- DL manuals

- OHAUS

- Scales

- EXPLORER

- Service Manual

OHAUS EXPLORER Service Manual - Service Manual

The information contained in this manual is believed to be accurate at the time of publication, but Ohaus

Corporation assumes no liability arising from the use or misuse of this material. Reproduction of this material

is strictly prohibited.

Material in this manual is subject to change.

© Copyright 2003 Ohaus Corporation, all rights reserved.

® Registered trademark of Ohaus Corporation.

SERVICE MANUAL

EXPLORER

®

BALANCES

EXPLORER

®

PRO

BALANCES

VOYAGER

®

BALANCES

>O/T<

>O/T<

OHAUS

®

Stable

g

Setup

Units

Mode

Enter

>O/T

<

>O/T

<

>O/T

<

>O/T

<

OHAU

S ®

Sta

ble

g

Setup

Units

Mode

Enter

*R%DFN

+HOS

3ULQW

(QWHU

2Q2II

0.0

WEIGHT

0%

100%

CONTRAST

GRAMS

STABLE

MOVE HIGHLIGHT

CONTRAST

MAIN MENU

0.00

BASIC WEIGHING

0%

100%

GRAMS

STABLE

Enter

Go Back

Heip

>O/T<

>O/T<

PRESS

>O/T<

>O/T<

Enter

Go Back

Help

OHAUS

®

0.000

BASIC WEIGHING

0%

100%

GRAMS

STABLE

PRESS

PRECISION

HIGH CAPACITY

ANALYTICAL

PRECISION

HIGH CAPACITY

ANALYTICAL

PRECISION

HIGH CAPACITY

ANALYTICAL

Explorer

®

Explorer

Pro

®

Voyager

®

Summary of EXPLORER

Page 1

Ohaus corporation 19a chapin road, p.O. Box 2033, pine brook, nj 07058-2033 (973) 377-9000 service manual explorer ® balances explorer ® pro balances voyager ® balances.

Page 3: Service Manual

The information contained in this manual is believed to be accurate at the time of publication, but ohaus corporation assumes no liability arising from the use or misuse of this material. Reproduction of this material is strictly prohibited. Material in this manual is subject to change. © copyright ...

Page 5

I table of contents chapter 1 introduction 1.1 introduction .......................................................................................... 1-1 1.2 service facilities .................................................................................... 1-2 1.3 tools and test equipment requ...

Page 6

Ii table of contents (cont.) 3.1.19 monoblock load cell removal from high capacity top loader balance ........................................................................................ 3-14 3.1.20 calibration motor removal from high capacity top loader balance ....................................

Page 7

Iii chapter 5 drawings and parts lists 5-1 drawings and parts lists ........................................................................ 5-1 5-2 parts lists .... ......................................................................................... 5-3 5.2.1 precision top loader base parts li...

Page 8

Iv list of tables table no. Title page no. 1-1 calibration points .............................................................................. 1-3 1-2 analytical specifications ................................................................... 1-4 1-3 precision top loader specifications ............

Page 9

V table of contents (cont.) list of illustrations figure no. Title page no. 3-1 analytical sensor board adjustment locations and connections ..... 3-3 3-2 analytical sensor board adjustment ................................................. 3-4 3-3 removing the vertical flexure .........................

Page 10

Vi table of contents (cont.) list of illustrations figure no. Title page no. 5-1 overall exploded view of precision top loader balance ................. 5-2 5-2 overall exploded view of analytical balance ................................... 5-4 5-3 exploded view of precision top loader base assembly...

Page 11

1-1 chapter 1 introduction 1.1 introduction this service manual contains the information needed to perform routine maintenance and service on the ohaus explorer ® , explorer pro ® and voyager ® balances. There are three basic configurations of balances: analytical, precision top loader and high capa...

Page 12

1-2 chapter 1 introduction 1.1 introduction (cont.) the contents of this manual is contained in five chapters with three appendices. Chapter 1 introduction - contains information regarding service facilities, tools, test equipment, calibration masses and specifications. Chapter 2 diagnosis - contain...

