- DL manuals

- Navien

- Water Heater

- NPE-180A

- Service Manual

Navien NPE-180A Service Manual

Getting Service

If your water heater requires service, you have several options for getting service:

●

Contact Technical Support at 1-800-519-8794 or on the website: www.navien.com.

- For Navien Service Specialists(NSS) ONLY, please have your 6-digit NSS ID Number ready

and use the available NSS hotlline at 1-877-670-5122.

* Refer to the website: http://us.navien.com/BecomeNSS.

●

Contact the technician or professional who installed your water heater.

●

Contact a licensed professional for the affected system (for example, a plumber or electrician).

When you contact Technical Support, please have the following information at hand:

●

Model number

●

Serial number

●

Date purchased

●

Installation location and type

●

Error code, if any appears on the front panel display.

Navien, Inc.

800.519.8794 www.Navien.com

20 Goodyear lrvine, CA 92618

Service Manual

NPE Condensing Water Heaters

T H E L E A D E R I N C O N D E N S I N G T E C H N O L O G Y

Version : 2.30 (Nov. 08. 2016)

Summary of NPE-180A

Page 1

Getting service if your water heater requires service, you have several options for getting service: ● contact technical support at 1-800-519-8794 or on the website: www.Navien.Com. - for navien service specialists(nss) only, please have your 6-digit nss id number ready and use the available nss hot...

Page 2

Warning if the information in these instructions is not followed exactly, a fire or explosion may result, causing property damage, personal injury or death. Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance. What to do if you smell gas ...

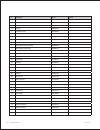

Page 4: Revisions

Revisions 3 version description of changes date 1.00 first issue september/31/12 1.01 specification change (pcb) april/19/13 2.00 additional models (npe-180s, 210s, 240s) july/22/13 2.10 additional funtion (front panel) september/12/13 2.20 additional sub error code list and supplement of comfortair...

Page 5: Contents

Version 2.21 4 npe service manual 1. Safety information 8 1.1 safety definitions 8 1.2 safety symbols 8 1.3 symbols used in the instructions 8 1.4 safety precautions 8 2. Product information 12 2.1 product information 12 2.2 layout and key components 13 3. Technical data 16 3.1 general specification...

Page 6: Navien Warranty

5 warranty service at its option, navien will replace the defective component (part(s) or heat exchanger), in accordance with the terms of this limited warranty, if it fails in normal use and service during the applicable warranty period identified above. The replacement component must be navien ori...

Page 7

Version 2.21 6 npe service manual ● performance problems caused by improper sizing of the water heater, the gas supply line, the venting connection, combustion air openings, electric service voltage, wiring, fusing or any other components, parts or specifications. ● improper conversion from natural ...

Page 8

7 abbreviation definition npe general name of npe-180a, npe-210a, npe-240a, npe-150s, npe-180s, npe-210s, and npe-240s ng natural gas lp propane gas ap air pressure aps air pressure sensor dhw domestic hot water fm fan motor garc gas air ratio control gpm gallons per minute gv gas valve : main and s...

Page 9: 1. Safety Information

Version 2.21 8 npe service manual 1.1 safety definitions all safety messages indicate the risk of potential hazards. Follow the instructions precisely to avoid the risk of injury. This is the safety alert symbol. It is used to alert you of potential personal injury hazards. Observe all of the safety...

Page 10

Safety information 9 danger hot water temperature setting ● water temperatures at or above 125°f (52°c) can cause severe burns instantly or death from scalds. ● households with small children, disabled, or elderly persons may require 120 °f (49°c) or lower temperature setting to prevent contact with...

Page 11

Version 2.21 10 npe service manual danger important safety preautions ● read and understand this safety information before operating or servicing this navien water heater. ● confirm the location of the gas shut-off valve. Close the manual shut-off valve if the navien water heater ever becomes subjec...

Page 12

Safety information 11 warning ● shut off the gas supply if the water heater is damaged. Have your installer or plumber show you the location of the gas shut off valve and demonstrate how to close the valve. If the water heater is damaged as a result of overheating, fire, flood, or any other reason, ...

Page 13: 2. Product Information

Version 2.21 12 npe service manual caution ● do not attempt to repair or replace any part of the water heater, unless it is specifically recommended in this manual. For all other service, contact an authorized technician or licensed professional. Improper adjustments, alterations, service, or mainte...

Page 14

Product information 13 2.2 layout and key components the following diagram shows the key components of the water heater. Component assembly diagrams and particular parts lists are included in the appendix. Intake air duct exhaust duct exhaust limit temperature sensor exhaust body ignition transforme...

Page 15

Version 2.21 14 npe service manual intake air duct exhaust duct exhaust limit temperature sensor exhaust body ignition transformer burner primary heat exchanger secondary heat exchanger flow sensor condensate trap front panel pcb box mixing valve water inlet filter power switch condensate drain fitt...

Page 16

Product information 15 intake air duct exhaust duct exhaust limit temperature sensor exhaust body ignition transformer burner primary heat exchanger secondary heat exchanger flow sensor condensate trap front panel pcb box mixing valve water inlet filter condensate drain fitting condensate drain lid ...

Page 17: 3. Technical Data

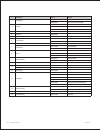

Version 2.21 16 npe service manual 3.1 general specifications the following table lists the specifications for the water heater. Additional specifications about water, gas, electric, and air supplies (venting) appear in the installation section. Item npe-150s npe-180(a) npe-180s npe-210(a) npe-210s ...

Page 18

Technical data 17 3.2 dimensions the following diagrams show the dimensions of the water heater and the table lists the supply connections. 27.4" (695mm) 28.8" (731mm) supply connections description diameter a air intake 2" b exhaust gas vent 2" c hot water outlet 3/4" d recirculation inlet (“a” mod...

Page 19: 4. System Details

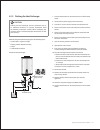

Version 2.21 18 npe service manual 4.1 schematic and flow diagram 2-way valve open for internal recirculation mode 2-way valve closed for external recirculation mode [npe-180a/ 210a /240a] primary heat exchanger secondary heat exchanger buffer tank flow sensor domestic water supply hot water supply ...

Page 20

System details 19 [npe-150s/ 180s / 210s / 240s] mixing valve flow adjustment valve flow sensor hot water supply cold water supply primary heat exchanger secondary heat exchanger.

