- DL manuals

- Oki

- Printer

- C810

- Maintenance Manual

Oki C810 Maintenance Manual

Summary of C810

Page 1

C810/c830 maintenance manual 0 609 a.

Page 2

Copyright information copyright © 2009 by oki data. All rights reserved disclaimer every effort has been made to ensure that the information in this document is complete, accurate, and up-to- date. The manufacturer assumes no responsibility for the results of errors beyond its control. The manufactu...

Page 3

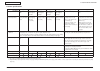

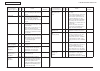

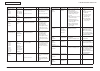

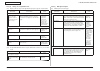

44015503th rev. 1 2 / oki data confidential document revision history rev. No. Date changed items person in charge no. Page description of change 1 2009-02-25 issue md11 wakana rev. No. Date changed items person in charge no. Page description of change document revision history.

Page 4

44015503th rev. 1 3 / oki data confidential this manual explains the maintenance methods for the c830. The manual has been prepared for use by the maintenance personnel. For operating methods of the c830, refer to the corresponding user’s manual. Note! • the contents of this manual are subject to ch...

Page 5

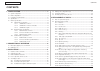

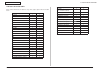

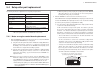

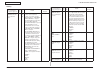

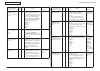

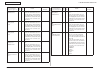

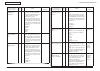

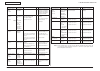

44015503th rev. 1 4 / oki data confidential contents contents 1. Configuration ..................................................................... 7 1.1 system configuration ......................................................................................... 8 1.2 printer configuration .........

Page 6

44015503th rev. 1 5 / oki data confidential contents 4.2.23 paper feed rollers (tray 2/3 (option)) ................................................... 100 4.2.24 paper feed roller (multi-purpose tray) ................................................. 102 4.3 portions lubricated ........................

Page 7

44015503th rev. 1 6 / oki data confidential contents 7.5.3.(3) white print (refer to figure 7-2 c.) ................................... 214 7.5.3.(4) black banding/black streaking in vertical direction ............ 215 7.5.3.(5) cyclic abnormality (refer to figure 7-2 e.) ...................... 215 ...

Page 8: Configuration

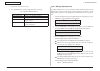

Oki data confidential 1. Configuration 1.1 system configuration ...................................................................8 1.2 printer configuration .....................................................................9 1.3 composition of optional items .......................................

Page 9

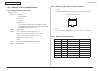

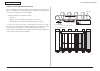

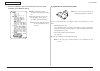

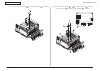

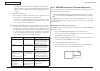

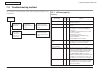

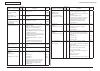

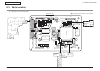

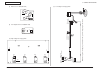

44015503th rev. 1 8 / oki data confidential 1. Configuration environmental humidity 20mhz centronics eep rom cc1 asic cif2 asic hdd lan usb cu board flash rom option ram cu fan cpu paper feed solenoid duplex fan front sensor in sensor cover- open sensor rear sensor bottom sensor hopping sensor p.E s...

Page 10

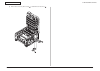

44015503th rev. 1 9 / oki data confidential 1. Configuration 1.2 printer configuration the internal part of the c830 printer is composed of the following sections: • electrophotographic processing section • paper paths • controllers (cu/pu) • operator panel • power supplies (high-voltage power suppl...

Page 11

44015503th rev. 1 10 / oki data confidential 1. Configuration 1.3 composition of optional items the following optional items are available for the c830 printer: (1) additional tray 型名 cab-s1 model name capacity mem256e 256 mb mem512c 512 mb (3) cabinet (4) additional memory (5) internal hard disk me...

Page 12

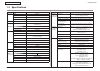

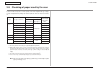

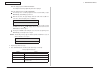

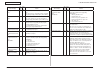

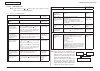

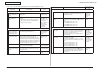

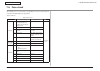

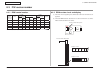

44015503th rev. 1 11 / oki data confidential 1. Configuration 1.4 specifications classification item specification(s) dimension width 485 mm depth 593 mm height 345 mm weight approx. 40 kg line length line length a4 lef print speed engine speed (a4) 30 ppm (color) 32 ppm (mono) print start first pri...

Page 13

44015503th rev. 1 12 / oki data confidential 1. Configuration classification item specification(s) service life transfer belt life 80,000 pages (a4 lef, 3 pages/job), counter automatic reset fuser unit life 100,000 pages (a4), counter automatic reset operation noise operating 54 dba (iso 7779 front)...

Page 14

44015503th rev. 1 13 / oki data confidential 1. Configuration classification item specification(s) option (removable) ram 256/512 mb dimm user-installable 2.5” ide hdd • standard internal hard disk • data protection kit a3 tray configuration 2nd tray and 3rd tray cassette universal (530 sheets) dupl...

Page 15

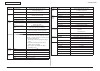

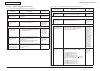

44015503th rev. 1 14 / oki data confidential 1. Configuration 1.5 interface specifications 1.5.1 usb interface specifications 1.5.1.1 usb interface overview (1) basic specifications usb (hi-speed usb supported) (2) transmission mode full speed (max. 12 mbps ± 0.25%) high speed (max. 480 mbps ± 0.05%...

Page 16

44015503th rev. 1 15 / oki data confidential 1. Configuration 1.5.2 network interface specifications 1.5.2.1 network interface overview basic specifications tcp/ip spec. Network layer arp, ip, icmp, ipv6 transport layer tcp, udp application layer lpr, port9100, ftp, http, https, ipp, snmpv1/v3, teln...

Page 17

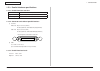

44015503th rev. 1 16 / oki data confidential 1. Configuration 1.5.3 parallel interface specifications 1.5.3.1 parallel interface overview item details supported modes compatible mode, nibble mode, ecp mode data bit length compatible mode: 8 bit, nibble mode: 4 bit, ecp mode: 9 bit 1.5.3.2 connector ...

Page 18: Description Of Operation

Oki data confidential 2. Description of operation 2.1 electrophotographic process mechanism ..................................18 2.2 printing process ..........................................................................21.

Page 19

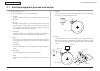

44015503th rev. 1 18 / oki data confidential 2. Description of operation (1) electrophotographic process the electrophotographic process is explained briefly below: 1. Charging a voltage is applied to the ch roller to electrically charge the surface of the opc drum. 2. Exposure the led head radiates...

Page 20

44015503th rev. 1 19 / oki data confidential 2. Description of operation (4) development toner adheres to the electrostatic latent image on the drum surface, thereby turning the electrostatic latent image into a toner image. 1. The sponge roller allows the toner to stick to the development roller. 2...

Page 21

44015503th rev. 1 20 / oki data confidential 2. Description of operation (6) fusing the toner image transferred on the paper is fused on the paper by heat and pressure when the paper passes through the heat roller and backup roller. The heat roller is heated by 800w and 350w internal halogen lamps, ...

Page 22

44015503th rev. 1 21 / oki data confidential 2. Description of operation 2.2 printing process the paper fed from tray 1 or tray 2 is carried by the paper feed roller, the registration roller l, and the transport roller. When the paper is fed from the mpt, it is carried by the mpt paper feed roller a...

Page 23

44015503th rev. 1 22 / oki data confidential 2. Description of operation registration roller u (stop) paper paper registration motor (clockwise) registration motor (counterclockwise) wr sensor wr sensor solenoid lever (solenoid: off) solenoid lever (solenoid: off) hopping gear assy hopping gear assy...

Page 24

44015503th rev. 1 23 / oki data confidential 2. Description of operation (4) up/down-motions of id units 1. The up/down-motions of the id units take place driven by the lift-up motor. 2. Figure 2-6 shows the motions of the different id units when the printer is operated for color print. As the lift-...

Page 25

44015503th rev. 1 24 / oki data confidential 2. Description of operation (5) fuser unit and paper ejection 1. As illustrated in figure 2-8, the fuser unit and the eject roller are driven by the dc motor. As the fuser motor rotates (counterclockwise), the heat roller rotates. This roller fixes toner ...

Page 26

44015503th rev. 1 25 / oki data confidential 2. Description of operation outline of color registration correction the color registration is corrected by reading correction patterns that are printed on the belt with the color registration sensors located inside the sensor shutter under the belt unit....

Page 27

44015503th rev. 1 26 / oki data confidential 2. Description of operation error checking methods and remedial methods the color registration correction test function among the other self-diagnostic functions is employed to check errors. (section 5.3.2.6) remedial methods against different errors • ca...

Page 28

44015503th rev. 1 27 / oki data confidential 2. Description of operation outline of density correction the density is corrected by reading the correction pattern that is printed on the belt with the density sensor located inside the sensor shutter under the belt unit. Automatic start timing of densi...

Page 29

44015503th rev. 1 28 / oki data confidential 2. Description of operation shielding plate toner sensor shutter error checking methods and remedies the density correction test function among the other self-diagnostic functions is employed to check errors. (section 5.3.2.7) remedial methods against dif...

Page 30

44015503th rev. 1 29 / oki data confidential 2. Description of operation counter specifications total page count mpt page count tray 1 page count tray 2 page count tray 3 page count color page count monochrome page count description total number of prints number of print media hopped from mpt number...

Page 31

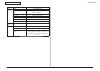

44015503th rev. 1 30 / oki data confidential 2. Description of operation a4/letter conversion table each count should increase, in relation to every sheet of paper, by the values in the table below. Paper size simplex duplex letter 1 2 executive 1 2 legal14 1 2 legal13.5 1 2 legal13 1 2 tabloidextra...