Page 13

1-3 chapter 1 introduction 1.3 tools and test equipment required in order to properly service the ohaus explorer balances, certain ohaus special tools and test items are required in addition to standard electronic tool kits. These items are listed as follows: 1.3.1 special tools 1. 476000-03 monoblo...

Page 14

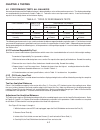

1-4 chapter 1 introduction capacity (g) 210 410 100/410 610 2100 4100 1000/4100 4100 6100 8100 readability (g) 0.001 0.001/0.01 0.01 0.01/0.1 0.1 repeatability (std. Dev.) (g) 0.0005 0.0005/0.005 0.005 0.01/0.05 0.05 linearity (g) (+) 0.002 0.002/0.005 0.02 0.02/0.05 0.1 tare range full capacity by ...

Page 15

2-1 chapter 2 diagnosis 2.1 troubleshooting this section of the manual specifies problem areas of the balance which can occur. Information is contained to isolate specific problems using table 2-1, diagnostic guide, and error codes, tables 2-2 through 2-4. Follow all directions step by step. Make ce...

Page 16

2-2 chapter 2 diagnosis probable cause(s) power cord not plugged in or properly connected to balance or defective. Display module not connected prop- erly. Defective display pc board. Defective membrane switch. Ic u11 defective. Display module cable defective. Internal cables may be touching a movin...

Page 17

2-3 chapter 2 diagnosis table 2-1. Diagnostic guide (cont.) unstable readings. Error message display. Excessive air currents. Vibration on table surface. Defective/damaged transducer. Defective main pc board. Check environmental conditions. Place balance on a stable surface or change averaging level...

Page 18

2-4 chapter 2 diagnosis displays err 8.5 internal calibration weight sensor indicates the weight is on the pan, check the connection between the calibration unit and the main pcb. Could be a problem with the calibration mechanism or the main pcb. Displays err 9.1 personality data corrupt. Reload usi...

Page 19

2-5 chapter 2 diagnosis displays error 1.0 usually caused by static discharge. If the error persists replace the pcb displays error 1.1 temperature channel duty cycle out of range. Failed temperature sensor or broken wire between the temperature sensor and the pcb displays error 2.0 unable to stabil...

Page 20

2-6 chapter 2 diagnosis table 2-4. Explorer pro error codes (cont.) displays err 9.4 factory internal calibration data failed checksum. Perform mfg and mfgwt. If the problem persists reload the tc data. If the problem still persists the main pcb must be reconfigured at ohaus. Displays err 9.5 factor...

Page 21

3-1 chapter 3 repair procedures 3.1 repair procedures depending upon the capacity of the balance, one of three different types of load cells are used. The analytical balances contain an analytical load cell or a monoblock load cell and the top loader balances contain one of two styles of monoblock l...

Page 22

3-2 chapter 3 repair procedures 3.1.2 analytical load cell (9) replacement after the load cell assembly has been repaired, it is installed as follows: 1.Carefully align the analytical load cell (9) in the base (18) (figure 5-3) so that there is equal space on both sides of the analytical load cell t...

Page 23

3-3 chapter 3 repair procedures 3.1.3 analytical load cell position sensor adjustment with test points when the analytical load cell assembly (9) has been repaired either an upper or lower flexure arm assembly or vertical flexure has been replaced, it may be necessary to adjust the position sensor. ...

Page 24

3-4 chapter 3 repair procedures when the analytical load cell assembly (9) has been repaired either an upper or lower flexure arm assembly or vertical flexure has been replaced, it may be necessary to adjust the position sensor. Refer to figures 3-2, 5-3 and 5-4. 1.Remove the analytical load cell fr...

Page 25

3-5 chapter 3 repair procedures 1.At the top of the load cell assembly (51), remove the two screws and washers which secure the pan support to the hanger. 2.Remove the three screws which secure bottom mounting plate to load cell base. 3.Remove vertical flexure per paragraph 3.1.5. 4.Carefully loosen...