Page 21

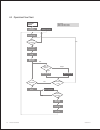

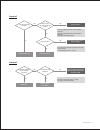

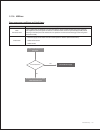

Version 2.21 20 npe service manual 4.2 operation flow chart ig : igniter mgv1 : main gas valve 1 mgv2 : main gas valve 2 no yes flow sensor ≥ 0.53 gpm 120v power applied system initialization displays version standby mode fan start-up & fan control stage 1 or stage 2 ? Dual venturi off stage 1 dual ...

Page 22

System details 21 1. Water flow begins ● water flow sensor sends pulses to the pcb when it registers water flow. ● pcb senses flow greater than 0.53 gpm (approximate). ● firing sequence begins. 2. Firing sequence ● pcb monitors inlet / outlet water temperature, temperature set point, and water flow ...

Page 23

Version 2.21 22 npe service manual ● 10-switch panel: switch function setting remark “a” models (npe-180a/ 210a / 240a) “s” models (npe-150s/180s/210s/240s) dip switch setting 1-3 recirculation mode- internal navien pump ("a" models only) no recirculation 1-off; 2-off; 3-off * intelligent preheating...

Page 24

System details 23 note ● to use the water heater at a specific altitude, the dip switches should be set as described above. ● when configuring a cascade system, all settings other than the high altitude, gas type and preheating settings are controlled by the dip switch settings on the master unit. ●...

Page 25

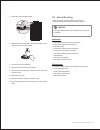

Version 2.21 24 npe service manual 4. Remove the water heater front cover by loosening the 4 phillips head screws securing it to the case. 5. Loosen the screw indicated in the figure below and connect a manometer to the pressure port. Reset the manometer to zero before use. Digital pressure manomete...

Page 26

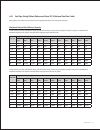

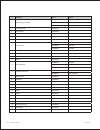

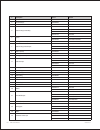

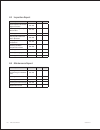

System details 25 4.4.1 gas pipe sizing tables (referenced from 2012 national fuel gas code) these tables are for reference only. Please consult the gas pipe manufacturer for actual pipe capacities. Maximum natural gas delivery capacity in cubic feet (ft 3 ) per hour (0.60 specific gravity; 0.5” wc ...

Page 27

Version 2.21 26 npe service manual maximum liquefied propane delivery capacity in thousands of btu/h (0.5” wc pressure drop) pipe size length (including fittings) 10' (3m) 20' (6m) 30' (9m) 40' (12m) 50' (15m) 60' (18m) 80' (24m) 100' (30m) 125' (38m) 150' (45m) 175' (53m) 200' (60m) 250' (76m) 1/2"...

Page 28

System details 27 4.5 selecting a recirculation mode on all “a“ model navien water heaters, you can choose from two pre-heating modes: internal recirculation mode or external recirculation mode. To select a recirculation mode, you must set the dip switches on the front panel, and set the position of...

Page 29

Version 2.21 28 npe service manual external recirculation mode to use the external recirculation mode: 1. Connect the water supply to support recirculation. Refer to the “installation manual (page 20)”. 2. Set the 2-way valve inside the water heater to “ext.“ 3. Set the front panel dip switches at t...

Page 30

System details 29 4.6 gas conversion npe series water heaters are configured for natural gas from the factory. If conversion to propane gas is required, the conversion kit supplied with the water heater must be used. Warning this conversion kit shall be installed by a qualified service agency* in ac...

Page 31

Version 2.21 30 npe service manual 6. Once the gas orifice is exposed, remove the two screws that hold the part in place. Remove the gas orifice from its housing and prepare the new gas orifice for the lp conversion for installation. Remove two (2) screws here figure 4. Access to gas orifice in fan ...

Page 32

System details 31 danger see figure 5. Inspect the o-ring between the gas valve and gas valve inlet adapter whenever they are disassembled. The o-ring must be in good condition and must be installed. Failure to comply will cause a gas leak, resulting in severe personal injury or death. Lp npe-150s n...

Page 33

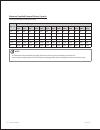

Version 2.21 32 npe service manual water heater fuel high fire low fire %co 2 %co 2 npe-150s ng 8.9 9.5 lp 10.2 10.8 npe-180a npe-180s ng 8.9 9.5 lp 10.2 10.8 npe-210a npe-210s ng 8.9 9.5 lp 10.2 10.8 npe-240a npe-240s ng 8.9 9.5 lp 10.2 10.8 table 2. Co 2 and co value (co 2 values must be within 0....

Page 34

System details 33 c. Fully open a hot water fixture and set the water heater to operate at 1-stage min mode (refer to page 40). Measure the offset value at low fire and compare it to the values in table 3. If the offset value is out of range, the gas valve set screw will need to be adjusted. If adju...

Page 35

Version 2.21 34 npe service manual a b c d e f g h i j k 4.7 the front panel the front panel allows you to adjust the water temperature and view the operating status or error codes. Remove the protective sheet from the front panel before using it. A error g master unit a code will appear on the disp...

Page 36

System details 35 4.7.2 adjusting the water temperature warning before adjusting the water temperature, read “hot water temperature setting” on page 40 carefully. Water temperatures above 120°f can cause instant scalding, severe burns, or death. The water heater is set to 120°f (49°c) by default. To...

Page 37

Version 2.21 36 npe service manual you can adjust the temperature by the below 10-degree increments, depending on the temperature range: temperature range adjusting the water temperature 98°f-120°f (fahrenheit mode) 36°c-50°c (celsius mode) 1°f or 0.5°c increments 120°f-140°f (fahrenheit mode) 50°c-...

Page 38

System details 37 4.7.6 lcd display display function description remark preheating icon displays when a recirculation mode is activated. When the remote controller is not connected: preheating will operate based on the setting of the dip switches on the front panel. When the remote controller is con...

Page 39

Version 2.21 38 npe service manual 4.7.7 button button description or name diagnostic reset power information plus minus short key function remark [diagnostic] short key display of information for service [info] short key display/confirmation of information for consumers [reset] short key error code...

Page 40

System details 39 4.7.8 power on/off 1. Turn the power on/off by pressing the [power] button for about 1 sec. 2. If the unit is experiencing an error, the error code will continue to display on the front panel even if the unit is turned off. Item description display method power on normal operation ...