Page 32: Installation

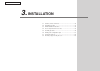

Oki data confidential 3. Installation 3.1 cautions, and do’s and don’ts ....................................................32 3.2 unpacking procedure ................................................................33 3.3 printer installation instructions ...............................................

Page 33

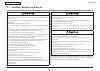

44015503th rev. 1 32 / oki data confidential 3. Installation 3.1 cautions, and do’s and don’ts • do not install the printer in any high-temperature location or a near heat source. • do not install the printer in a location where chemical reaction may occur (laboratory and the like). • do not install...

Page 34

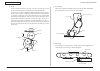

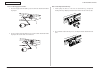

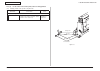

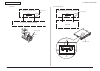

44015503th rev. 1 33 / oki data confidential 3. Installation 3.2 unpacking procedure personal injury may occur. Since the printer weights approximately 40 kg, it should be lifted by two or more people. • remove the four handles from the sides of the box, as illustrated below, and lift the corrugated...

Page 35

44015503th rev. 1 34 / oki data confidential 3. Installation 3.3 printer installation instructions • install the printer in a location where the following temperature and humidity are met: ambient temperature: 10 - 32°c ambient humidity: 20 - 80 % rh (relative humidity) maximum wet-bulb temperature:...

Page 36

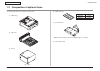

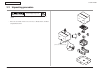

44015503th rev. 1 35 / oki data confidential 3. Installation 3.4 list of components and accessories • check to make sure that the components are free from damage, dirt or other irregularities in their appearance. • ensure that none of the accessories to the components is missing and that they are fr...

Page 37

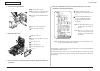

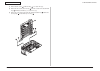

44015503th rev. 1 36 / oki data confidential 3. Installation 3.5 assembly procedure 3.5.1 assembly of the printer main unit removing the protective materials (1) remove the desiccant and protective paper from the top of the printer. (2) remove the protective tapes (three places) and protective paper...

Page 38

44015503th rev. 1 37 / oki data confidential 3. Installation installing the image drum cartridges (1) take out the image drum cartridge (four cartridges) gently. Note! • the image drum (green cylinder part) is very sensitive to scratches, therefore, special care should be taken on handling. • do not...

Page 39

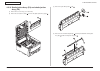

44015503th rev. 1 38 / oki data confidential 3. Installation (5) install the toner cartridges to the image drum cartridges. Note! The toner cartridges supplied with the product are capable of printing approximately 2,300 sheets (iso/iec 19798). A) take the toner cartridge out of its package and shak...

Page 40

44015503th rev. 1 39 / oki data confidential 3. Installation place the print side down. Paper size dial paper guide paper loading orientation a4, b5, letter loading paper in the paper cassette (1) pull out the paper cassette. Note! Do not remove the rubber from the plate. (2) adjust the paper stoppe...

Page 41

44015503th rev. 1 40 / oki data confidential 3. Installation set button quick guide bag for quick guide vents loading paper in the multi-purpose tray (1) open the multi-purpose tray and also the paper supporter. (2) move the manual feed guide to the paper size. (3) align the edges of the paper. (4) ...

Page 42

44015503th rev. 1 41 / oki data confidential 3. Installation o i 3.5.2 connection of the power cable power supply conditions • observe the following conditions: ac: 100v ± 10% power frequency: 50 hz or 60 hz ± 2 hz • if the available power is unstable, use a voltage regulator of the like. • the maxi...

Page 43

44015503th rev. 1 42 / oki data confidential 3. Installation turning off the power note! Turning off the power without taking proper shutdown steps may damage and disable the printer. Be sure to follow the steps below. (1) press the [shut down/restart] button for at least for four seconds. [shutting...

Page 44

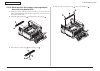

44015503th rev. 1 43 / oki data confidential 3. Installation 3.5.3 installation and recognition confirmation of options (1) installation of an additional tray unit an additional tray unit is intended for increasing the amount of paper that can be loaded in the printer, and two additional tray units ...

Page 45

44015503th rev. 1 44 / oki data confidential 3. Installation print the printer configuration by following the steps described in section 3.6. Check to make sure that every installed tray is shown in [print count] of [printer information]. Note! If every added tray is not shown there, remove every in...

Page 46

44015503th rev. 1 45 / oki data confidential 3. Installation settings for windows pcl/pcl xps printer driver for windows vista/ server 2008, select [start] - [control panel] - [printers]. For windows xp, select [start] - [control panel] - [printers and other hardware] - [printers and faxes]. For win...

Page 47

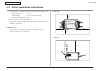

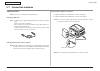

44015503th rev. 1 46 / oki data confidential 3. Installation (2) installation of a roller cabinet when placing the printer on the floor, it is recommended to use a roller cabinet. The printer main unit, or printer with additional trays can be set on the cabinet. This cabinet has rollers that allow u...

Page 48

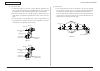

44015503th rev. 1 47 / oki data confidential 3. Installation 3. Place the printer on the stack of additional trays. Personal injury may occur. Since the printer weights approximately 40 kg, it should be lifted by two or more people. Proceed to step 5 when one additional tray is used. Printer added t...

Page 49

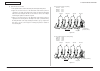

44015503th rev. 1 48 / oki data confidential 3. Installation side cover screw screw loosen a screw to detach the side cover of the printer. Unscrew the screw. Note! The screw is used to install the support plate, so make sure to keep it. Cabinet screw screw printer support plate install the support ...

Page 50

44015503th rev. 1 49 / oki data confidential 3. Installation screw fit an anti-tip bracket (for the rear side) to the left back corner of the cabinet. Attach it to the rear side with two screws. Attach the rest of anti-tip brackets (for each of the front side and the rear side) to the right side wit...

Page 51

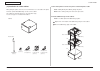

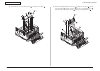

44015503th rev. 1 50 / oki data confidential 3. Installation note! • proper operation by use of an unspecified product cannot be guaranteed. Be sure to use oki product. • additional memory of 256 mb or more is recommended for long-sheet printing. • one memory slot is provided. (3) installation of an...

Page 52

44015503th rev. 1 51 / oki data confidential 3. Installation side cover screw 3. Remove the side cover. 4. Install the memory. Loosen the screw (one place). Remove the side cover. Pull it outward to remove the side cover by holding the upper edge of the side cover to lift. Cover plate cover plate no...

Page 53

44015503th rev. 1 52 / oki data confidential 3. Installation print the configuration report by following the steps instructed in section 3.6. Check the total memory size shown at “total memory size” in [system information] of [printer information]. Note! Reinstall the additional memory if the size a...

Page 54

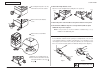

44015503th rev. 1 53 / oki data confidential 3. Installation side cover screw 1. Turn off the printer and disconnect the power cord. Turn off the printer by following the steps described under “turning off the power” in section 3.5.2. Note! • turning off the power without taking proper shutdown step...

Page 55

44015503th rev. 1 54 / oki data confidential 3. Installation cover plate open the metal cover plate. Fit the protrusions of the internal hard disk into the holes on the printer. Secure the internal hard disk with two screws. 4. Install an internal hard disk. Push the connector until it clicks. Close...

Page 56

44015503th rev. 1 55 / oki data confidential 3. Installation 8. Set up hard disk in the printer driver. Note! • administrator privileges on the computer are required. • the internal hard disk cannot be used with a windows pcl xps driver. Windows ps printer driver for windows vista/server 2008, selec...

Page 57

44015503th rev. 1 56 / oki data confidential 3. Installation settings for macintosh in macintosh, when options are added before installation of the printer driver, device information can be automatically obtained. When options are added after installing the printer driver, make the settings of optio...

Page 58

44015503th rev. 1 57 / oki data confidential 3. Installation 3.6 printing of the configuration report check that the printer operates correctly. You can check the status of installed printer options, menu settings of the printer, consumable usage, and so on. Load a4 paper in tray1. Check to make sur...

Page 59

44015503th rev. 1 58 / oki data confidential 3. Installation 3.7 connection methods note! Refer to the user’s manual for operating environment. Preparing a usb cable note! • no printer cable is supplied with the printer. Ask the user to prepare a printer cable. • ask the user to prepare a usb cable....

Page 60

44015503th rev. 1 59 / oki data confidential 3. Installation note! Refer to the user’s manual for operating environment. Preparing an ethernet cable note! An ethernet cable and a hub do not come with the printer. Ask the user to prepare an ethernet cable (a category 5 twisted pair cable, straight th...

Page 61

44015503th rev. 1 60 / oki data confidential 3. Installation 3.8 checking of paper used by the user load the media used by the user in the printer, make media weight/media type settings, execute configuration/demo printing, and check the printout to make sure that no toner flakes off. Type weight or...

Page 62: Replacement Of Parts

Oki data confidential this chapter describes the procedures of the field replacement of parts, assemblies and units. The procedures are to detach them. Reverse the procedures to attach them. The reference part numbers used in this manual (such as and ) do not identical to the part numbers in the mai...

Page 63

44015503th rev. 1 62 / oki data confidential 4. Replacement of parts 4.1 notes on replacement of parts (1) prior to replacing a part, unplug the ac cord and the interface cable. (a) be sure to use the following procedure to unplug the ac cord: turn off the printer (the power switch to the off (o) po...

