- DL manuals

- Northern Lights

- Engine

- OM150C12

- Operator's Manual

Northern Lights OM150C12 Operator's Manual

Summary of OM150C12

Page 2

Diesel engine exhaust and some of its constitu- ents are known to the state of california to cause cancer, birth defects, and other reproductive harm. — california — proposition 65 warning: northern lights 4420 14th avenue n.W. Seattle, wa 98107 tel: (206) 789-3880 fax: (206) 782-5455 copyright ©201...

Page 3: Operator'S Manual

Om150c12 11/11 1 read this operator's manual thoroughly before starting to operate your equipment. This manual contains information you will need to run and service your new unit. Operator's manual #om150c12 for model: m150c12 introduction ....................................................2 models...

Page 4

2 om150c12 11/11 servicing of marine engines and generator sets pres- ents unique problems. In many cases boats cannot be moved to a repair facility. Marine engines cannot be compared to the servicing of automobiles, trucks or even farm equipment. Failures often occur in remote areas far from compet...

Page 5

Om150c12 11/11 3 a warranty registration certificate is supplied with your set. The extent of coverage is described in the limited warranty statement. We recommend that you study the statement carefully. Note: if the warranty is to apply, the servicing instructions outlined in this manual must be fo...

Page 6

4 om150c12 11/11 safety rules always stop engine before fueling machine. Always fill portable fuel tank outdoors. Never fuel a hot engine. Prevent accidental discharge of starting fluids by storing all cans in a cool, safe place, away from sparks or open flame. Store with cap securely on container. ...

Page 7

Om150c12 11/11 5 safety rules (continued) install all safety guards direct contact with rotating fans, belts, pulley and drives can cause serious injury. Keep all guards in place at all times during engine operation. Wear close-fitting clothes. Stop the engine and be sure all fans, belts, pulleys an...

Page 8

6 om150c12 11/11 safety rules (continued) slowly loosen cap to relieve pressure before opening fully. Avoid high pressure fluids relieve pressure prior to disconnecting pressurized lines. Escaping fluid under pressure can penetrate the skin causing serious injury. Always relieve pressure before disc...

Page 9

Om150c12 11/11 7 safety rules (continued) use proper lifting equipment and techniques lifting heavy components incorrectly can cause severe injury or damage to machinery. Avoid unbalanced loads. Do not use lifting eyes. Lift the generator set using lifting bars inserted through the lifting holes on ...

Page 10

8 om150c12 11/11 component locations 1. Coolant fill 2. Dc alternator 3. Crankcase breather filter 4. Belt guard 5. Electric starter 6. Lube oil fill & dipstick 7. Coolant pump 8. Center banded mounts 9. Oil pan & filter 10. Lube oil drain 11. Expansion tank 12. Junction box 13. Air cleaner 14. Afte...

Page 11

Om150c12 11/11 9 northern lights control panel 1. Engine control switch to start the engine, hold this switch in the start position until the engine is running. Note: excessive cranking of marine sets equipped with water lift muffler systems can cause engine damage. After the engine starts, release ...

Page 12

10 om150c12 11/11 operating procedures before starting 1. Check the water level by removing the pressure cap from the expansion tank. In order to give the cooling water room to expand, the level should be about 1 3/4 in. (4-5 cm) below the filler cap sealing surface when the engine is cold. When fil...

Page 13

Om150c12 11/11 11 operating procedures 2. Do the following when your shutdown system is activated: a. Check the temperature gauge. If the temperature is above 205°f (97°c), shut off the engine immediately. B. Use the trouble shooting guide on pages 22- 24 to isolate the cause of the overheat. Cautio...

Page 14

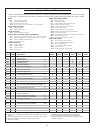

12 om150c12 11/11 the servicing schedule chart below shows the service schedule required for proper maintenance of your marine engine or generator set. More detailed coverage of each service point (sp) is listed on the page noted in the ‘page’ column. Daily: sp1 check oil level in engine sp8 check p...

Page 15

Om150c12 11/11 13 lubrication break-in oil 1. Use one of the following during the first 100 hours of operation: a. John deere engine break-in oil b. Api service category cc, cd, or ce oil c. Acea specification e1 2. Do not use john deere plus-50 oil or engine oils meeting api cg4, api cf4, acea e3, ...

Page 16

14 om150c12 11/11 sp6. Valve clearances caution: disconnect the negative (-) battery terminal before starting valve adjustments to prevent accidentally starting the engine. Valve clearance must be checked and adjusted with the engine cold. The following special tools will be needed: jde 820 or jde 8...

Page 17

Om150c12 11/11 15 fuels - general 1. Use only clean, high quality fuels of the following specifications, as defined by astm designation d975 for diesel fuels: a. Use grade no. 2 diesel at ambient temperatures above freezing 30°f (0°c). B. Use grade no.1 at ambient temperatures below freezing and for...

Page 18

16 om150c12 11/11 sp8-10. Fuel filters 1. Your engine or generator set should have a primary fuel filter installed. We recommend the racor brand of fuel filter - water separators. A. Check the primary fuel filter daily as recommended by the filter manufacturer. Empty the collection bowl as necessary...