Page 41

Version 2.21 40 npe service manual 4.7.10 setting the operation mode 1. Using the front panel, press and hold the diagnostics button for over 5 seconds until “1.Tst” is displayed. 2. Press the + (up) button once to change the display to “2.Opr”. 3. Press the information button once to acess the oper...

Page 42

System details 41 version 2.21 us/canada specification temperature range increase/ decrease value [+] key [+] continuous key operation [-] key [-] continuous key operation 98~120°f (36~50°c) 1°f( 0.5°c) short key increased every 100msec short key decreased every 100msec 120~140°f (50~60°c) 5°f ( 2°c...

Page 43

Version 2.21 42 npe service manual 4.7.14 error occurrence history display 1. At the or , press the [info] button for over 2 seconds to access the error history mode. The most recent error will be displayed first. 2. When the [+] / [-] button is pressed, the error history can be searched. A total of...

Page 44

System details 43 item description display method (b)hot water outlet temperature display of the current outgoing water temperature out temperature display ex) 120°f (c)water inlet temperature display of the current incoming water temperature in temperature display ex) 120°f (d)heat capacity display...

Page 45

Version 2.21 44 npe service manual item description display method (j)flame condition flame detection current ad value display flame on: 8bit ad value less than 70 flame off: 8bit ad value more than 175 display of the flame detection ad value 0~255 ex) 200 (k)exhaust gas temperature current exhaust ...

Page 46

System details 45 item description display method (n)number of currently working cascade units number of actually working units in the current cascade system cascade off cascade on: display of the number of working units ex) 8 units working (o)cascade information cascade on/off condition display ind...

Page 47

Version 2.21 46 npe service manual item description display method (q) altitude setting information displays the current altitude level setting 0~2,000ft 2,000~5,400ft 5,400~7,700ft 7,700~10,100ft (r) heat exchanger outlet temperature display of the current outlet temperature (applies to front panel...

Page 48

System details 47 4.7.16 test information menu 1. At the , press the [diagnostic] button for over 5 seconds to access the menu mode>. 2. Select the desired test mode in the information menu using the [+] / [-] button. 3. Press the [info] button once to get into the currently displayed item mode. 4. ...

Page 49

Version 2.21 48 npe service manual component test performed display dual venturi after starting the test, the dual venturi is turned on, and whenever the [+], [-] button is pressed, the condition is toggled as on → off or off → on. Whenever the [+], [-] button is pressed, the condition is toggled as...

Page 50

System details 49 3. In the r&d information menu, use the up (+) or down (-) buttons to move to 2.Par (parameter information mode), and then press the info button. No. Mode display method 1 technical information mode 2 parameter information mode 4. In the parameter information mode, use the up (+) o...

Page 51

Version 2.21 50 npe service manual mode description display method master setting mode set as master unit and assign id numbers to slave units master icon flashing slave id initialization condition when given an initialization command from the master unit slave id assignment condition when given an ...

Page 52

System details 51 configuration with a combination of nr, np and ch units follow these steps to replace an nr, np, or ch unit in a cascade system with an npe water heater: 1. In the parameter information mode, use the up (+) or down (-) buttons to select p.01 (cascade protocol mode), and then press ...

Page 53

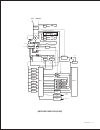

Version 2.21 52 npe service manual 4.8 wiring diagram con5 con6 con7 con8 con10 con1 con4 con2 con3 con11 tb1 bk bk fr on t p anel bk bk bk bk bk bk bk bk bk bk bk bk h igh limit s/w aps r w bk a ir p ressur e s ensor flo w s ensor r w bk b b inlet1 ther mist or b b b b o utlet2 ther mist or b b b b...

Page 54

System details 53 power switch con5 con6 con7 con8 con10 con1 con4 con2 con3 con11 tb1 bk bk bk bk bk bk bk bk bk bk bk bk bk bk high limit s/w aps r w bk air pressure sensor flow sensor r w bk b b inlet1 thermistor b b b b outlet2 thermistor b b b b inlet2 thermistor b b b b outlet1 thermistor b b ...

Page 55

Version 2.21 54 npe service manual 4.9 ladder diagram hot neutral venturi relay 1 relay 2 relay 3 relay 4 igniter pump speed control primary mcu 1 mcu 2 dc24v flow sensor aps dc12v fan water adjust valve flow control dc15v uart communication interface ready link interface ready link fan hall sensor ...

Page 56

System details 55 hot neutral venturi relay 1 relay 2 relay 3 relay 4 igniter pump speed control primary mcu 1 mcu 2 dc24v flow sensor aps dc12v fan water adjust valve dc15v uart communication interface ready link interface ready link fan hall sensor outlet thermistor 2 inlet thermistor 1 inlet ther...

Page 57

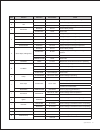

Version 2.21 56 npe service manual 4.10 electrical diagnostic points.

Page 58

System details 57 point function wire color normal value check a high temperature limit switch black-black dc 0 v normally shorted. Confirm rms voltage. B aps red-black dc 5 v confirm steady voltage. White-black dc 0.3~4.5 v voltage changes according to the aps operation. C flow sensor red-black dc ...

Page 59

Version 2.21 58 npe service manual 4.11 key components description 4.11.1 pcb part check point function to control each component and also to check the overall performance of the unit. Failure event malfunctioning pcb. Effects a component may not operate within the unit and could produce an error co...

Page 60

System details 59 4.11.2 high limit switch check point check point function 1. Overheat prevention switch. 2. If the unit detects extremely high temperatures, it will automatically trip and shut down the unit. 3. Excessively high water temperatures (more than 197.6 °f or 92 °c) in heat exchanger wil...

Page 61

Version 2.21 60 npe service manual 4.11.3 thermistor part check point function measure inlet, outlet, and internal heat exchanger temperatures in the water heater. Failure event unable to properly measure water temperature within the water heater. Effects 1. If any of the thermistors fail, an error ...

Page 62

System details 61 4.11.4 fan motor part check point function to provide combustion air into the burner and to purge exhaust flue gas. To maintain the gas input with a long vent run, the fan operates with aps for ideal combustion. Failure event 1. Fan speed failure: the fan rpm is around 0 rpm. 2. Th...

Page 63

Version 2.21 62 npe service manual 4.11.5 flame rod assembly part check point function to ignite gas by repeatedly discharging a high voltage spark to the main burner until gas ignites. Failure event 1. Unable to ignite during the ignition process. 2. Produces multiple unsuccessful attempts to ignit...

