- DL manuals

- Ocean Aire

- Freezer

- CAC series

- Engineering, Installation And Service Manual

Ocean Aire CAC series Engineering, Installation And Service Manual

Summary of CAC series

Page 1

Engineering, installation and service manual cac series portable air-cooled spot cooler form eism-cac 030115 rev 1.

Page 2: Forward

Page general information …................................. 1 product data and specifications ............ 2 unit description standard features................................... 3 applications / operation.......................... 4 electrical.................................................. 5 con...

Page 3: General Information

General information the oceanaire cac is a portable air-cooled spot cooler designed for permanent or temporary spot cooling. The entire air conditioning unit has been built in a premium sheet metal cabinet, equipped with heavy-duty casters for mobility. The cac can be operated as a stand-alone spot ...

Page 4: Technical Specifications

2 technical specifications model: cac cooling capacity 12,000 btu/h voltage 115 v cooling amps 12.0 a max fuse size 15 a cooling watts 1180 w in rush amps 63 a eer 10.0 compressor type rotary compressor motor 1 hp compressor rla 9.5 a compressor lra 50 a evaporator blower centrifugal evap cfm - high...

Page 5: Standard Features

Standard features cabinet the cac series spot cooler has a cabinet that is constructed of 18 gauge steel with a polyester powder coated finish. The matte black finish compliments any surrounding space, and the cabinet is lined with sound-absorbing insulation for cool, quiet comfort. The cac comes eq...

Page 6: Applications

4 applications spot cooler the cac can be used in an open environment to cool specific objects or "spots". Spot cooling is a convenient and economical way to provide air conditioning where cooling the entire space is impractical. Cool air is discharged from the unit and is directed where it is neede...

Page 7: Not Repaired

5 service cord the cac is equipped with a 10-foot long service cord with a lcdi (leakage current detection & interruption) device that serve as a means of electrical protection. Do not use the lcdi as an on/off switch for the unit a damaged lcdi power supply cord must be replaced with a new power su...

Page 8: Condensate

6 condensate the cac has a 2-gallon polyethylene tank for collecting condensate. The tank is located in the lower, front section of the unit. When the high water is reached, a cut-out switch will automaticall y cycle off the compressor/condenser fan. The evaporator fan will continue to run and circu...

Page 9: Installation Instructions

7 handles locking casters (front) control panel lcdi power cord installation instructions receiving—inspection upon receiving your cac unit, inspect the packaging for any damage. All units are shipped on a skid, and packaged in a triple-wall carton for added protection. Before installing check the u...

Page 10

8 uni-strut installation use (4) 5/16-18 x 1” bolts and washers to secure unit to unit-strut use (4) 5/16-18 x 1” bolts and washers to secure unit to unit-strut caution - when hanging or permanently connecting the cac, all applicable local/state/federal building codes must be followed. The structura...

Page 11: Use Copper

9 installation—permanently connected the cac power cord can be removed and permanently connected to a power source. Once the cac is installed and secured for a stationary installation, the unit can be permanently wired. 1. Remove the left side panel and locate the power cord/strain relief at the rea...

Page 12: Installation—Stacking Kit

10 installation—stacking kit sk-1 two or three cool cube units are needed when: redundancy is needed cooling large areas high heat loads and only a small amount of floor space is available. The cac can be stacked on top of each other to produce a capacity of 24,000 or 36,000 btu/h, while maintaining...

Page 13: Rck-1

11 installation—rack mounting kit rck-1 the 19-inch rack kit allows for the cool cube to be installed into any eia-310-d, 4-post or 2-post rack enclosure. The kit includes: (2) heavy duty rails, (4) side mounting brackets, and a rear mounting rail. The rails have a vibration dampening foam layer sec...

Page 14: Accessories

Accessories 12 condensate pump kit cpc-1 condenser return panel ccp-8 nozzle kit cnk-1 evaporator return panel cep-6 condenser discharge condenser return 8-inch discharge adapter cda-8 condenser discharge baffle condenser discharge ring rack diffuser crd-1.