Page 26

3-6 chapter 3 repair procedures 3.1.8 removing the lever and coil. 1.Remove the hanger and shims. 2.Remove the vane (e) from the lever. 3.Remove the 4 screws (f) holding the magnet holder. 4.Remove the magnet holder. Caution: the magnet is made of brittle material, care should be taken not to break ...

Page 27

3-7 chapter 3 repair procedures 3.1.10 replacing the lever and coil. 1.Before replacing the lever make sure the guides have been checked or replaced in necessary, and the magnet system is cleaned. 2.Place the lever in the chassis and lock by turning the up/down stop to the original position. 3.Insta...

Page 28

3-8 chapter 3 repair procedures 3.1.11 monoblock load cell removal precision top loader balance and analytical (cont.) 10. Remove the two screws (3) on top of the pc board (11). 11. Remove the hex screws (14) and washers (25) at the rear of the balance which secure the connectors on the pc board (11...

Page 29

3-9 chapter 3 repair procedures 3.1.13 position sensor assembly removal from monoblock in precision top loader balance 1.Remove four screws which secure the overload protection to the monoblock and remove the overload protection. 2.Unscrew the three fastener screws of the position sensor assembly. 3...

Page 30

3-10 chapter 3 repair procedures 3.1.14 installing the position sensor assembly for monoblock precision top loader balance 3.1.15 changing the load cell board for precision top loader balance 1.Unsolder temperature sensor board cable (1) (figure 3-12). 2.Unsolder position sensor assembly from cell b...

Page 31

3-11 chapter 3 repair procedures 108 106 1.Remove four screws which secure the overload protection to the monoblock. See figure 5-5. 2.Unscrew fastener screws at formed chassis and remove monoblock with lever from formed chas- sis. Some monoblocks have 4 screws. Note: hold monoblock only at the fron...

Page 32

3-12 chapter 3 repair procedures 1.Place force coil lever assembly in the des- ignated position; check whether the alumi- num sleeves are correctly positioned. See figure 3-16. 2.Turn back vertical adjustment screw (3) to the original position. (see figure 3-16). 3.Insert centring pins in the holes ...

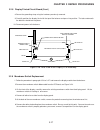

Page 33

3-13 chapter 3 repair procedures 3.1.18 vertical stop adjustment for monoblock in precision top loader balance note note note note note: if the position sensor assembly is changed, it may be necessary to readjust the vertical stop. Adjusting vertical stop 1.Attach voltmeter to 2 pin connector locate...

Page 34

3-14 chapter 3 repair procedures 3.1.19 monoblock load cell removal from high capacity top loader balance refer to figure 5-6 in chapter 5 for location of components called out in this procedure and figure 3-19. To remove the monoblock load cell, proceed as follows: 1.With the balance turned off and...

Page 35

3-15 chapter 3 repair procedures 3.1.20 calibration motor removal from high capacity top loader balance (cont.) figure 3-20. Position sensor assembly mounting. Figure 3-21. Force coil removal. 3.1.22 installing the position sensor assembly for monoblock high capacity top loader balance 1.When replac...

Page 36

3-16 chapter 3 repair procedures 3.1.24 installing the force coil lever assembly in monoblock for high capacity top loader balance figure 3-22. Force coil lever installation. 1.Place lever in designated position: check that the aluminum sleeves are properly positioned. 2.Turn back height adjustment ...

Page 37

3-17 chapter 3 repair procedures 3.1.26 changing servomotor on high capacity top loader balance figure 3-24. Servomotor installation. A note: the replacement motor is supplied without eccen- tric and without motor holder, the corresponding parts of the old motor should be used. 1.Refer to paragraph ...

Page 38

3-18 chapter 3 repair procedures 3.1.27 vertical stop adjustment for monoblock in high capacity top loader balance note note note note note: the position sensor can be aligned by eye with the mounting holes. - if the sensor board has been replaced, it may be necessary to adjust the vertical stop. - ...