Page 64

System details 63 4.11.6 ignition transformer part check point function to ignite gas by repeatedly discharging a high voltage spark to the main burner until gas ignites. Failure event 1. Unable to ignite during the ignition process. 2. Produces multiple unsuccessful attempts to ignite. Effects 1. T...

Page 65

Version 2.21 64 npe service manual 4.11.7 aps part check point function detecting the air pressure entering the burner system. Failure event 1. Combustion noise occurs. 2. Imperfect and/or abnormal flame occurs. 3. Occurs when aps does not detect proper voltage. Effects 1. The water heater is not op...

Page 66

System details 65 4.11.8 main gas valve part check point function 1. To control the amount of gas supplied to the burner based on fan speed. 2. When the unit experiences abnormal combustion, it shuts off the gas valve automatically and prevents unsafe situations. Failure event unable to open/close e...

Page 67

Version 2.21 66 npe service manual 4.11.9 burner part check point function 1. Pre-mix system reduces emissions and increase efficiency. 2. The burner facilitates the air/gas mixture necessary to produce the proper heat during combustion. Failure event 1. Unable to initialize/sustain combustion. 2. D...

Page 68

System details 67 4.11.10 water adjustment valve part check point function to control the water flow to maintain steady hot water temperatures. Failure event the valve cannot modulate or open/close in cascade mode. Effects 1. Water adjustment valve is not operating properly. 2. Abnormal flow detecte...

Page 69

Version 2.21 68 npe service manual 4.11.11 flow sensor part check point function to detect water flow in gpm (gallons per minute) for steady hot water temperatures. Failure event 1. Unable to detect or measure water flow rate. 2. Damage to and/or water leakage from the water flow sensor. Effects ign...

Page 70

System details 69 4.11.12 primary heat exchanger part check point function 1. Main part for heat transfer from the burner. 2. There are multiple paths of water pipes on the heat exchanger surface as well as inside the combustion chamber which minimizes the heat loss. Failure event 1. Water and/or ex...

Page 71

Version 2.21 70 npe service manual 4.11.13 secondary heat exchanger part check point function 1. Main part for heat transfer from the burner. 2. There are multiple paths of water pipes on the heat exchanger as well as inside the combustion chamber which minimizes heat loss. Failure event 1. Water an...

Page 72

System details 71 4.11.14 buffer tank (“a” models only) part check point function to provide hot water at a steady temperature and to operate without a minimum flow rate with the use of the internal circulation pump. Failure event cracking and/or water leakage due to wear. Effects temperature fluctu...

Page 73

Version 2.21 72 npe service manual 4.11.15 circulation pump (“a” models only) part check point function 1. Pump operates when using internal or external hot water circulation. 2. Internal circulation will minimize the effect of temperature fluctuations and external circulation delivers hot water to ...

Page 74: 5. Troubleshooting

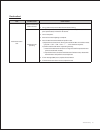

Troubleshooting 73 5.1 error code list error code sub code function self-diagnostic/action e003 0 ignition failure * check to see if the main gas supply valve is open. * verify that gas pressure is within operating range. * check gas system and orifice. * check dual venturi for proper operation. * c...

Page 75

Version 2.21 74 npe service manual error code sub code function self-diagnostic/action e407 1 abnormal hot water outlet thermistor (open) ● check the thermistor. ● replace the thermistor. 2 abnormal hot water outlet thermistor (short) e421 1 abnormal cold water inlet thermistor (open) ● check the th...

Page 76

Troubleshooting 75 error code sub code function self-diagnostic/action e615 0 abnormal input data from high limit switch of heat exchanger ● check the pcb. 1 abnormal input data from exhaust sensor ● check the exhaust sensor wiring connection. ● check the exhaust sensor. 2 abnormal input data from f...

Page 77

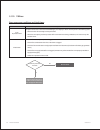

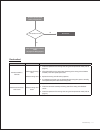

Version 2.21 76 npe service manual 5.1.1 003error error occurrence conditions and check items error description e03 ignition failure in the case of an ignition failure, the water heater will attempt ignition 10 times. If no flame is detected, the system displays the error message 03e (manually clear...

Page 78

Troubleshooting 77 scenario2 check the flame rod power off the unit check connector check that gas valve is open or check lp supply check the voltage between #1 and #3 of con 4: 22-24 vdc check the voltage between #2 and #3 of con 4: 22-24 vdc (see page 52 for wiring diagram) in case of lp gas model...

Page 79

Version 2.21 78 npe service manual check method failure mode cause check method ignition failure gas supply error 1. Check if the main gas valve is open. 2. Check the gas supply pressure. ● ng: 3.5” - 10.5” w.C, lp: 8” - 13” w.C ● lp pressure drop occurs frequently in the winter. 3. Check the flexib...

Page 80

Troubleshooting 79 failure mode cause check method ignition failure electrode gap 3.5~4.5mm(1/8") electrode gap error no spark from electrode when no spark is made from the electrode at ignition: ● remove the electrode and check if there is a crack on the insulator. ● adjust the gap if there is a di...

Page 81

Version 2.21 80 npe service manual failure mode cause check method ignition failure main gas valve 1. Check the primary/secondary power supply to the main gas valve. ● check, with a multimeter, if the input power is dc 22-24 v. 2. Replace the pcb if power is not supplied. 3. If power supply is norma...

Page 82

Troubleshooting 81 failure mode cause check method flame loss and noise occurs at ignition check if there are any blockages in the gas orifice plate. Ignition failure will occur if the gas orifices are clogged. ● remove the gas inlet pipe and check the orifice plate. Improper air intake air supply r...

Page 83

Version 2.21 82 npe service manual error description check items 1. Check if gas leaks due to defective seals on the main gas valve. 2. Check if proper spark is discharged from the electrode. 3. Check if gas is supplied within the proper pressure range. 4. Check the pcb and replace if defective. Ext...

Page 84

Troubleshooting 83 5.1.3 012error error occurrence conditions and check items error description e012 flame loss if the system detects loss of flame during combustion, the system stops supplying fuel, attempts to restart, counts the incidents of flame loss, and if the incident occurs 20 times consecu...

