- DL manuals

- Oki

- Printer

- C5650

- Maintenance Instructions Manual

Oki C5650 Maintenance Instructions Manual

Summary of C5650

Page 1

Oki data confidential c5650/c6050/c6150/mps6150c maintenance manual 080409b.

Page 2

Copyright information copyright © 2008 by oki data. All rights reserved disclaimer every effort has been made to ensure that the information in this document is complete, accurate, and up-to-date. The manufacturer assumes no responsibility for the results of errors beyond its control. The manufactur...

Page 3: P R E Fac E

43827101th rev.2 3 / oki data confidential p r e fac e this manual explains the maintenance methods for the c5650/c6050/c6150. The manual has been prepared for use by the maintenance personnel. For operating methods of the c5650/c6050/c6150, refer to the corresponding user's manual. Note! • the cont...

Page 4: Contents

43827101th rev.2 4 / oki data confidential contents 1. Configuration ............................................................................................... 8 1.1 system configuration ...............................................................................................................

Page 5

43827101th rev.2 5 / oki data confidential 4.2.4 rear cover ............................................................................................................... 73 4.2.5 led assy/led assy springs .................................................................................... 74 4.2.6...

Page 6

43827101th rev.2 6 / oki data confidential 5.3.3 various types of print on the individual printer equipped with controller ................ 154 5.3.4 functions of keys when depressed at power-on ................................................... 154 5.4 setup after replacement of parts ...............

Page 7

43827101th rev.2 7 / oki data confidential 7.5.3.(3) blank print (fig.7.2 c ) ................................................................................ 225 7.5.3.(4) vertical lines are printed .............................................................................. 226 7.5.3.(5) cyclic ...

Page 8

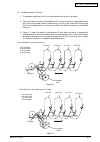

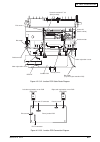

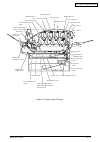

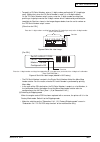

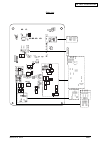

43827101th rev.2 8 / oki data confidential 1. Configuration 1.1 system configuration c6150/c6050 figure 1-1-1 represents the system configuration of the printer. Figure 1-1-1 rfid centronics eep rom k led head y led head m led head c led head operator panel pcb t oner sensor pcb high-voltage pcb low...

Page 9

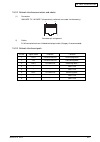

43827101th rev.2 9 / oki data confidential c5650 figure 1-1-2 represents the system configuration of the printer. Figure 1-1-2 color registration pcb right color registration pcb left k led head y led head m led head c led head front sensor pcb duplex pcb 2nd tra y pcb in1 in2 wr m id m hop m idup m...

Page 10

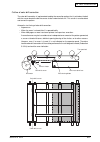

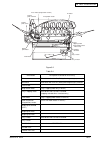

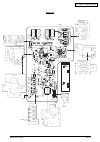

43827101th rev.2 10 / oki data confidential 1.2 printer configuration the internal part of the c6050/c6150 printer is composed of the following sections: • electrophotographic processing section • paper paths • control sections (cu sect./pu sect.) • operator panel • power supply sections (high-volta...

Page 11

43827101th rev.2 11 / oki data confidential the internal part of the c5650 printer is composed of the following sections: • electrophotographic processing section • paper paths • control sections (cu sect./pu sect.) • operator panel • power supply sections (high-volatge sect./low-voltage sect.) figu...

Page 12

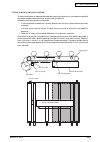

43827101th rev.2 12 / oki data confidential 1.3 composition of optional items the following optional items are available for the printer: (1) second tray (c5650/c6050/c6150) (2) duplex unit (c5650/c6050/c6150) (3) expansion memory (c6050/c6150) 256 mb / 512 mb for long printing, it is recommended to...

Page 13

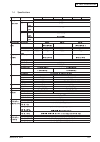

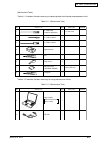

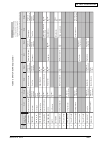

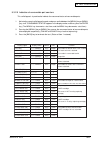

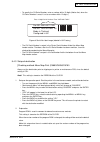

43827101th rev.2 13 / oki data confidential 1.4 specifications division item c5650 c6150 c6050 32/22ppm 32/26ppm 26/22ppm external dimensions width 435mm depth with duplex 621mm without duplex 563.5mm height 340mm mass with duplex approx.29kg without duplex approx.26kg print width print width a4 eng...

Page 14

43827101th rev.2 14 / oki data confidential division item c5650 c6150 c6050 32/22ppm 32/26ppm 26/22ppm service life printer life 420,000 pages, 5 years print duty (m=l/12, a=l/12/5) max. 50,000 pages / mo. Average 4,000 pages / mo. Mtbf (2.3% duty) not applicable mpbf 40,000 pages mttr 20 minutes to...

Page 15

43827101th rev.2 15 / oki data confidential division item c5650 c6150 c6050 32/22ppm 32/26ppm 26/22ppm paper thickness 1st tray 64~120gsm 2nd tray 64~176gsm manual & auto (mpt) 64-203gsm ohp sheets available two-sided 64~105gsm operator panel lcd 16 characters in 2 line (roman alphabet/japanese kana...

Page 16

43827101th rev.2 16 / oki data confidential note! Expansion memories for c5650 and those for c6050/c6150 are not compatible with each other. Division item c5650 c6150 c6050 32/22ppm 32/26ppm 26/22ppm optional item (detacchable) ram set 64, 256 mb 256, 512 mb tray mechanism 2nd tray mechanism cassett...

Page 17

43827101th rev.2 17 / oki data confidential 1.5 interface specifications 1.5.1 parallel interface specifications 1.5.1.1 parallel interface overview 1.5.1.2 parallel interface connector and cable (1) connector printer: 36pconnector (female) 57le-40360-12 (d56) (ddk ltd.) equivalent product cable: 36...

Page 18

43827101th rev.2 18 / oki data confidential 1.5.1.4 timing chart ■ compatible mode a) data reception timing b) online/online sw for offline switching timing c) offline/online sw for online switching timing d) nlnit timing (default invalid) parallel data (data bits 1 to 8) nstrobe nack busy 0.5 µs mi...

Page 19

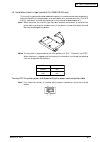

43827101th rev.2 19 / oki data confidential 1.5.1.5 parallel interface signal the name of the interface signal and pin number is indicated in table 9-1. Table 1-1 signals nibble mode signal names are indicated in the ( ). Only indicates the compatible mode functions. This printer supports the ieee 1...

Page 20

43827101th rev.2 20 / oki data confidential 1.5.2 usb interface specifications (c5650/c6050/c6150) 1.5.2.1 outline of usb interface (1) basic specifications usb (hi-speed usb supported) (2) transmission mode full speed (max. 12mbps ± 0.25%) high speed (max.480mbps ± 0.05%) (3) power control self pow...

Page 21

43827101th rev.2 21 / oki data confidential network protocol application 1.5.3 network interface specifications (c5650/c6050/c6150) 1.5.3.1 outline of network interface 1.5.3.1.1 basic specifications of network interface (c5650) 1.5.3.1.2 basic specifications of network interface (c6050/c6150) proto...

Page 22

43827101th rev.2 22 / oki data confidential 1.5.3.2 network interface connectors and cables (1) connectors 100 base-tx / 10 base-t (automatically switched, not usable simultaneously) connector pin assignment 2) cables rj-45 connectorized non-shielded twisted-pair cable (category 5 recommended) 1.5.3...

Page 23

43827101th rev.2 23 / oki data confidential 2. Explanation of operation 2.1 electrophotographic processing mechanism (1) electrophotographic process the electrophotographic process is explained briefly below: 1. Charging a voltage is applied to the ch roller to electrically charge the surface of the...

Page 24

43827101th rev.2 24 / oki data confidential 2. Exposure the light emitted from the led head is radiated onto the charged surface of the opc drum. The charge of the radiated part of the opc drum attenuates according to the intensity of the light, forming an electrostatic latent image on the opc drum ...

Page 25

43827101th rev.2 25 / oki data confidential 4. Transfer a sheet of paper is placed over the opc drum surface, and an electric charge is given to the paper from its back side by the transfer roller. When a high voltage is applied to the transfer roller from the power source, the charge induced on the...

Page 26

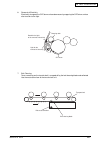

43827101th rev.2 26 / oki data confidential 7. Belt cleaning toner remaining on the transfer belt is scraped off by the belt cleaning blade and collected into the waste toner box of the transfer belt unit. Transport belt belt waste toner box belt cleaning blade 6. Removal of electricity electrically...

Page 27

43827101th rev.2 27 / oki data confidential 8. Fuser the toner image which was transferred to the paper is applied heat and pressure as it passes between the heat roller and the backup roller, and it is therefore fused onto the paper. For the sake of safety, a thermostat is provided; it comes on to ...

Page 28

43827101th rev.2 28 / oki data confidential 2.2 printing process the paper fed from tray 1 or tray 2 is carried by the paper feed roller, register roller l and transport roller. When the paper is fed from the mpt, it is carried by the mpt paper feed roller and register roller u. Then, an unfixed ton...

Page 29

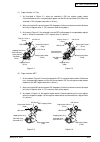

43827101th rev.2 29 / oki data confidential (1) paper fed from 1st tray 1. As illustrated in figure 2-1, when the solenoid is on, the register motor rotates (counterclockwise turn), transporting the paper until the in1 sensor comes on. (when the solenoid is on, the paper feed roller is driven.) 2. A...