Page 39

3-19 chapter 3 repair procedures 3.2 replacement of major components when using this section of the service manual, you will find it necessary to refer to other sections. References are made to the exploded views which are located and identified in chapter 5, drawings and parts lists. The decision t...

Page 40

3-20 chapter 3 repair procedures 3.2.1 analytical balances main printed circuit board (pcb) (cont.) caution when handling the p.C. Board, handle by edges only! Do not touch foil side of board. Static discharge may damage some components. 11. Switch the following components from the defective main pc...

Page 41

3-21 chapter 3 repair procedures 3.2.2 analytical balance - position sensor pc board when the position sensor pc board (51c) (see figure 5-4) has been determined that it is defective and requires replacement, proceed as follows: 1.Remove power from the balance. 2.Proceed to paragraph 3.1.1 load cell...

Page 42

3-22 chapter 3 repair procedures 3.2.3 precision top loader balances main printed circuit board (pcb) (cont.) see figure 5-3 for remaining steps. 6.Remove the two hex screws (1) from the subplatform (2). 7.Remove the subplatform (2). 8.Remove two screws (3) which secure shield (4) in place. 9.Remove...

Page 43

3-23 chapter 3 repair procedures 3.2.4 high capacity top loader balances main printed circuit board (pcb) and power supply ( pcb) refer to figure 5-6 in chapter 5 for location of components called out in this procedure. There are two printed circuit boards; one is the main pcb and the other is a pow...

Page 44

3-24 chapter 3 repair procedures 3.2.5 high capacity top loader balances connector printed circuit board (pcb) refer to figure 5-6 in chapter 5 for location of components called out in this procedure. The connector pcb is located on the left side of the balance. To remove the board, proceed as follo...

Page 45

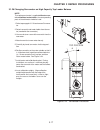

3-25 chapter 3 repair procedures 3.2.6 removing the display module on explorer precision top loader balances (cont.) figure 3-26. Display removal/installation for explorer precision top loader balance. 3.2.7 removing the display module on explorer high capacity top loader balances (see figure 3-20) ...

Page 46

3-26 chapter 3 repair procedures 3.2.7 removing the display module on explorer high capacity top loader balances (cont.) figure 3-27. Display removal/installation for explorer high capacity top loader balance. 3.2.8 display printed circuit board >o/t >o/t 1 2 3 4 5 1.Remove the display module as per...

Page 47

3-27 chapter 3 repair procedures 3.2.8 display printed circuit board (cont.) 8.Secure the grounding strap using the hardware previously removed. 9.Carefully position the display flush with the top of the balance and press into position. The tabs underneath the balance should lock into place. 10. Rec...

Page 48

3-28 chapter 3 repair procedures 3.2.9 membrane switch replacement (cont.) 7.Insert the flat cable from the membrane switch and ground cable through the holes on the display panel. See figure 3-29. Caution be careful not to bend the ribbon cable sharply. If it is creased, use another membrane switch...

Page 49

3-29 chapter 3 repair procedures 3.2.11 removing the display module voyager and explorer pro models (see figure 3-23) 1.Remove power from the balance. 2.Underneath the front of the balance, press the two tabs (1) towards the rear of the balance, this will release the display. 3.Carefully lift the di...

Page 50

3-30 chapter 3 repair procedures 3.2.12 display pcb/lcd assembly replacement this procedure describes the replacement of either the pcb assembly or lcd assembly. 1.Remove the display module as per paragraph 3.2.11. 2.Turn display module over exposing display pcb assembly. See figures 3-31 and 5-9. 3...

Page 51

3-31 chapter 3 repair procedures 3.2.13 bulb replacement this procedure describes the replacement of the bulb on the lcd display assembly. See figure 3-32. Note: this procedure requires that all hardware items that are removed be saved as they are not available as spare parts. 1.Remove the display m...

Page 52

3-32 chapter 3 repair procedures figure 3-32. Lcd assembly bulb replacement. Bulb end cap diffuser panel bracket lcd assembly plastic push in fastener bulb wire.