Page 64

44015503th rev. 1 63 / oki data confidential 4. Replacement of parts maintenance tools: table 4-1-1 shows the tools necessary to replace printed-circuit boards and units: table 4-1-1: maintenance tools no. Maintenance tool quantity use remarks 1 no. 2-200 screwdriver with magnetic tip 1 3- to 5-mm s...

Page 65

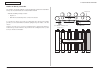

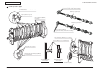

44015503th rev. 1 64 / oki data confidential 4. Replacement of parts lock handle (blue) lock handle (blue) 4.2 part replacement procedure this section describes the procedure for replacing the parts and assemblies shown in the disassembly diagram. 4.2.1 belt unit (1) open the top cover. (2) remove t...

Page 66

44015503th rev. 1 65 / oki data confidential 4. Replacement of parts 4.2.2 fuser unit (1) open the top cover. (2) pull the fuser unit lock lever (blue) in the direction of the arrow and detach the fuser unit . Top cover fuser unit lock lever (blue) fuser unit lock lever (blue).

Page 67

44015503th rev. 1 66 / oki data confidential 4. Replacement of parts 4.2.3 left side cover (1) open the top cover. (2) open the multi-purpose tray. (3) open the front cover. (4) remove the screw (silver-colored) to detach the left side cover (tool number 1). Front cover multi-purpose tray top cover.

Page 68

44015503th rev. 1 67 / oki data confidential 4. Replacement of parts 4.2.4 right side cover (1) open the top cover. (2) open the multi-purpose tray. (3) open the front cover. (4) loosen the screw and detach the right side cover (tool number 1). Top cover front cover (loosened) multi-purpose tray.

Page 69

44015503th rev. 1 68 / oki data confidential 4. Replacement of parts 4.2.5 rear cover assy. (1) pull out the duplex unit . (2) remove the two screws (silver-colored) (tool number 1). (3) sliding the rear cover assy in the direction of the arrow, detach it..

Page 70

44015503th rev. 1 69 / oki data confidential 4. Replacement of parts 4.2.6 led assy. (1) open the top cover. (2) remove the ffc cables. As shown in diagram (1), applying force in the direction of the arrow, unlatch the portion a, and then the portion b, to detach the led assy. . Top cover latch a la...

Page 71

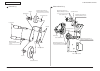

44015503th rev. 1 70 / oki data confidential 4. Replacement of parts 4.2.7 main controller pcb, image drum motor, image drum lift-up motor and feed motor (1) open the top cover. (2) remove the right side cover (see section 4.2.4). (3) remove the ten screws (silver-colored) and the plate shield assy....

Page 72

44015503th rev. 1 71 / oki data confidential 4. Replacement of parts (7) remove the four screws (silver-colored) to detach the image drum motor (tool number 1). (5) remove the rear cover assy. (see section 4.2.5). (6) remove the five screws (silver-colored) to detach the main controller pcb ..

Page 73

44015503th rev. 1 72 / oki data confidential 4. Replacement of parts (8) remove the two screws (silver-colored) and the cable to detach the feed motor . (9) remove the two screws (silver-colored) and the cable to detach the image drum lift-up motor ..

Page 74

44015503th rev. 1 73 / oki data confidential 4. Replacement of parts print engine controller pcb rfid cuif dchea t relay hvolt fsns pe ssns dc id ope power belt option powfan hsol fsnsol hopidup size 4.2.8 print engine controller pcb (1) remove the plate shield assy. (see section 4.2.7, (1) through ...

Page 75

44015503th rev. 1 74 / oki data confidential 4. Replacement of parts figure 4-2-8-1: print engine controller pcb cable routing diagram figure 4-2-8-2: print engine controller pcb connection diagram power belt option powfan hsol fsnsol relay hvolt hopidup size f s n s p e s s n s d c id o p e rfid cu...

Page 76

44015503th rev. 1 75 / oki data confidential 4. Replacement of parts 4.2.9 top cover assy. (1) remove the left side cover (see section 4.2.3). (2) remove the right side cover (see section 4.2.4). (3) remove the rear cover assy. (see section 4.2.5). (4) remove the plate assy. Shield (see section 4.2....

Page 77

44015503th rev. 1 76 / oki data confidential 4. Replacement of parts (7) remove the two screws and the fan assy. (see section 4.2.7, (6)). (8) remove the five screws (silver-colored) and slide out the main controller pcb assy. Rearward (tool number 1) (see section 4.2.7, (7)). (9) remove the screw (...

Page 78

44015503th rev. 1 77 / oki data confidential 4. Replacement of parts 4.2.10 top cover (1) remove the top cover assy. (see section 4.2.9). (2) remove the eleven screws (black) , the three screws (black) , the cable cover and the top cover (tool number 1). (4) warp and remove the auxiliary top cover ....

Page 79

44015503th rev. 1 78 / oki data confidential 4. Replacement of parts 4.2.11 operator panel assy. (1) open the top cover. (2) open the multi-purpose tray. (3) open the front cover. (4) remove the left and right side covers (see sections 4.2.3 and 4.2.4). (5) remove the plate shield assy. (see section...

Page 80

44015503th rev. 1 79 / oki data confidential 4. Replacement of parts 4.2.12 board prp (1) open the top cover. (2) unlatch the operator cover assy. At the two points a, remove the ffc and the assy. (3) as shown in diagram (2), unlatch the operator panel cover assy. At the two points b, remove the boa...

Page 81

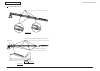

44015503th rev. 1 80 / oki data confidential 4. Replacement of parts 4.2.13 shaft-ejection assy. (fu) and shaft-ejection assy. (fd) (1) remove the rear cover assy. (see section 4.2.5). (2) remove the screw (silver-colored) to remove the guide-ejection-assy.-upper . (3) remove the gears-idler-ejectio...

Page 82

44015503th rev. 1 81 / oki data confidential 4. Replacement of parts 4.2.14 guide-ejection assy.-lower, color-registration assy. And relay board (p6y) (1) remove the left side, right side and rear covers, the top cover assy., the print engine controller pcb and the guide-ejection assy.-upper (see se...

Page 83

44015503th rev. 1 82 / oki data confidential 4. Replacement of parts (6) remove the right and left ffc connectors and the two connectors from the relay board (p6y) , and the connector from the color-registration assy . Remove the five screws (silver-colored) to detach color-registration assy. . (5) ...

Page 84

44015503th rev. 1 83 / oki data confidential 4. Replacement of parts (8) remove the two connectors and , and the ffc connector and the two screws (silver-colored) to detach the relay board (p6y) . (tool number 1) (7) remove the screw (silver-colored) to remove the contact assy. (tool number 1). Lcr ...

Page 85

44015503th rev. 1 84 / oki data confidential 4. Replacement of parts figure 4-2-14-11: relay board (p6y) cable routing diagram figure 4-2-14-2: relay board (p6y) connection diagram density sensor fuser entrance sensor color registration sensor color registration sensor p6y board pu interface connect...

Page 86

44015503th rev. 1 85 / oki data confidential 4. Replacement of parts 4.2.15 fan (fuser), high-voltage power supply board, contact assy., fuser sensor assy. (1) remove the left side cover (see section 4.2.3). (2) pull out the connector from the high-voltage power supply board , and remove the two scr...

Page 87

44015503th rev. 1 86 / oki data confidential 4. Replacement of parts (5) remove the screw (silver-colored) to remove the fuser sensor assy. (tool number 1). (4) remove the four screws (silver-colored) to detach the contact assy. ..

Page 88

44015503th rev. 1 87 / oki data confidential 4. Replacement of parts unlatched point 4.2.16 mpt assy., mpt hopping roller, separator and pick-up roller (1) remove the paper cassette. (2) open the multi-purpose tray, warp and remove the stay on each side and detach the mpt assy. . (3) lift the pick-u...

Page 89

44015503th rev. 1 88 / oki data confidential 4. Replacement of parts 4.2.17 registration roller assy. (1) remove the operator panel assy. (see section 4.2.11). (2) remove the motor (see section 4.2.7, (8)). (3) remove the left side cover (see section 4.2.3). (4) remove the mpt assy. (see section 4.2...

Page 90

44015503th rev. 1 89 / oki data confidential 4. Replacement of parts 4.2.18 gear box, registration/hopping roller assy. And solenoid (1) remove the registration roller assy. (see section 4.2.17). (2) unclamp the cable from the solenoid and remove the screw (silver-colored) to detach the solenoid. (3...

Page 91

44015503th rev. 1 90 / oki data confidential 4. Replacement of parts (5) remove the two screws (silver-colored) and lift out the gear box . (4) remove the two screws (silver-colored) to remove the cable cover ..

Page 92

44015503th rev. 1 91 / oki data confidential 4. Replacement of parts (6) remove the four screws (silver-colored) , and pull up the hopping roller assy. Toward the front of the printer (tool number 1)..

Page 93

44015503th rev. 1 92 / oki data confidential 4. Replacement of parts 4.2.19 holder-switch assy., low-voltage power supply fan and low-voltage power supply electric shock hazard. When replacing the low-voltage power supply, due to potential electric shock, wear insulated gloves or be careful not to t...

Page 94

44015503th rev. 1 93 / oki data confidential 4. Replacement of parts (8) remove the ac switch , the two screws (silver-colored) , the ground screw and the ac power supply cable . (7) remove the screw (silver-colored) , the two screws (silver-colored) , the ac cord connector and the power supply cove...

Page 95

44015503th rev. 1 94 / oki data confidential 4. Replacement of parts 4.2.20 belt motor assy. And fuser motor assy. (1) remove the main control pcb, print engine roller pcb (see sections 4.2.7 and 4.2.8). (2) remove the low-voltage power supply (see section 4.2.19, (7)). (3) remove the insulator . (4...