Page 30

43827101th rev.2 30 / oki data confidential (3) transport belt 1. As the transport belt motor rotates in the direction of the arrow, the transport belt is driven. The belt unit consists of one transport roller placed immediately underneath each color drum, with a transport belt inserted in between t...

Page 31

43827101th rev.2 31 / oki data confidential lift-up motor (cw) lift uplink id unit operations during color printing c-id unit c-id unit down m-id unit down y-id unit down k-id unit down m-id unit y-id unit k-id unit lift-up motor (ccw) lift uplink id unit operations during monochrome printing c-id u...

Page 32

43827101th rev.2 32 / oki data confidential (5) fuser unit and paper output 1. As illustrated in figure 2-8, the fuser unit and delivery roller are driven by the dc motor. As the fuser motor rotates (counterclockwise turn), the heat roller is turned. This roller fixes a toner image by heat and press...

Page 33

43827101th rev.2 33 / oki data confidential outline of color drift correction the color drift correction is implemented reading the correction pattern that is printed on the belt with the sensor located inside the sensor shutter under the belt unit. This sensor is used to detect and correct the patt...

Page 34

43827101th rev.2 34 / oki data confidential error checking methods and remedial methods the color drift correction test function among the other self-diagnostic functions is employed to check errors. (subsection 5.3.2.6) remedial methods against different errors • calibration (l or r), dynamicrange ...

Page 35

43827101th rev.2 35 / oki data confidential outline of density correction method the density correction is implemented reading the correction pattern that is printed on the belt with the sensor located inside the sensor shutter under the belt unit. Automatic start timing of density correction: • if ...

Page 36

43827101th rev.2 36 / oki data confidential error checking methods and remedial methods the density correction test function among the other self-diagnostic functions is employed to check errors. (subsection 5.3.2.7) remedial methods against different errors • calibration err, dens sensor err check ...

Page 37

43827101th rev.2 37 / oki data confidential principle of toner sensor detection toner low is detected by the toner sensor (reflection sensor) installed inside the printer. The shielding plate is mounted inside the id and rotates in synchronization with toner agitation. Moreover, the id has a shutter...

Page 38

43827101th rev.2 38 / oki data confidential 3. Installation 3.1 cautions, and do's and don'ts • do not install the printer at high temperature or near fire. • do not install the printer in a location where chemical reaction can take place (laboratory, etc.). • do not install the printer in the proxi...

Page 39

43827101th rev.2 39 / oki data confidential • do not install the printer in a location where its vent hole is blocked. • do not install the printer directly on a shaggy carpet or rug. • do not install the printer in a sealed room or other location with poor ventilation or permeability. • install the...

Page 40

43827101th rev.2 40 / oki data confidential 3.2 unpacking method make sure to lift up this printer by two or more persons, since it weighs approx. 29kg (with duplex)/ approx. 26kg (w/o duplex) • remove the four handles from the sides of the box, as illustrated below, and lift up the corrugated fiber...

Page 41

43827101th rev.2 41 / oki data confidential 3.3 printer installation instructions • install the printer in a location where the following temperature and humidity are met: ambient temperature: 10 - 32˚c ambient humidity: 20 - 80 %rh(relative humidity) max. Wet-bulb temperature: 25˚c • use caution to...

Page 42

43827101th rev.2 42 / oki data confidential 3.4 listing of component units and accessories • check to make sure that the component units are free from damage, dirt or other zirregularities in the appearance. • ensure that none of the accessories to the units is missing and that they are free from br...

Page 43

43827101th rev.2 43 / oki data confidential 3.5 assembling method 3.5.1 assembly of printer main body removing the protective materials 1) peel off the protective tapes (5) and the slip of paper from the front part of the printer, and also peel off the protective tapes (2) from the back of the print...

Page 44

43827101th rev.2 44 / oki data confidential installing the image drum cartridges 1) take out the image drum cartridges (4) gently along with the toner cartridges attached. Note! • the image drum (green tubular section) is extremely vulnerable. Exert good caution in handling it. • do not expose the i...

Page 45

43827101th rev.2 45 / oki data confidential 4) match the label colors of the image drum cartridges to those on the printer. 5) gently put the image drum cartridges (4) back in their respective positions. 6) turn the blue levers (4) of the toner cartridges fully into the direction of the arrow. Note!...

Page 46

43827101th rev.2 46 / oki data confidential loading paper in the paper cassette 1) pull out the paper cassette. Note! Do not peel off the rubber attached to the plate. 2) set the paper stopper securely, according to the paper size. 3) loosen the paper well and line up its vertical and lateral edges....

Page 47

43827101th rev.2 47 / oki data confidential loading paper in the multi-purpose tray 1) open the multi-purpose tray and also the paper supporter. 2) set the manual feed guide to the paper size. 3) line up the vertical and lateral edges of the paper. 4) insert the paper, print-face up, along the manua...

Page 48

43827101th rev.2 48 / oki data confidential storing the quick guide paste the dedicated quick guide bag to the printer, and put the quick guide in it. Turning back the dedicated quick guide bag and peeling off the adhesive double coated tapes (2). Pasting the dedicated bag to the printer. Note! When...

Page 49

43827101th rev.2 49 / oki data confidential 3.5.2 connection of power cable power supply conditions • observe the following conditions: ac: 110~127v ±10%/220~240v±10% power frequency: 50hz or 60hz ± 2hz approx. 29kg (with duplex)/approx. 26kg (w/o duplex) • if the available power is unstable, use a ...

Page 50

43827101th rev.2 50 / oki data confidential connecting the power cord note! Ensure that the power switch is in off (o). 1) insert the power cord into the printer. 2) after connecting the grounding wire to the ground terminal of the power outlet, insert the power plug into the power outlet. Pressing ...

Page 51

43827101th rev.2 51 / oki data confidential turning off the power on the c6050/c6150 which is not equipped with the built-in type hard disk (optional) or the c5650, the power can be turned off as is. Note! Do not turn off the power while the printer is printing. On the c6050/c6150 equipped with the ...

Page 52

43827101th rev.2 52 / oki data confidential 3.5.3 installation of optional items (1) installation of expansion memory set note! • be sure to use genuine oki data parts. If any other parts are used, the printer will not function. • adding 64-mb memory is recommended for (600 x 600dpi x 2bit) banner-s...

Page 53

43827101th rev.2 53 / oki data confidential remove side cover 1) loosen the screw (1). 2) remove the side cover. To remove the side cover, slide it while holding up its upper part. Installing the memory on the c6150/c6050 1) before taking the memory out of the bag, place the bag in contact with a me...

Page 54

43827101th rev.2 54 / oki data confidential on the c5650 1) before taking the memory out of the bag, place the bag in contact with a metal part to eliminate its static electricity. 2) insert the memory into the idle slot. 3) ensure that it is securely fastened by the right and left lock levers. Note...

Page 55

43827101th rev.2 55 / oki data confidential (2) installation of second tray unit this tray is intended to increase the amount of paper that can be loaded in the printer. It holds 530 sheets of 70kg ream weight paper, allowing to print 930 sheets continuously when combined with the standard paper cas...

Page 56

43827101th rev.2 56 / oki data confidential (3) installation of duplex unit this unit is used for printing on two sides of paper. Note! For two-sided printing, it is recommended to add an expansion memory. For details, see "expansion memories." turning off the printer power and disconnecting the pow...

Page 57

43827101th rev.2 57 / oki data confidential (4) installation of built-in type hard disk (on c6050/c6150 only) this is a built-in type hard disk to be added to the printer. It is used to conduct confirmation print, authentication print, to store print jobs, or to make buffer print, and also when the ...

Page 58

43827101th rev.2 58 / oki data confidential opening the top cover and front cover 1) open the top cover by pressing the open button. 2) push up the handle located in the center of the front cover and pull the front cover forward. Note! The way the front cover is opened is different from that of the ...

Page 59

43827101th rev.2 59 / oki data confidential detaching the side cover 1) loosen the screw (1). 2) remove the side cover. To remove the side cover, slide it while holding up its upper part. Memo if you have difficult detaching the side cover, check to see if the front cover is open. Installing the bui...

Page 60

43827101th rev.2 60 / oki data confidential attaching the side cover 1) mount the side cover. 2) fasten it with the screw (1). 3) close the top cover and front cover. Connecting the power cord and printer cable to the printer, and turning on the power executing the menu map print, and ensuring that ...

Page 61

43827101th rev.2 61 / oki data confidential 3.5.4 confirmation of recognition of optional items to check to see whether or not the optional items have been installed properly, execute the menu map print by referring to "3.6 menu map print. (1) confirmation of recognition of expansion memory checking...

Page 62

43827101th rev.2 62 / oki data confidential 3.6 menu map print this print is intended to ensure that the printer operates normally. On the c5650/c6050/c6150 1) load a4 paper in the tray. 2) press the "menu +" switch several times to cause [information menu] to be displayed. 3) press the "set" switch...

Page 63

43827101th rev.2 63 / oki data confidential.

Page 64

43827101th rev.2 64 / oki data confidential 3.7 connection methods preparing a usb cable note! • no printer cable is supplied with the printer. Provide one separately. • prepare a usb type cable separately. • when connection is to be made in "hi-speed" mode of usb2.0, use a usb cable conforming to t...

Page 65

43827101th rev.2 65 / oki data confidential (centronics i/f model) 1. Prepare a parallel cable. 2. Power off printer and personal computer 3. Connect personal computer and printer (1) connect a parallel cable into a parallel interface connector of printer and use metal fittings to secure the cable. ...