Page 53

4-1 chapter 4 testing 4.1 testing before servicing the explorer balance, an operational test and various performance tests should be made to ascertain whether or not the balance meets specifications. Turn the balance on and allow it warm up for at least one hour before performing these tests. Make s...

Page 54

4-2 chapter 4 testing 4.2 performance tests all balances accurate performance of the explorer balance is determined by a series of four performance tests. The displayed readings are compared with the tolerances listed in table 4-1. Tolerance values are expressed in counts. A one count change is equa...

Page 55

4-3 chapter 4 testing 4.2.2 off-center load test (cont.) adjustment for analytical balances (cont.) see figure 5-3 for remaining steps. 5.Remove two screws (3) which secure shield (4) in place. 6.Remove shield (4) from the balance. 7.Remove the two screws (3) on top of the pc board (11). 8.Remove th...

Page 56

4-4 chapter 4 testing 15. Repeat the off-center load test. 16. Turn the balance off and unplug power cord. 17. Remove the pan (5). 18. Remove cable extenders, connect the two cable connectors from the analytical load cell (9) to the main pc board edge connectors j3, j6 and the sensor cable. The sens...

Page 57

4-5 chapter 4 testing adjustment for monoblock used in precision top loader balances (210g to 8100g) this adjustment requires that the balance be partially disassembled to gain access to the load cell for adjustments. Refer to figures 5-1 and 5-3 in chapter 5 for location of components called out in...

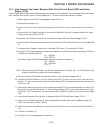

Page 58

4-6 chapter 4 testing eckenlast abgleichen · + · + · + · + · · · · · · position of the test weight filling position with + display 400 viewed from front of balance adjusting the cornerload on precision top loader balances the monobloc measuring cell is not adjusted by means of the cornerload screws,...

Page 59

4-7 chapter 4 testing adjustment for monoblock used in high capacity top loader balances (12000g to 32000g) this adjustment requires that the balance be partially disassembled to gain access to the load cell for adjustments. Refer to figure 5-6 in chapter 5 for location of components called out in t...

Page 60

4-8 chapter 4 testing 4.2.3 linearity test the linearity test is used to determine the span and linearity of the balance throughout its operating range and is in accordance with the specifications listed in tables 1-2, 1-3 and 1-4. The masses used to perform this test must meet or exceed astm class ...

Page 61

4-9 chapter 4 testing 4.2.4 rs232 communication test the rs232 interface in the explorer balance can have its performance monitored using an external printer or computer connected to the balance. The rs232 interface is a bi-directional interface which enables the balance to communicate with a printe...

Page 62

4-10 chapter 4 testing.

Page 63

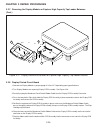

5-1 chapter 5 drawings and parts lists 5.1 drawings and parts lists this section of the manual contains exploded views for the explorer balances with associated parts lists.. The exploded view drawings are designed to identify the parts which can be serviced on the balance in the field. To facilitat...

Page 64

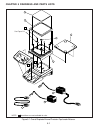

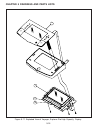

5-2 chapter 5 drawings and parts lists figure 5-1. Overall exploded view of precision top loader balance. >o/t >o/t 3 8 7 6 1 5 1 2 10 9 11 see figure 5-2 note: boxed items are not available for sale..

Page 65

5-3 chapter 5 drawings and parts lists 5.2 parts lists this section of the manual contains the replaceable parts for all models of the the explorer / voyager / explorer pro balances. 5.2.1 precision top loader base parts list table 5-1. Precision top loader base parts list (see figure 5-1) key no. P...

Page 66

5-4 chapter 5 drawings and parts lists figure 5-2. Overall exploded view of analytical balance. 1 5 6 8 >o/t >o/t 9 3 4 10 13 11 18 14 16 12 17 15 7 2 note: boxed items are not available for sale..

Page 67

5-5 chapter 5 drawings and parts lists 5.2.2 analytical base parts list table 5-2. Analytical base parts list (see figure 5-2) key no. Part no. Description 1 11108322 seal, lft cover, explorer, voyager, explorer pro 3 11108701 top door assembly, explorer, voyager 4 11108702 right door assembly, expl...

