- DL manuals

- O.S. Engine

- Engine

- MAX-40FX

- Owner's Instruction Manual

O.S. Engine MAX-40FX Owner's Instruction Manual

It is of vital importance, before attempting to

operate your engine, to read the general

'SAFETY INSTRUCTIONS AND WARNINGS'

section on pages 2-6 of this booklet and to strictly

adhere to the advice contained therein.

●

Also, please study the entire contents of this

instruction manual, so as to familiarize yourself

with the controls and other features of the

engine.

Keep these instructions in a safe place so that

you may readily refer to them whenever

necessary.

It is suggested that any instructions supplied

with the aircraft, radio control equipment, etc.,

are accessible for checking at the same time.

●

●

Summary of MAX-40FX

Page 1

It is of vital importance, before attempting to operate your engine, to read the general 'safety instructions and warnings' section on pages 2-6 of this booklet and to strictly adhere to the advice contained therein. ● also, please study the entire contents of this instruction manual, so as to famil...

Page 2: Contents

Safety instructions and warnings about your o.S. Engine features of fx series engines, before installing the engine basic engine parts needle-valve location installation of the engine throttle linkage, silencer fuel tank location glowplug fuel, propellers mixture controls before starting running-in ...

Page 3: Warnings

Remember that your engine is not a "toy", but a highly efficient internal- combustion machine whose power is capable of harming you, or others, if it is misused. As owner, you, alone, are responsible for the safe operation of your engine, so act with discretion and care at all times. If at some futu...

Page 4: Warnings

Warnings model engine fuel is poisonous. Do not allow it to come into contact with the eyes or mouth. Always store it in a clearly marked container and out of the reach of children. Never operate your engine in an en- closed space. Model engines, like auto- mobile engines, exhaust deadly carbon- mon...

Page 5: Notes

Notes • • • • • this engine was designed for model aircraft. Do not attempt to use it for any other purpose. Mount the engine in your model securely, following the manufacturers' recommenda- tions, using appropriate screws and lock- nuts. Be sure to use the silencer (muffler) supplied with the engin...

Page 6: Notes

Notes • • always check the tightness of the propeller nut and retighten it, if necessary, before restarting the engine, particularly in the case of four-stroke-cycle engines. If a safety locknut assembly is provided with your engine, always use it. This will prevent the propeller from flying off in ...

Page 7: Notes

Notes • • • • • adjust the throttle linkage so that the engine stops when the throttle stick and trim lever on the transmitter are fully retarded. Alternatively, the engine may be stopped by cutting off the fuel supply. Never try to stop the engine physically. Take care that loose clothing (ties, sh...

Page 8: Before Installing The Engine

This range of engines is ideally suited to a variety of r/c aircraft, including trainer, sports, aerobatic and scale types. A separate precision-made needle-valve unit is installed at the rear, where manual adjustment is safely remote from the rotating propeller. With the 50sx, 61fx and 91fx, the ne...

Page 9: Needle-Valve Location

The procedure for relocating the needle-valve vertically is as follows: as delivered from the factory, the max-61fx and max-91fx ring have their needle-valve assembly installed horizontally. However, if more convenient for a particular installation, the needle-valve may be reinstated vertically behi...

Page 10

Inlet holder plug screw (50sx/91fx) fuel inlet needle-valve assembly needle extension inlet holder fuel inlet needle-valve assembly 45mm fuel inlet needle-valve assembly plug screw (50sx/91fx) fuel inlet needle-valve assembly needle extension 45mm 61fx 50sx/91fx use hexagon-head brass inlet holder (...

Page 11: Installation of The Engine

Hardwood mounting beams o.S. Radial motor mount (cast aluminum) how to fasten the mounting screws. Make sure that the mounting beams are parallel and that their top surfaces are in the same plane. Front view side view top surfaces are not in the same plane. Opposite beam top surfaces are not in the ...

Page 12: Silencer

The exhaust outlet of the silencer can be rotated to any desired position in the following manner: loosen the locknut and assembly screw. Set the exhaust outlet at the required position by rotating the rear part of the silencer. Re-tighten the assembly screw, followed by the locknut. Silencer 1) 2) ...