Page 96

44015503th rev. 1 95 / oki data confidential 4. Replacement of parts (5) remove the four screws (silver-colored) to detach the fuser motor assy. ..

Page 97

44015503th rev. 1 96 / oki data confidential 4. Replacement of parts 4.2.21 side-r assy. And side-l assy. (1) see sections 4.2.1 to 4.2.20. (2) remove the two screws (silver-colored) to remove the image drum lift-up gear bracket . (3) remove the e-shaped ring and the image drum lift-up gear (r) (too...

Page 98

44015503th rev. 1 97 / oki data confidential 4. Replacement of parts (6) remove the four screws (silver-colored) to remove the base plate . (7) remove the four screws (silver-colored) to remove the plate beam . (8) remove the two screws (silver-colored) to remove the plate-beam-rear . The side l ass...

Page 99

44015503th rev. 1 98 / oki data confidential 4. Replacement of parts 4.2.22 paper feed roller (tray 1) note! When replacing the paper feed roller of the tray 1, be sure to replace the separator of the tray 1. (1) turn off the printer and remove the paper cassette of the tray 1. (3) remove the spring...

Page 100

44015503th rev. 1 99 / oki data confidential 4. Replacement of parts notes on attaching separator: 1. Insert the hole of one leg of a new separator onto the support of the leg and, bending the other leg, push the separator from above so as to insert the other support into the hole of the other leg. ...

Page 101

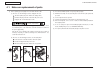

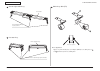

44015503th rev. 1 100 / oki data confidential 4. Replacement of parts 4.2.23 paper feed rollers (tray 2/3 (option)) note! Be sure to replace all of the three paper feed rollers. (1) turn off the printer and remove the paper cassette of the tray 2/3. (2) pressing the protrusions of the two paper feed...

Page 102

44015503th rev. 1 101 / oki data confidential 4. Replacement of parts notes on attaching paper feed rollers: 1. Insert a new paper feed roller (with a gear) onto the inside shaft and turn it all the way in place. 2. Insert a new paper feed roller (with no gears) onto the outside shaft and turn all t...

Page 103

44015503th rev. 1 102 / oki data confidential 4. Replacement of parts 4.2.24 paper feed roller (multi-purpose tray) (1) turn off the printer and open the multi-purpose tray. (2) lift the paper pick-up section and, pressing the protrusion of the paper feed roller of the multi-purpose tray outward, re...

Page 104

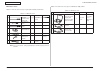

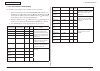

44015503th rev. 1 103 / oki data confidential 4. Replacement of parts 4.3 portions lubricated class amount applied (cc) width (mm) sample s a b c d e f 0.0005 0.003 0.005 0.01 0.03 0.05 0.1 1.24 2.25 2.67 3.37 4.86 5.76 7.26 w portions lubricated are shown in this section. The other portions must no...

Page 105

44015503th rev. 1 104 / oki data confidential 4. Replacement of parts class-a em-30l to bearings class-a em-30l to bearings class-a em-30l to posts enlarged view gear-planet (z12)-hp stopper-hp holder-planet stopper-z45-48-hp shaft-hopping shaft-hopping class-c em-30l to gear bearing surfaces class-...

Page 106

44015503th rev. 1 105 / oki data confidential 4. Replacement of parts gear-holder-assy. Class-c molykote (em-30l) to hatched areas post-gear-holder spacer-coupled spacer-gear gear-planet-z24 gear-planet-z24 back of gear-planet-z24 class-b molykote (em-30l) to post holder-gear-a class-b em-30l to hat...

Page 107

44015503th rev. 1 106 / oki data confidential 4. Replacement of parts class-c molykote (em-30l) to hatched areas class-c molykote (em-30l) to hatched areas bearing-registration bearing -1 roller-assy.-registration (lower) -2 roller-assy.-registration (lower) class-c molykote (em-30l) to entire gear ...

Page 108

44015503th rev. 1 107 / oki data confidential 4. Replacement of parts guide-ejection-upper paper paths free of grease paper paths free of grease small-amount class-a molykote (em-30l) to 7 hatched areas small-amount class-a molykote (em-30l) to 7 hatched areas class-c molykote (em30l) to bearings cl...

Page 109

44015503th rev. 1 108 / oki data confidential 4. Replacement of parts motor-assy.-belt class-c molykote (em-30l) to 2 posts class-c molykote (em-30l) to gear tooth surfaces class-c molykote (em-30l) to gear end face gear-reduction-belt gear-idler-belt plate-belt-caulked -1 plate-main-assy. Moderate-...

Page 110

44015503th rev. 1 109 / oki data confidential 4. Replacement of parts -2 plate-main-assy. Class-f em-30l to 4 gear end faces gear-idler-drum gear-reduction id gear-idler-a plate-main-caulked gear-idler-b class-c em-30l to gear tooth surface and end face class-a em-30l to tooth surface class-f em-30l...

Page 111

44015503th rev. 1 110 / oki data confidential 4. Replacement of parts moderate-amount class-c molykote (hp300) to tooth tips moderate-amount class-c molykote (hp300) to posts spring-planet re2-sk gear-planet-roller posts-planet bush-4 washer gear-planet-release plate-planet-fu planet-assy. Plate-mai...

Page 112

44015503th rev. 1 111 / oki data confidential 4. Replacement of parts class-c em-30l to entire 4 hatched areas class-c em-30l to entire 4 hatched areas plate-side-r view a back of a-view -1 plate-side-r-assy. -2 plate-side-r-assy. Class-c molykote (em-30l) to hatched area plate-side-r.

Page 113

44015503th rev. 1 112 / oki data confidential 4. Replacement of parts -3 plate-side-r-assy. Moderate-amount class-c molykote (hp300) to hatched areas gear-idler-fuser motor-assy.-fuser plate-side-r-assy. Class-c em-30l to entire hatched area gear-cassette-r -4 plate-side-r-assy. Small-amount class-a...

Page 114

44015503th rev. 1 113 / oki data confidential 4. Replacement of parts guide-cassette-l class-c em-30l to entire hatched area -1 plate-side-l-assy. -2 plate-side-l-assy. Class-c molykote (em-30l) to hatched area plate-side-l.

Page 115

44015503th rev. 1 114 / oki data confidential 4. Replacement of parts -3 plate-side-l-assy. Small-amount class-a molykote (em-30l) to hatched areas small-amount class-a molykote (em-30l) to hatched areas enlarged view enlarged view (5-mm width) rack-lift-up-l class-a em-30l to hatched areas.

Page 116

44015503th rev. 1 115 / oki data confidential 4. Replacement of parts sensor-registration-assy. Cassette-assy. Class-c molykote (em-30l) to posts (3 places) fuser-shutter class-c em-30l to rotational support points and sides frame-separation-assy. 1 2 areas free of grease roller-assy.-idler (fd) gre...

Page 117

44015503th rev. 1 116 / oki data confidential 4. Replacement of parts class-c molykote (em30-l) to posts (2 places) class-c molykote (em-30l) to entire gear tooth surfaces gear-reduction-l-up3 plate-lift-up-caulked gear-reduction-l-up2 -1 printer-unit cover-assy.-top sprint-torsion-r spring-torsion-...

Page 118

44015503th rev. 1 117 / oki data confidential 4. Replacement of parts -2 printer-unit shaft-lift-up (1) (2) (3) (4) (1) apply a moderate amount (class c) of molykote (em-30l) to the inner wall of the hole (the hatched area). (2) insert the shaft-lift-up from the plate-side-r side. (3) apply a modera...

Page 119

44015503th rev. 1 118 / oki data confidential 4. Replacement of parts -3 printer-unit 40 100 40 100 small-amount class-a pm to hatched areas (1) to apply: wipe the hatched areas with material like a cloth impregnated with a small amount of pm. (2) after applying pm, make sure that, by pulling out an...

Page 120: Maintenance Menus

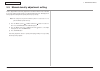

Oki data confidential c830 can be adjusted by using maintenance utility, or button operation on its operator panel. On the panel, maintenance menus are provided in addition to general menus. Select the menu intended for each adjustment purpose. 5.1 system maintenance menu (for maintenance personnel)...

Page 121

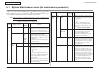

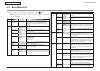

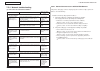

44015503th rev. 1 120 / oki data confidential 5. Maintenance menus 5.1 system maintenance menu (for maintenance personnel) turning on each printer while the menu up-arrow ( ), menu down-arrow ( ) and help button combination is used on its operator panel starts its system maintenance menu. The menu i...

Page 122

44015503th rev. 1 121 / oki data confidential 5. Maintenance menus category option (1st row) settings (2nd row) df function system mainte- nance persona- lity ibm 5577 enable disable * changes the support pdl language default based on the destination of the printer. Under ‘print setup’-‘personality’...

Page 123

44015503th rev. 1 122 / oki data confidential 5. Maintenance menus 5.2 maintenance utility the adjustments described in table 5-2 should be made by using maintenance utility. Details on the utility are as follows: (1) maintenance utility operation manuals: 42678801fu01 rev. 21 or higher (japanese) 4...

Page 124

44015503th rev. 1 123 / oki data confidential 5. Maintenance menus option adjustment section in maintenance utility operation manual operation from operator panel (section in this maintenance manual) 12 destina- tion/ pnp information setup sets or checks the (cu) destination, device identification a...