Page 19

Om150c12 11/11 17 servicing fuel system caution: do not open the high pressure fuel system. Serious injury can be caused by the high-pressure fluid in the fuel lines. Do not disconnect or attempt to repair fuel lines, sensors, or any components between the high-pressure fuel pump and nozzles on engi...

Page 20

18 om150c12 11/11 servicing there is a chamber at the top of the pump and at the bottom that holds fuel. This fuel is pressurized in each chamber when the pump camshaft rotates. Excess fuel goes through the overflow orifice (14-b) back to the fuel tank. The fuel temperature sensor (14-d) measures th...

Page 21

Om150c12 11/11 19 servicing 3. If chlorides, sulfates or total dissolved solids are higher than the above given specification, the water must be distilled, demineralized, or deionized before it is used in a cooling system. 4. If total hardness is higher than 170 ppm and all other parameters are with...

Page 22

20 om150c12 11/11 important 1. Do not use methyl alcohol or methoxy propanol base egc. These concentrates are not compatible with chemicals used in supplemental coolant additives. Damage can occur to rubber seals on cylinder liners which are in contact with coolant. 2. Do not use an egc containing s...

Page 23

Om150c12 11/11 21 servicing reproduced by permission of deere & company, c2007. Deere & company. All rights reserved. Rg15325, rg15326, & rg15327 figure 18, a. B & c on all engines: note: the heat exchanger core may be removed from hoursing when either end is removed. It is strongly recommended that...

Page 24

22 om150c12 11/11 servicing note: for proper orinetation of the tube bundle, the core divider plate must be in line with inlet end cap divider slot with arrow pointing in the correct direction. 3. Install rear end cap (fig 20, a) over tube bundle with core divider plate in slot on cap. Reproduced by...

Page 25

Om150c12 11/11 23 servicing 6. Inspect impeller for damages such as tears, stress cracks, excess abrasions on vane ends, or chunks of material missing. Impellers that are run dry will overheat and fail the impeller blades at the root. Impellers that swell and stick, fail the impeller in the middle o...

Page 26

24 om150c12 11/11 servicing reproduced by permission of deere & company, c2007. Deere & company. All rights reserved. Rg14950 figure 23 note: raw water flange may have two more ounting cap screws than illustrated. Remove/install proce- dure is unchanged. 3. Remove two capscrews (fig 23, c) and remov...

Page 27

Om150c12 11/11 25 servicing 4. Then, connect negative (-) terminal of booster battery to ground on the engine block (see figure 18) . 5. Remove booster battery after starting engine. 6. Sealed batteries: see manufacturer charging and booster instructions. Sp21-22. Battery care - lead/acid type batte...

Page 28

26 om150c12 11/11 if you cannot correct problems with these procedures, see your lugger or northern lights dealer. Crankcase oil too heavy: • fill with oil of appropriate viscosity. Loose or corroded connections: • clean and tighten loose connections. A starter and hour meter function but rest of el...

Page 29

Om150c12 11/11 27 troubleshooting if you cannot correct problems with these procedures, see your lugger or northern lights dealer. A engine overheats engine overloaded. • reduce the load. Low coolant level: • fill tank or radiator to proper level. • check hoses for loose connections and leaks. Keel ...

Page 30

28 om150c12 11/11 troubleshooting if you cannot correct problems with these procedures, see your lugger or northern lights dealer. A high fuel consumption engine overloaded. • reduce load. Air in fuel system: • bleed fuel system. Improper type of fuel: • use correct fuel for temperature. Clogged or ...

Page 31

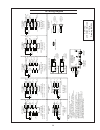

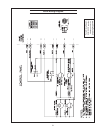

Om150c12 11/11 29 3. Dele te neutral co nnec tion if l- n vo lt ag e is no t required . No tes: 600v ac , stranded , ex cept as no ted . 1. All inst alla tion co ndu ct ors are to be aw g 14, ty pe mt w, 105°c , 4. Co nnec t leads se ven and eight to terminals seven and eight on the sx460. Remove an...

Page 32

30 om150c12 11/11 dc wiring - m150c12.25 12 vdc standard ground drawing d-4517a dc wiring diagram.

Page 33

Om150c12 11/11 31 panel wiring diagram panel wiring diagram s-3b/s-3c oceanline/ viewline panels 12v drawing a12574a.

Page 34

32 om150c12 11/11 item description quantity 1 lube oil filter 4 2 air filter element 1 3 fuel filter 2 4 fuel filter element 4 5 fuel lift pump 1 6 injector 1 7 thermostat 2 8 thermostat seal ring 2 9 thermostat cover gasket 1 10 rocker cover gasket 1 11 engine overhaul gasket kit 1 12 zinc anode* 6...

Page 36

Www.Northern-lights.Com 4420 14th ave. Nw., seattle wa 98107 tel: (206) 789-3880 • 1-800-762-0165 • fax: (206) 782-5455 northern lights and lugger are registered trademarks of northern lights, inc. © 2011 all rights reserved. Litho usa..