- DL manuals

- Oce

- Printer

- CS9065

- User Manual

Oce CS9065 User Manual

Summary of CS9065

Page 1

Océ cs9065 océ cs9090 user guide eco solvent.

Page 2

User’s guide cs9000 eco-solvent series printer 2 ap-75037, rev. 1.1, 24/04/2006 this page is intentionally left blank.

Page 3

User’s guide cs9000 eco-solvent series printer 3 ap-75037, rev. 1.1, 24/04/2006 copyright notice copyright © 2006 océ-technologies b.V. All rights reserved. This document may not be reproduced by any means, in whole or in part, without written permission of the copyright owner. This document is furn...

Page 4

User’s guide cs9000 eco-solvent series printer 4 ap-75037, rev. 1.1, 24/04/2006 this page is intentionally left blank.

Page 5

User’s guide cs9000 eco-solvent series printer 5 ap-75037, rev. 1.1, 24/04/2006 table of contents 1 safety instructions ................................................................................................................................... 7 1.1 introduction.................................

Page 6

User’s guide cs9000 eco-solvent series printer 6 ap-75037, rev. 1.1, 24/04/2006 this page is intentionally left blank.

Page 7: 1 Safety Instructions

Chapter 1 : safety instructions 7 ap-75037, rev. 1.1, 24/04/2006 1 safety instructions 1.1 introduction ..............................................................................8 1.2 warnings, cautions and notes ................................................8 1.3 important safety instructions...

Page 8: 1.1 Introduction

Chapter 1 : safety instructions 8 ap-75037, rev. 1.1, 24/04/2006 1.1 introduction this chapter explains the meaning of safety terms for personnel operating this equipment, important safety instructions, and the positions of the warning labels. Warning : • be sure to follow all instructions and warni...

Page 9

Chapter 1 : safety instructions 9 ap-75037, rev. 1.1, 24/04/2006 ¾ be sure to use the specified voltage (ac 100 v to 120v, or ac 220v to 240v). Otherwise, electrical shock or fire may occur. ¾ use electricity directly from a power outlet (ac 100 v to 120v, or ac 220v to 240v). Do not put many loads ...

Page 10

Chapter 1 : safety instructions 10 ap-75037, rev. 1.1, 24/04/2006 ¾ have four or more people unpack and assemble the printer. ¾ when lifting the printer out of the packing box, be sure to remove the vinyl cover first, and then grab the holding grips on the sides of the printer. Lifting the printer w...

Page 11: 1.4 Warning Labels

Chapter 1 : safety instructions 11 ap-75037, rev. 1.1, 24/04/2006 1.4 warning labels the handling, attachment locations, and types of warning labels are explained below. Warning labels are attached on areas which require attention. Read and understand the positions and contents thoroughly before per...

Page 12

Chapter 1 : safety instructions 12 ap-75037, rev. 1.1, 24/04/2006 no. Type 1 2 3 4 5.

Page 13

Chapter 1 : safety instructions 13 ap-75037, rev. 1.1, 24/04/2006 1.4.2.2 location and types of warning labels on back part. No. Type 3 caution this unit has two power supply cords, when winding unit is provided. To reduce the risk of electrical shock, disconnect all power supply cords before servic...

Page 14

Chapter 1 : safety instructions 14 ap-75037, rev. 1.1, 24/04/2006 1.5 maintenance and operation labels 1.6 labels in function of transportation nr. Description 1 before powering on printer, remove dummy cartridges..

Page 15: 2 Product Overview

Chapter 2 : product overview 15 ap-75037, rev. 1.1, 24/04/2006 2 product overview 2.1 introduction…………………………………………………........16 2.2 features.................................................................................16 2.3 part names and functions ..................................................

Page 16: 2.1 Introduction

Chapter 2 : product overview 16 ap-75037, rev. 1.1, 24/04/2006 2.1 introduction this chapter explains the features, part names, and functions of the printer. 2.2 features the features of the printer are explained below. (1) high speed output the 2 models of the cs9000 eco-solvent series feature new ...

Page 17: 2.3 Part Names and Functions

Chapter 2 : product overview 17 ap-75037, rev. 1.1, 24/04/2006 2.3 part names and functions part names and functions are explained below. 2.3.1 front no name function 1 heater plate supports and heats the media during printing. 2 front cover keeps the operator safe from the drive parts of the printe...

Page 18

Chapter 2 : product overview 18 ap-75037, rev. 1.1, 24/04/2006 2.3.2 connections on the back no connection 1 ethernet connector 2 card reader slot 3 smartchip label 4 harddisk bracket cover 5 centronics connector 6 foot switch connector 7 power inlet 8 environmental label 9 db-25 connector 10 id lab...

Page 19

Chapter 2 : product overview 19 ap-75037, rev. 1.1, 24/04/2006 2.3.3 position and function of the heating elements heater element temperature function pre-heater (heater a) 20 – 50°c → to open the pores to make the media more receptive for eco solvent ink. Fixer (heater b) 20 – 70°c → to establish o...

Page 20

Chapter 2 : product overview 20 ap-75037, rev. 1.1, 24/04/2006 2.3.4 operation panel the operation panel is used to set operational conditions, display the status of the printer, and set other functions. The names and functions of the operation keys and status lamps are explained below. 2.3.4.1 oper...

Page 21

Chapter 2 : product overview 21 ap-75037, rev. 1.1, 24/04/2006 2.3.4.2 lcd monitor and status lamps no. Name colour status function 10 lcd monitor - - the monitor displays the operation status and error messages of the printer. On the printer is on. 11 power lamp green off the printer is off. Flashi...

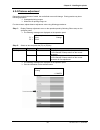

Page 22: 2.4 Printer Status

Chapter 2 : product overview 22 ap-75037, rev. 1.1, 24/04/2006 2.4 printer status the status of the printer is explained below. 2.4.1 normal indicates that the printer can receive print data when media has been loaded. You can also change printer settings using the operation panel. The contents disp...

Page 23

Chapter 2 : product overview 23 ap-75037, rev. 1.1, 24/04/2006 2.4.3 changing the printer status 2.4.3.1 changing the status from normal to the setting menu display press either [menu Ç ] or [menu È ] on the operation panel when the printer is in normal status. ¾ the display of the operation panel c...

Page 24

Chapter 2 : product overview 24 ap-75037, rev. 1.1, 24/04/2006 this page is intentionally left blank.

Page 25: 3 Setting Up The Unit

Operation instructions océ cs9000 eco-solvent printer series chapter 2 : setting up the unit 25 ap-75037, rev. 1.1, 24/04/2006 3 setting up the unit 3.1 unpacking..............................................................................26 3.1.1 packing of the product 26 3.1.2 unpacking the main ...

Page 26: 3.1 Unpacking

Operation instructions océ cs9000 eco-solvent printer series chapter 2 : setting up the unit 26 ap-75037, rev. 1.1, 24/04/2006 3.1 unpacking caution : • when unpacking, always work with at least 4 people. • when removing the printer or stand from the packaging box, always remove the vinyl plastic, a...

Page 27

Operation instructions océ cs9000 eco-solvent printer series chapter 2 : setting up the unit 27 ap-75037, rev. 1.1, 24/04/2006 step 3 : remove the top board (1) and take out the packaging material (2) at the right upper side and left upper side as shown on the image below. 1 = top board 2 = packagin...

Page 28

Operation instructions océ cs9000 eco-solvent printer series chapter 2 : setting up the unit 28 ap-75037, rev. 1.1, 24/04/2006 3.1.3 unpacking the stand packaging box unpack the package of the stand according to the following procedure. Procedure (2 steps) : step 1 : move the packaging of the stand ...

Page 29: 3.2 Verifying The Items

Chapter 3 : setting up the unit 29 ap-75037, rev. 1.1, 24/04/2006 3.2 verifying the items after unpacking the packaging box, inspect if the unit is not damaged and that all necessary parts are present. Notes : • the contents of the packages may be different depending on the market where they are use...