Page 125

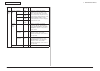

44015503th rev. 1 124 / oki data confidential 5. Maintenance menus 5.3 user maintenance menu functions 5.3.1 maintenance menu (for end-users) some general menu categories on the operator panel of c830 serve as maintenance menus (but are not system maintenance menus). The options available in the men...

Page 126

44015503th rev. 1 125 / oki data confidential 5. Maintenance menus option settings function system adjust (cont.) print position adjust (cont.) y adjust 0.00 mm +0.25 mm to -2.00 mm +2.00 mm to -0.25 mm adjusts the position of a whole printing image (in 0.25-mm increments) parallel to the direction ...

Page 127

44015503th rev. 1 126 / oki data confidential 5. Maintenance menus option settings function enter password xxxxxxxxxxxx enters a password to start the administrator menu. Network setup print setup postscript setup pcl setup color setup memory receive buffer size auto 0.5 mb 1 mb 2 mb 4 mb 8 mb 16 mb...

Page 128

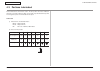

44015503th rev. 1 127 / oki data confidential 5. Maintenance menus 5.3.2 self-diagnostic mode this section describes level 0 and level 1. 5.3.2.1 operator panel the following description on operating the self-diagnostic is provided, premised on the following operator panel layout: self-diagnostic mo...

Page 129

44015503th rev. 1 128 / oki data confidential 5. Maintenance menus level1 (1) menu option display switching use the menu up ( ) or menu down-arrow ( ) button to select the option shown in a shaded area ( xxxxx ), and press enter to execute the option. Use enter or back to display the option shown in...

Page 130

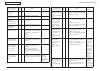

44015503th rev. 1 129 / oki data confidential 5. Maintenance menus 5.3.2.2 normal self-diagnostic mode (level 1) the normal self-diagnostic mode menus are as follows: option self-diagnostic menu adjustment maintenance utility 1 switch scan test switch scan checks an input sensor or switch. No. 18 2 ...

Page 131

44015503th rev. 1 130 / oki data confidential 5. Maintenance menus 5.3.2.3 switch scan test the switch scan test is used for checking entrance sensors and switches. 1. Enter the self-diagnostic mode (level 1) and, until switch scan appears on the upper display, press the menu up-arrow ( ) or menu do...

Page 132

44015503th rev. 1 131 / oki data confidential 5. Maintenance menus table 5-3: switch scan detail lower display shows asterisk (*) when function on upper display is unavailable. *1: an l is displayed when cover is open. Upper display 1 2 3 4 detail lower display detail lower display detail lower disp...

Page 133

44015503th rev. 1 132 / oki data confidential 5. Maintenance menus 5.3.2.4 motor and clutch test the motor and clutch test is used for testing motors and clutches. 1. Enter the self-diagnostic mode (level 1) and, until motor & clutch test appears on the upper display, press the menu up-arrow ( ) or ...

Page 134

44015503th rev. 1 133 / oki data confidential 5. Maintenance menus table 5-4 unit name displayed driving restriction remarks id motor all of the (black, yellow, magenta and cyan) image drums must be removed. − belt motor all of the (black, yellow, magenta and cyan) image drums must be removed. − fus...

Page 135

44015503th rev. 1 134 / oki data confidential 5. Maintenance menus 5.3.2.5 test printing the test printing is used for printing test patterns stored in the pu. Other patterns are stored in the controller. 1. Enter the self-diagnostic mode (level 1) and, until test print appears on the upper display,...

Page 136

44015503th rev. 1 135 / oki data confidential 5. Maintenance menus 4. With print execute on the lower display after the operation in step 2, pressing the enter button executes test printing by using the setting made in 4.2 steps 2 and 3. The test printing is cancelled by pressing the cancel button. ...

Page 137

44015503th rev. 1 136 / oki data confidential 5. Maintenance menus • the following message appears when a test pattern is printed. P=*** w=*** p: number of test pages w: wait time • the above displays are switched to the following by pressing the menu up- arrow ( ) button. T=*** u=***[###] h=***%l=*...

Page 138

44015503th rev. 1 137 / oki data confidential 5. Maintenance menus • the above displays are switched to the following by pressing the menu up- arrow ( ) button. Belt=**** frm [***] ( xxx ) belt: a belt motor constant-speed timer value (a set input/output value) (in hex). Frm: three asterisks in squa...

Page 139

44015503th rev. 1 138 / oki data confidential 5. Maintenance menus 5.3.2.6 color registration adjustment test the color registration adjustment test is used for adjusting color registration or investigating the cause(s) of color misregistration. Chapter 2 about description on color registration adju...

Page 140

44015503th rev. 1 139 / oki data confidential 5. Maintenance menus 4. Repeat steps 2 and 3 when necessary. 5. Press the back button to end the test (the state if step 1 is restored). Color registration adjustment test item option detail reg adj execute executes color registration adjustment. Reg adj...

Page 141

44015503th rev. 1 140 / oki data confidential 5. Maintenance menus when the displayed option is dens adj par-set: the setting for the density adjustment parameter is displayed. When the displayed option is auto calibration: the density sensor sensitivity adjustment value is automatically set (the on...

Page 142

44015503th rev. 1 141 / oki data confidential 5. Maintenance menus 5.3.2.8 consumable counter display the consumable counter display is used for viewing the usage of consumables. 1. Enter the self-diagnostic mode and, until consumable status appears, press the menu up-arrow ( ) or menu down-arrow ( ...

Page 143

44015503th rev. 1 142 / oki data confidential 5. Maintenance menus 5.3.2.9 print counter display the print counter display is used for viewing print counter values. 1. Enter the self-diagnostic mode and, until printer status appears, press the menu up-arrow ( ) or menu down-arrow ( ) button (the men...

Page 144

44015503th rev. 1 143 / oki data confidential 5. Maintenance menus 5.3.2.11 self-diagnostic function setting the self-diagnostic function setting is used for enabling or disabling the error detection by sensors. The detection can be enabled or disabled temporarily for troubleshooting. Allowing for s...

Page 145

44015503th rev. 1 144 / oki data confidential 5. Maintenance menus 5.3.2.12 led head serial number display the led head serial number display is used for viewing whether downloaded data about led heads agrees with the serial numbers marked on the led heads. 1. Enter the self-diagnostic mode and, unt...

Page 146

44015503th rev. 1 145 / oki data confidential 5. Maintenance menus 5.3.4 functions of buttons after power-on after the printer is turned on, buttons on the operator panel of c830 function as described below. When held down until the upper and lower displays on the panel show pam check and three or f...

Page 147

44015503th rev. 1 146 / oki data confidential 5. Maintenance menus 5.4 setup after part replacement ii. When the printer operates properly, the operator panel shows online. When the printer has an error, it indicates an error, but the printer is internally online, being ready to communicate. 2. When...

Page 148

44015503th rev. 1 147 / oki data confidential 5. Maintenance menus • the pu serial number is shown at printer serial number in the header of the printer’s configuration report (a menu map) output from the printer. After the pu serial number is changed, it can be checked by printing the report from t...

Page 149

44015503th rev. 1 148 / oki data confidential 5. Maintenance menus 5.5 manual density adjustment setting c830 is shipped with the auto density adjustment mode enabled. When the mode is disabled by a user, the printer may print density out of adjustment while being used. Manually perform density adju...

Page 150

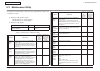

44015503th rev. 1 149 / oki data confidential 5. Maintenance menus 5.6 boot menu list to display boot menu, turn on the printer while holding down the set ( ) button. Memo displaying boot menu requires entry of a password. The password defaults to six as (aaaaaa). Category option settings function e...

Page 151

44015503th rev. 1 150 / oki data confidential 5. Maintenance menus category option settings function power setup peak power control normal low sets the control of peak low power. Power save enable disable sets whether to enable or disable the power save mode. Usb host power off on sets the usb host ...

Page 152: Cleaning

Oki data confidential 6. Cleaning 6.1 cleaning ...................................................................................152 6.2 led lens array cleaning ...........................................................153 6.3 pick-up roller cleaning ..................................................

Page 153

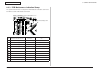

44015503th rev. 1 152 / oki data confidential 6. Cleaning the inside and outside of c830 must be cleaned with a waste cloth and a handy vacuum cleaner when necessary. Note! Do not directly touch the image drum terminals, led lens array and the led head connectors. 6.1 cleaning.

Page 154

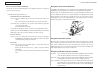

44015503th rev. 1 153 / oki data confidential 6. Cleaning 6.2 led lens array cleaning the led lens array must be cleaned when a vertical white belt or line (void or light print) occurs. Led head cleaning the led heads must be cleaned when a white line or blurred text is printed. (1) shut down and tu...

Page 155

44015503th rev. 1 154 / oki data confidential 6. Cleaning (3) lightly wipe the (four) led head lens surfaces with soft tissue paper. Note! Solvents, such as methyl alcohol or thinner, damage the led heads. Do not use them. (4) close the top cover. Led head.

Page 156

44015503th rev. 1 155 / oki data confidential 6. Cleaning 6.3 pick-up roller cleaning the pick-up rollers must be cleaned when a vertical line occurs on printed output. Note! Use a soft cloth to clean the pick-up rollers so as not to damage their surfaces. Paper feed roller and pad cleaning when fre...

Page 157: Troubleshooting Procedure

Oki data confidential 7. Troubleshooting procedure 7.1 before starting the repair work ................................................157 7.2 confirmation items before taking corrective action against abnormalities ...........................................................................157 7.3 p...