Page 68

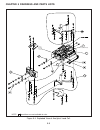

5-6 chapter 5 drawings and parts lists figure 5-3. Exploded view of precision top loader base assembly. 1 23 3 2 4 26 5 24 23 to j2 to j6 3 9 11 j7 j5 j6 j3 j4 j8 j2 j1 switch position to j6 to j2 cable to display module to j6 to j4 to j3 7 10 8 13 9 17 16 20 21 22 24 23 19 18 15 25 14 12 note: boxe...

Page 69

5-7 chapter 5 drawings and parts lists 5.2.3 precision top loader base parts list table 5-3. Precision top loader base parts list (see figure 5-3) key no. Part no. Description 2 11108720 pan support, 6.8" x 6.8" & 8" x 8", explorer, voyager, explorer pro 7 11108412 cable, display, explorer, voyager,...

Page 70

5-8 chapter 5 drawings and parts lists figure 5-4. Exploded view of analytical load cell. 51d 51c 51e lever (ratio beam) 51f gold wires note: boxed items are not available for sale..

Page 71

5-9 chapter 5 drawings and parts lists 5.2.4 analytical load cell parts list table 5-4. Analytical load cell parts list (see figure 5-4) key no. Part no. Description 51a 12106751 flexure, load, kit of 3, explorer, voyager 51b 12106732 guide assembly, top, explorer, voyager analytical 51c 00228006 po...

Page 72

5-10 chapter 5 drawings and parts lists pr-zelle explo figure 5-5. Exploded view of monoblock load cell for precision top loader. 4 1 500 3 2.

Page 73

5-11 chapter 5 drawings and parts lists 5.2.5 precision top loader monoblock load cell parts list table 5-5. Precision top loader monoblock load cell parts list (see figure 5-5) key no. Part no. Description 1 00217401 position sensor assembly monoblock, explorer, voyager, explorer pro, hi capacity 2...

Page 74

5-12 chapter 5 drawings and parts lists figure 5-6. Exploded view of high capacity top loader balance (sheet 1 of 2). 28 30 13 1 19 27 10 12 15 31 36 12 16 39 14 29 12 3 note: boxed items are not available for sale..

Page 75

5-13 chapter 5 drawings and parts lists 5.2.6 high capacity top loader balance parts list table 5-6. High capacity top loader balance parts list (see figure 5-6, sheet 1) key no. Part no. Description 1 21201901 platform, high capacity 3 12301097 weigh below hook, voyager, explorer high capacity 13 2...

Page 76

5-14 chapter 5 drawings and parts lists figure 5-6. Exploded view of high capacity top loader balance (sheet 2 of 2). 3 31 18 31 24 23 25 9 8 31 12 26 7 34 31 35 11 32 6 20 22 33 5 31 17 2 4 37 38 note: boxed items are not available for sale..

Page 77

5-15 chapter 5 drawings and parts lists 5.2.7 high capacity top loader balance parts list table 5-6. High capacity top loader balance parts list (see figure 5-6, sheet 2) key no. Part no. Description 2 11107001 pan mount, (high capacity) 4 00239040 cover, housing, (high capacity) 6 21201770 main pcb...

Page 78

5-16 chapter 5 drawings and parts lists figure 5-7. Exploded view of monoblock load cell for high capacity top loader balance 3 2 5 4 note: boxed items are not available for sale..

Page 79

5-17 chapter 5 drawings and parts lists 5.2.8 monoblock high capacity top loader balance parts list table 5-7. Monoblock high capacity top loader parts list (see figure 5-7) key no. Part no. Description 2 21100003 position sensor pcb, (high capacity) 4 00217400 force coil lever assembly monoblock, e...

Page 80

5-18 chapter 5 drawings and parts lists figure 5-8. Exploded view of explorer display. 1 2 3 >o/t >o/t 4.