Page 30

Chapter 3 : setting up the unit 30 ap-75037, rev. 1.1, 24/04/2006 3.2.2 verifying the stand packaging box no° description quantity 1 stay 1 2 weight support 2 3.2.3 verifying the uw/w 100 packaging box note : • please refer to the user’s guide of the uw/w 100 to verify the content..

Page 31

Chapter 3 : setting up the unit 31 ap-75037, rev. 1.1, 24/04/2006 3.2.4 verifying the machine starters kit packaging box no description quantity 1 user’s guide 1 2 user documentation cd 1 3 keyboard label 1 4 heater label 1 5 irritating label 1 6 maintenance label set (6 languages) 1 7 ink starter s...

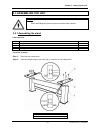

Page 32: 3.3 Assembling The Unit

Chapter 3 : setting up the unit 32 ap-75037, rev. 1.1, 24/04/2006 3.3 assembling the unit caution : • when assembling this product, always work with at least 4 people. 3.3.1 assembling the stand parts and tools : no° description quantity 1 weight support 2 2 stay 1 3 hexagon socket head cap screws m...

Page 33

Chapter 3 : setting up the unit 33 ap-75037, rev. 1.1, 24/04/2006 3.3.2 mounting the main unit to the stand the procedure below describes how to mount the main unit to the stand, assembled in the previous chapter. Parts and tools : no° description quantity 1 stand 1 2 main unit 1 3 hexagon socket he...

Page 34

Chapter 3 : setting up the unit 34 ap-75037, rev. 1.1, 24/04/2006 3.3.3 adjusting the position of the main unit to the stand after installation of the main unit onto the stand, please check if there is no gap between the printer body and the stand. When you notice that there is a gap between the pri...

Page 35

Chapter 3 : setting up the unit 35 ap-75037, rev. 1.1, 24/04/2006 3.3.5 removing the protective packaging material caution : • be careful not to pinch your fingers when opening and closing the front cover. Caution : • remove the head locker before powering on the printer ! Remove all protective pack...

Page 36

Chapter 3 : setting up the unit 36 ap-75037, rev. 1.1, 24/04/2006 part 2 : removing the head locker (3 steps) step 1 : open the front cover (1). (see image below) 1 = front cover step 2 : remove the head locker (2) as shown on the image below. 1 = wing bolt 2 = head locker step 3 : close the front c...

Page 37: 3.4 Installation

Chapter 3 : setting up the unit 37 ap-75037, rev. 1.1, 24/04/2006 3.4 installation product installation is explained below. 3.4.1 choosing a place for the printer install the unit on a proper location referring to the following : warning : • do not place the printer on a location under the following...

Page 38

Chapter 3 : setting up the unit 38 ap-75037, rev. 1.1, 24/04/2006 notes : • avoid the following temperature and humidity conditions. Otherwise, printed images may appear differently from what you expect: o places where sudden changes in temperature and humidity are expected, even though the conditio...

Page 39

Chapter 3 : setting up the unit 39 ap-75037, rev. 1.1, 24/04/2006 3.4.2 leveling the printer part 1 : leveling the printer in y – direction (3 steps) step 1 : position the printer in its final position. Step 2 : turn down all feet of the printer stand (not those of the uw/w 100) with an equal pressu...

Page 40

Chapter 3 : setting up the unit 40 ap-75037, rev. 1.1, 24/04/2006 part 2 : leveling the printer in x – direction (3 steps) step 1 : position the level on the print platform. Step 2 : turn the left and right weight supports an equal amounts of turns. (see picture below) note : • make sure to turn the...

Page 41: 4 Preparing For A Job

Chapter 4 : preparing for a job 41 ap-75037, rev. 1.1, 24/04/2006 4 preparing for a job 4.1 introduction ............................................................................43 4.2 connecting the power cable ..................................................43 4.3 connecting the foot switch f...

Page 42

Chapter 4 : preparing for a job 42 ap-75037, rev. 1.1, 24/04/2006 4.9 working with océ’s smartchip management system............71 4.9.1 introduction 71 4.9.2 explaining the smartchip management system 71 4.9.3 inserting smartchip card in the card reader of the printer 73 4.9.4 switching between cas...

Page 43: 4.1 Introduction

Chapter 4 : preparing for a job 43 ap-75037, rev. 1.1, 24/04/2006 4.1 introduction the procedures needed before using the printer are explained below. 4.2 connecting the power cable warnings : warning : • make sure that the enclosed power cable is used. Use of a different cable may result in electri...

Page 44

Chapter 4 : preparing for a job 44 ap-75037, rev. 1.1, 24/04/2006 caution : • follow the instructions below when handling the power plug. Otherwise, fire may occur. O wipe away dust and any other residue before inserting the plug. O ensure that the plug is firmly inserted as far as it will go. • ens...

Page 45: Roller

Chapter 4 : preparing for a job 45 ap-75037, rev. 1.1, 24/04/2006 4.3 connecting the foot switch for the pressure roller if the pressure roller needs to be raised or lowered, it is possible to control this motion from the foot switch, instead of doing so at the operation panel. Caution : • when hand...

Page 46: 4.4 Turning The Power On/off

Chapter 4 : preparing for a job 46 ap-75037, rev. 1.1, 24/04/2006 4.4 turning the power on/off caution : • before powering on the unit for the first time, make sure to: remove the dummy cassettes remove the waste tube clamps remove the bag enclosing the waste tubes connect the waste tubes 4.4.1 turn...

Page 47

Chapter 4 : preparing for a job 47 ap-75037, rev. 1.1, 24/04/2006 4.4.2 turning the power off procedure (4 steps) : step 1 : verify the following regarding the operational condition of the unit : • there is no printing operation being performed. • the operation panel is in a normal status. Step 2 : ...

Page 48

Chapter 4 : preparing for a job 48 ap-75037, rev. 1.1, 24/04/2006 step 4 : the product will perform the power off operation. • following message is displayed on the operation panel. Power off please wait • all lamps and the lcd of the operation panel will turn off. • the product will automatically t...

Page 49

Chapter 4 : preparing for a job 49 ap-75037, rev. 1.1, 24/04/2006 4.5 installing eco solvent ink cassettes purpose : the installation of océ ijc930 eco-solvent ink cassettes for the first time into the unit is explained below. Caution and notes : read these first before to perform a first ink load !...

Page 50

Chapter 4 : preparing for a job 50 ap-75037, rev. 1.1, 24/04/2006 parts needed: before powering on the unit for the first time, please be sure to have: • 8 cassettes with eco-solvent cleaning • 8 cassettes with eco-solvent ink (2 x cmyk) first ink load procedure: step 1 : verify if the waste bottle ...

Page 51

Chapter 4 : preparing for a job 51 ap-75037, rev. 1.1, 24/04/2006 step 7 : empty the waste bottle as requested on the display below. Please empty waste ink tank step 8 : remove all eco-solvent cleaning cassettes when the message below appears. Please remove cassettes step 9 : insert the correct conf...

Page 52

Chapter 4 : preparing for a job 52 ap-75037, rev. 1.1, 24/04/2006 step 10 : wait until the ink refill sequence has been finished, the display will show the remaining minutes, 9 min for a 65” machine and 13 min for a 90” machine : ink refill rest 13 min (or 9 min for 65” machines) please note that yo...

Page 53: 4.6 Media Handling

Chapter 4 : preparing for a job 53 ap-75037, rev. 1.1, 24/04/2006 4.6 media handling media handling, attaching media, and setting media type are explained below. 4.6.1 loading sheet media you can use the following sheet media with your printer : machine media width printing width cs 9065 1653 mm 164...