Page 158

44015503th rev. 1 157 / oki data confidential 7. Troubleshooting procedure 7.1 before starting the repair work 7.2 confirmation items before taking corrective action against abnormalities 7.3 precautions when taking corrective action against abnormality 7.4 preparation for troubleshooting (1) displa...

Page 159

44015503th rev. 1 158 / oki data confidential 7. Troubleshooting procedure 7.5 troubleshooting method when a trouble occurs in this printer, perform troubleshooting by following the steps described below. 7.5.1 lcd message list initializing panel display on line lamp inspec- tion lamp details please...

Page 160

44015503th rev. 1 159 / oki data confidential 7. Troubleshooting procedure panel display on line lamp inspec- tion lamp details erasing disk nnn% off off indicates that it is in elimination process for hard disk. The erasure process for hard disk can be actuated from [storage setup] of boot menu - [...

Page 161

44015503th rev. 1 160 / oki data confidential 7. Troubleshooting procedure normal panel display (the mark indicates no message in the upper row.) on line lamp inspec- tion lamp details remedial measure ready to start printing on off indicates that a printer is in the on line status. — off line off o...

Page 162

44015503th rev. 1 161 / oki data confidential 7. Troubleshooting procedure panel display (the mark indicates no message in the upper row.) on line lamp inspec- tion lamp details remedial measure deleting data blink varies cancel of the job is indicated. A printer is discarding the data until end of ...

Page 163

44015503th rev. 1 162 / oki data confidential 7. Troubleshooting procedure warning panel display (the mark indicates no message in the upper row.) on line lamp inspec- tion lamp details remedial measure %color% amount of toner becomes scarce. Varies on (blink) (off) indicates that amount of toner be...

Page 164

44015503th rev. 1 163 / oki data confidential 7. Troubleshooting procedure panel display (the mark indicates no message in the upper row.) on line lamp inspec- tion lamp details remedial measure %color% image drum is reaching near life end. Varies on (off) indicates that the image drum is reaching n...

Page 165

44015503th rev. 1 164 / oki data confidential 7. Troubleshooting procedure panel display (the mark indicates no message in the upper row.) on line lamp inspec- tion lamp details remedial measure belt reflex error varies on belt reflectance check error because the pu firmware does not notice this sta...

Page 166

44015503th rev. 1 165 / oki data confidential 7. Troubleshooting procedure panel display (the mark indicates no message in the upper row.) on line lamp inspec- tion lamp details remedial measure %color% low density error varies on density correction id error. This error occurs when abnormal density ...

Page 167

44015503th rev. 1 166 / oki data confidential 7. Troubleshooting procedure panel display (the mark indicates no message in the upper row.) on line lamp inspec- tion lamp details remedial measure job is being restricted. Varies on job is being restricted. — file is being erased. Varies on confidentia...

Page 168

44015503th rev. 1 167 / oki data confidential 7. Troubleshooting procedure panel display (the mark indicates no message in the upper row.) on line lamp inspec- tion lamp details remedial measure the encrypted authentication print job that has exceeded the retention term is deleted. Press the on line...

Page 169

44015503th rev. 1 168 / oki data confidential 7. Troubleshooting procedure if a printer detects an un-recoverable error, the following service call error is displayed on the lcd. Service call nnn: error note! Nnn indicates an error code. When a service call is displayed, the error code and the assoc...

Page 170

44015503th rev. 1 169 / oki data confidential 7. Troubleshooting procedure display on operator panel on line lamp inspec- tion lamp contents code nnn wait for a while. Message data is being received. Varies varies indicates that the message data to be updated is being processed. Error (online) wait ...

Page 171

44015503th rev. 1 170 / oki data confidential 7. Troubleshooting procedure display on operator panel on line lamp inspec- tion lamp contents code nnn change the toner cartridge. %color% for details please see help. Off blink indicates that the waster toner of %color% is full requiring replace toner....

Page 172

44015503th rev. 1 171 / oki data confidential 7. Troubleshooting procedure display on operator panel on line lamp inspec- tion lamp contents code nnn open the cover. Paper is remaining. Top cover for details please see help. Off blink indicates due to occurrence of paper jam, the continuously fed pa...

Page 173

44015503th rev. 1 172 / oki data confidential 7. Troubleshooting procedure display on operator panel on line lamp inspec- tion lamp contents code nnn replace the fuser. It is lifetime of fuser. For details please see help. Off blink informs the image drum has reached end of line. This error is issue...

Page 174

44015503th rev. 1 173 / oki data confidential 7. Troubleshooting procedure display on operator panel on line lamp inspec- tion lamp contents code nnn wait for a while. Program data is being written. Off blink indicates that the nic program data to be updated is being written. Error reboot the printe...

Page 175

44015503th rev. 1 174 / oki data confidential 7. Troubleshooting procedure table 7-1-2 service call error list display cause error details remedial measure contact the service center. 001: error machine check exception replace cu board reboot the printer. 002: error ~ 007: error cpu exception does t...

Page 176

44015503th rev. 1 175 / oki data confidential 7. Troubleshooting procedure display cause error details remedial measure restart the printer. 074: error xxxxxxxx 075: error xxxxxxxx video error error is detected when expanding the video data. Is the cu assembly installed correctly? No yes re-install ...

Page 177

44015503th rev. 1 176 / oki data confidential 7. Troubleshooting procedure display cause error details remedial measure contact the service center. 150: error ~ 153: error the id unit fuse has blown out. (150=yellow, 151=magenta, 152=cyan, 153=black) is the id unit installed normally? Does this erro...

Page 178

44015503th rev. 1 177 / oki data confidential 7. Troubleshooting procedure display cause error details remedial measure contact the service center. 181: error 182: error 183: error option unit i/f error (181=duplex unit, 182=2nd tray, 183=3rd tray) does this error recur? Does this error recur? Yes y...

Page 179

44015503th rev. 1 178 / oki data confidential 7. Troubleshooting procedure display cause error details remedial measure contact the service center. 257: error disk security mode error yes turn the power off/on. Execute the re-formation of hard disk. If it still does not improve the situation, change...

Page 180

44015503th rev. 1 179 / oki data confidential 7. Troubleshooting procedure 7.5.2 preparation for troubleshooting note! When replacing the pu board, read the eeprom chip contents of the old board first, and copy them to the new board upon completion of the replacement. (refer to section 5.4.1 precaut...

Page 181

44015503th rev. 1 180 / oki data confidential 7. Troubleshooting procedure 7.5.2.(1) lcd display error memo for the numbers from to after the name of the respective connectors, refer to section 7.5.2 (19) “wiring diagram”. (1-1) lcd does not display anything. Check item check work action to be taken...

Page 182

44015503th rev. 1 181 / oki data confidential 7. Troubleshooting procedure check item check work action to be taken at ng (1-1-5) lsi operation check i/f signal supplied from the pu board to the operator panel board. Check if the signal is output to the ope connector of the pu board or not. Pin-7: s...

Page 183

44015503th rev. 1 182 / oki data confidential 7. Troubleshooting procedure 7.5.2.(2) abnormal operations of printer after the power is turned on (2-1) any operation does not start at all. Check item check work action to be taken at ng (2-1-1) check the peripherals of the power supplies primary ac po...

Page 184

44015503th rev. 1 183 / oki data confidential 7. Troubleshooting procedure check item check work action to be taken at ng (2-2-3) check the jumping phenomena of gear tooth. (abnormal load of the consumable item) operating conditions of the respective motors check if operations of the respective moto...

Page 185

44015503th rev. 1 184 / oki data confidential 7. Troubleshooting procedure (3) paper jams when paper jams occur or paper remains in the printer, "paper jam", or "paper remain" is displayed on the operation panel. By pressing the help button, a method to remove the paper is displayed, remove the pape...

Page 186

44015503th rev. 1 185 / oki data confidential 7. Troubleshooting procedure pull the tray. Paper jam [tray name] pull the tray. Paper remains. [tray name] when the above messages are displayed. Tray1 is applied here as an example. (1) pull the displayed tray. (2) remove paper. (3) return the tray to ...

Page 187

44015503th rev. 1 186 / oki data confidential 7. Troubleshooting procedure open the cover. Paper jam front cover open the cover. Paper remains. Front cover when the above messages are displayed. (1) open the multipurpose tray. (2) push up the center handle (blue), to open the front cover. (3) slowly...

Page 188

44015503th rev. 1 187 / oki data confidential 7. Troubleshooting procedure open the cover. Paper jam top cover open the cover. Paper remains. Top cover when the above messages are displayed. (1) open the top cover. (2) touch the screw with a hand to discharge static. (3) uninstall the four image dru...

Page 189

44015503th rev. 1 188 / oki data confidential 7. Troubleshooting procedure jam release level (c) if you see the bottom edge of the jammed paper pull out the jammed paper, slowly while pulling up the jam release lever of the fuser unit. (d) if f paper is jammed in the fuser unit, bending down the fix...

Page 190

44015503th rev. 1 189 / oki data confidential 7. Troubleshooting procedure (6) set four image drums in the printer. (7) close the top cover..

Page 191

44015503th rev. 1 190 / oki data confidential 7. Troubleshooting procedure check the duplex unit. Paper jam check the duplex unit. Paper remains. When the above messages are displayed. (1) hold and press down the jam release lever of the duplex print unit to open the duplex print unit cover. (2) rel...

Page 192

44015503th rev. 1 191 / oki data confidential 7. Troubleshooting procedure 7.5.2.(3) paper feed jam (error code 391: 1st tray) (3-1) jam occurs immediately after the power is turned on. (1st tray) check item check work action to be taken at ng (3-1-1) check condition of the paper running path paper ...