Page 85

Version 2.21 84 npe service manual check method fault possible causes check method flame loss and noise occurs after ignition low gas supply pressure 1. Check the gas supply pressure. ● ng: 3.5” - 10.5” w.C, lp: 8” - 13” w.C ● lp pressure drop occurs frequently in the winter. 2. While the static pre...

Page 86

Troubleshooting 85.

Page 87

Version 2.21 86 npe service manual fault possible causes check method flame loss and noise occurs after ignition model gas type offset npe-150s ng -0.04"±0.01" lp -0.03"±0.01" npe-180a npe-180s ng -0.04"±0.01" lp -0.03"±0.01" npe-210a npe-210s ng -0.04"±0.01" lp -0.02"±0.01" npe-240a npe-240s ng -0....

Page 88

Troubleshooting 87 fault possible causes check method tightness of screw or ground bolt check the tightness of the screw or ground bolt in the chamber + sc heat exchanger. - cause: screw or ground bolt in the chamber and sc heat exchanger can be loosened by the vibration or external impact when oper...

Page 89

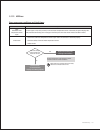

Version 2.21 88 npe service manual 5.1.4 016error error occurrence conditions and check items error description e16 bimetal overheated if the overheat controller on the heat exchanger is initiated during combustion/standby of the water heater, the system displays the 016e (manually cleared) message ...

Page 90

Troubleshooting 89 check method fault possible causes check method defective safety device defective overheat controller check if the contact point of the overheat controller is defective. ● use a multimeter to see if the resistance is normal (0.3Ω) or abnormal (∞). Overheat controller check if the ...

Page 91

Version 2.21 90 npe service manual fault possible causes check method other trouble capacity setting 1. If the max switch #1 of 1-1 is on, set the switch to the normal operation position. 2. Pcb dip s/w capacity setting error can suddenly increase the hot water temperature. ● check the pcb dip s/w c...

Page 92

Troubleshooting 91 5.1.5 030error error occurrence conditions and check items error description e030 exhaust gas temperature error if the overheat controller on the top of the exhaust duct is initiated, the system displays the heat exchanger bimetal overheat message 30e (cleared manually) on the fro...

Page 93

Version 2.21 92 npe service manual check method fault possible causes check method heat exchanger overheated damaged or clogged heat exchanger 1. The error occurs due to high exhaust gas temperature caused by a damaged or clogged heat exchanger. 2. Flush the heat exchanger to remove scale deposits. ...

Page 94

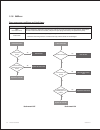

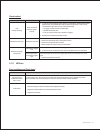

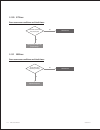

Troubleshooting 93 5.1.6 046error error occurrence conditions and check items replace heat exchanger thermistor. Check connector ( #1 and #2 of con 6) 1 step: flushing, clean filter 2 step: try to restart 3 step: replace pcb yes yes is heat exchanger thermistor normally operating? Is resistance with...

Page 95

Version 2.21 94 npe service manual 5.1.8 060error error occurrence conditions and check items error description e060 dual venturi error this error message is displayed on the front panel if the wiring is disconnected or the dual venturi malfunctions. The water heater switches into lock-out, and perf...

Page 96

Troubleshooting 95 check method fault possible causes check method dual venturi action error defective dual venturi cable or harness 1. Disconnect all cables from the dual venturi. 2. Using a multi-meter, test the dual venturi electrical wiring. Dual venturi not operating 1. Turn off the power to th...

Page 97

Version 2.21 96 npe service manual 5.1.9 109error error occurrence conditions and check items error description e109 fan motor rpm error the system checks the rpm signal after the fan starts to run, and displays the error message 109e (cleared manually) in the following cases: 1. If the rpm remains ...

Page 98

Troubleshooting 97 check method fault possible causes check method fan action error no fan operation 1. Check the power supply to the blower. ● black+red, approx. Dc 127~184 v 2. Replace the pcb if voltages are abnormal. (when replacing the pcb, turn off the unit and then wait for at least 10 second...

Page 99

Version 2.21 98 npe service manual 5.1.10 110error error occurrence conditions and check items error description e110 air pressure error the system senses the air volume and the rpm signal, and displays 110e on the front panel in the following cases: 1. When the initial fan auto-adjust is not perfor...

Page 100

Troubleshooting 99 check method fault possible causes check method 110e exhaust blockage abnormal flow of intake air supply / exhaust 1. If 110e occurs intermittently during ignition or combustion, compare the standard rpm with the current rpm at min / max combustion (dip switch 1-1&1-2). If the cur...

Page 101

Version 2.21 100 npe service manual 5.1.12 421error error conditions and check items error description e421 heat exchanger input temperature sensor open if an error (open: 14°f (-10°c) or lower) in the heat exchanger input temperature sensor is detected, the system displays the 421e error on the fro...

Page 102

Troubleshooting 101 5.1.13 432error error occurrence conditions and check items error description e432 cold water water temperature sensor open if an error (open: 14°f(-10°c) or lower) in the cold water temperature sensor is detected, the system displays the 432e (cleared automatically) error messag...

Page 103

Version 2.21 102 npe service manual check method fault possible causes check method defective sensor defective temperature sensor connector check if the cold water temperature sensor is open and if the connector is attached properly. Temperature sensor ● measure the temperature sensor resistance. (d...

Page 104

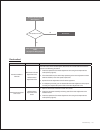

Troubleshooting 103 check connector motor resistance (con8) (see page 52 for wiring diagram) panel test operation mode (wav operation) reset the unit yes is the operation normal? No check method fault possible causes check method remote controller / pcb error malfunction of water adjustment valve de...

Page 105

Version 2.21 104 npe service manual emergency measures for a blocked water adjustment valve * (refer to page 47 for component test mode information) 1. Switch off power, shut off water supply to the unit, and drain water from the unit. 2. Remove the top/bottom clips of the water adjustment valve. 3....

Page 106

Troubleshooting 105 5.1.15 438error ("a" models only) error occurrence conditions and check items error description e438 pump error connect the power, start the pump, and check if the system senses water flow. If flow is not sensed after the pump has started, the system displays 438e (cleared automa...

Page 107

Version 2.21 106 npe service manual check method fault possible causes check method pump malfunction defective flow sensor check the current flow rate displayed on the front panel. The flow sensor is defective if the water flow displayed is 0.0 gal/min when the pump is operating or when water is dis...