Page 54

Chapter 4 : preparing for a job 54 ap-75037, rev. 1.1, 24/04/2006 step 3 : verify if the sheet lamp on the operation panel is unlit. Step 4 : press the [f4] key on the operation panel to lower the pressure rollers. ¾ the media set lamp will light orange. ¾ the following message is displayed on the o...

Page 55

Chapter 4 : preparing for a job 55 ap-75037, rev. 1.1, 24/04/2006 step 7 : set the right edge of the media (1) paralleled with the media loading position (2). 1 = sheet media 2 = media loading position notes : • the media set position is a guideline for setting up the media. • if the right edge of t...

Page 56

Chapter 4 : preparing for a job 56 ap-75037, rev. 1.1, 24/04/2006 step 10 : the media initial menu is displayed on the operation panel. (see below) * paperinitialmenu * roll ← f2 f3 → leverup user1 ← f4 f2, f4 → enter or f3 notes : • to change the media type, follow the directions in 4.6.4 setting m...

Page 57

Chapter 4 : preparing for a job 57 ap-75037, rev. 1.1, 24/04/2006 4.6.2 loading roll media 4.6.2.1 installing the media roll procedure (7 steps) : step 1 : determine the printable side of the media roll (inside or outside printing) and lay down the media roll as shown in the images below. Step 2 : p...

Page 58

Chapter 4 : preparing for a job 58 ap-75037, rev. 1.1, 24/04/2006 step 4 : lock one roll unit to the roll unit bar step 5 : place one side of the roll over the flange of the locked unit. Step 6 : slide the flange of the other roll unit into the roll and lock the unit by using the its handle. Step 7 ...

Page 59

Chapter 4 : preparing for a job 59 ap-75037, rev. 1.1, 24/04/2006 step 7 : load media through the rear tensioning system as shown below. Printable side on the outside of the roll printable side on the inside of the roll 1 = unwinder 2 = rear tensioning system 3 = media insertion slot of the printer ...

Page 60

Chapter 4 : preparing for a job 60 ap-75037, rev. 1.1, 24/04/2006 note : • with a small intervention it is possible to reverse your winding direction. Mount a cable between the control box and the front motorized unit cable. Note : • you can use the roll-off foot switch during loading of roll media..

Page 61

Chapter 4 : preparing for a job 61 ap-75037, rev. 1.1, 24/04/2006 4.6.4 setting media type the procedure for setting media type is explained below. (4 steps) step 1 : turn the printer on and load the media. ¾ once the media has been set, the media initial menu will be displayed. Step 2 : press one o...

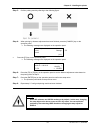

Page 62: 4.7 Testprinting

Chapter 4 : preparing for a job 62 ap-75037, rev. 1.1, 24/04/2006 4.7 testprinting follow the 7 steps below to do a test print and confirm if your printer operates correctly. Step 1 : turn the power of the unit on and load the media. Step 2 : make sure that your printer is in normal status. Step 3 :...

Page 63

Chapter 4 : preparing for a job 63 ap-75037, rev. 1.1, 24/04/2006 4.7.1 setup list purpose : use this function to check the current status of the printer. Note : • to print the setup list, see 4.7 testprinting (page 62) end of the setup list topic.

Page 64

Chapter 4 : preparing for a job 64 ap-75037, rev. 1.1, 24/04/2006 4.7.2 nozzlecheck purpose : use this function to check if there is any clogging of nozzles, missing dots or faint printing. Notes and cautions : note : • if printing quality declines, or if missing dots are evident after the nozzleche...

Page 65

Chapter 4 : preparing for a job 65 ap-75037, rev. 1.1, 24/04/2006 4.7.3 alignment purpose : use this function to adjust the print quality for best results. Note : • the print quality of your printer is pre-adjusted when it is shipped. When the installation environment of the printer or media type ha...

Page 66

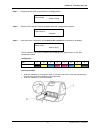

Chapter 4 : preparing for a job 66 ap-75037, rev. 1.1, 24/04/2006 4.7.4 colour palette purpose : use this function to compare the pen colour settings of the computer with the print colour of the printer. Notes : • to print the colour palette, see 4.7 testprinting (page 62) • this palette is printed ...

Page 67

Chapter 4 : preparing for a job 67 ap-75037, rev. 1.1, 24/04/2006 4.7.5 maintenance record purpose : use this function to check the life cycles of the printer parts. Notes : • a part's life cycle is shown by the amount of the * mark. When a part's life cycle comes to an end, the * mark reduces. • to...

Page 68

Chapter 4 : preparing for a job 68 ap-75037, rev. 1.1, 24/04/2006 4.8 connecting the printer to your pc please find below some instructions how to connect the printer to your pc. 4.8.1 system requirements to use your printer with the driver, you need a pc that complies with the following system requ...

Page 69

Chapter 4 : preparing for a job 69 ap-75037, rev. 1.1, 24/04/2006 4.8.3 connecting the centronics interface the procedure for connecting the centronics interface is explained below. To connect the printer to your computer, follow the steps below. Procedure (3 steps) : step 1 : turn off the printer a...

Page 70

Chapter 4 : preparing for a job 70 ap-75037, rev. 1.1, 24/04/2006 4.8.4 connecting the network interface caution : • follow the instructions below when connecting the network interface cable. Otherwise, electrical shock or fire may occur. O do not touch the connector. O do not connect the network ca...

Page 71: System

Chapter 4 : preparing for a job 71 ap-75037, rev. 1.1, 24/04/2006 4.9 working with ocÉ’s smartchip management system 4.9.1 introduction the smartchip management system allows the user to control the ink volumes of the smartchip cards either on the cassettes or centrally in the printer. Caution : don...

Page 72

Chapter 4 : preparing for a job 72 ap-75037, rev. 1.1, 24/04/2006 b. Printer mode transferring ink volume and printing is performed in 2 stages. See the step – action table below : stage description user’s action remark 1 transferring ink volume to the chip manager system. See image stage 1 below. I...

Page 73

Chapter 4 : preparing for a job 73 ap-75037, rev. 1.1, 24/04/2006 4.9.3 inserting a smartchip card in the card reader of the printer insert the smartchip card (1) in the printer’s card reader slot (2) as shown on the image below. 1 = smartchip card 2 = card reader slot 3 = label 4.9.4 switching betw...

Page 74

Chapter 4 : preparing for a job 74 ap-75037, rev. 1.1, 24/04/2006 4.9.5 setting the colour mode procedure (2 steps) : step 1 : go to inkmanager Æ colormode in the printer’s menu (in printer mode ! ) * c o l o r m o d e * 2 * 4 1 * 6 1 * 8 - 2 * 4 - ( 1 / 1 ) step 2 : choose between 2 x 4, 1 x 6 and ...

Page 75

Chapter 4 : preparing for a job 75 ap-75037, rev. 1.1, 24/04/2006 step 4 : perform the correct action, based on the table below : if… then … a cleaning card is detected (see display below) * l o a d t o p r i n t e r * c l e a n i n g a c c e p t e d ! R e m o v e c a r d - > e n t e r remove the sm...

Page 76

Chapter 4 : preparing for a job 76 ap-75037, rev. 1.1, 24/04/2006 step 5 : remove the smartchip card after the transfer of the ink value and press enter (see image below) * l o a d t o p r i n t e r * t r a n s f e r o k ! M l a d d e d : 4 4 0 m l r e m o v e c a r d - > e n t e r the system now go...

Page 77

Chapter 4 : preparing for a job 77 ap-75037, rev. 1.1, 24/04/2006 4.9.7 operational items automatic sequences in printer mode o longstore : only possible in cassette sms mode: uses only cleaning and requires frequent removal and placing back of cassettes. Near end warning o “chipmgr printer : low” r...

Page 78

Chapter 4 : preparing for a job 78 ap-75037, rev. 1.1, 24/04/2006 this page is intentionally left blank..

Page 79: 5 Handling The Printer

Chapter 5 : handling the printer 79 ap-75037, rev. 1.1, 24/04/2006 5 handling the printer 5.1 introduction ............................................................................83 5.2 printing flow ...........................................................................83 5.3 using media .....

