Designed, engineered & assembled in the u.S.A. 7351101 (rev. D 6/12/17) in st al la tio n an d o pe ra tio n m an ua l how to install, operate and maintain your ultra demand automatic water conditioner city softener model nsr 17cs point-of-entry system tested and certified by nsf international for n...

2 table of contents page specifications & dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 before you start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

3 specifications & dimensions model nsr 17cs model code cs17 nominal media tank size 9” dia. X 35” softening capacity (grains @ salt dose) 9,388 @ 1.85 lbs. 14,175 @ 3.12 lbs. 18,951 @ 5.66 lbs. Efficiency (grains/pound of salt @ min. Salt dose) 5,075 @ 1.85 lbs. Water used during regeneration @ min...

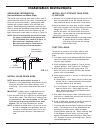

4 location requirements consider all of the following when selecting an installa- tion location for the water softener. = do not locate the water softener where freezing temperatures occur. Do not attempt to treat water over 120ºf. Freezing temperatures or hot water damage voids the warranty. = to c...

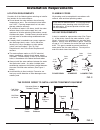

5 installation requirements valve drain requirements using the flexible drain hose (included), measure and cut to the length needed. Flexible drain hose is not allowed in all localities (check your plumbing codes). If local codes do not allow use of a flexible drain hose, a rigid valve drain run mus...

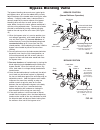

6 installation instructions turn off water supply 1 . Close the main water supply valve, located near the well pump or water meter. 2 . Shut off the electric or fuel supply to the water heater. 3 . Open all faucets to drain all water from house pipes. Note: be sure not to drain water from the water ...

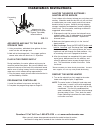

7 installation instructions fig. 11 top cover brine tank overflow elbow brine tank overflow grommet 13/16” hole brinewell cover salt storage tank stand tube brine tubing salt lid float stem brine valve brinewell nozzle venturi assembly fig. 9 turbine turbine support assembly valve outlet fig. 12 cli...

8 installation instructions install salt storage tank over- flow hose 1 . Measure, cut to needed length and connect the 3/8” drain line (provided) to the salt storage tank over- flow elbow and secure in place with a hose clamp. 2 route the hose to the floor drain, or other suitable drain point no hi...

9 installation instructions add water and salt to the salt stor age tank 1 . Using a container, add about three gallons of clean water into the salt storage tank. 2 . Add salt to the storage tank. Use nugget, pellet or coarse solar salts with less than 1% impurities. Plug in the power supply during ...

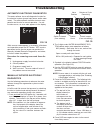

10 programming the water softener program the softener when the power supply is plugged into the electrical outlet, the model code (cs17) and a test number (example: j3.8), are briefly shown in the display. Then the words “present time” appear and 12:00 pm begins to flash. Set present time of day if...

11 start a recharge 1 . Press the recharge button and hold for three seconds, until “recharge” begins to flash in the display, starting a recharge. This recharge draws the sanitizing bleach into and through the water softener. Any air remaining in the water softener is purged to the drain. During th...

12 data displays with repeated presses of the data button, you can ob - tain operational information about your water softener. Capacity (remaining) this is the percentage of water softening capacity remaining. Immediately after a regeneration, 100% shows. Then, as water is used, the percentage decr...

13 model code the model code is factory set at assembly and testing. The model code should never require resetting, but to check, or to set if previously omitted, follow the steps below. 1 . Press the set button and hold for three seconds, until the “recharge time” screen (figure 26) is dis- played....

14 12 or 24 hour clock all time displays are shown in 12 hour (am/pm) clock format at the default setting. If 24 hour clock format is desired, follow steps below: 1 . Press the set button and hold for three seconds, until the “recharge time” screen is displayed. 2 . Again, press the set button and h...

15 water softener maintenance refilling with salt brine (salt dissolved in water) is needed for every regeneration. The water for making brine is metered into the salt storage area by the softener valve and timer. If the water softener uses all the salt before more is added, hard water will result. ...

16 cap o-ring seal screen support screen nozzle & venturi gasket *flow plug (hvdc) nozzle & venturi housing *flow plug screen important: be sure small holes in the gasket are centered directly over the small holes in the nozzle & venturi housing. *install with numbered side up concave side down. Be ...

17 troubleshooting problem cause correction no soft water no salt in the storage tank. Add salt (see page 15) and then initiate a “recharge now,” as shown on page 11. Salt is “bridged.” break salt bridge (see page 15) and then initi- ate a “recharge now,” as shown on page 11. If display is blank, po...

18 troubleshooting while an error code appears in the display, all buttons are inoperable except the set button. Set remains operational so the service person can perform the manually initiated electronic diagnostics, see below, to further isolate the problem. Procedure for removing error code from ...

19 motor turbine support & shaft position switch sensor housing turbine valve outlet fig. 41 troubleshooting this check verifies proper operation of the valve motor, brine tank fill, brine draw, regeneration flow rates, and other controller functions. Always make the initial checks, and the manual i...

20 water softener exploded view 1 4 2 3 5 6 7 10 8 9 15 16 valve assembly see pages 22 & 23 for parts 13 14 12 17 18 20 19 23 25 24 11 26 22 21.

21 water softener parts list ¢ not illustrated u filled media tank for refiner includes activated carbon, resin, top and bottom distributors, associated o-rings, neck clamp kit and shipping cap, assembled. Key no. Part no. Description – 7331177 tank neck clamp kit (includes key nos. 1 & 2) 1 á retai...

22 valve assembly exploded view 51 50 52 53 55 56 59 58 57 60 61 66 67 62 63 64 68 69 70 71 72 73 74 75 65 76 79 84 wear strip seal cross-section view 85 86 87 88 89 90 91 92 54 70 93 82 80 81 77 83 78.

23 valve parts list key no. Part no. Description 50 7338111 screw, #6-19 x 1-3/8” (2 req.) 51 7281291 motor 52 7337474 motor mount 53 7284964 cam & gear 54 7030713 switch – 7331185 drain hose adaptor kit (includes key nos. 55-59) 55 á clip, drain 56 á drain hose adaptor 57 á hose clamp 58 á o-ring, ...

24 bypass blending valve the bypass blending valve works as a typical push- pull bypass valve, but has the added ability to finely adjust hardness of the treated water leaving the water softener. If slightly harder water is desired than is normally output by the water softener, this bypass blend ing...