Page 13: Fuel Tank Location

Suggested fuel tank capacities are listed opposite. These will allow 12-13 minute flights. Locate the fuel tank so that the top of the tank is 5- 10mm (1/4-3/8") above the level of the needle-valve. Be sure to use a pressurized fuel system by connecting the muffler pressure nipple to the vent- pipe ...

Page 14: Glowplug

The role of the glowplug with a glowplug engine, ignition is initiated by the application of a 1.5-volt power source. When the battery is disconnected, the heat retained within the combustion chamber remains sufficient to keep the plug filament glowing, thereby continuing to keep the engine running....

Page 15: Fuel

Fuel propellers suggested propeller sizes are listed on page 15. The suitability of the prop depends on the size and weight of the model and type of flying. Determine the best size and type after the engine has been run in. Check the balance of the propeller before fitting it to the engine. Unbalanc...

Page 16: Mixture Controls

Mixture controls 50sx 40fx 46fx 61fx 91fxring 10 ✕ 6,10.5 ✕ 6,11 ✕ 6 ~ 7 10.5 ✕ 6,11 ✕ 6 ~ 8,12 ✕ 6 ~ 7 12 ✕ 6 ~ 8,13 ✕ 6 ~ 7 15 ✕ 8,16 ✕ 6 ~ 8,17 ✕ 6 14 ✕ 7 (3-blade) sport 13 ✕ 11 ~ 13,14 ✕ 10 ~ 11 11 ✕ 8 ~ 10,12 ✕ 7 ~ 9 (tuned silencer used) 12 ✕ 9 ~ 11 (tuned silencer used) aerobatic never touch...

Page 17: Before Starting

Before starting tools, accessories, etc. The following items are necessary for operating the engine. 1 fuel model glowplug engine fuel of good quality, preferably containing a small percentage of nitromethane. 2 glowplug o.S. No.8 glowplug is fitted to the engine. 3 propeller suggested size is 10x6(...

Page 18: Starting

12v battery starter 6 fuel tank for installation in the model, a 300cc (10.6oz.) for 50sx and 40,46fx, a 350cc (12oz.) for 61fx, a 450cc (15.8oz.) for 91fx tank, is suggested. 7 fuel bottle or pump for filling the fuel tank, a simple, polyethylene "squeeze" bottle, with a suitable spout,is all that ...

Page 19

6. Connect battery leads to glowplug. Bring electric starter into contact with spinner-nut or spinner and depress starter switch for one or two seconds. Repeat if necessary. When the engine starts, withdraw the starter im- mediately. 7. Attention : do not choke the carburettor air intake when applyi...

Page 20: Running-In ("breaking-In")

Running-in ("breaking-in") all internal-combustion engines benefit from extra care when they are run for the first few timesknown as running-in or breaking-in. This allows the working parts to mate together under load at operating temperature. Therefore, it is vitally important to complete the break...

Page 21

Slowly advance the throttle to its fully open position, then gradually close the needle-valve until the exhaust note begins to change. (4-cycle to 2-cycle) at this point, disconnect the battery from the glowplug, taking care that the battery leads or glowplug clip do not come into contact with the r...

Page 22

20 ° ~ 45 ° needle-valve adjustment diagram this diagram is for reference purposes only. Actual needle positions may differ from those shown. To stop the engine, close the throttle completely to cut off fuel/air supply. Note : • practical best(optimum) needle-valve setting exhaust note starts to cha...

Page 23: Idling Adjustment Chart

Idling adjustment chart start the engine. Make sure that the throttle is fully open. Adjust the neede-valve. Close the throttle gradually. Find the idling position. Fix the idling position. Open the throttle fully. Does the engine regain full power? Continue running at high speed for 10 seconds. Clo...

Page 24

Mixture control valve adjustment realignment of mixture control valve with the engine running, close the throttle and allow it to idle for about five seconds, then open the throttle fully. If, at this point, the engine is slow to pick up and produces an excess of exhaust smoke, the mixture is too ri...

Page 25: Subsequent Readjustment

Subsequent starting procedure subsequent readjustment once the optimum needle-valve setting has been es- tablished (see page 19, needle-valve adjustment dia- gram) the procedure for starting may be simplified as follows. Open the needle-valve one half-turn (180 ° ) from the optimum setting. Set the ...