Page 80

Chapter 5 : handling the printer 80 ap-75037, rev. 1.1, 24/04/2006 5.4.2.17 media feed compensation menu.......................................... 100 5.4.2.18 change media feed compensation value menu................... 101 5.4.2.19 printing by media feed compensation menu........................ 1...

Page 81

Chapter 5 : handling the printer 81 ap-75037, rev. 1.1, 24/04/2006 5.4.5 setup menu 4/7 120 5.4.5.1 utility menu ............................................................................ 120 5.4.5.2 errordisplay menu ................................................................. 121 5.4.5.3 me...

Page 82

Chapter 5 : handling the printer 82 ap-75037, rev. 1.1, 24/04/2006 5.4.8 setup menu 7/7 144 5.4.8.1 version check menu ............................................................. 144 5.5 operating from the operation panel .....................................145 5.5.1 controlling the heater elemen...

Page 83: 5.1 Introduction

Chapter 5 : handling the printer 83 ap-75037, rev. 1.1, 24/04/2006 5.1 introduction this chapter explains how to handle your printer. 5.2 printing flow the following flow chart illustrates the procedure for printing with the printer. Refer to each item as necessary. Step 1 : create the printing data...

Page 84: 5.3 Using Media

Chapter 5 : handling the printer 84 ap-75037, rev. 1.1, 24/04/2006 5.3 using media this section describes details on available media for the printer. 5.3.1 media type the type and quality of the media affect the results of drawing enormously. Refer to the description below and use the appropriate me...

Page 85

Chapter 5 : handling the printer 85 ap-75037, rev. 1.1, 24/04/2006 5.3.3 precaution on storing media when storing media, pay attention to the following. Notes : • do not store media in high temperature, high humidity, or direct sunlight. • store sheet media in the original bag after unpacking. • unu...

Page 86

Chapter 5 : handling the printer 86 ap-75037, rev. 1.1, 24/04/2006 5.3.5 distance adjustment depending on the thickness of media, the media feed amount will change. Printing results may show following symptoms: ¾ overlapped printing images ¾ white lines on printing image, etc for above cases, adjust...

Page 87

Chapter 5 : handling the printer 87 ap-75037, rev. 1.1, 24/04/2006 step 3 : confirm printing result by referring to the following figure. Step 4 : when printing by distance adjustment has been finished, press the [cancel] key on the operation panel. ¾ the following messages are displayed on the oper...

Page 88

Chapter 5 : handling the printer 88 ap-75037, rev. 1.1, 24/04/2006 5.4 menu setup on the operation panel this section describes how to set the menu settings on the operation panel, and setup items. Follow the 2 steps below to set the menu settings. Step 1 : make sure that the operation panel is in n...

Page 89

Chapter 5 : handling the printer 89 ap-75037, rev. 1.1, 24/04/2006 5.4.1 setup menu 5.4.1.1 introducing the setup menu * setupmenu * f1 → inkstatus originset ← f2 f3 → testprint mediaset ← f4 (1/7) * setupmenu * f1 → printmode command ← f2 f3 → layout function ← f4 (2/7) * setupmenu * f1 → rollsetup...

Page 90

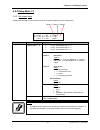

Chapter 5 : handling the printer 90 ap-75037, rev. 1.1, 24/04/2006 5.4.1.2 setup menu structure setup items parameters description ink status displays the information (ink status) for each ink cassette installed in the ink cassette slot. Refer to ink status menu origin setting sets the printing star...

Page 91

Chapter 5 : handling the printer 91 ap-75037, rev. 1.1, 24/04/2006 5.4.2 setup menu 1/7 5.4.2.1 ink status menu displays the information (ink status) for each ink cassette installed in the ink cassette slot. Param.1 param.2 param.3 * inkstatus * k : u 100 y : +100 c : u 100 m : u 100 m : + 100 c : u...

Page 92

Chapter 5 : handling the printer 92 ap-75037, rev. 1.1, 24/04/2006 5.4.2.2 origin setup menu sets the printing start position (origin) for printing data. Set this when you want the re-print to blank area of the printed media by changing the layout of the printing data. * origin * f1 → forward left ←...

Page 93

Chapter 5 : handling the printer 93 ap-75037, rev. 1.1, 24/04/2006 5.4.2.3 test print menu perform test print. * testprint * f1 → setup nozzlecheck ← f2 f3 → adj. Uni-d adj. Bi-d ← f4 (1/2) * testprint * f1 → palette maintenance ← f2 (2/2) setup items parameters description setupprint performs setup...

Page 94

Chapter 5 : handling the printer 94 ap-75037, rev. 1.1, 24/04/2006 5.4.2.5 media type menu set media type for printing. * setupmenu * f1 → user 1 user 2 ← f2 f3 → user 3 user 4 ← f4 (1/2) * setupmenu * f1 → user 5 user 6 ← f2 f3 → user 7 user 8 ← f4 (2/2) setup items parameters description user medi...

Page 95

Chapter 5 : handling the printer 95 ap-75037, rev. 1.1, 24/04/2006 5.4.2.6 user media menu * user 1 * f1 → thinout inkdrytime ← f2 f3 → headheight stiff ← f4 (1/3) * user 1 * f1 → thick heater ← f2 f3 → drier fixer ← f4 (2/3) * user 1 * f1 → post fixer hstatus ← f2 f3 → dist. Adj (3/3) setup items p...

Page 96

Chapter 5 : handling the printer 96 ap-75037, rev. 1.1, 24/04/2006 5.4.2.7 thin out: ink amount menu sets the amount of ink discharged while printing, according to the media type. * thinout * 50% - 100% + ← f2 100% - ← f4 f2, f4 → enter setup items parameters description amount of ink 50 %- use the ...

Page 97

Chapter 5 : handling the printer 97 ap-75037, rev. 1.1, 24/04/2006 5.4.2.9 head height menu sets the distance (head height) between the print head and the media. Head height can be changed to three levels according to media thickness. * headheight * f1 → low middle ← f2 f3 → high current parameter →...

Page 98

Chapter 5 : handling the printer 98 ap-75037, rev. 1.1, 24/04/2006 5.4.2.11 thickness menu sets the media thickness. * thick * 50 µ m – 1500 µ m + ← f2 100 µ m - ← f4 f2, f4 → enter setup items parameters description thickness 50µm--1500µm change media thickness by operating the following keys. • [f...

Page 99

Chapter 5 : handling the printer 99 ap-75037, rev. 1.1, 24/04/2006 5.4.2.13 fixer menu set the temperature of the fixer. * fixer (b) * off – 70°c + ← f2 70°c - ← f4 f2, f4 → enter use the [f2] or [f4] key to select the requested temperature for the fixer. 5.4.2.14 post fixer menu set the temperature...

Page 100

Chapter 5 : handling the printer 100 ap-75037, rev. 1.1, 24/04/2006 5.4.2.16 hstatus menu check the temperature of the heating elements. * hstatus * a: 49 b: 26 c: 27 d : 49 heating not ready notes : a stands for the heater. B stands for the fixer. C stands for the post fixer. D stands for the dryer...

Page 101

Chapter 5 : handling the printer 101 ap-75037, rev. 1.1, 24/04/2006 5.4.2.18 change media feed compensation value menu changes the media feed compensation value. * change * 90.00% - 110.00% + ← f2 110.00% - ← f4 f2, f4 → enter setup items parameters description change 90.00%--110.00% changes the med...

Page 102

Chapter 5 : handling the printer 102 ap-75037, rev. 1.1, 24/04/2006 5.4.2.20 cut size menu when setting sheet media in the tray, set the method for detecting the size of the media. * cutsize * f1 → auto length ← f2 f3 → width current parameter → - length - (1/1) setup items parameters description th...

