2.13 218error error conditions and check items error description e218 heat exchanger input temperature sensor open if an error (open: mΩ) in the heat exchanger input temperature sensor is detected, the system displays the 218e error on the front panel. If this oc...

Page 110

110 nhb service manual version 1.0 check method fault possible causes check method defective sensor defective temperature sensor connector check if the temperature sensor is open and if the connector is connected properly. Temperature sensor check the resistance of the temperature sensor. (defective...

Page 111

Nhb service manual 111 version 1.0 5.2.14 271error error conditions and check items error description e271 temperature differential limit if the temperature differential (supply temperature - return temperature) is higher than 54°f(30°c), the alarm code (e271) is displayed. The system operates norma...

Page 112

112 nhb service manual version 1.0 5.2.15 278error error conditions and check items error description e278 system supply temperature sensor open if an error (open: mΩ) in the system supply temperature sensor is detected, the system displays the 278e error on the front panel. If this occurs, the boil...

Page 113

Nhb service manual 113 version 1.0 5.2.16 279error error conditions and check items error description e279 system return temperature sensor open if an error (open: mΩ) in the system return temperature sensor is detected, the system displays the 279e error on the front panel. If this occurs, the boil...

Page 114

114 nhb service manual version 1.0 5.2.17 291error error conditions and check items error description e291 supply / return inversion limit if the return temperature is higher than “supply temperature + 10°f (5.5°c)”, the system stops operation and displays error code (e291) on the front panel. Check...

Page 115

Nhb service manual 115 version 1.0 5.2.18 302error error conditions and check items error description e302 low water if the water pressure sensor senses low water level as the heating pipe pressure is low, the system stops operation of the boiler and error (e302) is displayed on the front panel. Che...

Page 116

116 nhb service manual version 1.0 5.2.19 352error error conditions and check items error description e352 high water pressure upon receiving a signal from the water pressure sensor, the system displays the error(e352) on front panel. High water level error if the water level of 56.6 psi or higher c...

Page 117

Nhb service manual 117 version 1.0 5.2.20 353error error conditions and check items error description e353 abnormal water pressure sensor if an error (under 0.3v or over 2.8v) in the water pressure sensor is detected continuously for 3 seconds, the system displays the error message e353 on the front...

Page 118

118 nhb service manual version 1.0 5.2.21 515error error occurrence conditions and check items error description e515 error if an error occurs in the internal circuit of the pcb (e.G., resistance, transistor or relay fault), the system displays 515e (cleared manually) on the pcb. Check items 1. Defe...

Page 119

Nhb service manual 119 version 1.0 5.2.22 517error error occurrence conditions and check items are the dip s / w on the pcb properly set? Change the dip s / w to the proper settings * if problem persists, replace the pcb reset the unit yes no 5.2.23 594error error occurrence conditions and check ite...

Page 120

120 nhb service manual version 1.0 5.2.24 615error error occurrence conditions and check items error description e615 error abnormal signal input by pcb. Check items 1. Turn the power reset switch off then on (or unplug and replug the power supply. 2. If the system still displays e615, replace the m...

Page 121

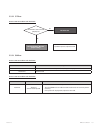

Nhb service manual 121 version 1.0 5.2.26 777error error conditions and check items is the factory jumper installed properly on cn24? Is the lwco installed properly? Is the output voltage normal on cn25? (ac 24v) is proper power being supplied to the lwco? Replace the main pcb check lwco check the f...

Page 122

122 nhb service manual version 1.0 5.2.27 782error error occurrence conditions and check items is the wiring from the front panel properly connected to the pcb? Reconnect panel to the pcb 1. Step: reset the unit. 2. Step: if problem persists, replace the pcb and front yes no 5.2.28 784error error oc...

Page 123

Nhb service manual 123 version 1.0 5.3 troubleshooting guide by symptom 5.3.1 noise error type cause check method vibration noise defective installation incorrect mounting to the wall or in an improper location. ● check for improper installation and reinstall the unit if necessary. Fan vibration noi...

Page 124

124 nhb service manual version 1.0 5.3.2 water temperature issue error type cause check method boiler is not operating properly. Front panel power off hot water does not run if the front panel is switched off. Defective heating supply thermistor the temperature is sensed higher than the actual tempe...

Page 125

Nhb service manual 125 version 1.0 5.3.3 circuit breaker operation error type cause check method circuit breaker trips power supply the circuit breaker trips immediately as soon as the power cord is plugged in the receptacle. Check the sheath of power cord, or if there is short-circuit. Check the co...

Page 126: 6. Replacement of Parts

126 nhb service manual version 1.0 6.1 replacement procedure caution 1. When performing maintenance and/or servicing the boiler, always turn off the electric power, gas and water shut-off valve. Wait for the boiler to become cool. Be careful to avoid injury to your fingers on sharp edges. 2. Drain a...

Page 127

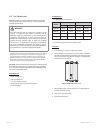

Nhb service manual 127 version 1.0 6.2.2 fuse 1. Turn off the gas supply to the unit. 2. Disconnect the unit from the power supply. 3. Locate the fuse housing shown in figure 3 below. Open the housing to expose the fuse. Figure 3 4. Replace the old fuse with the new part. 5. Ensure that the new fuse...