Page 193

44015503th rev. 1 192 / oki data confidential 7. Troubleshooting procedure check item check work action to be taken at ng (3-2-4) check the system connection paper feed motor drive cable check the connection condition of the cable. Check if the connector is connected in the half- way only or not, an...

Page 194

44015503th rev. 1 193 / oki data confidential 7. Troubleshooting procedure 7.5.2.(4) feed jam (error code 380) (4-1) jam occurs immediately after the power is turned on. Check item check work action to be taken at ng (4-1-1) check condition of the paper running path paper running path of the front u...

Page 195

44015503th rev. 1 194 / oki data confidential 7. Troubleshooting procedure 7.5.2.(5) paper feed jam (error code 390: multipurpose tray) (5-1) jam occurs immediately after the power is turned on. (multipurpose tray) check item check work action to be taken at ng (5-1-1) check condition of the paper r...

Page 196

44015503th rev. 1 195 / oki data confidential 7. Troubleshooting procedure (5-2) jam occurs immediately after paper feed is started. (multipurpose tray) check item check work action to be taken at ng (5-2-1) check condition of the paper running path paper running path of the multipurpose tray check ...

Page 197

44015503th rev. 1 196 / oki data confidential 7. Troubleshooting procedure 7.5.2.(6) paper running jam (error code 381) (6-1) jam occurs immediately after the power is turned on. Check item check work action to be taken at ng (6-1-1) check condition of the running path. Paper running path of the fro...

Page 198

44015503th rev. 1 197 / oki data confidential 7. Troubleshooting procedure check item check work action to be taken at ng (6-2-4) check the system connection paper feed motor drive cable, id motor drive cable, belt motor drive cable, id up motor drive cable, fuser motor drive cable check the connect...

Page 199

44015503th rev. 1 198 / oki data confidential 7. Troubleshooting procedure (6-4) jam occurs immediately after paper has reached the fuser. Check item check work action to be taken at ng (6-4-1) motor operation check fuser motor confirm that the fuser motor works normally by using the motor & clutch ...

Page 200

44015503th rev. 1 199 / oki data confidential 7. Troubleshooting procedure (7-2) paper unloading jam occurs after a paper is taken into printer. Check item check work action to be taken at ng (7-2-1) check condition of the paper running path face up stacker cover confirm that it is either fully open...

Page 201

44015503th rev. 1 200 / oki data confidential 7. Troubleshooting procedure 7.5.2.(8) two-sided printing jam (error code: 370, 371, 372, 373, 383) (8-1) two-sided printing jam occurs immediately after the power is turned on. Check item check work action to be taken at ng (8-1-1) check condition of th...

Page 202

44015503th rev. 1 201 / oki data confidential 7. Troubleshooting procedure (8-3) two-sided printing jam occurs in the process of reversing paper. Check item check work action to be taken at ng (8-3-1) sensor lever operation check dup-in sensor lever open the rear cover. Touch the dup-in sensor lever...

Page 203

44015503th rev. 1 202 / oki data confidential 7. Troubleshooting procedure 7.5.2.(9) paper size error (error code 400 and 401) (9-1) jam occurs when paper end is located near the in1 sensor. Check item check work action to be taken at ng (9-1-1) check paper feed condition multifeed of papers open th...

Page 204

44015503th rev. 1 203 / oki data confidential 7. Troubleshooting procedure check item check work action to be taken at ng (10-1-3) sensor check up/down sensor lever (unified structure with the left link lever) check if shape and movement of the sensor levers have any abnormality or not. Replace the ...

Page 205

44015503th rev. 1 204 / oki data confidential 7. Troubleshooting procedure check item check work action to be taken at ng (11-2-2) temperature increase of fuser unit installation position of the upper thermistor check if the upper thermistor is installed in the far position from the specified positi...

Page 206

44015503th rev. 1 205 / oki data confidential 7. Troubleshooting procedure (12-3) all fans of the printer do not rotate. Check item check work action to be taken at ng (12-3-1) 24v power supply pu board fuses f4, f5 check if the fuses f4 and f5 are not open- circuit or not. Replace the pu board. 24v...

Page 207

44015503th rev. 1 206 / oki data confidential 7. Troubleshooting procedure check item check work action to be taken at ng (14-1-2) check the system connection check the system connection from the pu board to the option tray board (v7y pcb). Check that the cable between the pu board option connector ...

Page 208

44015503th rev. 1 207 / oki data confidential 7. Troubleshooting procedure 7.5.2.(16) toner cartridge cannot be recognized. (error code 540, 541, 542, 543) (16-1) error caused by the consumable items. Check item check work action to be taken at ng (16-1-1) consumable items installation condition id ...

Page 209

44015503th rev. 1 208 / oki data confidential 7. Troubleshooting procedure (16-3) error caused by the defective mechanism check item check work action to be taken at ng (16-3-1) mechanical load applied to the id unit id unit check if a heavy mechanical load is being applied to the id unit due to bre...

Page 210

44015503th rev. 1 209 / oki data confidential 7. Troubleshooting procedure 7.5.2.(18) humidity sensor error (error code 123) (18-1) humidity sensor error check item check work action to be taken at ng (18-1-1) check the system connection connection between the pu board and operator panel check if th...

Page 211

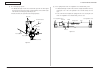

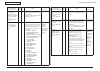

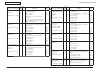

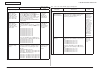

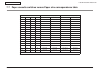

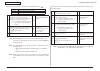

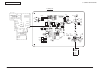

44015503th rev. 1 210 / oki data confidential 7. Troubleshooting procedure hvolt duplex unit cable43 sns03 sns12 sns4 c l 1 c l 2 m o t o r m a in 1 f a n duplex fan sns03 sns12 psz c l 1 c l 2 m o t o r m a in 1 m a in 2 board-v7y-11 2nd (3rd) tray board-v7y-4 shutter solenoid hopping motor relay r...

Page 212

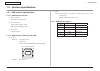

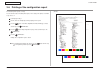

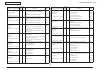

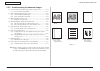

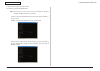

44015503th rev. 1 211 / oki data confidential 7. Troubleshooting procedure 7.5.3 troubleshooting the abnormal images a overall faded-out blurred b stain on white print c entirely white d black banding/ black streaking in vertical direction e cyclic abnormality f white banding/ white streaking in ver...

Page 213

44015503th rev. 1 212 / oki data confidential 7. Troubleshooting procedure 7.5.3.(1) color has faded-out and blurred entirely. (refer to figure 7-2 a.) (1-1) color are faded-out and blurred. Check item check work action to be taken at ng (1-1-1) toner remaining amount of toner check if the message "...

Page 214

44015503th rev. 1 213 / oki data confidential 7. Troubleshooting procedure 7.5.3.(2) stain on white print (refer to figure 7-2 b.) (2-1) stain on white print (partial stain) check item check work action to be taken at ng (2-1-1) id unit exposure of drum to light is the drum left in a circumstance in...

Page 215

44015503th rev. 1 214 / oki data confidential 7. Troubleshooting procedure 7.5.3.(3) white print (refer to figure 7-2 c.) (3-1) white print over entire page check item check work action to be taken at ng (3-1-1) toner condition remaining amount of toner confirm that sufficient amount of toner remain...

Page 216

44015503th rev. 1 215 / oki data confidential 7. Troubleshooting procedure 7.5.3.(4) black banding/black streaking in vertical direction (4-1) thin vertical line (with color) (refer to figure 7-2 d.) check item check work action to be taken at ng (4-1-1) id unit condition filming of the id unit is p...

Page 217

44015503th rev. 1 216 / oki data confidential 7. Troubleshooting procedure 7.5.3.(6) heavy color registration error (6-1) display of the message "color adjustment is in progress" appears only short time. Check item check work action to be taken at ng (6-1-1) result of color registration error correc...

Page 218

44015503th rev. 1 217 / oki data confidential 7. Troubleshooting procedure ground charge roller developer roller toner feed roller figure 7-3 7.5.3.(8) for the entire monochrome print, it does not being printed. (8-1) setting by mistake of the specific color print menu check item check work action t...

Page 219

44015503th rev. 1 218 / oki data confidential 7. Troubleshooting procedure 7.5.4 network troubleshooting (1) print cannot be activated from utilities. Check item check work action to be taken at ng (1) check the link lamp check if the link lamp (green) is illuminating or not. Check if the hub and a ...

Page 220

44015503th rev. 1 219 / oki data confidential 7. Troubleshooting procedure 7.5.4.1.1 is the certificate created? Log-on in as the administrator, and select "security" "encryption (ssl/tls)". If the following screen is displayed, certificate of the printer is not created yet. (the same screen is disp...

Page 221

44015503th rev. 1 220 / oki data confidential 7. Troubleshooting procedure 7.5.4.1.3 check version number of the web browser check version number of the web browser in use. How to check version number. For internet explorer launch the browser and select "help" "version information". Recommended vers...

Page 222

44015503th rev. 1 221 / oki data confidential 7. Troubleshooting procedure 7.5.4.1.4 confirm encryption strength of a printer version display of the browser that is confirmed by section "7.5.4.1.3 check version number of the web browser" has description on encryption strength of the browser. The bro...

Page 223

44015503th rev. 1 222 / oki data confidential 7. Troubleshooting procedure 5. Check the "encryption strength". 6. Set the "encryption strength" to "weak" and press the "apply" button. 7. Check the setup contents, and press "ok". 9. If the printer is displayed in the printer list, the setup is comple...