Page 66

43827101th rev.2 66 / oki data confidential network interface connector preparing a lan cable switching off the printer and computer 1) plug the ethernet cable into the network interface connector of the printer. 2) insert the ethernet cable into the hub..

Page 67

43827101th rev.2 67 / oki data confidential media type * 1 media weight 55-64kg (64-74g/m 2 ) 65-89kg (75-104g/m 2 ) 90-103kg (105-120g/m 2 ) 104-172kg (121-200g/m 2 ) - - less than 0.1-0.17mm 0.17-0.2mm - weight types setting * 2 for [media weight] of the printer driver light medium heavy ultra hea...

Page 68

43827101th rev.2 68 / oki data confidential (2) do not disassemble the printer as long as it is operating normally. (3) limit disassembly to a necessary minimum. Do not remove other parts than those specified in the part replacement procedure. (4) use the designated maintenance tools. (5) conduct di...

Page 69

43827101th rev.2 69 / oki data confidential [maintenance tools] table 4-1-1 indicates the tools necessary to replace printed-circuit boards and component units. Table 4-1-1 maintenance tools table 4-1-2 indicates the tools necessary for using maintenance utilities. Table 4-1-2 maintenance tools no. ...

Page 70

43827101th rev.2 70 / oki data confidential 4.2 part replacement methods this subsection explains the replacement methods for the parts and assemblies illustrated in the disassembly system diagram below. 4.2.1 left side cover (1) open the top cover. (2) open the feeder unit. (3) remove screw (silver...

Page 71

43827101th rev.2 71 / oki data confidential 4.2.2 right side cover (1) open the top cover. (2) open the feeder unit. (3) loosen screw 1, and detach right side cover 2. Figure 4-2-2 right side cover 2 1 feeder unit top cover (loosen).

Page 72

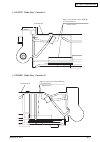

43827101th rev.2 72 / oki data confidential 4.2.3 face-up tray (1) open face-up tray 1 into the direction of the arrow, free the engagement on either side of it while deflecting the tray, and remove the tray. Figure 4-2-3 face-up tray 1.

Page 73

43827101th rev.2 73 / oki data confidential 4.2.4 rear cover (1) open the face-up tray. (2) remove two screws (silver) 1. (3) insert the flat-tipped screwdriver into hole a, as illustrated in figure (2), and release two claws a. (4) now, release two claws b, and pull the upper part of rear cover 2 i...

Page 74

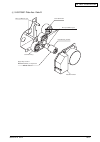

43827101th rev.2 74 / oki data confidential 4.2.5 led assy/led assy springs (1) open the top cover. (2) after disconnecting the cable, first free hook part a by applying force in the direction of the arrow, as illustrated in figure (2), and then, free hook part b, to finally remove led assy 1. (in t...

Page 75

43827101th rev.2 75 / oki data confidential 4.2.6 cu pcb c6150/c6050 (1) open the top cover. (2) detach the right side cover. (see subsection 4.2.2.) (3) remove eight screws (silver) 1, and detach plate shield assembly (pdl) 2 by releasing connector claws a. (4) remove screw 3, and disconnect head c...

Page 76

43827101th rev.2 76 / oki data confidential c5650 (1) open the top cover. (2) detach the right side cover. (see subsection 4.2.2.) (3) remove eight screws (silver) 1, and detach plate shield assy(gdi)2 by releasing claws a. (4) remove screw (silver) 3, and disconnect head cable 4. (5) remove seven s...

Page 77

43827101th rev.2 77 / oki data confidential 4.2.7 print engine controller pcb (1) remove the plate shield assy(pcl/gdi). (see subsection 4.2.6 (1) through (3).) (2) remove all the connectors and two screws (silver) 1, and disassemble the print engine controller pcb 2. Figure 4-2-7-1 print engine con...

Page 78

43827101th rev.2 78 / oki data confidential rfid dcheat relay hvolt cuif hop hsol powfan fsns pe rfid ssns dcid ope option power beltidup toner sensor id motor control panel controller pcb fuser motor pe cable fsns(front sensor) cable option (dup & 2nd) paper feed solenoid option (2nd) cable junctio...

Page 79

43827101th rev.2 79 / oki data confidential 4.2.8 top cover assembly (1) detach the left side cover. (see subsection 4.2.1.) (2) detach the right side cover. (see subsection 4.2.2.) (3) detach the rear cover. (see subsection 4.2.4.) (4) remove the plate assembly shield (gdi), and then, the control p...

Page 80

43827101th rev.2 80 / oki data confidential 4.2.9 top cover (1) detach the top cover assembly. (see subsection 4.2.8.) (2) remove ten screws (black) 1, and detach cable cover 2 and top cover 3. Figure 4-2-9 top cover 1 1 1 1 3 2.

Page 81

43827101th rev.2 81 / oki data confidential 4.2.10 controller panel assy 1) open the top cover. (2) open the feeder unit. (3) detach the right side cover. (see subsection 4.2.3.) (4) remove the plate shield assembly. [see subsection 4.2.7 (2).] (5) after unplugging the connector of the control panel...

Page 82

43827101th rev.2 82 / oki data confidential 4.2.11 operator panel pcb/ top cover handle (1) detach the control panel assembly. (see subsection 4.2.10.) (2) release two claws a, as illustrated in figure (2), and remove frame op1, lever lock 2 and spring compression 3. (3) release two claws b by forci...

Page 83

43827101th rev.2 83 / oki data confidential 4.2.12 low-voltage power supply / low-voltage fan / hopping motor / fuser motor (1) remove the cassette assembly. (2) disassemble the print engine controller pcb. (see subsection 4.2.7.) (3) disassemble the cu pcb. (see subsection 4.2.6.) (4) disconnect al...

Page 84

43827101th rev.2 84 / oki data confidential 4.2.13 guide eject assy / color register assy / junction pcb (1) detach the left side cover, right side cover, rear cover, and top cover assembly. (see subsections 4.2.1, 4.2.2, 4.2.4, and 4.2.8.) (2) remove the print engine controller pcb, control pcb, an...

Page 85

43827101th rev.2 85 / oki data confidential sns cn sns cn fuser exit lcr dens rcr replay exit sensor belt motor belt thermistor belt thermistor color registration sensor junction pcb density sensor belt motor (to print engine controller pcb) color registration sensor heater ac (black & white) heater...

Page 86

43827101th rev.2 86 / oki data confidential 4.2.14 fan (fuser)/ belt motor / high-voltage power supply board / cover-open switch (1) detach the left side cover. (see subsection 4.2.1.) (2) remove screw (silver) 1, unplug the connector, and disassemble belt motor 2. (3) detach rear cover 3. (see subs...

Page 87

43827101th rev.2 87 / oki data confidential 4.2.15 mpt assy (1) open mpt assy 1. (2) release the two stoppers by opening the two arms of mpt assy 1 toward the outside, pull the assembly in the direction of the arrow to free the two fulcrums, and detach mpt assy 1. Figure 4-2-15 mpt-assy 1 stoppers (...

Page 88

43827101th rev.2 88 / oki data confidential 4.2.16 feeder unit / front sensor pcb/ mpt hopping roller / frame assy separator / cover front (1) open the top cover. (2) remove the plate shield, and unplug the connector. (see subsection 4.2.6.) (3) free the claws of stay l 1 and stay r 2, and remove fe...

Page 89

43827101th rev.2 89 / oki data confidential 4.2.17 toner sensor pcb lift-up motor/solenoid/paper-end sensor (1) detach the left side cover, right side cover, rear cover, top cover unit, and feeder unit. (see subsections 4.2.1, 4.2.2, 4.2.4, 4.2.8 and 4.2.16.) (2) disassemble the print engine control...

Page 90

43827101th rev.2 90 / oki data confidential figure 4-2-17 toner sensor pcb lift-up motor/solenoid/paper-end sensor align the motor and connector in position to the arrow. Install aligninig the two position cut as mark figure. Lift-up motor install aligninig the two position cut as mark figure. 1 2 9...

Page 91

43827101th rev.2 91 / oki data confidential 4.2.18 feed roller (1) remove the cassette. (2) release the latch, and remove feed roller 1. Figure 4-2-18 feed roller 1 latch.

Page 92

43827101th rev.2 92 / oki data confidential 4.2.19 shaft eject assy(fu) / shaft eject assy(fd) / eject sensor (1) remove the eject assy. (see subsection 4.2.13.) (2) free the two claws, and divide the assy between guide into lower 1 and guide eject upper 2. (3) remove gear idle eject 3, and disassem...

Page 93

43827101th rev.2 93 / oki data confidential 4.2.20 fuser unit (1) open the top cover. (2) lift up the lock levers 1 (2, blue) of the fuser unit in the direction of the arrow, and remove fuser unit 2. Figure4-2-20 fuser unit 2 1 (blue) top cover.

Page 94

43827101th rev.2 94 / oki data confidential 4.2.21 belt unit (1) open the top cover. (2) remove id unit 1. (3) turn the lock levers (2, blue) of belt unit 2 in the direction of the arrow , and hold belt unit 2 by the levers (blue) to remove it. Figure 4-2-21 belt unit 2 1 top cover lock lever (blue)...

Page 95

43827101th rev.2 95 / oki data confidential 4.3 lubricating points this subsection indicates the lubricating points of the printer. Conversely, it means that any other parts than the specified lubricating points must not be lubricated. There is no need to lubricate in the midst of a disassembling jo...

Page 96

43827101th rev.2 96 / oki data confidential 1 43070301 plate-assy.-base gear-z24-50-hp stopper-z45-48-hp gear-planet-hp holder-planet-hp stopper-hp plate-gear-hp-caulking shaft-hopping end surfaces gear bottom surface em-30l class c side faces of shaft groove section em-30l class c gear teeth and en...