Page 108

Troubleshooting 107 5.1.16 439error error occurrence conditions and check items error description e439 flow sensor error as one or more units are operating in the cascade system, if no flow is detected while the system opens the water adjustment valve, the system considers it as a defective flow sen...

Page 109

Version 2.21 108 npe service manual check method fault possible causes check method no hot water flow cold water supply error 1. Check if the water adjustment valve is opening/closing properly. 2. Check if the cold water line is frozen. 3. Check if the cold water filter is clogged. Water heater not ...

Page 110

Troubleshooting 109 1. Drain water from the unit, then remove the 4 screws and retaining clips from the flow sensor. 2. Detach the 2 wire connectors that connect the flow sensor to the pcb. 3. Blow air through the flow sensor. Check that the impeller rotates freely..

Page 111

Version 2.21 110 npe service manual 5.1.17 441error error occurrence conditions and check items before measuring resistance of the thermistor, detach the connector from the pcb. Check connector ( #3 and #4 of con 7) (see page 52 for wiring diagram) replace heat exchanger outlet thermistor resistance...

Page 112

Troubleshooting 111 check connector motor resistance (con9) (see page 52 for wiring diagram) panel test operation mode (mixing valve operation) reset the unit yes is the operation normal? No check method fault possible causes check method remote controller / pcb error malfunction of mixing valve def...

Page 113

Version 2.21 112 npe service manual emergency measures for a blocked mixing valve * (refer to page 47 for component test mode information) 1. Switch off power, shut off water supply to the unit, and drain water from the unit. 2. Remove the top/bottom clips of the mixing valve. 3. Disassemble the mot...

Page 114

Troubleshooting 113 5.1.19 515error error occurrence conditions and check items error description e515 error if an error occurs in the internal circuit of the pcb (e.G., resistance, transistor or relay fault), the system displays 515e (cleared manually) on the pcb. Check items 1. Defective pcb 2. Ch...

Page 115

Version 2.21 114 npe service manual 5.1.20 517error error occurrence conditions and check items change the dip s/w to the proper settings reset the unit yes are the dip s/w on the pcb properly set? No 5.1.21 593error error occurrence conditions and check items replace front panel reset the unit yes ...

Page 116

Troubleshooting 115 5.1.22 594error error occurrence conditions and check items error description e594 error if the communication is abnormal in parts of pcb, the system displays e594 on the pcb. Check items 1. Check the pcb. Check method fault possible causes check method e594 error abnormal commun...

Page 117

Version 2.21 116 npe service manual 5.1.24 736error error occurrence conditions and check items reconnect cascade wire reset the unit yes is the ready-link cascade cable properly installed on all units? No 5.1.25 782error error occurrence conditions and check items reconnect panel to the pcb 1 step:...

Page 118

Troubleshooting 117 5.1.26 740error error occurrence conditions and check items error description e740 abnormal outdoor sensor if an error (under 2.2kΩ or over 122.2kΩ) in the outdoor sensor is detected continuously for 3 seconds, the system displays the error message e740 on the front panel. If thi...

Page 119

Version 2.21 118 npe service manual 5.2 troubleshooting guide by symptom 5.2.1 noise error type cause check method vibration noise defective installation incorrect mounting to the wall or in an improper location. ● check for improper installation and reinstall the unit if necessary. Fan vibration no...

Page 120

Troubleshooting 119 5.2.2 water temperature issue error type cause check method water heater is not operating properly. Front panel power off hot water does not run if the front panel is switched off. Defective flow sensor the water heater does not work due to the defective flow sensor. ● the flow s...

Page 121

Version 2.21 120 npe service manual 5.2.3 circuit breaker operation error type cause check method circuit breaker trips power supply the circuit breaker trips immediately as soon as the power cord is plugged in the receptacle. Check the sheath of power cord, or if there is short-circuit. Check the c...

Page 122: 6. Replacement of Parts

Replacement of parts 121 6.1 replacement procedure caution 1. When performing maintenance and/or servicing the water heater, always turn off the electric power, gas and water shut-off valve. Wait for the water heater to become cool. Be careful to avoid injury to your fingers on sharp edges. 2. Drain...

Page 123

Version 2.21 122 npe service manual 4. Replace the old fuse with the new part. 5. Ensure that the new fuse is of an equivalent rating and that it is properly fixed inside the housing. 6. Close the fuse housing. 7. Turn on water supply, power supply, and gas supply to the unit. 6.2.3 fan motor (combu...

Page 124

Replacement of parts 123 12. Reinstall the fan assembly to the bracket by using the mounting screw. 13. Attach the gas valve connection back to the fan assembly by using the 4 screws as shown in figure 5. 14. Reconnect the wiring connector from the fan assembly. 15. Turn on water supply, power suppl...

Page 125

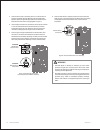

Version 2.21 124 npe service manual 5. Disconnect the wiring connector from the ignition transformer (figure 9). Figure 9 6. Remove the 2 screws from the ignitor transformer. Figure 10 7. Pull out the ignition transformer. 8. Replace the old ignition transformer with the new part, and then use the 2...

Page 126

Replacement of parts 125 6. Remove the 2 screws that attaches the air pressure sensor to the burner assembly. 7. Pull out the air pressure sensor. 8. Replace the old air pressure sensor with the new part. 9. Reattach the air pressure sensor hose. 10. Connect the air pressure sensor wiring connector....

Page 127

Version 2.21 126 npe service manual figure 15 8. Remove the 4 screws directly from the bottom of the gas valve to remove the elbow. 9. Replace the o-ring where the gas valve assembly attaches to the elbow. Make sure the old o-ring is discarded. 10. Replace the old gas valve with the new part and rea...

Page 128

Replacement of parts 127 7. Loosen the clip that secures the hose to the condensate trap, and then pull off the hose. Figure 18 8. Remove the old condensation trap and replace it with the new part. 9. Reconnect the hose to the condensate trap. 10. Reattach the condensation trap to the unit and secur...

Page 129

Version 2.21 128 npe service manual 6. Pull out the flow sensor. 7. Replace with old flow sensor with the new part. 8. Reinstall the flow sensor into the cold water inlet pipe and reattach the stainless clip. Ensure that the flow sensor is properly connected to the cold water inlet pipe and that the...

Page 130

Replacement of parts 129 11. Turn on water supply, power supply, and gas supply to the unit. 12. Carefully open a hot water tap and ensure there are no leaks at the buffer tank connections. Note 1. Use caution when removing the buffer tank from the unit as it may contain scalding hot water. 2. Use p...