Page 81

5-19 chapter 5 drawings and parts lists 5.2.9 explorer display parts list table 5-8. Explorer display parts list (see figure 5-8) key no. Part no. Description 1 11108414 switch, membrane, explorer 2 11136112 cover, display, coated, explorer, voyager, explorer pro, high capacity 3 11108413 display pc...

Page 82

5-20 chapter 5 drawings and parts lists 1 2 3 >o/t >o/t figure 5-9. Exploded view of explorer high capacity display..

Page 83

5-21 chapter 5 drawings and parts lists 5.2.10 explorer high capacity display parts list table 5-9. Explorer high capacity display parts list (see figure 5-9) key no. Part no. Description 1 11108481 membrane switch, explorer, high capacity 2 11136112 cover, display, coated, explorer, voyager, high c...

Page 84

5-22 chapter 5 drawings and parts lists figure 5-10. Exploded view of explorer pro, voyager display. >o/t >o/t 3 10 1 11.

Page 85

5-23 chapter 5 drawings and parts lists 5.2.11 explorer pro, voyager display parts list table 5-10. Explorer pro, voyager display parts list (see figure 5-10) key no. Part no. Description 1 11136410 switch, membrane, voyager 1 11136409 switch, membrane, explorer pro, 3 11136406 lcd display pcb (top)...

Page 86

5-24 chapter 5 drawings and parts lists figure 5-11. Exploded view of voyager, explorer pro high capacity display. >o/t >o/t 3 10 1 11.

Page 87

5-25 chapter 5 drawings and parts lists 5.2.12 voyager, explorer pro, high capacity, display parts list table 5-11. Voyager, explorer pro, high capacity display parts list (see figure 5-11) key no. Part no. Description 1 11136480 membrane switch, explorer pro, high capacity 1 11108480 membrane switc...

Page 88

5-26 chapter 5 drawings and parts lists.

Page 89: A.2 Limitations

Appendix a - explorer ep loader a-1 a.1 requirements for ep loader • pentium 90mhz or higher microprocessor • vga 640x480 or higher resolution screen • microsoft windows nt 4.0 or later, or microsoft windows 95 or later • minimum 24 mb ram for windows 95/98, 32 mb for windows nt • minimum 10 mb free...

Page 90: A.4 Run Ep Loader Software

Appendix a - explorer ep loader a-2 a.4 run ep loader software 1. Click on ep loader icon located in start>programs>ep loader 2. The following screen will be displayed:.

Page 91

Appendix a - explorer ep loader a-3 a.5 setup the balance in manufacturing mode 1. Remove power from the balance 2. Remove the pan. A. It may be necessary to remove two screws holding the display assembly in place under the balance. 3. Unclip the display module and ease it forward until the module i...

Page 92

Appendix a - explorer ep loader a-4 a.7 personality data label entry 1. Locate the personality data label on the balance. Refer to figure a-1. A. The data will be located on the rf shield. Caution this software cannot be used to download personality data for models having internal calibration (autoc...

Page 93

Appendix a - explorer ep loader a-5 a.7 personality data label entry (cont.) 3. Confirm that the balance personality data from the label matches the data that was inputted into the personality data section of the ep loader. If not edit the data. If only the personality data is to be loaded uncheck t...

Page 94

Appendix a - explorer ep loader a-6 a.8 temperature compensation (tc) data entry 1. Locate the tc data label on the balance. For the location see figure a-1. A. There are 2 major styles of label currently in use, please refer to figure a-3. 2. Identify the values labeled in the diagram as “a” to “j”...

Page 95

Appendix a - explorer ep loader a-7 a.8 temperature compensation (tc) data entry (cont.) 2.(cont.) a. When the first entry of the autocal tc data “h” is entered the main screen will change. See below. The added grid is for loading the autocal data in explorer pro balances. It is not used for explore...

Page 96: A.11 Opening Data Files

Appendix a - explorer ep loader a-8 a.9 downloading personality data and/or tc data into the balance 1. In the data type box of the ep loader , there are two check fields to allow selections of personality data and/or tc data to be downloaded into the balance. If both types of data need to be downlo...