Page 97

43827101th rev.2 97 / oki data confidential 2 42049701 guide-assy.-cassette-l 3 43294901 guide-assy.-cassette-r em-30l class c guide-casette-l apply a normal amount of molycoat(em-30l) to the hatched portions em-30l class c guide-casette-r apply a normal amount of molycoat(em-30l) to the hatched are...

Page 98

43827101th rev.2 98 / oki data confidential 5 43072101 gear-planet-assy class b spring-planet-heat holder-gear-a em-30l class c apply a normal amount of molycoat(em-30l) to the hatched areas apply a amount of hp-300 to the hatched areas 4 43073201 gear-assy.-hp.

Page 99

43827101th rev.2 99 / oki data confidential 6-1 43070501 plate-ass.-side-r em-30l class c bracket-inner(caulking) apply a normal amount of molycoat(em-30l) to the hatched areas apply molykote (em-30l) in a large quantity to the gear tooth flanks at over 120 deg. Enlarged view em-30l class f gear-idl...

Page 100

43827101th rev.2 100 / oki data confidential em-30l class f gear-idle-heat_z14-z32 gear-planet-assy motor-dc-fc-45m grease prohibition to post grease prohibition to gear. Apply a large around of molykote (em-30l) to all gear teeth. Gear-idle-exit-z32 6-3 43070501 plate-ass.-side-r.

Page 101

43827101th rev.2 101 / oki data confidential 6-4 43070501 plate-ass.-side-r (5) em-30l classa em-30l classa em-30l classb em-30l classc em-30l classc em-30l classc em-30l classc em-30l classc link-liftup-r gear-liftup-z58z25 gear-liftup-z121z32 gear-idleliftup-z28 gear-liftupr-z32 gear-liftupr-z32 m...

Page 102

43827101th rev.2 102 / oki data confidential 7 43074901 plate-ass.-side-l link-liftup-l post-gearldle-l gear-liftup-z32 gear-liftup-z32 gear-liftup-z56 (5) em-30l class c em-30l class a em-30l class a em-30l class c apply molykote (em-30l) in a normal quantity to the gear tooth tips. Apply molykote ...

Page 103

43827101th rev.2 103 / oki data confidential 9 42071901 holder assy.-regist-r 8 42071401 holder assy.-regist-l holder-regist-l em-30l class c apply molykote (em-30l) in a normal quantity to the hatched parts (parts having the rotation shafts inserted). Holder-regist-r em-30l class c apply molykote (...

Page 104

43827101th rev.2 104 / oki data confidential frame-separation-assy lever-release cam-release gear-idle-(z21) gear-fuser-(z35) plate-side-r-caulking(fuser) do not apply grease to the boss. Do not apply grease to the gears. Assemble after applying molykote (em-30l) to the hatched parts in the illustra...

Page 105

43827101th rev.2 105 / oki data confidential b 43301501 guide-assy.-eject-l shaft-assy.-eject(fd) guide-eject-upper shaft-assy.-eject(fu) em-30l class c em-30l class c em-30l class c em-30l class d em-30l class a part y part x apply molykote (em-30l) in a normal quantity to the gear tooth flanks, sh...

Page 106

43827101th rev.2 106 / oki data confidential c 43070201 frame-assy.-base cassette-assy. Pm class c apply pm in a small quantity to the hatched part. (1) applying method: wipe the part with a cloth slightly impregnated with pm. (2) after applying pm, insert and pull out the cassette several times to ...

Page 107

43827101th rev.2 107 / oki data confidential d-1 43070101 printer-unit plate-ass.-side-l plate-driver-pu(caulking) gear-idle-belt em-30l class c em-30l class c em-30l class c em-30l class c apply molykote (em-30l) in a normal quantity to the tips of the terminals (4 points). Applied r ange of g reas...

Page 108

43827101th rev.2 108 / oki data confidential d-2 43827301 printer-unit plate-ass.-side-r spring-torsion-l em-30l class c (2 places)(at both sides) spring-torsion-r apply molykote (em-30l) in a normal quantity to the hatched parts. Apply pm to the slot parts of the solid coiling of this torsion sprin...

Page 109

43827101th rev.2 109 / oki data confidential e 43079601pa belt-unit em-30l class a em-30l class a em-30l class c em-30l classa em-30l class c apply molykote (em-30l) in a small quantity to the inside of bearing-tr (belt) (4 points). Apply molykote (em-30l) in a normal quantity to the bearings (both ...

Page 110

43827101th rev.2 110 / oki data confidential f 42626501 sensor-assy-color-regist plate-sensor-c.Regist cover-sensor-c.Regist shaft-cover-sensor em-30l class a apply molykote (em-30l) in a small quantity to the hatched parts (at both sides)(8 points). Molykote must not stick to the surfaces of cover ...

Page 111

43827101th rev.2 111 / oki data confidential g 43081301 roller-assy.-idle(fd) 1 2 grease applying method: before assembling 2 to 1, apply molykote (em-30l) in a very small quantity (class s) to the sliding parts (hatched parts) between 1 and 2. Disassembled view range in which grease must not stick.

Page 112

43827101th rev.2 112 / oki data confidential h 43301601 roller-assy.-bias(fu)c 1 2 3 grease applying method: range in which grease must not stick before assembling 3 to 2, apply molykote (em-30l) in a very small quantity (class s) to the sliding parts (hatched parts) of 2..

Page 113

43827101th rev.2 113 / oki data confidential 5. Maintenance menus the adjustment of this printer can be implemented using the maintenance utility and also by key input through the operator panel. This printer provides maintenance menus, apart from the normal menus. Select the menu that best suits th...

Page 114

43827101th rev.2 114 / oki data confidential function item(1st line) value(2nd line) df category function this menu is displayed on the printers for all destinations. Type1: does not indicate russian/ greek. Type2: indicates russian/greek. When the menu is dismissed, the printer is automatically reb...

Page 115

43827101th rev.2 115 / oki data confidential personality (c6150/c6050/ ) change password engine diag mode changes the default of support pdl language for each destination. The pdl language disabled in this menu will no longer be displayed in "user menu" - "sys config menu" - "personality." if print ...

Page 116

43827101th rev.2 116 / oki data confidential 5.2 maintenance utility the maintenance utility is used to perform the adjustments of table 5-2. Details of the maintenance utility are described below. (1) maintenance utility operation manual: 42678801fu01 rev5 or later (japanese) 42678801fu02 rev5 or l...

Page 117

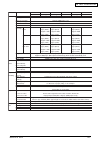

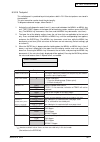

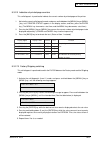

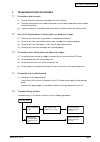

43827101th rev.2 117 / oki data confidential table 5-2 maintenance utility adjustment items (1/3) operation on operator panel (section no. Corresponds to the maintenance manual) item section no. Of the maintenance utility operation adjustment 1 2 3 4 5 6 7 8 9 10 11 invalid operation invalid operati...

Page 118

43827101th rev.2 118 / oki data confidential table 5-2 maintenance utility adjustment items (2/3) operation on operator panel (section no. Corresponds to the maintenance manual) item section no. Of the maintenance utility operation adjustment 12 16 17 18 19 20 18 19 20 21 22 23 24 25 26 prohibited t...

Page 119

43827101th rev.2 119 / oki data confidential table 5-2 maintenance utility adjustment items (3/3) operation on operator panel (section no. Corresponds to the maintenance manual) item section no. Of the maintenance utility operation adjustment 27 28 29 30 prohibited to use subsect.5.3.2.8 subsect. 5....

Page 120

43827101th rev.2 120 / oki data confidential 5.3 functions of user's maintenance menu 5.3.1 maintenance menu (for end users) there is a maintenance menu category among the normal menu categories. (different from the system maintenance menus) the items that can be set under this menu are indicated be...

Page 121

43827101th rev.2 121 / oki data confidential to correct variations in print results caused by temperature/humility conditions and difference in print density/frequency. Change the setting when background is dark. Maintenance menu bg setting -3 -2 -1 0 +1 +2 +3 function category item (upper display) ...

Page 122

43827101th rev.2 122 / oki data confidential 5.3.2 self-diagnostic mode individual explanation of level0 and level1. 5.3.2.1 operator panel the explanation of the operations relating to the self-diagnosis presupposes, the following operation panel arrangement is required. (1) transition of menu item...

Page 123

43827101th rev.2 123 / oki data confidential level0 [back](2seconds) engine status indication heater temperature environmental temperature & humidity setup table transfer voltage transfer-off voltage *belt temperature side thermistor [online](2seconds) [menu-] [menu-] indication of each voltage duri...

Page 124

43827101th rev.2 124 / oki data confidential (1) transition of menu items transition of is selected with [menu+] or [menu-] and executed pressing [enter]. Transition to is executed with [enter] or [back]. Select an item with [menu+] or [menu-] following the transition. Pressing [enter] executes the ...

Page 125

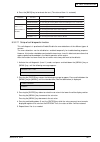

43827101th rev.2 125 / oki data confidential 5.3.2.2 normal self-diagnostic mode (level 1) the menus of the normal self-diagnostic mode are indicated below. Table 5-3 maintenance utility adjustment items maintenance utility 1 2 3 4 5 6 7 8 9 10 11 not operable not operable not operable not operable ...

Page 126

43827101th rev.2 126 / oki data confidential 5.3.2.2.1 activation method for self-diagnostic mode (level 1) 1. The system maintenance menu mode is activated when the power is turned on with the menu+ and menu- keys held down simultaneously 2. Press the menu+ or menu- key several times, until "engine...