Page 103

Chapter 5 : handling the printer 103 ap-75037, rev. 1.1, 24/04/2006 5.4.2.22 media cut menu set media cut method after printing. * mediacut * f1 → off auto ← f2 f3 → manual current parameter → - auto - (1/1) setup items parameters description auto after printing has been completed, the media is sent...

Page 104

Chapter 5 : handling the printer 104 ap-75037, rev. 1.1, 24/04/2006 5.4.3.2 printing mode setup menu to perform various settings for printing mode. For each setup value of printing mode, four settings of "printing mode 1" - "printing mode 4" can be set. * prnmode1 * f1 → colourmode condition ← f2 f3...

Page 105

Chapter 5 : handling the printer 105 ap-75037, rev. 1.1, 24/04/2006 5.4.3.3 printing quality menu to select the required print quality * condition * f1 → 360 x 360 720 x 360 ← f2 f3 → 360 x 720 diag720 ← f4 current parameter → - 360 x 360 - (1/4) * condition * f1 → 720 x 720 1080 x 1080 ← f2 f3 → 14...

Page 106

Chapter 5 : handling the printer 106 ap-75037, rev. 1.1, 24/04/2006 5.4.3.4 interlace setup menu to set the over printing method (interlace method) for printing. * interlace * f1 → 1pass 1passfew ← f2 f3 → 2pass 4pass ← f4 current parameter → - 1pass - (1/1) setup items parameters description 1 pass...

Page 107

Chapter 5 : handling the printer 107 ap-75037, rev. 1.1, 24/04/2006 5.4.3.7 repeat times menu to set the number of repeats per line of printing. * count * 1 cnt – 99 cnt + ← f2 1 cnt - ← f4 f2, f4 → enter setup items parameters description times to 99 times to change repeat times by operating the fo...

Page 108

Chapter 5 : handling the printer 108 ap-75037, rev. 1.1, 24/04/2006 5.4.3.10 command setup menu to perform various settings for printer commands. * command * f1 → command step ← f2 f3 → position terminator ← f4 (1/2) * command * f1 → resolu. Onlinetimer ← f2 f3 → overwrite halftone ← f4 (2/2) setup ...

Page 109

Chapter 5 : handling the printer 109 ap-75037, rev. 1.1, 24/04/2006 5.4.3.11 command select menu to make the settings for the conditions of printer commands sent from the computer to the printer. * command * f1 → ml – gl. Gl2 ml – gl2 ← f2 f3 → rtl – pass current parameter → - rtl –pass - (1/1) setu...

Page 110

Chapter 5 : handling the printer 110 ap-75037, rev. 1.1, 24/04/2006 5.4.3.14 terminator menu to set the functions for when printing has been completed for printer commands included in printing data. * terminator * f1 → normal special ← f2 current parameter → - normal - (1/1) setup items parameters d...

Page 111

Chapter 5 : handling the printer 111 ap-75037, rev. 1.1, 24/04/2006 5.4.3.16 online time out menu to set time from the moment of receiving termination of printing data sent by computer to the recognition of end of printing data. * onlinetimer * off – 800sec + ← f2 30sec - ← f4 f2, f4 → enter setup i...

Page 112

Chapter 5 : handling the printer 112 ap-75037, rev. 1.1, 24/04/2006 5.4.3.18 halftone menu when creating prints of mh-gl/gl2 (vector) data and rtl-pass (raster) data that has not been converted into binary, to set the screening method. * halftone. * f1 → speed quality ← f2 f3 → thin current paramete...

Page 113

Chapter 5 : handling the printer 113 ap-75037, rev. 1.1, 24/04/2006 5.4.3.20 layout method menu to set the layout method for printing data. * direct... * f1 → command max-min ← f2 current parameter → - command - (1/1) setup items parameters description if there is a page size specification command f...

Page 114

Chapter 5 : handling the printer 114 ap-75037, rev. 1.1, 24/04/2006 5.4.3.23 function setup menu to perform various settings for processing of printing data. * function * f1 → cmy → k scale ← f2 f3 → mirror (1/1) setup items parameters description cmy Æ k makes settings for printing method to presen...

Page 115

Chapter 5 : handling the printer 115 ap-75037, rev. 1.1, 24/04/2006 5.4.3.25 scale menu to set the enlargement and reduction ratios for printing data. * scale * 25% - 400% + ← f2 100% - ← f4 f2, f4 → enter setup items parameters description scale 25% - - 400% use the following keys to change enlarge...

Page 116

Chapter 5 : handling the printer 116 ap-75037, rev. 1.1, 24/04/2006 5.4.4 setup menu 3/7 5.4.4.1 roll media setup menu to perform various settings for roll media. * rollsetup * f1 → disable roll1 ← f2 f3 → roll2 roll3 ← f4 (1/1) setup items parameters description disable set this when roll media set...

Page 117

Chapter 5 : handling the printer 117 ap-75037, rev. 1.1, 24/04/2006 5.4.4.4 network setting menu to make the settings for the network interface. Notes : • the network settings menu is displayed if the network interface board has been installed. • be sure to consult the network administrator before m...

Page 118

Chapter 5 : handling the printer 118 ap-75037, rev. 1.1, 24/04/2006 5.4.4.5 ip address menu to set the ip address of the product. * ipaddress * f1 → ← 000.000.000.000 + ← f2 f3 → → - ← f4 (1/1) setup items parameters description ip address - 255.255.255.254 use the following keys to change the ip ad...

Page 119

Chapter 5 : handling the printer 119 ap-75037, rev. 1.1, 24/04/2006 5.4.4.7 gateway menu the product sets the ip address of the connected gateway. * gateway * f1 → ← 000.000.000.000 + ← f2 f3 → → - ← f4 (1/1) setup items parameters description gateway - 223.255.255.254 use the following keys to chan...

Page 120

Chapter 5 : handling the printer 120 ap-75037, rev. 1.1, 24/04/2006 5.4.4.10 version menu the following software versions of the network interface board can be checked. • main version: software version (main version) • sub version: boot version * version * current parameter → main ver. 1.00 a curren...

Page 121

Chapter 5 : handling the printer 121 ap-75037, rev. 1.1, 24/04/2006 5.4.5.2 errordisplay menu to set display method to the operation panel when a minor error occurred. * errordisp. * f1 → off on ← f2 current parameter → - off - (1/1) setup items parameters description no errordisplay. On to perform ...

Page 122

Chapter 5 : handling the printer 122 ap-75037, rev. 1.1, 24/04/2006 5.4.5.4 power on cleaning menu when cleaning should be performed automatically with the power is turned on. * oncleaning * f1 → off on ← f2 current parameter → - off - (1/1) setup items parameters description power on cleaning is no...

Page 123

Chapter 5 : handling the printer 123 ap-75037, rev. 1.1, 24/04/2006 5.4.5.6 print and wipe menu to take care of possible condensation on the head nozzle plate, it is possible to wipe while printing. *prn + wipe* off – low + off - f2 , f4 → enter setup items parameters description off no wiping durin...

Page 124

Chapter 5 : handling the printer 124 ap-75037, rev. 1.1, 24/04/2006 5.4.5.9 cap cycle menu perform a tubingflush every 1 to 24 hours. Notes : • a tubing flush is automatically performed after 10 minutes of idle and before shut down of the printer. * capcycle * f1 → off-24hours + ← f2 1 hour - ← f4 f...

Page 125

Chapter 5 : handling the printer 125 ap-75037, rev. 1.1, 24/04/2006 5.4.5.10 file management setup menu makes various settings for the processing method of the printing data sent from computer to the installed hard disk in the printer. Notes : • the items on the file management menu are displayed if...

Page 126

Chapter 5 : handling the printer 126 ap-75037, rev. 1.1, 24/04/2006 5.4.5.11 write mode menu to set writing method of printing data to the hard disk and printing method. Notes : • write mode menu is not displayed if no hard disk has been installed on the product. • when writing printing data to the ...