Page 97

Appendix b - explorer pro ep loader b-1 b.1 requirements for ep loader • pentium 90mhz or higher microprocessor • vga 640x480 or higher resolution screen • microsoft windows nt 4.0 or later, or microsoft windows 95 or later • minimum 24 mb ram for windows 95/98, 32 mb for windows nt • minimum 10 mb ...

Page 98: B.3 Run Ep Loader Software

Appendix b - explorer pro ep loader b-2 b.3 run ep loader software 1. Click on ep loader icon located in start>programs>ep loader 2. The following screen will be displayed:.

Page 99

Appendix b - explorer pro ep loader b-3 b.4 setup the balance in manufacturing mode 1. Remove power from the balance. 2. Remove the pan. A. It may be necessary to remove two screws holding the display assembly in place under the balance. 3. Unclip the display module and ease it forward until the mod...

Page 100

Appendix b - explorer pro ep loader b-4 b.5 connect the balance to a pc 1. Connect the rs232 interface cable between the balance and the pc. A. Note that for a 9-pin to 9-pin cable; ensure the connector marked bal is connected to the balance. 2. Check communication between the balance and the pc. A....

Page 101

Appendix b - explorer pro ep loader b-5 b.6 temperature compensation (tc) data entry (cont.) a. When the first entry of the autocal tc data “h” is entered the main screen will change. See next page. The added grid is for loading the autocal data..

Page 102

Appendix b - explorer pro ep loader b-6 b.6 temperature compensation (tc) data entry (cont.) 1. Confirm that the tc data from the label was correctly inputted into the tc data of the ep loader.

Page 103

Appendix b - explorer pro ep loader b-7 b.7 personality data label entry 1. Locate the personality data label and the autocal data label on the balance. They will be located on the base under the display module there will be one for standard units and two for units with internal calibration. 2. In t...

Page 104

Appendix b - explorer pro ep loader b-8 b.7 personality data label entry (cont.) 4. Confirm that the balance personality data from the label matches the data that was inputted into the personality data section of the ep loader. If not, edit the data..

Page 105: B.10 Opening Data Files

Appendix b - explorer pro ep loader b-9 b.8 downloading personality data and/or tc data into the balance 1. In the data type box of the ep loader , there are two check fields to allow selections of personality data and/or tc data to be downloaded into the balance. If both types of data need to be do...

Page 106

Appendix b - explorer pro ep loader b-10

Page 107: C.1 Preparation

Appendix c - production mode calibration c-1 c.1 preparation 1. Remove power from the balance. 2. Remove the pan. It may be necessary to remove two screws holding the display assembly in place under the balance. 3. Unclip the display module and ease it forward until the module is clear of the edge o...

Page 108

Appendix c - production mode calibration c-2 c.3 manufacturing weight calibration (mfgwt) procedure this calibration is required if the balance has internal calibration. This procedure restores the internal weight calibration factor that is erased by the mfg calibration. 1. Press and release setup. ...

Page 109: Voyager Pro Balances

Appendix d - replacing bottom display board d-1 this procedure is used when replacing the bottom display board on the voager, explorer pro and voyager pro balances. D.1 replacing the bottom display board on voyager, explorer pro and voyager pro balances the bottom board of the display can be replace...

Page 110: (Cont.)

Appendix d - replacing bottom display board d-2 d.2 explorer pro, voyager and voyager pro display flash instructions (cont.) 3. Install the flash loader program by running the setup.Exe file and following the prompts of the install shield wizard. 4. Unzip the required bank files into their own indiv...

Page 111: (Cont.)

Appendix d - replacing bottom display board d-3 d.2 explorer pro, voyager and voyager pro display flash instructions (cont.) 10. Select the balance you are downloading to then click on browse and select the location of the bank files to be installed. 11. Click on the download button to start the dow...

Page 112

Appendix d - replacing bottom display board d-4.

Page 114

Pn 80250985 service manual - explorer, explorer pro and voyager balances *80250985*.