Page 131

Version 2.21 130 npe service manual 9. Disconnect the wiring connector at the pump assembly. Figure 27 10. Carefully remove the pump. Figure 28 11. Replace with the new pump. 12. Place the new pump back into its original position and ensure that all connections are tightly sealed. 13. Secure the pum...

Page 132

Replacement of parts 131 5. Remove the 4 stainless steel clips from the connections (2 round clips and 2 flat clips). Figure 30 6. Disconnect the wiring connector at the 2-way valve. Figure 31 18. Use the 4 screws at the bottom of the case to fix the pump to the unit. 19. Install front panel using 4...

Page 133

Version 2.21 132 npe service manual figure 33 5. Remove the 2 stainless steel clips from the water adjustment valve connections. Figure 34 6. Remove the water adjustment valve. 7. Replace with the new water adjustment valve. 8. Place the 2 stainless steel clips back onto the valve connections. Ensur...

Page 134

Components diagram and part list 133 7.1 case assembly 12 7 13 8 9 10 18 2 1 3 4 6 5 17 16 15 14 11 7. Components diagram and part list.

Page 135

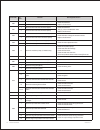

Version 2.21 134 npe service manual # description part # remark 1 intake air duct assembly 30008662b 2 intake air filter 20007667a 3 case 20019078c npe-180a/210a/240a 20026559b npe-150s/180s/210s/240s 4 air pressure sensor 30010346a 5 panel bracket 20018388a 6 cover 30008678b npe-180a/210a/240a 3001...

Page 136

Components diagram and part list 135 7.2 burner assembly(npe-180a/ 210a/ 240a) 7 6 18 13 3 7-1 10 9 12 19 21 19 21 8 14 11 12 4-1 6-1 4 12 17-1 11-1 12 12 1 15 17 12 6 6-1 14 5 2 17 6-1 6-1 6-1 6-1 19 20 19 20

Page 137

Version 2.21 136 npe service manual # description part # remark 1 heat exchanger assembly 30012711a npe-180a 30012712a npe-210a 30012713a npe-240a 2 fan o-ring (g50) 20003019a 3 fan bracket(f) 20022095a 4 flow sensor assembly 30008571a 4-1 thermistor 30008366a 5 fan braket(r) 20022096a 6 cold inlet ...

Page 138

Components diagram and part list 137 7.3 burner assembly(npe-150s/ 180s/ 210s/ 240s) 10 4 10 5 3 2 13 12 1 18 17 10 15 23 9 10 10 14 6 20 9 10 7 10 9 24 16 21 10 17 15 10 6 9 10 25 19 22 8 9 10 11.

Page 139

Version 2.21 138 npe service manual # description part # remark 1 ignition transformer 30010455a 2 fan bracket (r ) 20022096a 3 thermistor 30009478a exhaust 4 heat exchanger assembly 30015922a npe-150s 30012711a npe-180s 30012712a npe-210s 30012713a npe-240s 5 ignitor 30214183a npe-150s 30012226a np...

Page 140

Components diagram and part list 139 7.4 waterway assembly(npe-150s/ 180s/ 210s/ 240s) 1 15 16 8 3 10 9-2 9-3 11 7 8-2 4-1 8-1 3-5 9-1 3-2 3-1 5 2 12 2-4 2-3 2-1 4-2 2-5 2-2 8-3 12 13 14 8-4 9-3 7-1 12-1 12-2 12-3 12-4 12-5 11 6 9 11 17 3-3 3-4 4-3 11 4 5 2-4 # description part # remark 1 buffer tan...

Page 141

Version 2.21 140 npe service manual # description part # remark 3-2 o-ring (p20) 20017212a 3-3 o-ring (p19) 20017211a 3-4 water filter 30008171a 3-5 pipe clip 20007733b 4 circulation pump 30010780a 4-1 pump air seperator 30006831b 4-2 drain plug 30008630a 4-3 o-ring (p18) 20006947a 5 fastner 2001772...

Page 142

Components diagram and part list 141 7.5 waterway assembly(npe-150s/ 180s/ 210s/ 240s) 10 15 2 12 6 6 13 8 14 11 10 11 8 9 11 8 12 11 17 16 8 6 7 6 5 4 3 2 1 6 10 15 2 12 6 6 13 8 14 11 10 11 8 9 11 8 12 11 17 16 8 6 7 6 5 4 3 2 1 6.

Page 143

Version 2.21 142 npe service manual # description part # remark 1 bracket 20026489a 2 thermistor 30008366a 3 water filter 30008171a 4 cold water inlet adapter 30011597a 5 o-ring (p15) 20017217a 6 fastner 20007859a 7 flow sensor 30011534a 8 o-ring (p16) 20017210a 9 flow sensor outlet adapter 20025959...

Page 144

Components diagram and part list 143 7.6 fan(gas) assembly 98 95 9 10 94 97 12 9 11 99 9 10 93 9 15 9 10 91 9 13 9 14 96 92 [npe-180s/180a/210s/210a/240s/240a] 6 12 11 7 16 13 3 10 2 10 10 5 14 8 4 [npe-150s].

Page 145

Version 2.21 144 npe service manual # description part # remark 1 gas adapter 30009921a npe-180s/180a 30009922a npe-210s/210a/240s/240a 2 gas pipe 30014329a npe-150s 30013323a npe180s/180a 30008431a npe-210s/210a/240s/240a 3 gas connector 20018430a 4 gas valve 30008429a 5 gas inlet adapter 20023809a...

Page 146

Inspection and maintenance schedule 145 8.1 maintenance this section describes various maintenance procedures that may need to be performed on the water heater from time to time. 8.1.1 cleaning the water heater caution make sure the water heater is turned off and the power supply is disconnected bef...

Page 147

Version 2.21 146 npe service manual 6. Remove the pump inlet filter from the bottom of the water heater. Pump inlet filter pump drain plug cold water inlet filter 7. Open the pump drain plug. 8. Remove the cold water inlet filter. 9. Allow the residual water to drain from the water heater. 10. When ...

Page 148

Inspection and maintenance schedule 147 8.1.3 flushing the heat exchanger caution flushing the heat exchanger shall be performed only by an authorized technician or licensed professional. Read the following instructions carefully before attempting this procedure. Keep in mind that improper maintenan...