Page 224

44015503th rev. 1 223 / oki data confidential 7. Troubleshooting procedure solution: set the encryption strength to "weak". How to change encryption strength with telnet note! Telnet cannot be used if it remains in the default setting. To change the encryption strength, telnet must be set to enable....

Page 225

44015503th rev. 1 224 / oki data confidential 7. Troubleshooting procedure 7.5.4.2 print operation is not possible if print operation is not possible by using the encrypted ipp printer, check the followings. Establish connection by "https://. 1) if the printer setting page is displayed, the followin...

Page 226

44015503th rev. 1 225 / oki data confidential 7. Troubleshooting procedure 7.5.4.3 cannot create certificate when certificate cannot be created, the following causes are probable. Take an appropriate measure by referring to the following items. * required input items are not fully entered refer to s...

Page 227

44015503th rev. 1 226 / oki data confidential 7. Troubleshooting procedure 7.5.4.4.2 "network card is initialized" if network card is initialized (to default setup) while creation of certificate of certifying authority is in progress (during the period starting from creation of csr up until installa...

Page 228

44015503th rev. 1 227 / oki data confidential 7. Troubleshooting procedure 7.5.4.5 other questionnaires other probable questionnaires are described below. 7.5.4.5.1 time required for creation of certificate it takes several ten seconds for creation of certificate. 7.5.4.5.2 communication time when t...

Page 229

44015503th rev. 1 228 / oki data confidential 7. Troubleshooting procedure 2. Press the "general" tab of the displayed certificate information, and press "install certificate" button. 3. The "certificate import wizard" is displayed. Install certificate in accordance with the displayed procedure. Sel...

Page 230

44015503th rev. 1 229 / oki data confidential 7. Troubleshooting procedure 7.5.4.6 restrictions when using internet explore 7 several restrictions are imposed when using internet explore 7. This is because security restriction became more severe in ie7. 7.5.4.6.1 warning indication when ssl is made ...

Page 231

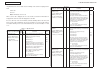

44015503th rev. 1 230 / oki data confidential 7. Troubleshooting procedure if the following error is issued, check the corresponding fuse of the cu control board, pu control board and high voltage power supply board. (refer to table 7-6.) table 7-6 fuse error fuse name error description insert point...

Page 232

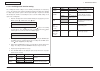

44015503th rev. 1 231 / oki data confidential 7. Troubleshooting procedure 7.7 paper cassette switches versus paper size correspondence table bit number dial indication size (oel) dial indication size (oda) 1 2 3 4 tray1 tray2/3 tray1 tray2/3 h h h h no cassette no cassette no cassette no cassette l...

Page 233

44015503th rev. 1 232 / oki data confidential 7. Troubleshooting procedure ide bus ide bus cu board hdd conversion board dpk-a3 7.8.1 data protection kit-a3 (dpk-a3) overview purpose: by encrypting data to be stored in hdd, data is protected from eavesdropping even when hdd is stolen. Method: the co...

Page 234

44015503th rev. 1 233 / oki data confidential 7. Troubleshooting procedure specification for safety: • if the data protection kit-a3 is removed from printer or swapped by others, it is informed to user as a warning. (error processing) • program download and eeprom read-out are prohibited so that the...

Page 235

44015503th rev. 1 234 / oki data confidential 7. Troubleshooting procedure error processing flow when error 252, 253, 256 has occurred (hdd related error - ) error display error contents error 252 data protection kit-a3 does not exist. Error 253 user’s data protection kit-a3 does not exist, but diff...

Page 236

44015503th rev. 1 235 / oki data confidential 7. Troubleshooting procedure error processing flow when error 250, 257 has occurred (hdd related error - ) error display error contents error 250 hdd data damage or hardware failure error 257 hdd data damage or hardware failure step 1 250: does the print...

Page 237: Connection Diagrams

Oki data confidential 8. Connection diagrams 8.1 resistance value check ...........................................................237 8.2 parts location ...........................................................................241 8.3 f/w version number ...............................................

Page 238

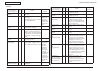

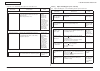

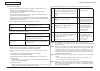

44015503th rev. 1 237 / oki data confidential 8. Connection diagrams 8.1 resistance value check unit electrical circuit diagram, connection part outside view resistance value transport belt motor red blown yellow blue m 1 2 3 4 between pin-1 and pin-2: 3.4 Ω between pin-3 and pin-4: 3.4 Ω id motor f...

Page 239

44015503th rev. 1 238 / oki data confidential 8. Connection diagrams unit electrical circuit diagram, connection part outside view resistance value id up/down motor m 1 2 3 4 between pin-1 and pin-2: 6.1 Ω between pin-3 and pin-4: 6.1 Ω fuser unit motor ip1 across both ends of ip1: 1 Ω or less.

Page 240

44015503th rev. 1 239 / oki data confidential 8. Connection diagrams unit electrical circuit diagram, connection part outside view resistance value feed motor m 1 2 3 4 between pin-1 and pin-2: 3.4 Ω between pin-3 and pin-4: 3.4 Ω both-sided print motor m 1 2 3 4 between pin-1 and pin-2: 2.4 Ω betwe...

Page 241

44015503th rev. 1 240 / oki data confidential 8. Connection diagrams unit electrical circuit diagram, connection part outside view resistance value fuser unit 1 2 3 4 5 6 7 a7 a6 a5 a4 a3 a2 a1 b6 b5 b4 b3 b2 b1 1 2 3 4 5 6 upper #2 350w upper #1 800w lower 50w correction thermistor (pt3-312) upper ...

Page 242

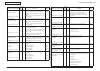

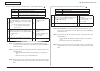

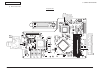

44015503th rev. 1 241 / oki data confidential 8. Connection diagrams 8.2 parts location (1) print engine controller pcb (pu pcb) component side r9 r79 c6 rm1 r23 r24 r27 r83 r25 r82 r5 c7 c37 fet1 fet3 fet4 rm4 r103 r105 rm3 rm5 fet2 c13 c19 r54 r85 r56 r84 r35 c11 c12 c9 c10 c8 r42 r99 c45 c18 r39 ...

Page 243

44015503th rev. 1 242 / oki data confidential 8. Connection diagrams soldering side c562 r612 r615 r613 r614 r513 r644 c563 c565 c564 c506 rm501 q508 q507 c514 c519 c516 c540 c538 c539 fet504 fet509 fet510 q506 q505 r558 r549 r582 r581 r592 r591 r595 d503 fet506 fet505 r651 c545 r646 r600 c559 fet50...

Page 244

44015503th rev. 1 243 / oki data confidential 8. Connection diagrams (2) main controller pcb component side nicsw lan c156 c158 c165 c164 c166 c172 r174 r173 r120 r121 r122 c171 c169 c167 c168 r85 ic4 r88 r102 r101 r99 c72 p ad33v1 r98 c84 r90 cc12a1 c87 c86 c85 testpn cleq1 cleq2 r119 rm72 rm74 rm7...

Page 245

44015503th rev. 1 244 / oki data confidential 8. Connection diagrams ic508 c510 ic501 ic502 c511 r525 r518 r513 r536 c532 r533 r519 c517 c533 c521 c513 r534 r522 r521 r515 c518 c535 c524 c516 c519 c520 r517 c553 c548 c545 c538 c537 c531 c528 c526 r530 c555 c557 c547 c544 c536 c530 c527 c525 c539 c50...

Page 246

44015503th rev. 1 245 / oki data confidential 8. Connection diagrams (3) rellay pcb(p6y pcb) component side soldering side lcr cp1 cp2 dens rcr 4 1 fuserin 3 1 5 1 4 1 j2 j3 10 1 21 1 fuser puif 1 6 exit j1 j4 j7 c1 j6 j5 bfuse bfucut.

Page 247

44015503th rev. 1 246 / oki data confidential 8. Connection diagrams (4) both-sided printing control pcb(v7y-4 pcb) component side soldering side main1 1 j11 13 j8 j9 j20 cp2 sns03 sns12 1 1 6 6 j24 j21 j18 osc j3 j26 j2 j4 j12 j13 j25 j19 j17 j1 j31 j32 j33 j29 j27 j6 j7 j10 j28 j5 j15 j16 j30 j34 ...

Page 248

44015503th rev. 1 247 / oki data confidential 8. Connection diagrams (5) second tray control pcb(v7y-11 pcb) component side soldering side main1 1 j11 13 main2 1 14 j8 j9 j20 cp2 sns03 sns12 1 1 6 6 j24 j21 j18 osc j3 j26 j2 j4 j12 j13 j25 j19 j17 j1 j31 j32 j33 j29 j27 j6 j7 j10 j28 j5 j15 j16 j30 ...

Page 249

44015503th rev. 1 248 / oki data confidential 8. Connection diagrams (6) control panel pcb(prg pcb) component side soldering side (7) toner low sensor pcb(prz pcb) ssns r1 ktnr r2 ytnr r3 mtnr a ctnr 1 11 sw6 sw1 led1 led2 sw7 sw0 cn3 1 sw3 sw2 sw5 sw4 49 1 48 16 17 32 33 64 j518 cp501 j501 r511 c51...

Page 250

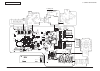

44015503th rev. 1 249 / oki data confidential cn3 cn6 cn2 t o lo w v oltage f am t o pu pcb po wer connector note : 100v system shor ting plug is mounted. 230v system shor ting plug is not mounted. Shor t-circuit plug for cn6 t o fuser unit i/f connector 8. Connection diagrams (8) entrance sensor pc...

Page 251