Page 26: Carburetor Cleanliness

Carburetor cleanliness engine care and maintenance at the end of each operating session, drain out any fuel that may remain in the fuel tank. Next, energize the glowplug and try to restart the engine to burn off any fuel that may remain inside the engine. Repeat this procedure until the engine fails...

Page 27: Exploded View (50Sx)

Y t r e w q = - 0 7 6 5 4 3 2 1 c.M3 ✕ 15 c.M2.6 ✕ 18 i u c.M3 ✕ 8 s.M3 ✕ 3 9 8 q -1 i -1 i -2 i -3 i -4 i -5 i -6 i -7 i -8 i -9 i -10 o ✽ type of screw c … cap screw f … flat head screw n … round head screw s … set screw exploded view (50sx) 26.

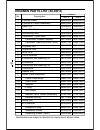

Page 28: Enginen Parts List (50Sx)

1 2 3 4 5 6 7 8 9 0 - = q q -1 w e r t y u i i -1 i -2 i -3 i -4 i -5 i -6 i -7 i -8 i -9 i -10 o 25204010 25203100 25303400 25203200 25206000 25217000 25205000 25681010 25281140 23981700 23210007 23209003 27708010 27708200 46120000 26731002 25201000 26730005 25202010 25214000 25207010 25207100 2408...

Page 29: Exploded View (40,46Fx)

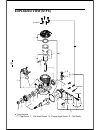

= - 0 9 8 7 5 4 3 2 1 6 6 -2 6 -1 q t e w r -7 r -6 r -5 r -4 r -3 r -2 r -1 r c.M3x15 n.+m3.5x6 s.M3x3 c.M3x8 ✽ type of screw c … cap screw f … flat head screw n … round head screw s … set screw exploded view (40,46fx) 28.

Page 30: Enginen Parts List (40,46Fx)

Enginen parts list (40,46fx) specifications are subject to alteration for improvement without notice. 1 2 3 4 5 6 6 -1 6 -2 7 8 9 0 - = q w e r r -1 r -2 r -3 r -4 r -5 r -6 r -7 t code no. No. Description 25604000 25603000 25406000 24817100 25305002 25681010 46215000 25081700 23210007 23209003 2560...

Page 31: Exploded View (61Fx)

Exploded view (61fx) ✽ type of screw c … cap screw f … flat head screw n … round head screw s … set screw c.M3 ✕ 15 1 e t 2 4 3 5 6 -1 6 -2 6 7 w 8 9 0 - = q n.M3.5 ✕ 6 r -1 r -5 r -3 r -4 r -2 r --10 r -11 r -6 r -7 r -8 c.M3 ✕ 8 c.M3.5 ✕ 8 r r -9 30

Page 32: Enginen Parts List (61Fx)

Enginen parts list (61fx) specifications are subject to alteration for improvement without notice. No. 1 2 3 4 5 6 6 -1 6 -2 7 8 9 0 - = q w e r r -1 r -2 r -3 r -4 r -5 r -6 r -7 r -8 r -9 r -10 r -11 t 27754000 27753000 26606008 27917000 26025000 27783000 46215000 25081700 45010002 28009002 277580...

Page 33: Exploded View (91Fx

Exploded view (91fx ring ) ✽ type of screw c … cap screw f … flat head screw n … round head screw s … set screw c.M3 ✕ 15 y y 2 3 4 7 r 6 5 8 -1 8 -2 8 n.M3.5 ✕ 6 q = - 9 0 0 -1 e t -10 t -1 t -8 t -5 t -2 t -3 t -4 t -7 t t -9 c.M3.5 ✕ 10 s.M3 ✕ 3 t -6 w 32.

Page 34: Engine Parts List (91Fx

Engine parts list (91fx ring ) no. 1 2 3 4 5 6 7 8 8 -1 8 -2 9 0 0 -1 - = q w e r t t -1 t -2 t -3 t -4 t -5 t -6 t -7 t -8 t -9 t -10 y 29504000 29503100 29503400 29053200 45406000 27917000 29505000 29581000 29015019 25081700 45910100 29508000 29008219 46120000 26731002 29501000 29030001 29502000 2...

