User manual dynamic rowing machine.

Introduction base length 2.23m/7’4” seat height 41cm/16” front leg width 66cm/26” flywheel height 90cm/35” thankyou for purchasing the oartec dx. Indoor rowing is one of the best overall fitness exercises for the body. Dynamic indoor rowing makes it even better because you are achieving the same wor...

Table of contents 1. Assembly 3 unpacking the box 3 box contents 3 step 1: attaching rear leg, seat base to rail assembly 4 step 2: building front leg assembly 5 step 3: front assembly to rail assembly 6 step 4: front leg to rail assembly 7 step 5: seat to seat base 7 2. Getting started 8 adjusting ...

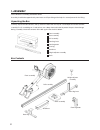

Box contents unpacking the box 1. Assembly please follow the assembly procedures below. Assembly should take approximately 20 minutes and if possible get the help of a second person for the lifting. Carefully unpack the box contents and lay out on the floor. With the help of a second person remove t...

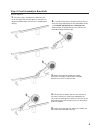

Step 1: rear leg and seat base to rails tools required: 17mm wrench 4 1. Remove the rear extrusion mounts from the seat base bolts. 5. Carefully roll the assembly over and rest on floor. Attach the rear leg to the seat base bolts. 7. Turn assembly over and rest on floor. 4. Insert the seat base bolt...

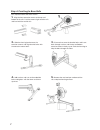

Tools required: 17mm wrench step 2: assemble front leg 5 1. Remove all parts from height adjuster threaded axle assembly. 2. Insert the 20mm pin into the inner front leg hole with the thread aligned vertically. 3. Screw the threaded flange into and through the threaded pin by about 25mm/1”. Add m16 ...

Step 3: front assembly to base rails no tools required 6 2. Carefully lift the front assembly and align the rail ends with the gap between the top and bottom rollers. ** if available, get the help of a second person. Slide the front assembly onto the rails until the rails protrude through the other ...

Step 4: front leg to base rails 7 tools required: 16mm and 17mm wrench 1. Align the front extrusion mounts to the top and bottom of the rails. Push the mounts tight onto the rails and level with the end of rails. 2. Slide the front leg bracket over the extrusion mounts and align bracket holes with t...

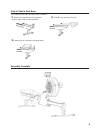

Tools required: 8mm wrench, phillips head screwdriver step 5: seat to seat base assembly complete 8 1. Remove the rear end stop using the 8mm spanner and a phillips head screwdriver. 2. Slide the seat onto the seat track. 3. Replace the rear end stop and tighten bolts..

Adjusting the bottom roller wheels 2. Getting started congratulations on completing the dx assembly process. Please read the following final steps to set up before you use your dx for the first time. The dx roller wheel settings are preset during the factory assembly, however if the rolling frame is...

10 locking the rolling frame the rolling frame of the dx can be easily locked in place so that it can be moved around and also stood upright to minimise space required when not in use. Follow the procedure below to securely lock the front assembly in place before moving or standing upright. Tip: loc...

11 storing the dx upright the dx can easily be moved around and stood upright to minimise the space required when not in use. To lock the rolling frame see locking the rolling frame on previous page. There are wheel located on the front leg to make it easy to manouevre the dx around and into a stand...

12 adjusting the footstraps adjusting the feet height storing the handle the footplate is fitted with a height adjustable footflex to set the feet at the most comfortable height for you. Set the feet height so that at the catch the top of your knees are just below your armpits. Tighten the footstrap...

13 adjusting the resistance move the intake dial up to make resistance easier move the intake dial down to make resistance harder ready to row the dx uses an adjustable air resistance system to provide the resistance when rowing. The resistance is adjusted by moving the air intake dial on the side o...

14 3. Oartec training monitor otm-2 setting date and time installing the batteries before you use the otm for the first time, please ensure that the correct date and time are set. Once time and date are set it will remain current, even when replacing the main batteries, as the otm has a smaller back...

15 quick start guide turning the monitor on/off the otm turns on automatically once you start rowing. To manually turn on press the menu/back button. The otm will turn itself off after no activity for 3 minutes. To manually turn the monitor off, press and hold the menu/back for 3 seconds. Main menu/...

16 just row just row workouts are ideal for quick warm ups or for rowing as far as you feel like going. Time and distance values both start from zero and count up as you row. With no set finish point, the workout ends when you stop rowing and the flywheel slows. Time and distance will stop at the la...

17 4. Maintenance please follow the procedures set out below to maintain your dx model in optimal working condition. Cleaning the rails frequency: after every use. Tools required: soft cloth, kitchen cleaner use a gentle kitchen cleaner and soft cloth to wipe down the rails of sweat, dirt and partic...

18 maintenance adjusting the bottom roller wheels frequency: as required – check adjustment regularly. Tools required: 4mm & 5mm allen key, 13mm/16mm wrench check regularly the adjustment of the bottom roller wheels for optimal performance and prolonged life of the wheels and rail coating. The dynam...

19 adjusting the bottom roller wheels 6. Test the movement of the front assembly along the rails. It should move freely along the rails but tight enough to have a stable connection to the rails. Make small adjustments to tighten or loosen the roller tension. 8. Repeat the same process in steps 5, 6 ...

20 7. Replace outer cover and align overlap in mesh. Tighten bolts making sure the nut thread correctly onto the bolt before tightening. Cleaning the flywheel and flywheel housing frequency: after 100 hours of use or every 6- 12 months. Tools required: 5mm allen key, 16mm wrench dust can build up in...

21 if you are experiencing any issues with your dx, please check the troubleshooting list below. If unable to fix or determine the cause of the issue contact oartec or go to www.Oartec.Com/dxserviceandsupport for all troubleshooting and servicing procedures. Chain has jumped off drive sprocket remov...

22 the standard warranty term for the dx is 3 years on the frame and 2 years on parts. This warranty is under the following terms and conditions: i. Warranty frame oartec will replace or repair, at its option, the dx frame assembly or components that fail due to a defect in materi- al or workmanship...

More information contact oartec at info@oartec.Com or visit our website www.Oartec.Com.