Page 127

Chapter 5 : handling the printer 127 ap-75037, rev. 1.1, 24/04/2006 5.4.5.12 re-print menu set following items when you want to draw printing data saved on the hard disk. • file name • printing media number notes : • re-print menu is displayed if a hard disk has been installed on the product. • when...

Page 128

Chapter 5 : handling the printer 128 ap-75037, rev. 1.1, 24/04/2006 5.4.5.13 file delete menu set this when you delete printing data saved on the hard disk. Notes : • file delete menu is displayed if a hard disk has been installed. • if you delete a file by the file delete menu, you cannot retrieve ...

Page 129

Chapter 5 : handling the printer 129 ap-75037, rev. 1.1, 24/04/2006 5.4.5.14 rename menu to change file name of printing data saved in the hard disk. Notes : • rename menu is displayed if a hard disk has been installed. • the file name of printing data sent from the computer is always set to "tempfi...

Page 130

Chapter 5 : handling the printer 130 ap-75037, rev. 1.1, 24/04/2006 5.4.5.15 format menu to perform formatting of the hard disk. Notes : • format menu is displayed if a hard disk has been installed. • if formatting of the hard disk is performed, all data saved on the hard disk will be deleted. * for...

Page 131

Chapter 5 : handling the printer 131 ap-75037, rev. 1.1, 24/04/2006 5.4.5.16 initialize setup menu returns parameters to the factory settings. * initial. * f1 → all mediaset ← f2 f3 → printmode command ← f4 (1/3) * initial. * f1 → layout function ← f2 f3 → rollsetup centro. ← f4 (2/3) * initial. * f...

Page 132

Chapter 5 : handling the printer 132 ap-75037, rev. 1.1, 24/04/2006 5.4.5.17 all initialize menu all setup values are set to the factory default settings. * all * f1 → no ok ← f2 current parameter → - no - (1/1) setup items parameters description no initialization. Ok to perform initialization. All ...

Page 133

Chapter 5 : handling the printer 133 ap-75037, rev. 1.1, 24/04/2006 5.4.5.20 command setup initialize menu setup values of commandsetup menu are set to the factory default settings. * command * f1 → no ok ← f2 current parameter → - no - (1/1) setup items parameters description no initialization. Ok ...

Page 134

Chapter 5 : handling the printer 134 ap-75037, rev. 1.1, 24/04/2006 5.4.5.23 roll media setup initialize menu setup values of roll media setup menu are set to the factory default settings. * rollsetup * f1 → no ok ← f2 current parameter → - no - (1/1) setup items parameters description no initializa...

Page 135

Chapter 5 : handling the printer 135 ap-75037, rev. 1.1, 24/04/2006 5.4.5.26 utility initialize menu setup values of utility menu are set to the factory default settings. * utility * f1 → no ok ← f2 current parameter → - no - (1/1) setup items parameters description no initialization. Ok to perform ...

Page 136

Chapter 5 : handling the printer 136 ap-75037, rev. 1.1, 24/04/2006 5.4.6 setup menu 5/7 5.4.6.1 data dump menu to perform dump printing for online function check. * datadump * f1 → start/end all ← f2 (1/1) setup items parameters description start/end notes : • dump printing is used by service perso...

Page 137

Chapter 5 : handling the printer 137 ap-75037, rev. 1.1, 24/04/2006 5.4.6.2 ink manager menu to perform a ‘head wash’, “ink load’ or ‘ink change’. * ink manager * f1 → headwash f3 → inkload inkchange ← f4 (1/2) * ink manager * f1 → inksupply ← f3 f3 → chipmgr colormode ← f4 (2/2) setup items paramet...

Page 138

Chapter 5 : handling the printer 138 ap-75037, rev. 1.1, 24/04/2006 5.4.6.3 head wash menu to perform a head wash to remove all ink of the ink supplying system. * headwash * f1 → no yes ← f2 (1/1) setup items parameters description no do not wash the ink supplying system. Yes to wash the ink supplyi...

Page 139

Chapter 5 : handling the printer 139 ap-75037, rev. 1.1, 24/04/2006 5.4.6.5 ink change menu to perform an ink change. * inkchange * f1 → no yes ← f2 (1/1) setup items parameters description no do not perform an ink change. Yes to start the ink change cycle. Ink change - • [cancel] key: shifts to the...

Page 140

Chapter 5 : handling the printer 140 ap-75037, rev. 1.1, 24/04/2006 5.4.6.6 inksupply menu reserved for future use ! Caution : • please set inksupply to off to ensure normal printer behaviour ! * inksupply* f1 → off on ← f2 -off- (1/1) setup items parameters description off reserved for future use o...

Page 141

Chapter 5 : handling the printer 141 ap-75037, rev. 1.1, 24/04/2006 5.4.7 setup menu 6/7 5.4.7.1 head unlock menu * h.Unlock * to lock heads press - > enter (1/1) setup items parameters description h.Unlock - • [cancel] key: shifts to the previous menu. Refer to setup menu 5.4.7.2 wiper clean menu t...

Page 142

Chapter 5 : handling the printer 142 ap-75037, rev. 1.1, 24/04/2006 5.4.7.3 tank change menu to change the waste fluid tank. Set when changing the waste fluid tank. Notes : • refer to "replacing the waste liquid tank" for details regarding the procedure for changing the waste fluid tank. Changed was...

Page 143

Chapter 5 : handling the printer 143 ap-75037, rev. 1.1, 24/04/2006 5.4.7.4 tubing flush menu to remove rest fluids out of the capping station and waste tubes. Warning : ¾ the tubing flush sequence will not remove fluids out of the head nor out of the ink supply tubes. The tubing flush feature inclu...

Page 144

Chapter 5 : handling the printer 144 ap-75037, rev. 1.1, 24/04/2006 5.4.8 setup menu 7/7 5.4.8.1 version check menu to check the installed firmware version. * versioncheck * rj : rh x.Xx heat sys : y.Yy setup items parameters description version check - • [cancel] key: shifts to the previous menu. R...

Page 145

Chapter 5 : handling the printer 145 ap-75037, rev. 1.1, 24/04/2006 5.5 operating from the operation panel this section describes functions operated on the operational panel when the printer is in the normal status. Notes : • for information of the name and function of each key, refer to 2.3.4 opera...

Page 146

Chapter 5 : handling the printer 146 ap-75037, rev. 1.1, 24/04/2006 5.5.1.1 change the heater temperature to change the temperature of the heater, press the [f1] key on the operation panel. The display will mention the following: * heater (a) * off – 50°c + ← f2 50°c - ← f4 f2, f4 → enter press the ...

Page 147

Chapter 5 : handling the printer 147 ap-75037, rev. 1.1, 24/04/2006 5.5.1.4 change the dryer temperature to change the temperature of the dryers, press the [f4] key on the operation panel. The display will mention the following: press the [f2] key to decrease the temperature. Press the [f4] key to i...

Page 148

Chapter 5 : handling the printer 148 ap-75037, rev. 1.1, 24/04/2006 5.5.2 feeding media when you want to feed media forward or backward, follow the steps below : step 1 : verify the following regarding the condition of the printer. ¾ it is not currently printing ready to print heaters cleaning f3 → ...

Page 149

Chapter 5 : handling the printer 149 ap-75037, rev. 1.1, 24/04/2006 5.5.3 operating the pressure rollers when you want to switch the up and down movement of the pressure rollers follow the instructions below. Press the [f4] key on the operation panel. ¾ the printer works as follows. Ready to print h...

Page 150

Chapter 5 : handling the printer 150 ap-75037, rev. 1.1, 24/04/2006 5.5.4 print mode check use the following procedure to check the print mode currently set. Step 1 : press the [enter] key on the operation panel. ¾ the following information is displayed on the operation panel for three seconds. * pr...