Page 35

9 8 7 6 5 4 3 2 1 1 -1 1 -2 2 -1 n.+m3.5x6 9 8 7 6 5 4 3 2 1 2 -1 1 -2 1 -1 n.+m3.5x6 carburetor 40b (50sx,40,46fx) 1 1 -1 1 -2 2 2 -1 3 4 5 6 7 8 9 throttle lever assembly throttle lever fixing screw throttle lever mixture control valve "o"ring carburettor rotor rotor spring carburettor body thrott...

Page 36

1 2 3 -1 3 -2 3 n.M3.5 ✕ 6 8 7 6 4 5 n.+m3 ✕ 6 carburetor 60f (91fx ring ) 1 2 3 3 -1 3 -2 4 5 6 7 8 throttle lever assembly carburettor rotor mixture control valve assembly "o" ring (l) "o" ring (s) carburettor body rotor guide screw fuel inlet (w / washer) carburetor gasket carburetor retaining sc...

Page 37

■ no.8 (71608001) a5 (71605100) ■ for 50sx. 40.46fx ■ ■ ■ ■ 73101000 73101010 1/4"-28 5/16"-24 50sx. 40. 46fx 61fx. 91fx 25425500 26625410 50sx. 40.46fx(873) 61fx(e-4010). 91fx(e-4020) 25425600 26625340 26625500 50sx. 40.46fx(873) 61fx(e-4010).91fx(e-4020) length 35mm 61fx(e-4010).91fx(e-4020) a3 (7...

Page 38

■ (72101230) for 61fx ¡ 91fx ■ (72403050) ■ (71531000) ■ (72101120) (71521000) ■ ■ 55500002 55500003 50sx. 40.46fx 61fx.91fx m3 m4 ■ 72105337 72101338 40.46fx 61fx.91fx ■ 25425020 26028010 873s e-4010s 50sx. 40 ¡ 46fx 61fx for 61fx exhaust header pipe code no. Size type of engine super silencers cod...

Page 39: 50Sx

Max- 50sx ring displacement bore stroke practical r.P.M. Power output weight 8.17 cc (0.499 cu.In.) 22.0mm (0.866 in.) 21.5mm (0.847 in.) 2,000 ~ 20,000 r.P.M. 1.8 bhp / 17,000 r.P.M. 390g (13.76 oz.) ■ ■ ■ ■ ■ ■ specifications dimensions(mm) unf1/4-28 52 36 44 17.5 60.7 25 18.3 28 70.5 121 7.5 37.7...

Page 40: 40Fx

Max - 40fx max - 46fx 17.5 44 unf1/4-28 60.5 19.5 70 88 35 51 36.3 displacement bore stroke practical r.P.M. Power output weight 6.47 cc (0.395 cu.In.) 20.5mm (0.807 in.) 19.6mm (0.772 in.) 2,000 ~ 17,000 r.P.M. 1.36 bhp / 16,000 r.P.M. 386g (13.6 oz.) ■ ■ ■ ■ ■ ■ specifications displacement bore st...

Page 41: 61Fx

Max - 61fx 43 61 unf5/16-24 66.5 29.1 43 79 100.5 ø4.2 42 25 ø4.2 52 displacement bore stroke practical r.P.M. Power output weight 9.95 cc (0.607 cu.In.) 24.0mm (0.945 in.) 22.0mm (0.866 in.) 2,000 ~ 17,000 r.P.M. 1.9 bhp / 16,000 r.P.M. 550g (19.42 oz.) ■ ■ ■ ■ ■ ■ specifications dimensions(mm) 40

Page 42: 91Fx

Max - 91fx ring dimensions(mm) displacement bore stroke practical r.P.M. Power output weight 14.95 cc (0.912 cu.In.) 27.7mm (1.091 in.) 24.8mm (0.976 in.) 2,000 ~ 16,000 r.P.M. 2.8 bhp / 15,000 r.P.M. 550g (19.42 oz.) ■ ■ ■ ■ ■ ■ specifications 41 4- φ 4.2 66.5 29.5 unf5/16-24 24.7 42.6 43.5 61 25 5...

Page 43

C copyright 2001 by o.S.Engines mfg. Co., ltd. All rights reserved. Printed in japan. 110101 tel. (06) 6702-0225 fax. (06) 6704-2722 6-15 3-chome imagawa higashisumiyoshi-ku osaka 546-0003, japan u n eq ua ll ed qua lity precision & per for m an ce es ta blis hing the standards of e xce ll en ce url...