Page 127

43827101th rev.2 127 / oki data confidential figure 5-1 switch sensor positions rfid antenna m toner sensor c rfid antenna c rfid antenna y rfid antenna k toner sensor m toner sensor y toner sensor k fuser unit thermistor upper fuser unit thermistor upper, compensation exit sensor duplex print inlet...

Page 128

43827101th rev.2 128 / oki data confidential table 5-3 switch scan display detail no functionality *1: indication only, without functionality *2: l is indicated when a cover is open. *3: status of 1st cassette is indicated. This function is effective only when a 2nd tray is installed. 12 3 4 no uppe...

Page 129

43827101th rev.2 129 / oki data confidential 5.3.2.4 motor clutch test this self-diagnosis is practiced to test motors and clutches. 1. Activate the self-diagnostic mode (level 1), press and hold down the menu+ or menu- key, until "motor & clutch test" appears in the upper line of the display sectio...

Page 130

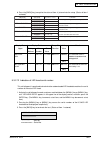

43827101th rev.2 130 / oki data confidential figure 5-2 table 5-4 description of control for unit driving id motor belt motor fuser motor registration motor tray 1 hopping motor front motor color registration (registration) shutter duplex print solenoid (exit) duplex print motor duplex print clutch ...

Page 131

43827101th rev.2 131 / oki data confidential 5.3.2.5 test print this self-diagnosis is practiced to print test patterns built in pu. Other test patterns are stored in the controller. This print cannot be used to check the print quality. To diagnose abnormal images, follow section 7. 1. Activate the ...

Page 132

43827101th rev.2 132 / oki data confidential 4. When the enter key is depressed while "print execute" remains displayed in the lower line of the display section in the operation of item 2., the test print takes place with the set values specified in items 2 and 3. Pressing the cancel key stops the t...

Page 133

43827101th rev.2 133 / oki data confidential pattern 5 pattern 6 pattern 7 pattern 3 pattern 4 note! If the solid print (pattern 7) available among the local print functions is conducted with 100% of each color, offset will take place. To prevent this offset, it will be necessary to make the print s...

Page 134

43827101th rev.2 134 / oki data confidential • when print is executed, the following message is displayed: p=*** w=*** t=*** u=***[###] h=*** %l=***[###] kr=*.** yr=*.** mr=*.** cr=*.** ktr=*.** ytr=*.** mtr=*.** ctr=*.** etmp=*** utmp=*** reg=**** ext=*** p: number of test-print pages (unit: sheets...

Page 135

43827101th rev.2 135 / oki data confidential belt=**** frm[***](xxx) db:k**y**m**c** tr1:k**y**m**c** tr2:k**y**m**c** belt: constant speed timer value of belt motor (i/o set value) [unit: hex] frm : [***] = ad value of frame thermistor reading [unit: hex] (xxx) = frame temperature [unit: ˚c] • pres...

Page 136

43827101th rev.2 136 / oki data confidential 5.3.2.6 color registration adjustment test this self-diagnosis is practiced to conduct testing on the color registration function of the printer and to locate the cause of color drift. Restore the normal operation of the printer by following the troublesh...

Page 137

43827101th rev.2 137 / oki data confidential display function reg adj execute execution of color registration adjustment reg adj result viewing of the color registration adjustment result blt reflect test execution of the judgment of good or bad color registration adjustment belt reflectivity blt re...

Page 138

43827101th rev.2 138 / oki data confidential > the same as the key operation of item 2 in the execution of dens adj execute. > indication only, without functionality. > 1 automatic setting of a density sensor sensitivity correction value is made. ([ready] light blinking) 2 when the test ends, the te...

Page 139

43827101th rev.2 139 / oki data confidential 5.3.2.8 indication of consumable part counters this self-diagnosis is practiced to indicate the consumed states of consumable parts. 1. Activate the normal self-diagnostic mode, and press and hold down the [menu+] key or [menu- ] key, until "consumable st...

Page 140

43827101th rev.2 140 / oki data confidential 5.3.2.9 indication of printed page counters this self-diagnosis is practiced to indicate the current number of printed pages of the printer. 1. Activate the normal self-diagnostic mode, and press and hold down the [menu+] key or [menu- ] key, until "print...

Page 141

43827101th rev.2 141 / oki data confidential 5.3.2.11 setup of self-diagnostic function this self-diagnosis is practiced to enable/disable the error detections of the different types of sensors. The error detections can be disabled or enabled temporarily for troubleshooting purposes. However, this f...

Page 142

43827101th rev.2 142 / oki data confidential 6. Press the [back] key (except for the status of item 4.) to terminate the setup. (status of item 1 restored) k ** ** ** **** xxxxxxxxxxxxx ** ** ** **** : rev no. Xxxxxxxxxxxxx : serial no. Indication toner sensor belt unit check id unit check reg adjus...

Page 143

43827101th rev.2 143 / oki data confidential 5.3.2.13 details of panel indications display initializing menu resetting ram check **************** wait a moment network initial flash check flash format checking file system erasing disk nnn% the controller side is initializing. Indicates that eeprom o...

Page 144

43827101th rev.2 144 / oki data confidential description level ready led attention led lcd (english) ( ■ ■ means no display in upper line) checking sectors nnn% program update mode wait a moment data receive wait a moment data received ok check data rec data error wait a moment data writing power of...

Page 145

43827101th rev.2 145 / oki data confidential description level ready led attention led lcd (english) ( ■ ■ means no display in upper line) communication error status mode online offline file accessing data arrive processing data printing print demo page print font print menu map print file list prin...

Page 146

43827101th rev.2 146 / oki data confidential description level ready led attention led lcd (english) ( ■ ■ means no display in upper line) ■ ■ copy kkk/lll verifying job canceling job canceling job (jam) canceling job canceling job (buffer full) c m y k ■ ■ adjusting temp ■ ■ optimizing temp ■ ■ pow...

Page 147

43827101th rev.2 147 / oki data confidential description level ready led attention led lcd (english) ( ■ ■ means no display in upper line) pu downloading ■ ■ order %color% toner ■ ■ %color% waste toner full. Replace toner ■ ■ non oem %color% toner detected ■ ■ %color% toner regional mismatch varies ...

Page 148

43827101th rev.2 148 / oki data confidential description level ready led attention led lcd (english) ( ■ ■ means no display in upper line) ■ ■ non genuine %color% toner ■ ■ ps3 emul error ■ ■ order %color% image drum ■ ■ order fuser ■ ■ order belt ■ ■ fuser life ■ ■ belt life varies blink varies var...

Page 149

43827101th rev.2 149 / oki data confidential description level ready led attention led lcd (english) ( ■ ■ means no display in upper line) ■ ■ %color% toner empty ■ ■ %color% toner not installed ■ ■ %color% drum life ■ ■ belt reflex error ■ ■ density shutter error2 ■ ■ density shutter error1 ■ ■ den...

Page 150

43827101th rev.2 150 / oki data confidential description level ready led attention led lcd (english) ( ■ ■ means no display in upper line) ■ ■ density black calibration error ■ ■ density black sensor error sensor calibration error ■ ■ %color% image drum smear error ■ ■ %color% low density error ■ ■ ...

Page 151

43827101th rev.2 151 / oki data confidential description level ready led attention led lcd (english) ( ■ ■ means no display in upper line) ■ ■ registration sensor error n ■ ■ %color% head data error ■ ■ %tray% empty ■ ■ hard disk full ■ ■ disk write disabled press online sw collate fail press online...

Page 152

43827101th rev.2 152 / oki data confidential description level ready led attention led lcd (english) ( ■ ■ means no display in upper line) press online sw log buffer full. Job rejected ■ ■ file erasing ■ ■ deleting encrypted job ■ ■ erased data full press online sw expired secure job press online sw...

Page 153

43827101th rev.2 153 / oki data confidential description level ready led attention led lcd (english) ( ■ ■ means no display in upper line) invalid data was received. Press the on-line switch and eliminate the warning. Displayed when unsupported pdl command is received or a spool command is received ...

Page 154

43827101th rev.2 154 / oki data confidential 5.3.3 various types of print on the individual printer equipped with controller menu map printing information on the program versions, controller configuration, network settings, etc., is printed. Operation: 1 press the menu+ key several times to cause “i...

Page 155

43827101th rev.2 155 / oki data confidential 5.4 setup after replacement of parts this subsection describes the necessary adjustments to be made when parts have been replaced. Replaced part adjustment led head not necessary image drum cartridge not necessary (y, m, c, k) fuser unit not necessary bel...

Page 156

43827101th rev.2 156 / oki data confidential • to specify a pu serial number, enter a 11-digit number prefixed with "0" (single-byte zero). (notice that, when the pu serial number is read, it is a 10-digit number.) on the "pu serial number setup" screen, enter the 11-digit number resulting from pref...

Page 157

43827101th rev.2 157 / oki data confidential item description count description fuser unit fuser unit life count number of printed pages since the installation of a new fuser unit, converted into a number of a4-size sheets. Belt unit belt unit life count number of printed pages since the installatio...

Page 158

43827101th rev.2 158 / oki data confidential 5.4.2.1 replacement of eeprom after replacement of pdl cu pcb (c6150/c6050) the eeprom of the pdl cu pcb is installed in the ic socket. Replace the eeprom in the following manner: 1. Remove the eeprom and mac address sticker label attached to the new pcb....

Page 159

43827101th rev.2 159 / oki data confidential figure of serial no. Label image (labeled in uk factory) • to specify the cu serial number, enter a number within 12 digits (notice that, when the cu serial number is read, it is also a number within 12 digits.) enter 12-digit serial number. Enter "4ael40...