Page 151

Chapter 5 : handling the printer 151 ap-75037, rev. 1.1, 24/04/2006 5.6 operating panel during printing 5.6.1 when heaters are not ready the printer will not start printing before heaters are ready. Following message will be displayed : * wait heating * f1 → dist. Adj. Cleaning f2 f3 → a:h b:h c:h d...

Page 152

Chapter 5 : handling the printer 152 ap-75037, rev. 1.1, 24/04/2006 step 3 : change the value in the ‘change’ menu (below) according to decision table below : * change * 90.00%-110.00% + ← f2 110.00 - ← f4 f2, f4 → enter decision table for step adjustment : when there is … then … overlap on the prin...

Page 153

Chapter 5 : handling the printer 153 ap-75037, rev. 1.1, 24/04/2006 5.6.2.2 on the fly cleaning while printing, it could be possible that some nozzles drop out, in that case, perform a little, normal or powerful cleaning. Please follow the 4 steps below to perform a cleaning. Step 1 : go to the “pri...

Page 154

Chapter 5 : handling the printer 154 ap-75037, rev. 1.1, 24/04/2006 5.6.2.3 adjust heaters while printing, the heater values can be changed. For example: when noticing cockling. Please follow the steps below to adjust the heater temperatures. Step 1 : go to the “printing” menu in the menu structure....

Page 155

Chapter 5 : handling the printer 155 ap-75037, rev. 1.1, 24/04/2006 5.7 operations after printing the operations performed after printing, are described here. 5.7.1 automatically cutting media roll media is automatically cut after printing when "auto" is set on the cut media menu and roll media has ...

Page 156

Chapter 5 : handling the printer 156 ap-75037, rev. 1.1, 24/04/2006 step 4 : press the [f1] key on the operation panel. Media cut? Enter or cancel ¾ the media is cut at its position when the [enter] key has been pressed. End of the media cutting procedure.

Page 157

Chapter 5 : handling the printer 157 ap-75037, rev. 1.1, 24/04/2006 5.7.2 manually cutting media this section explains how to cut the media manually. Procedure (6 steps) : step 1 : set the parameter to “manual’ in the media cut menu, the media can be cut manually step 2 : make sure that the media se...

Page 158

Chapter 5 : handling the printer 158 ap-75037, rev. 1.1, 24/04/2006 note : • when cutting roll media, be careful of the following. Incorrect handling can result in injury to the hands and fingers from the cutting blade. Step 6 : press the [enter] key of the operation panel. ¾ the unit enters the nor...

Page 159: 6 Troubleshooting

Chapter 6 : troubleshooting 159 ap-75037, rev. 1.1, 24/04/2006 6 troubleshooting 6.1 introduction ..........................................................................160 6.2 failures and malfunctions of the printer...............................160 6.3 error messages..............................

Page 160: 6.1 Introduction

Chapter 6 : troubleshooting 160 ap-75037, rev. 1.1, 24/04/2006 6.1 introduction this chapter explains troubles that may occur when using the printer and how to solve them. If you encounter an error not described in this chapter, refer to "error messages" and contact your local océ representative. No...

Page 161

Chapter 6 : troubleshooting 161 ap-75037, rev. 1.1, 24/04/2006 (3) the printer does not work after data has been sent from a computer. No. Possible cause solutions reference 1 you did not connect the interface cable. Connect the interface cables. Refer to ‘connecting the centronics interface’ refer ...

Page 162

Chapter 6 : troubleshooting 162 ap-75037, rev. 1.1, 24/04/2006 (7) media jams occur frequently. Note : • we cannot ensure correct media feeding with media other than recommended media. No. Possible cause solutions references 1 you did not use recommended media. Use recommended media. Refer to ‘media...

Page 163

Chapter 6 : troubleshooting 163 ap-75037, rev. 1.1, 24/04/2006 (10) ink is not used though you performed initial ink charge. No. Possible cause solutions references 1 the ink cassette is cold or frozen. Leave the ink cassette in normal temperature for three hours at least, and perform cleaning a few...

Page 164

Chapter 6 : troubleshooting 164 ap-75037, rev. 1.1, 24/04/2006 (12) media is damaged during media initial. Note : • remove the jammed or damaged media. No. Possible cause solutions references 1 you did not use recommended media. Use recommended media. Refer to ‘media type’ 2 the loading position of ...

Page 165

Chapter 6 : troubleshooting 165 ap-75037, rev. 1.1, 24/04/2006 (15) media is crooked while printing. No. Possible cause solutions references 1 you did not use recommended media. Use recommended media. Refer to ‘media type’ 2 the loading position of the media is not correct. Load the media correctly....

Page 166

Chapter 6 : troubleshooting 166 ap-75037, rev. 1.1, 24/04/2006 (19) lines are missing. No. Possible cause solutions references 1 the validity date of the ink cassette has been expired. Use a new ink cassette. Refer to ‘replacing ink cassettes’ 2 you did not use recommended media. Use recommended med...

Page 167: 6.3 Error Messages

Chapter 6 : troubleshooting 167 ap-75037, rev. 1.1, 24/04/2006 6.3 error messages this chapter explains the messages displayed on the operation panel both when the printer works normally and when an error occurs, and possible solutions. 6.3.1 status messages the following are the status messages whi...

Page 168

Chapter 6 : troubleshooting 168 ap-75037, rev. 1.1, 24/04/2006 6.3.2 message type error display and solutions the following are the message type error display and solutions. The following message type errors are displayed when an error occurs while operating the printer. When one of the following me...

Page 169

Chapter 6 : troubleshooting 169 ap-75037, rev. 1.1, 24/04/2006 6.3.2.3 other error messages the following error message is displayed on the forth line of the operation panel inkstatus no ink [1 2 3 ] no. Display descriptions solutions references 1 ink status cassette [*] ink cassette(s) is (are) emp...

Page 170

Chapter 6 : troubleshooting 170 ap-75037, rev. 1.1, 24/04/2006 6.3.4 command error display and solutions following are command error descriptions and possible solutions during printer operations. Command errors are displayed when an error has occurred while converting the command data sent from comp...

Page 171

Chapter 6 : troubleshooting 171 ap-75037, rev. 1.1, 24/04/2006 no. Message descriptions solutions references 1 e system error*** {{{{{{{{{{ [ ] an error which cannot be solved promptly has occurred. 1. If foreign materials such as a piece of media or media dust are involved in the driving system, re...

Page 172: 6.4 When Media Jams Occur

Chapter 6 : troubleshooting 172 ap-75037, rev. 1.1, 24/04/2006 6.4 when media jams occur if the loaded media gets jammed in the printer, follow the steps below to remove the media. 6.4.1 how to remove a piece of media (cut media) step 1 : press [f4] to raise the pressure rollers. • the media set lam...

Page 173: 7 Maintenance

Chapter 7 : maintenance 173 ap-75037, rev. 1.1, 24/04/2006 7 maintenance 7.1 the user maintenance kit for 6 months autonomy ..............174 7.2 periodical service done by the end user .............................174 7.2.1 weekly maintenance 175 7.2.1.1 clean the edges of the caps and the area aro...

Page 174: Autonomy

Chapter 7 : maintenance 174 ap-75037, rev. 1.1, 24/04/2006 7.1 the user maintenance kit for 6 months autonomy content : user maintenance kit for 6 months autonomy (code number 29801288) no° description quantity 1 wipers 24 2 absorbent plate 1 3 flush box absorbent 6 4 eco solvent cleaning bottle 250...

Page 175

Chapter 7 : maintenance 175 ap-75037, rev. 1.1, 24/04/2006 notes : • all cleaning in “ink areas” must be done with eco solvent cleaning. • above maintenance cycle is based on use: 8 hours / day, 5 days / week, 44 weeks / year. If machine is used more, maintenance periods will come earlier. 7.2.1 wee...

