Summary of Geopro RE

Page 1

Re010070948en operation manual geopro re read these instructions carefully!.

Page 3: Contents

Contents 1. Introduction ....................................................................................................................................4 2. Ground source heat pump operation principle...............................................................................5 2.1. Re ground...

Page 4

Re010070948en 4/23 1. Introduction these instructions are made for geopro –ground source heat pump user. Remember to ask installator to fill in implementation record, which is returned to manufacturer. Installation report is prerequisite for manufacturer quarantee. Read these instructions carefully ...

Page 5

Re010070948en 5/23 2. Ground source heat pump operation principle 1. Vaporiser 2. Compressor 3. Superheating exhausting 4. Condenser 5. Subcooler image 1. Ground source heat pump operating principle. Heat pump unit operation is based on vaporisation and circulation of refrigerant in heat pump. Refri...

Page 6

Re010070948en 6/23 2.1. Re ground source heat pump operation principle 1. Vaporiser 6. Subcooler buffer tank 2. Compressor, de-superheating, option 7. Warm water 3. Condenser 8. Hc 1 heating circuit 4. Sub cooler, option 9. Cold water 5. Superheating buffer tank image2. Re ground source heat pump op...

Page 7

Re010070948en 7/23 2.3. Coefficient of perfomance heat pump efficiency ratio is measured with coefficient of performance, cop. Cop indicates the amount of heat energy transferred into compressor in relation to used electrical energy. Cop depends largely on heat source and heating network temperature...

Page 8

Re010070948en 8/23 3. Geopro controller operation 3.1. Operating display functions 1. Tap –button, dhw heating mode selection 2. Heating mode selection cooling (activated with cooling button, not in use) automatic (according to programmed time) comfort setpoint reduced setpoint frost protection setp...

Page 9

Re010070948en 9/23 3.2. Operation browsing through menus: 1. Press ok –button to access menu levels. 2. Select desired menu level using adjusting wheel, and press ok -button. 3. Find submenu or value you want to adjust, and press ok -button. 4. Turn adjusting wheel to change value or selection. If y...

Page 10

Re010070948en 10/23 3.3.4. Changing room temperature settings desired room temperature can be changed by turning adjusting wheel at standard mode.. When turning adjusting wheel flashing setting appears on display, and it can be raised or lowered using adjusting wheel. Accept change by pressing ok –b...

Page 11

Re010070948en 11/23 3.3.7. Setting holiday heating circuit at menu level holiday heating circuit 1 (2) user can set dates when room temperature is reduced, for example during vacation. Setting is operational only when heating circuit is set on automatic mode. 3.3.8. Adjusting domestic hot water temp...

Page 12

Re010070948en 12/23 3.4. Additional equipment control additional equipment has to be ordered separately, and is not in use in standard models. 3.4.1. Cooling circuit 1 if cooling circuit is installed to ground source heat pump, cold water from drilled well can be used for cooling with air conditione...

Page 13

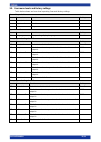

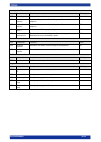

Re010070948en 13/23 3.5. User menu levels and factory settings table below shows end user level operating lines and factory settings. Time of day and date line parameter function setting 1 hours / minutes set time. - 2 day / month set date. - 3 year set year. - operator section line parameter functi...

Page 14

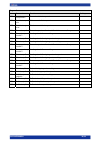

Re010070948en 14/23 time prog 4 dhw line parameter function setting 600 preselection select dates for time limits. Mon - sun 601 1. Phase on clock time when temperature level is raised to comfort setpoint. 04:00 602 1. Phase off clock time when temperature level is lowered to reduced setpoint. 09:00...

Page 15

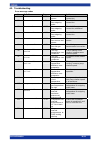

Re010070948en 15/23 heating circuit 2 line parameter function setting 1000 operating mode set operation mode. Automatic 1010 comfort setpoint set room temperature for heating circuit to reach at comfort setpoint. 20 1012 reduced setpoint set room temperature for heating circuit to reach at reduced s...

Page 16

Re010070948en 16/23 diagnostics consumers line parameter function setting 8700 outside temperature current outside temperature. 8701 outside temp min minimum outside temperature. 8702 outside temp max maximum outside temperature. 8740 room temp 1 room temperature for circuit 1 outside sensor, if any...

Page 17

Re010070948en 17/23 4. Maintenance 4.1. Cleaning collector circuit filter warning! Switch off electricity from device before maintenance work. Open screen carefully, there is fluid in pipe. Note! Check that you have necessary tools available. 1. Switch off device from main switch. 2. Close screen is...

Page 18

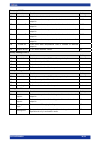

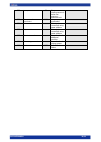

Re010070948en 18/23 4.2. Troubleshooting error message codes no. Definition sensor cause action 10 outside sensor b9 no outside sensor. Check outside sensor connection. 30 flow sensor 1 b1 no measurement from outgoing water check l1 flow sensor connection. 32 flow sensor 2 b12 no measurement from ou...

Page 19

Re010070948en 19/23 225 low pressure e9 compressor intake pressure is below low pressure minimum limit 226 compressor 1 overloaded e11 compressor overloaded 324 bx same sensors bx-outputs connected using same address 325 bx/e'module same sens. Bx- outputs connected using same address 327 e’module sa...

Page 20

Gssh010020904fi_draft 4/23.

Page 22

Oilon home oy p.O.Box 5, 15801 lahti visiting address : tarmontie 4, 15860 hollola tel. (03) 85 761 fax (03) 857 6239 info@oilon.Com www.Oilon.Com.