Page 160

43827101th rev.2 160 / oki data confidential 5.5 about the manual setup of print density adjustment the printer is shipped out of the factory with its automatic density correction mode set to "auto". However, if that mode is changed to "manual" by the user, the density setting may be displaced with ...

Page 161

Oki data confidential 43827101th rev.2 161 / 6. Periodical maintenance 6.1 recommended replacement parts oki data recommends that heavy users only replace the following parts. (if those parts are not replaced, the print quality is not guaranteed, and malfunctions may even result.) parts are replaced...

Page 162

Oki data confidential 43827101th rev.2 162 / cleaning the led head execute this cleaning if an output shows a light fuzzy print or white stripes, or characters are blurred. (1) turn off the power of the printer. O i (2) open the top cover by pressing the open button. The fuser unit is extremely hot....

Page 163

Oki data confidential 43827101th rev.2 163 / 6.4 cleaning of pickup rollers if vertical stripes are observed in the print face, clean the pickup rollers. Note! For cleaning, use a soft piece of cloth to avoid scratching the roller surface. Cleaning the feed rollers and pad execute this cleaning if [...

Page 164

Oki data confidential 43827101th rev.2 164 / 6.5 internal cleaning of printer cleaning the interior of the printer. Depending on the print pattern, toner may adhere to the metal shaft located between the fuser unit and the cyan image drum cartridge. Execute this cleaning if the metal shaft has an ad...

Page 165

Oki data confidential 43827101th rev.2 165 / (4) take out the fuser unit. The fuser unit is extremely hot. Be careful not to touch it. If the fuser unit is hot, do not try yourself to clear paper but wait until the fuser unit becomes cool. Personal injuries may occur. 1. Raise the fuser unit lock le...

Page 166

Oki data confidential 43827101th rev.2 166 / 7. Troubleshooting procedures 7.1 precautions prior to repair (1) confirm the basic check items indicated in the user's manual. (2) through hearing from the user, obtain information, as far in detail as possible, on the situation concerning the fault. (3)...

Page 167

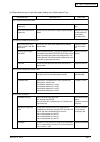

Oki data confidential 43827101th rev.2 167 / 7.5.1 lcd message list when the printer detects an irrecoverable error, it displays a service call error in the lcd like the one given below: service call nnn: error note! "nnn" is an error code. When a service call error is issued, an error code is displ...

Page 168

Oki data confidential 43827101th rev.2 168 / table 7-1-1 operator alarm (2/9) description code nnn display on operator panel ready led attention led load %media_size%/ %media_type% and press online switch %errcode%:%tray% size mismatch load %media_size%/ %media_type% and press online switch %errcode...

Page 169

Oki data confidential 43827101th rev.2 169 / description code nnn display on operator panel ready led attention led table 7-1-1 operator alarm (3/9) load %media_size% %errcode%:%tray% empty load %media_size% and press online switch %errcode%:mp tray empty install paper cassette %errcode%:tray1 open ...

Page 170

Oki data confidential 43827101th rev.2 170 / description code nnn display on operator panel ready led attention led table 7-1-1 operator alarm (4/9) protec paper %errcode%:error trust paper %errcode%:error trust paper %errcode%:error trust paper %errcode%:error protec paper %errcode%:error protec pa...

Page 171

Oki data confidential 43827101th rev.2 171 / description code nnn display on operator panel ready led attention led table 7-1-1 operator alarm (5/9) replace toner %errcode%:%color% toner regional mismatch replace toner %errcode%:incompatible %color% toner replace toner %errcode%:incompatible %color%...

Page 172

Oki data confidential 43827101th rev.2 172 / description code nnn display on operator panel ready led attention led table 7-1-1 operator alarm (6/9) install toner %errcode%:%color% toner missing check toner cartridge %errcode%:%color% toner sensor error open front cover %errcode%:paper size error ch...

Page 173

Oki data confidential 43827101th rev.2 173 / description code nnn display on operator panel ready led attention led table 7-1-1 operator alarm (7/9) install duplex unit %errcode%:duplex unit open replace image drum %errcode%:%color% drum life replace image drum %errcode%:%color% drum life replace fu...

Page 174

Oki data confidential 43827101th rev.2 174 / description code nnn display on operator panel ready led attention led table 7-1-1 operator alarm (8/9) check belt %errcode%:belt missing power off and wait for a while %errcode%:motor overheat close cover %errcode%:cover open close cover %errcode%:duplex...

Page 175

Oki data confidential 43827101th rev.2 175 / description code nnn display on operator panel ready led attention led shutting down shutdown please pow off shutdown comp power off and wait for a while %errcode%:condensing error power off/on %errcode%:fatal error service call %errcode%:fatal error serv...

Page 176

Oki data confidential 43827101th rev.2 176 / table 7-1-2 service call error (1/7) service call 001:error power off/on 002:error ~ 005:error 006:error 007:error service 020:error service call 025:error service call 030:error service call 031:error service call 036:error service call 040:error service...

Page 177

Oki data confidential 43827101th rev.2 177 / table 7-1-2 service call error (2/7) error description message cause solution service call 042:error ~ 043:error 045:error power off/on 052:error power off/on 070:error power off/on 072:error xx power off/on 073:error xxxxxxxx power off/on 074:error xxxxx...

Page 178

Oki data confidential 43827101th rev.2 178 / table 7-1-2 service call error (3/7) service call 104:error service call 106:error service call 111:error service call 112:error service call 120: error service call 121:error service call 122:error service call 123:error service call 124:error power off/...

Page 179

Oki data confidential 43827101th rev.2 179 / table 7-1-2 service call error (4/7) service call 142:error service call 150:error ~ 153:error service call 154:error service call 155:error service call 160:error ~ 163:error service call 167:error service call 168:error service call 169:error is id unit...

Page 180

Oki data confidential 43827101th rev.2 180 / table 7-1-2 service call error (5/7) service call 170:error 171:error service call 172:error 173:error service call 174:error service call 175:error service call 176:error 177:error service call 181:error 182:error power off/on 190:error service call 200:...

Page 181

Oki data confidential 43827101th rev.2 181 / table 7-1-2 service call error (6/7) service call 220:error service call 230:error service call 231:error service call 241:error service call 242:error service call 250:error service call 251:error power off/on 901:error 902:error take off the hdd or repl...

Page 182

Oki data confidential 43827101th rev.2 182 / error description message cause solution connect cable set properly again. Turn power on again. Replace belt thermistor and leave aside for 30 min. Then turn power on again. Check to see if the duplex is properly installed. Check to see if the fan is prop...

Page 183

Oki data confidential 43827101th rev.2 183 / 7.5.2 preparing for troubleshooting (1)lcd display malfunction .......................................................................................... 183 (1-1)nothing is displayed in lcd ...................................................................

Page 184

Oki data confidential 43827101th rev.2 184 / note! When the pu pcb is replaced, first read the data of the eeprom chip of the old pcb, and then, copy it to the new pcb after the replacement. (see 5.4.1 precautions on the replacement of engine control pcb). (14)led head is not recognized(error 131,13...

Page 185

Oki data confidential 43827101th rev.2 185 / 7.5.2.(1) lcd display malfunction (1-1)nothing is displayed in lcd f5 (fuse) of pu pcb connection between low- voltage power supply unit and pu pcb cord assy interconnecting the low-voltage power supply unit and the pu pcb connection between pu pcb and op...

Page 186

Oki data confidential 43827101th rev.2 186 / (1-2)the first line is black display in lcd connection between low- voltage power supply unit and pu pcb cord assy interconnecting the low-voltage power supply unit and the pu pcb connection between pu pcb and operator panel pcb ffc interconnecting the pu...

Page 187

Oki data confidential 43827101th rev.2 187 / (1-3)please wait (the display changes to “communication error” if you leave them as they are) connected state between pu pcb and cu pcb check to see if the option ram dimm/hdd is used in the cu pcb. Upgrading of pu firmware version confirmation tasks chec...

Page 188

Oki data confidential 43827101th rev.2 188 / (1-5)“ram check” or “initializing” are displayed 7.5.2.(2) irregular operation of the device after turning on the power (2-1)no operation operator panel indications check to see if the option ram dimm/hdd is used in the cu pcb. Confirmation tasks the indi...

Page 189

Oki data confidential 43827101th rev.2 189 / (2-2)abnormal sound operating state of motors state of motor cords operating state of motors operating state of motors installed state of consumables laying of peripheral cords around each cooling fan check the installed state of the sill plates under the...

Page 190

Oki data confidential 43827101th rev.2 190 / (2-3)abnormal odor fuser unit low voltage power supply unit life count of fuser unit check for foreign matter in fuser unit confirmation tasks take out the fuser unit, and check for the smell. Take out the lower-voltage power supply unit, and check for th...

Page 191

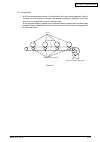

Oki data confidential 43827101th rev.2 191 / (3) error number and jam location at paper jam diagram of jam location j7(382:exit) j8(383:duplex entry) j1(370:duplex reversal) dup-in sensor dup-b sensor 2nd-in sensor in1 sensor in2 sensor wr sensor dup-f sensor exit sensor j4(373:multifeed in duplex u...

Page 192

Oki data confidential 43827101th rev.2 192 / jam release method 1 removing the jammed paper front cover section (codes: 372, 380, 390, 391, 400) open the front cover, and if the leading end or trailing end of the jammed paper is visible, pull out the paper slowly. If code 400 is issued, the paper ma...