Page 15: Accessories

Accessories ceiling panel duct kit, ck-8 a ceiling panel kit is available for discharging the condenser air above a drop ceiling. The ceiling panel duct kits are furnished with an 8-inch white vinyl coated flexible duct that allows for convenient installation. A 2ft x 2ft ceiling duct-panel is inclu...

Page 16: Accessories

Accessories condensate pump kit , cpc-1 the condensate pump provides for the automatic removal of condensate water during the cooling pro- cess. The pump is capable of pumping against a 20 foot height, allowing for the routing of the drain line above the drop-ceiling to a nearby drain. The pump is c...

Page 17: Accessories

Accessories discharge air nozzle kit assembly, cnk-1 the optional discharge nozzle kits are used to direct the conditioned air to a specific target area. By concen- trating the airflow, the nozzles increase the air velocity towards production lines to cool personnel and/or equipment. In server rooms...

Page 18: Evaporator Return Air

16 evaporator return air plenum, cep-6 an evaporator return air plenum is available for installations where it is required to duct air to the inlet of the evaporator. The return air plenum allows the user to connect round duct (flexible or rigid) to the return air intake and reduce air noise, while ...

Page 19

17 oceanaire deluxe electronic controller when power is connected, the controller will display “888” momentarily, and will then disappear. Press the power button, then press the temp select button until the set point is displayed. Adjust the set point to the desired temperature, and the unit will co...

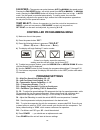

Page 20: Controller Programming Menu

18 controller programming menu 1) make sure the unit has power . 2) press the power button “off”. 3) press the following buttons in sequence “ s-u-d-s” ( s elect— u p arrow — d own arrow — s elect) 4) the display will begin flashing p1 and a number. If there is no display, repeat the sequence, makin...

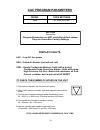

Page 21: Cac Program Parameters

19 model code settings cac p1 = 80, p2 = 50 cac program parameters notice program parameters are not controller default values. They are oceanaire factory settings display faults lac….Low ac line power aaa…failed air sensor (unit will not run) con… empty condensate bucket—units with a bucket condens...

Page 22: Troubleshooting Guide

20 troubleshooting guide the following steps and procedures are recommended for correcting the problems indicated. In the event that the problem can not be corrected, service may be required. Problem: unit does not power up cause: power interruption remedy: check external power supply making sure th...

Page 23: Replacement Parts Procedure

21 replacement parts procedure it is recommended that all oceanaire units be serviced by a licensed technician warning —to avoid injury, disconnect unit power prior to servicing a. Fan motors 1. Remove cabinet left-side panel (when looking at the front of the unit). 2. Evaporator fan motor—disconnec...

Page 24: Preventive Maintenance

22 preventive maintenance cac spot coolers are designed to last a long time and to give maximum performance and reliability with minimum maintenance. To prolong the life of the unit, regular maintenance must be performed as specified below: blower motors the motors on all units have permanently lubr...

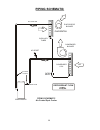

Page 25: Piping Schematic

23 piping schematic air-cooled spot cooler suction line discharge line filter/ drier access valves compressor evaporator blower condenser coil evapotator coil capillary tubes hp reset air air condenser blower refrigerant flow piping schematic evaporator.

Page 26: Cac1211 Wiring Diagram

24 air-cooled spot cooler model cac1211 115 v / single-phase power module condensate tank full switch nc no com optional condensate pump 2dpc-1 (115v) install safety switch in low-voltage loop replacing tank full switch o a cean ire cac1211 wiring diagram when field wiring—-use copper conductors onl...

Page 27: Limited Warranty

25 limited warranty the manufacturer (oceanaire, inc.) warrants to the original owner that the product will be free from defects in material or workmanship for a period not to exceed one (1) year from date of installation. If upon examination by the manufacturer, the product is shown to have a defec...

Page 28: End User Information

End user information model: serial number: date purchased: installed by: date installed: for technical support, or to locate a distributor for service parts, contact oceanaire at (847) 583-0311 or 1-866-getaire (438-2473) . Please indicate the model number and serial number of the unit to assure pro...