Page 176

Chapter 7 : maintenance 176 ap-75037, rev. 1.1, 24/04/2006 step 3 : clean the area around the caps with a polyknit wiper. 1 = gloves 2 = polyknit wiper step 4 : press the [enter] key in the active display (=wiperclean menu) * wiperclean * changed wiper? → enter the head will cap in and be locked. En...

Page 177

Chapter 7 : maintenance 177 ap-75037, rev. 1.1, 24/04/2006 step 4 : clean the edges of the heads with a swab (1) wetted by eco-solvent cleaning fluid as shown on the image below. Caution : • make sure you do not touch the nozzle plate; this would lead to poorer print quality. • we recommend to wear ...

Page 178

Chapter 7 : maintenance 178 ap-75037, rev. 1.1, 24/04/2006 7.2.2 every 2 weeks maintenance 7.2.2.1 cleaning the wipers procedure (3 steps) : step 1 : power on the printer and go to the “wiperclean-menu”, don’t press enter when in it. * wiperclean * changed wiper? → enter this will cause the unlockin...

Page 179

Chapter 7 : maintenance 179 ap-75037, rev. 1.1, 24/04/2006 7.2.3 monthly maintenance 7.2.3.1 replacing the wipers procedure (8 steps) : step 1 : go to the wiperclean menu and don’t press enter when in it. * wiperclean * changed wiper? → enter going to the wiperclean menu will unlock the head step 2 ...

Page 180

Chapter 7 : maintenance 180 ap-75037, rev. 1.1, 24/04/2006 step 6 : insert the moistened wiper with a pair of tweezers as shown on the image below. Step 7 : push the wiper until it clicks in the wiper holder. (see image below) step 8 : close the front cover and press the [enter] key in the active di...

Page 181

Chapter 7 : maintenance 181 ap-75037, rev. 1.1, 24/04/2006 7.2.3.2 replacing the sponge in the spitting box. Note : • use gloves and tweezers to change the absorbent in the flushing box. Procedure (5 steps) : step 1 : go to the wiperclean menu and don’t press enter when in it. * wiperclean * changed...

Page 182

Chapter 7 : maintenance 182 ap-75037, rev. 1.1, 24/04/2006 step 4 : install the new absorbents in the flushing box. Note : • make sure that the 2 holes are on the right side of the flushing box and that the pins of the black box are in the holes of the absorbent. 1 = two holes 2 = pin of black box s...

Page 183

Chapter 7 : maintenance 183 ap-75037, rev. 1.1, 24/04/2006 7.2.4 every 6 months maintenance 7.2.4.1 change upper sponge at back of the capping station. Procedure (4 steps) : step 1 : go to the wiperclean menu and don’t press enter when in it. * wiperclean * changed wiper? → enter going to the wiperc...

Page 184

Chapter 7 : maintenance 184 ap-75037, rev. 1.1, 24/04/2006 step 4 : close the front cover and press the [enter] key in the active display (=wiperclean menu) * wiperclean * changed wiper? → enter the head will cap in and be locked. End of the procedure.

Page 185

Chapter 7 : maintenance 185 ap-75037, rev. 1.1, 24/04/2006 7.2.5 replacing the cutting blade 7.2.5.1 replacement time replace the cutting blade under the following conditions. A. Media cannot be cut cleanly the message "media cut error" appears on the operation panel if a media cutting error occurs....

Page 186

Chapter 7 : maintenance 186 ap-75037, rev. 1.1, 24/04/2006 note : • replace the cutting blade as quickly as possible. If you leave the carriage at the cutting blade replacement position, the head may be clogged with ink. Step 5 : while pressing the cutting blade holder tab, rotate the cutting blade ...

Page 187

Chapter 7 : maintenance 187 ap-75037, rev. 1.1, 24/04/2006 1 = cutting blade step 7 : insert the new cutter into the media cutting blade holder. Step 8 : while slightly pressing the cutting blade holder tab, return the cutting blade lever to its original position. Notes : • do not push the cutting b...

Page 188

Chapter 7 : maintenance 188 ap-75037, rev. 1.1, 24/04/2006 7.2.6 replacing the waste liquid tank read following information on when and how to replace the waste liquid tank. (1) replacement time replace the waste liquid tank under the following conditions. A. When the waste liquid tank is nearly ful...

Page 189

Chapter 7 : maintenance 189 ap-75037, rev. 1.1, 24/04/2006 step 4 : remove the waste liquid tank from the tank tray of the stand. Note : • put the used waste liquid tank in a plastic bag and follow the local regulations when disposing. Step 5 : open the cap of a new waste liquid tank and put the tan...

Page 190: Technician

Chapter 7 : maintenance 190 ap-75037, rev. 1.1, 24/04/2006 7.3 maintenance services done by a service technician the maintenance items and their frequency are shown in the table below : no° description frequency 1 changing the dampers every 6 months 2 changing the spitting box + tube + l connection ...

Page 191: 7.4 Cleaning

Chapter 7 : maintenance 191 ap-75037, rev. 1.1, 24/04/2006 7.4 cleaning you need to clean the printer periodically to keep it in best working condition. Warning : • do not insert or drop metal or inflammable objects into openings, such as ventilation outlets. Doing so may result in electrical shock ...

Page 192

Chapter 7 : maintenance 192 ap-75037, rev. 1.1, 24/04/2006 7.4.2 cleaning the inside of the printer (1) cleaning frequency clean once a month. (2) cleaning procedure the following are instructions for cleaning the inside of the printer. Follow the steps below. Step 1 : open the front cover. 1 = fron...

Page 193

Chapter 7 : maintenance 193 ap-75037, rev. 1.1, 24/04/2006 7.4.3 head cleaning if printouts become faint or partially missed, perform head cleaning to clean the surface of the head and the nozzles. Follow the 9 steps below to perform head cleaning. Note : • remove media before performing head cleani...

Page 194

Chapter 7 : maintenance 194 ap-75037, rev. 1.1, 24/04/2006 step 6 : press the [f2] key on the operation panel to change the parameters. Key parameter description small small cleaning is performed. Normal normal cleaning is performed. F2 strong strong cleaning is performed. Step 7 : press the [enter]...

Page 195

Chapter 8 : appendix 195 ap-75037, rev. 1.1, 24/04/2006 7.5 transfer and transportation this section explains transferring and transporting the printer. 7.5.1 transferring the printer following are instructions for transferring the printer. Caution : • keep the printer horizontally during transfer. ...

Page 196

Chapter 8 : appendix 196 ap-75037, rev. 1.1, 24/04/2006 (2) after the transfer follow the 4 steps below to prepare the printer to be used after the transfer. Step 1 : make sure that you place the printer on an adequate place. Note : • for connecting cables, refer to the following. → connecting the p...

Page 197: 8 Appendix

Chapter 8 : appendix 197 ap-75037, rev. 1.1, 24/04/2006 8 appendix 8.1 introduction ..........................................................................198 8.2 product specifications .........................................................198 8.3 interface specifications.........................

Page 198: 8.1 Introduction

Chapter 8 : appendix 198 ap-75037, rev. 1.1, 24/04/2006 8.1 introduction this section explains the specifications and installation procedures for optional parts. 8.2 product specifications printers 65”- model 90”- model technology drop-on-demand micro piezo inkjet technology. Variable drop mass outp...

Page 199: 8.3 Interface Specifications

Chapter 8 : appendix 199 ap-75037, rev. 1.1, 24/04/2006 8.3 interface specifications this section explains the specifications for the interfaces supported by this product. 8.3.1 centronics bidirection parallel interface:ieee1284 specifications 8.3.1.1 interface specifications item specifications tra...

Page 200

Chapter 8 : appendix 200 ap-75037, rev. 1.1, 24/04/2006 8.3.2. Network interface specifications item specifications network type ethernet ieee802.3 network i/f 10 base-t,100 base-tx(automatic switching) (rj-45 connector, twisted pair cable, category 5) protocol tcp/ip mode • ftp • lpr • socket funct...