Page 193

Oki data confidential 43827101th rev.2 193 / jam release method 2 fuser unit section (codes: 381, 382, 383,385) the fuser unit can be very hot. Be careful not to touch it. If the unit remains hot, do not hasten to work, but wait, until after the unit has cooled down a little, and then remove the pap...

Page 194

Oki data confidential 43827101th rev.2 194 / (4) hold the fuser unit again by the handle and put it gently back in the printer. (5) push the lock levers (2, blue) of the fuser unit toward the rear, and fasten the unit note! After a jammed paper has been removed from the fuser unit section, unfixed t...

Page 195

Oki data confidential 43827101th rev.2 195 / (2) take out the image drum cartridges (4), and place them on a flat table. (3) cover the image drum cartridges thus taken out with a black sheet of paper. Note! • the image drums (green tubular parts) are extremely vulnerable. Use good caution in handlin...

Page 196

Oki data confidential 43827101th rev.2 196 / when neither the leading end nor the trailing end is visible first slide the jammed paper into the direction of the arrow, and then, pull it out slowly. Fuser unit paper when the trailing end of the paper is visible while pushing the lever of the fuser un...

Page 197

Oki data confidential 43827101th rev.2 197 / jam release method 3 two-sided print unit section (optional)(codes: 370, 371, 373) (1) open the two-sided print unit cover by pushing the jam releasing lever of the two-sided print unit section. Jam release lever duplex unit cover (2) take out the jammed ...

Page 198

Oki data confidential 43827101th rev.2 198 / 7.5.2.(3) paper feed jam(error 391:1st tray) (3-1)paper feed jam occurs right after turning on the power (1st tray) paper running route in front unit check the sensor levers of inlet sensors 1 and 2. Check the state of sensor signal detection. Check the o...

Page 199

Oki data confidential 43827101th rev.2 199 / feed motor feed motor driver feed motor drive cord feed motor drive cord feed motor feed solenoid feed solenoid feed solenoid cord feed solenoid cord (3-2-4) check of connections (3-2-3) check of operating state of motors confirmation items confirmation t...

Page 200

Oki data confidential 43827101th rev.2 200 / 7.5.2.(4) paper feed jam (error 390:multi-purpose tray) (4-1)paper feed jam occurs right after turning on the power (multi-purpose tray) paper running route in front unit check the sensor levers of inlet sensor 2 and wr sensor. Check the state of sensor s...

Page 201

Oki data confidential 43827101th rev.2 201 / (4-2)paper feed jam occurs right after paper feeding starts (multi-purpose tray) paper running route in multi- purpose tray sheet receive (reed) of multi- purpose tray check sensor levers at the entrance sensor 2 and wr sensor lever planetary gears for pa...

Page 202

Oki data confidential 43827101th rev.2 202 / 7.5.2.(5) paper path jam(error 381) (5-1)paper path jam occurs right after turning on the power paper running route in front unit check sensor levers of wr sensor check the state of sensor signal detection. Check the output level of the wr sensor. Check t...

Page 203

Oki data confidential 43827101th rev.2 203 / (5-2)paper path jam occurs right after feeding paper paper running route on the belt check the sensor lever of the wr sensor feed motor, belt motor, id motor feed motor driver, id up- motor driver, and belt motor driver confirmation tasks remove the id un...

Page 204

Oki data confidential 43827101th rev.2 204 / feed motor drive cord, id motor drive cord, belt motor, id-up motor drive cord, fuser drive cord feed motor drive cord, id motor drive cord, belt motor, id-up motor drive cord feed motor, belt motor, id up- motor confirmation tasks check the connected sta...

Page 205

Oki data confidential 43827101th rev.2 205 / (5-3)paper path jam occurs in a path route feed motor, belt motor, id motor, id up/down-motor feed motor driver, belt motor driver, id up-motor driver confirmation tasks conduct the motor and clutch test of the self-diagnostic mode, and check to see if th...

Page 206

Oki data confidential 43827101th rev.2 206 / (5-4)paper path jam occurs right after reaching the fuser unit fuser motor heat roller detection temperature fuser unit confirmation tasks conduct the motor and clutch test of the self-diagnostic mode, and check to see if the fuser motor operates normally...

Page 207

Oki data confidential 43827101th rev.2 207 / 7.5.2.(6) paper exit jam(error 382) (6-1)paper exit jam occurs right after turning on the power paper running route in delivery section check the sensor lever of the delivery sensor check the state of sensor signal detection. Check the output level of the...

Page 208

Oki data confidential 43827101th rev.2 208 / (6-2)paper exit jam occurs right after feeding paper face-up stacker cover duplex pull-in gate rear panel running route in delivery section sensor lever of exit sensor fuser motor confirmation tasks check to see if the cover is completely open or closed. ...

Page 209

Oki data confidential 43827101th rev.2 209 / fuser motor drive cord fuser motor confirmation tasks check the connected state of the cord. Check visually for any incomplete connection or skew insertion of the dcheat connector of the pu pcb or any assembling problem of the cord. Action at ng correct t...

Page 210

Oki data confidential 43827101th rev.2 210 / 7.5.2.(7) duplex print jam(error 370,371,372,373,383) (7-1)duplex print jam occurs right after turning on the power paper running route in duplex unit check the sensor levers of the sensors of duplex. Check the state of sensor signal detection. Confirmati...

Page 211

Oki data confidential 43827101th rev.2 211 / (7-3)duplex print jam occurs in reverse of the paper dup-in sensor lever dup-in sensor duplex motor confirmation tasks open the rear cover and touch the dup-in sensor lever by hand. Check to see if its motion is stiff. Use the switch scan function of the ...

Page 212

Oki data confidential 43827101th rev.2 212 / 7.5.2.(8) paper size error (error 400) (8-1)paper jam occurs when the end of paper is near in1 sensor. Multiple feed of paper paper size inlet sensor 1 confirmation tasks open the front cover, and check to see if multiple sheets are fed through. Check to ...

Page 213

Oki data confidential 43827101th rev.2 213 / 7.5.2.(9) id unit up-down error(service call 140-143) (9-1)an error occurs in the operation of id unit up load in installing/removing of id unit greasing of right and left up- down link levers assembled state of right and left up/down link levers assemble...

Page 214

Oki data confidential 43827101th rev.2 214 / (9-2)an error occurs in the operation of id unit down load in installing/removing of id unit greasing of right and left up- down link levers assembled state of right and left up/down link levers at least the cyan id is installed. (9-2-1) check of load in ...

Page 215

Oki data confidential 43827101th rev.2 215 / 7.5.2.(10) fuser unit error(error 170-177) (10-1)an error occurs right after turning on the power upper thermistor, lower thermistor, frame thermistor installed state of fuser unit confirmation tasks check to see if the thermistors are short-circuited or ...

Page 216

Oki data confidential 43827101th rev.2 216 / 7.5.2.(11) motor fan error(error 120,127,051) (11-1)duplex fan does not rotate in duplex printing (11-2)every fan in the machine does not rotate connection and laying of duplex fan cord 24v fuse f501 of duplex pcb 24v supply of duplex pcb confirmation ite...

Page 217

Oki data confidential 43827101th rev.2 217 / 7.5.2.(12) print speed is slow (low performance) (12-1)print speed decreases up to 2ppm environmental temperature of the location where the printer is installed confirmation tasks check to see if the printer is located in such a small room that the enviro...

Page 218

Oki data confidential 43827101th rev.2 218 / (13-2)2nd tray unit is not recognized 7.5.2.(14) led head is not recognized(error 131,132,133,134) (14-1)service call 131-134(led head missing) 2nd tray unit connections from pu pcb to 2nd tray pcb correct the connections. Square connector connecting the ...

Page 219

Oki data confidential 43827101th rev.2 219 / 7.5.2.(15) toner cartridge is not recognized(error 540,541,542,543) (15-1)errors caused by consumables id units and toner cartridges confirmation tasks are the id units installed in the right positions? Check to see if the lock levers of the toner cartrid...

Page 220

Oki data confidential 43827101th rev.2 220 / (15-3)errors caused by machine defects id unit id motor confirmation tasks is a heavy load imposed on the id unit, for example, because the waste toner belt was ruptured? Use the switch scan function of the self-diagnostic mode to check to see if each id ...

Page 221

Oki data confidential 43827101th rev.2 221 / 7.5.2.(17) dew condensation errors (error 123) (17-1)dew condensation connection between pu pcb and high-voltage pcb ffc interconnecting the pu pcb and the high-voltage pcb heavy variation of environmental condition confirmation tasks check to see if the ...

Page 222

Oki data confidential 43827101th rev.2 222 / figure 7.2 light or faded image on whole page a vertical black belt or line d dirty background b defective image of regular interval e blank c vertical white belt or line f 7.5.3 image problem troubleshooting (1) color is totally pale (fig.7.2 a ) ..........

Page 223

Oki data confidential 43827101th rev.2 223 / 7.5.3.(1) color is totally pale (fig.7.2 a ) (1-1)color is pale remaining quantity of toner tape at the opening of toner cartridge led head lens installed state of led head type of medium id unit terminal lowest position of id unit (deficient transfer) co...

Page 224

Oki data confidential 43827101th rev.2 224 / 7.5.3.(2) background is dirty (fig.7.2 b ) (2-1)background is dirty (partly) (2-2)background is dirty (totally) type of medium id unit terminal confirmation tasks check to see if an especially thin medium is used for printing. Ensure visually that the hig...

Page 225

Oki data confidential 43827101th rev.2 225 / 7.5.3.(3) blank print (fig.7.2 c ) (3-1)blank on the whole page remaining quantity of toner led head connected state of led head drum shaft id unit terminal confirmation items (3-1-1) state of toner (3-1-2) state of exposure (3-1-3) high-voltage terminal ...