Page 128

128 nhb service manual version 1.0 6. Disconnect wiring connectors of fan and venturi. Figure 9 7. Remove the 2 screws from bracket of gas mix pipe. Figure 10 8. Remove hose of aps from intake pipe and lift up fan ass’y figure 11 figure 12 9. To detach the fan from the fan ass’y and replace it with ...

Page 129

Nhb service manual 129 version 1.0 6.2.4 flame rod 1. Turn off the gas supply to the unit. 2. Disconnect the unit from the power supply. 3. Turn off the water supply to the unit. 4. Remove the ignition transformer insulated cables. 5. Remove the 2 screws from the flame rod as shown in figure below. ...

Page 130

130 nhb service manual version 1.0 6.2.6 aps 1. Turn off the gas supply to the unit. 2. Disconnect the unit from the power supply. 3. Turn off the water supply to the unit. 4. Remove the air pressure sensor wiring connector (figure 19). Figure 19 5. Remove the hose from the air pressure sensor. Figu...

Page 131

Nhb service manual 131 version 1.0 6. Remove the 2 screws located at the bottom of the unit that are attached to the gas valve. Figure 24 remove the 4 screws directly on the bottom of the gas valve to remove the gas pipe. Figure 25 7. Remove the 4 screws directly from the top of the gas valve to rem...

Page 132

132 nhb service manual version 1.0 6.2.8 condensate trap 1. Turn off the gas supply to the unit. 2. Disconnect the unit from the power supply. 3. Turn off the water supply to the unit. 4. Remove the pin that secures the condensate drain cap and then remove the cap. Use a bucket to collect the conden...

Page 133

Nhb service manual 133 version 1.0 7.1 case assembly 10 1 3 4 2 8 7 9 9 5 6 9 10 1 3 4 2 8 7 9 9 5 6 9 7. Components diagram and part list.

Page 134

134 nhb service manual version 1.0 # description part # remark 1 case 20030085a nhb-110 / 150 20030088a nhb-055 / 080 2 cover 30013463a 3 pcb 30013044a 4 front panel 30013041a 5 exhaust pipe assembly 30008673a 6 intake air duct assembly 30008662b 7 intake air fillter 20007667a 8 air pressure sensor ...

Page 135

Nhb service manual 135 version 1.0 7.2 heat exchanger and waterway assembly 13 12 11 7 7 2 5 4 14 16 6 19 7 3 3 18 3 21 6 2 22 1 9 14 15 12 10 12 12 12 7 7 20 12 7 12 2 19 17 12 12 8 7.

Page 136

136 nhb service manual version 1.0 # description part # remark 1 heat exchanger assembly 30013575a nhb-110 / 150 30014060a nhb-055 / 080 2 o-ring (p29) 20017923a nhb-110 / 150 o-ring (Φ17.5x2.7t) 20006947a nhb-055 / 080 3 fastener 20017724a nhb-110 / 150 20007853a nhb-055 / 080 4 high limit switch 3...

Page 137

Nhb service manual 137 version 1.0 # description part # remark 13 air vent adapter 20030133a nhb-110 / 150 20031488a nhb-055 / 080 14 return / supply adapter 20030136a nhb-110 / 150 20030466a nhb-055 / 080 15 syphon 30014024a 16 h-ex connection adapter 1 20030135a nhb-110 / 150 20026917a nhb-055 / 0...

Page 138

138 nhb service manual version 1.0 7.3 combustion parts assembly 1 2 3 4 5 16 15 15 18 17 10-3 10-2 19 11 15 12 13 7 6 7 8 9 10-1 14.

Page 139

Nhb service manual 139 version 1.0 # description part # remark 1 ignition transformer 30010455a 2 mixed chamber 20030041a nhb-110 / 150 20030049a nhb-055 / 080 3 chamber packing 20022743a nhb-110 / 150 20027108a nhb-055 / 080 4 burner 30010246a nhb-110 / 150 30011854a nhb-055 / 080 5 burner packing ...

Page 140

140 nhb service manual version 1.0 # description part # remark 11 orifice packing 20022660a 12 gas orifice 20032404a nhb-150 (ng) 20032403a nhb-110 (ng) 20032402a nhb-055 / 080 (ng) 20032407a nhb-150 (lp) 20032406a nhb-110 (lp) 20032405a nhb-055 / 080 (lp) 13 o-ring (p34) 20019090a 14 gas pipe 30013...

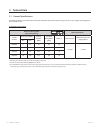

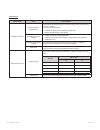

Page 141

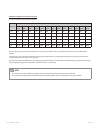

Nhb service manual 141 version 1.0 8.1 annual servicing in order to maintain its safe and efficient operation, it is recommended that the boiler is serviced annually. Caution servicing must be performed by a qualified service agency or gas supplier. Inspection ● visual inspection for general signs o...

Page 142: Memo

142 nhb service manual version 1.0 memo.

Page 143: Memo

Nhb service manual 143 version 1.0 memo.

Page 144: Memo

144 nhb service manual version 1.0 memo.

Page 145: Memo

Nhb service manual 145 version 1.0 memo.

Page 146: Memo

146 nhb service manual version 1.0 memo.

Page 147

Getting service if your boiler requires service, you have several options for getting service: ● contact technical support at 1-800-519-8794 or on the website: www.Navien.Com. ● for warranty service, always contact technical support first. ● contact the technician or professional who installed your ...