Page 149

Version 2.21 148 npe service manual 8.1.4 cleaning the inlet water filter and recirculation inlet filter to clean the filters: 1. Drain the water heater. 2. While the filters are removed, rinse it with clean running water (cold) and, if necessary, scrub it clean with a brush. Cold water inlet filter...

Page 150

Inspection and maintenance schedule 149 5. Pull the filter out of the water heater. 6. Remove the filter from the plastic assembly and clean it with a toothbrush and clean running water. 7. Allow the filter to dry completely. 8. Reinsert the filter into the plastic assembly. 9. Place the filter asse...

Page 151

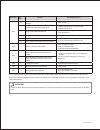

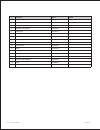

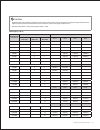

Version 2.21 150 npe service manual 8.3 inspection report inspection items references date: date: visual inspection for general signs of corrosion yes / no checking and adjusting the gas/air ratio yes / no checking flue gas yes / no carrying out a water leak test in operation yes / no carrying out a...

Page 152

Installation the outdoor vent cover 151 9.1 installing the outdoor vent cover this kit must be installed by a qualified installer in accordance with these instructions and all applicable codes and requirements of the authorities having jurisdiction. Keep this manual near the water heater for future ...

Page 153

Version 2.21 152 npe service manual 3. Tighten the screws on the front of the water heater. Warning make sure the front cover of the water heater is securely reattached to prevent any damages to the water heater. Note once the outdoor vent cover is installed, it does not need to be removed before re...

Page 154

Installation the outdoor vent cover 153 references descriptions minimum distances a directly below or adjacent to an opening; operable windows, doors and any fresh air openings 48" (usa) b c d from any adjacent wall 12" e below a gutter, sanitary pipework, eaves or overhang 36" f above ground 12" g ...

Page 155

Version 2.21 154 npe service manual 2. Align the grooves on the back of the water heater with the hooks on the mounting bracket and hang the water heater on the bracket. When mounted with the mounting bracket, the water heater will have a 5/8” (16mm) clearance from the back of the wall. Caution do n...

Page 156

Installation the outdoor vent cover 155 9.5 ventilation flow intake air flow exhaust gas flow.

Page 157

Version 2.21 156 npe service manual 9.6 common venting model : npe-150s, 180a, 180s, 210a, 210s, 240a, 240s when cascading the water heaters with other navien water heaters, you can install a common venting system. Do not use common venting if the water heater is used in a cascading system with othe...

Page 158

Installation the outdoor vent cover 157 caution ● regardless of the vent size listed in the table, the connection to the common vent must always be as large as the largest connector. If the largest connector and the recommended vent are the same size, use the next largest size for the vent. ● one sh...

Page 159

Version 2.21 158 npe service manual warning all installation should be done by a qualified expert and in accordance with the appropriate navien manual. Installing an electric appliance with improper methods or materials may result in serious injury or death due to fire. Electrical shock hazard. Disc...

Page 160

H2air+ + 159 wiring connection table terminal wiring connection ahu w1 connect to ahu w1 ahu w2 connect to ahu w2 ahu r connect to ahu r flow switch flow switch input terminal t/s w1 connect to thermostat w1 t/s w2 connect to thermostat w2 t/s r connect to thermostat r outdoor sensor outdoor sensor ...

Page 161

Version 2.21 160 npe service manual 10.2.2 installing the device in an npe-180a/240a water heater follow the instructions to install the navien h2air+ + in an npe-180a/240a water heater. 1. Turn off the power supply to the water heater. 2. Remove the water heater’s front cover by loosening the four ...

Page 162

H2air+ + 161 10.3 wiring the device this section provides information required to plan and install the system wiring. 10.3.1 system wiring examples refer to the following wiring diagrams to properly install wiring for various setups you may need in your system. Set dip switch (sw) #3 as specified fo...

Page 163

Version 2.21 162 npe service manual 2-stage thermostat / 2-stage control system set dip switch (sw) #3 to ‘on’ to configure the system to use a 2-stage thermostat / 2-stage control. 10.3.2 cable connections follow the instructions below to connect the cables to the h2air+ + . Connecting the outdoor ...

Page 164

H2air+ + 163 connecting the main control connector to connect the h2air+ + to the navien npe-180a/240a water heater, use the 13-pin main control connector supplied with the navien h2air+ + . Connect one end of the cable to the connector socket on the h2air+ + pcb. Then, connect the other end to the ...

Page 165

Version 2.21 164 npe service manual note ● install a spring check valve for vertical pipe runs. Do not use a swing check valve with vertical piping. ● install either a spring check valve or a swing check valve for a horizontal run. ● an outdoor sensor and a flow switch are supplied with the product....

Page 166

H2air+ + 165 10.5.2 entering the r&d information menu this section describes how to enter the r&d information mode to configure various parameters and control system functions. Entering the r&d information menu follow the instructions below to enter the r&d information menu. 1. On the front panel, p...

Page 167

Version 2.21 166 npe service manual note ● if no buttons are pressed for 10 seconds or if the info button is pressed, the current parameter value will be saved automatically. ● to return to the , press the [reset] button once. ● if no buttons are pressed for five minutes, the display will automatica...

Page 168

H2air+ + 167 outdoor reset control (p07–p10) the outdoor reset control feature can be used to enhance energy efficiency while maintaining optimal heating performance. Outdoor reset control automatically changes the space heating temperature setting based on the outdoor temperature and the current sp...

Page 169

Version 2.21 168 npe service manual outdoor high temperature set-point (p.08) to change the outdoor high temperature set-point: 1. In the parameter information time mode, use the up (+) or down (-) buttons to select p.08. Then, press the info button to enter the outdoor high temperature set-point mo...

Page 170

H2air+ + 169 heating max set-point (p.10) to change the heating max set-point: 1. In the parameter information time mode, use the up (+) or down (-) buttons to select p.10. Then, press the info button to enter the heating max set-point mode. 2. In the heating max set-point mode, use the up (+) or do...

Page 171

Version 2.21 170 npe service manual 10.7.3 npe-180a/240a pump p-q curve *gcfhvo (nqy)2/ 23%wtxg ft m note ● when the system uses an internal circulation pump with the npe-180a/240a water heaters, the flow rate may vary depending on the type and capacity of the ahu in use. ● if the system uses an int...