Page 226

Oki data confidential 43827101th rev.2 226 / 7.5.3.(4) vertical lines are printed (4-1)thin vertical lines (with color) (see fig.7.2 d ) filming of id unit confirmation tasks check to see if the print was conducted in the absence of toner. Action at ng replace the toner cartridge with a new one. If ...

Page 227

Oki data confidential 43827101th rev.2 227 / 7.5.3.(5) cyclic print trouble (refer to fig.7.2 e ) (5-1)vertical cyclic print trouble image drum development roller toner supply roller charging roller roller on the fuser unit transfer roller (black) transfer roller (color) confirmation items (5-1-1) p...

Page 228

Oki data confidential 43827101th rev.2 228 / 7.5.3.(6) color registration is wide. (6-1)"in adjusting color registration" is shown only a short time color registration time (approx. 50 sec if normal) remaining quantity of toner dirty sensor defects of the shutter operation confirmation tasks execute...

Page 229

Oki data confidential 43827101th rev.2 229 / figure 7.3 ground charging roller developing roller toner supply roller 7.5.3.(7) solid black print (7-1) solid black on a full page ch terminal ch terminal id unit terminal ch output confirmation tasks check visually from above to see if the terminal ext...

Page 230

Oki data confidential 43827101th rev.2 230 / 7.5.4 actions after forced initialization of hdd/flash this subsection explains the actions to be taken after a troubled hdd or flash has been subjected to forced initialization. 1) action after forced initialization of hdd if the hdd is forcibly initiali...

Page 231

Oki data confidential 43827101th rev.2 231 / 7.5.5 network troubleshooting (1)cannot print from utility. (1) check of link light check to see if network information can be printed correctly. Check the ip address, sub- net mask and gateway address. Check to see if a ping command can be sent from the ...

Page 232

Oki data confidential 43827101th rev.2 232 / 7.6 check of fuses if any of the following errors is issued, check the corresponding fuse on the cu pcb, pu pcb or high-voltage power supply pcb. (see table 7-6.) table 7-6 fuse error fuse name error description insert point f1 f2 f3 f4 f5 ip901 ip902 f50...

Page 233

Oki data confidential 43827101th rev.2 233 / 8. Connection diagrams 8.1 check of resistance values between pin 1 and pin 2: 3.4 Ω between pin 3 and pin 4: 3.4 Ω or between pin 1 and pin 2: 5 Ω between pin 3 and pin 4: 5 Ω both ends of ip1: 1 Ω or less transport belt motor id motor m 1 2 3 4 unit cir...

Page 234

Oki data confidential 43827101th rev.2 234 / between pin 1 and pin 2:6.1 Ω between pin 3 and pin 4:6.1 Ω or between pin 1 and pin 2: 8.5 Ω between pin 3 and pin 4: 8.5 Ω id up/down motor unit circuit diagram & configuration part schematic resistance value fuser unit motor ip1 both ends of ip1: 1 Ω o...

Page 235

Oki data confidential 43827101th rev.2 235 / between pin 1 and pin 2: 3.4 Ω between pin 3 and pin 4: 3.4 Ω or between pin 1 and pin 2: 5 Ω between pin 3 and pin 4: 5 Ω between pin 1 and pin 2: 2.4 Ω between pin 3 and pin 4: 2.4 Ω feed motor between pin 1 and pin 2: 3.4 Ω between pin 3 and pin 4: 3.4...

Page 236

Oki data confidential 43827101th rev.2 236 / unit circuit diagram & configuration part schematic resistance value between pin a -1 and pin a -6: several ohms to several tens of ohms between pin b -1 and pin b -6: several ohms to several tens of ohms between pin b -4 and pin b -5: approx. 590kohms to...

Page 237

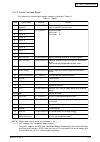

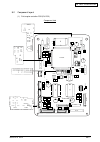

Oki data confidential 43827101th rev.2 237 / 8.2 component layout (1) print engine controller pcb (pu pcb) component side 91 12 1 q6 q3 d1 ic7 ic6 fm1 armored ic5 cp4 ic2 c13 r54 r56 c11 c12 c9 c10 c8 r41 r39 c18 r82 r81 c16 c17 c14 c15 r52 r53 r50 r51 r48 r49 r46 r47 r44 r45 r9 r86 c6 rm1 r23 r24 r...

Page 238

Oki data confidential 43827101th rev.2 238 / solder side r593 c554 c546 q509 q510 c556 r550 r543 r539 c531 c530 r542 r541 r540 r528 r527 c514 c564 r616 r613 r615 r614 r513 c563 c561 c562 c504 c506 rm504 c519 c516 r526 r529 c540 c538 c539 r544 c532 r551 fet504 q506 q505 r558 r549 r582 r581 r592 r591 ...

Page 239

Oki data confidential 43827101th rev.2 239 / (2)-1 main controller (pdl cu pcb)(c6150/c6050) component side c161 c72 r98 r99 cpuio c76 c80 c81 c82 c83 r52 r60 r61 c92 c96 c95 dbf1 chead 1 28 1 1 4 2 2 1 7 8 3 28 1 28 1 28 dbf2 dbf3 dbf4 dbf5 dbf6 dbf7 mhead yhead khead dbf8 usb lan nicsw c101 r34 c1...

Page 240

Oki data confidential 43827101th rev.2 240 / solder side c642 c643 sdram1 sdram2 sdram3 sdram4 c775 c776 c777 c720 c719 c644 c835 c836 c833 igtd501 c841 c760 c832 c837 c834 r778 r776 r773 r747 r746 c615 c611 c633 c591 f501 r508 r507 r522 r516 r515 ic502 c514 c523 c534 r548 c588 r542 r547 r546 r541 c...

Page 241

Oki data confidential 43827101th rev.2 241 / (2)-2 main controller pcb(gdi cu pcb)(c5650) component side c1 1 c18 c53 128 1 65 c63 c79 c75 khead yhead mhead chead 64 39 38 103 102 c83 c58 ic2 reg3 r1 r84 r90 c22 c21 c20 c19 cn1 1 2 9 10 r32 r30 r41 c80 tes t alm c29 c30 cp3 ic4 ic1 1 1 10 10 22 22 a...

Page 242

Oki data confidential 43827101th rev.2 242 / solder side c595 c594 c593 c592 r644 r643 r640 r645 r646 rm518 rm517 rm516 rm515 ic502 ic501 r167 r611 r587 r571 rm504 rm503 rm502 rm501 r650 r649 c589 c588 r641 r638 r619 r618 c581 r614 c553 c548 c545 c544 c572 c576 c562 c559 c569 c558 c556 c555 c550 c55...

Page 243

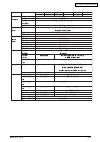

Oki data confidential 43827101th rev.2 243 / (3) junction pcb component side solder side fuser s1 c1 exit c2 lcr j1 cp1 dens rcr puif 8 1 4 1 24 1 5 1 4 1 3 1 bfuse bfucut.

Page 244

Oki data confidential 43827101th rev.2 244 / (4) duplex print control pcb component side solder side j24 j25 j20 sns03 sns12 flash cp2 osc main1 j11 j8 j9 j3 j26 j2 j4 j12 j13 j17 j21 j18 j22 j19 j1 sns4 j23 j6 j7 j10 j28 j5 d3 d4 d5 j30 j35 j34 cp1 cl1 cl2 motor j16 j15 c1 c2 j33 j32 j31 j27 j29 d6...

Page 245

Oki data confidential 43827101th rev.2 245 / (5) second tray control pcb component side solder side j24 j25 j20 sns03 sns12 flash cp2 osc main1 j11 13 1 j8 j3 j26 j2 j4 j12 j13 j17 j21 j18 j19 j1 j6 j7 j10 j28 j5 j30 j35 j34 cp1 cl1 motor j16 j15 c1 c2 j33 j32 j31 j27 j29 d2 1 2 14 6 1 6 1 7 1 j512 ...

Page 246

Oki data confidential 43827101th rev.2 246 / (6)-1 operator panel pcb component side solder side (7) toner-low sensor pcb s1 s6 d2 d1 s7 j2 s5 ic1 s8 sw4 sw3 s3 sw2 sw1 j13 s2 sw6 sw5 j8 j5 j6 j7 j4 s19 s20 j14 s24 j11 j15 cn cp1 s10 s11 1 9 r515 r514 r502 r501 r504 r505 r506 r510 r508 c504 c503 c50...

Page 247

Oki data confidential 43827101th rev.2 247 / (8) inlet sensor pcb (front sensor pcb) (9) color adjustment sensor pcb (10) high-voltage power supply pcb (11) low-voltage power supply pcb wr in2 in 1 cn r1 r2 5 1 sns cn c e a k cn4 cn2 cn5 cn3 cn1 tr-k tr-m tr-y tr-c to pu pcb power connector notes! C...

Page 248

Oki data confidential 43827101th rev.2 248 / (12) id unit (13) transfer belt unit fuse contacts id unit id unit (for consumables) contacts toner-low sensor pcb fuse transfer belt unit (for consumables) transfer belt unit driver junction pcb contacts contacts fuse.

Page 249

Oki data confidential 43827101th rev.2 249 / 8.3 f/w version 8.3.1 rom management number 8.3.2 f/w version display in pdl cu pcb rom revision 1 2 date 2007.07.13 2007.08.08 dco no. - sp6-1344 revision n0.61 n1.01 file rev. 1 2 nic f/w 08.51 08.51 web page w8.51 w8.51 file rev. 1 1 revision l01.02 l0...