- DL manuals

- Oki

- Copier

- MC-860 / CX2633MFP

- Service & Troubleshooting Manual

Oki MC-860 / CX2633MFP Service & Troubleshooting Manual

MC-860 / CX2633MFP

Service & Troubleshooting Guide

© 2009 OkiData Americas, Inc.

Disclaimer

Every effort has been made to ensure that the information in this document is complete, accurate, and up to date. The

manufacturer assumes no responsibility for the results of errors beyond its control. While all reasonable efforts have been made

to make this document accurate and helpful as possible, we make no warranty of any kind, expressed or implied, as to the

accuracy or completeness of the information contained herein. For the most up-to-date service information available, visit our

website,

www.okidata.com

© Okidata Americas, Inc. 2009

Summary of MC-860 / CX2633MFP

Page 1

Mc-860 / cx2633mfp service & troubleshooting guide © 2009 okidata americas, inc. Disclaimer every effort has been made to ensure that the information in this document is complete, accurate, and up to date. The manufacturer assumes no responsibility for the results of errors beyond its control. While...

Page 2: Chapter 1

2 chapter 1 maintenance procedures – printer / adf / scanner 1.1 exterior cleaning 1.2 cleaning the led lens array 1.3 cleaning the pickup roller 1.4 cleaning inside the printer 1.5 cleaning the adf and scanner chapter 2 service menus and adjustments 2.1 how to enter the service menu 2.2 service mai...

Page 3: Chapter 1

Chapter 1 maintenance procedures – printer 1.1 exterior cleaning clean inside and outside of the printer with a clean dry cleaning cloth and small vacuum cleaner as required. Note! Be careful not to touch the image drum terminals, the led lens array and the led head connectors. 1. Turn off the power...

Page 4: Caution

1.2 cleaning the led lens array • pull the document table lock lever to the front to release the lock, and raise the document table. Document table document table lock lever • press the top cover button and open the top cover. Caution failure to proceed with caution may result in burn injury. The fu...

Page 5

1.3 cleaning the pickup roller note ! Clean the pickup roller for tray 2 and tray 3 in the same procedure. For the mp tray, clean the pickup roller in the same procedure for the feed roller only. (pad is not used.) • pull out the tray. • clean the feeder roller (large) and the feeder roller (small) ...

Page 6

1.4 cleaning inside the printer. Toner can adhere to the metal shaft that is located in between the fuser and the cyan image drum cartridge depending on the print pattern. Perform cleaning of the inside of the mfp if toner has adhered to the metal shaft. • turn off the power of the mfp. • pull the d...

Page 7

• hold the handle of the fuser unit and remove it. Fuser handle fuser unit lock lever (blue) • remove the transfer belt unit from the mfp. Transfer belt retaining screws (blue) transfer belt • thoroughly clean the interior of the printer and re-install the transfer belt, fuser, and drum units. Inspe...

Page 8

1.5 cleaning the adf and scanner clean the paper path of the adf once every month or more in order to maintain high print quality and to transport the documents smoothly. • open the document cover open lever and open the document cover. Document cover open lever document cover • clean the document t...

Page 9

• open the document table cover. Platen glass scanning glass document retaining pad clean the surface of the document retaining pad, the platen glass and the scanning glass with a clean cloth wrung out using clean water or neutral detergent. 9.

Page 10: Chapter 2

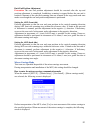

Chapter 2 service menus and adjustments the service function is to be used for the purposes of mfp maintenance by the experienced maintenance / service engineer, and are not open to general users. The respective items of the service function are contained in the service menu. 2.1 how enter the servi...

Page 11

Caution! The password can be changed by the “change password” menu of the “system maintenance” menu. It is highly recommended that you do not change this password. In the event that the changed password is lost, the main control board and hard disk drive would need replacement. This is not a covered...

Page 12

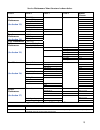

2.2 service maintenance menu – overview system maintenance screen panel maintenance screen copy maintenance screen scan maintenance screen fax maintenance screen printer maintenance screen 12.

Page 13

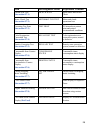

13 service maintenance menu structure is shown below. Level 1 level 2 level 3 level 4 reboot process okiuser when closed format hdd when executed format flash rom when executed menu reset none all reset when executed test print menu when closed system maintenance (see section 2.3) change password ne...

Page 14

2.3 system maintenance okiuser sets the mfp for the destination country. Note! Should always be set for oda (north america). Settings other than oda may result in erratic mfp operation. When the screen exits the service menu after this setting is changed, the mfp reboots automatically. Format hdd in...

Page 15

Menu reset (administrator password reset) returns the administrator password to the factory shipment setting (factory default) value. When [menu reset] is selected, the following confirmation screen is displayed. When [yes] is selected, the administrator password is reset to the factory shipment set...

Page 16

Change password note! The password can be changed by the “change password” menu of the “system maintenance” menu. It is highly recommended that you do not change this password. In the event that the changed password is lost, the main control board and hard disk drive would need replacement. This is ...

Page 17

Lcd test displays the test pattern on the lcd in order to check if there are inactive pixels on the lcd. Operating procedure the following three kinds of test patterns can be displayed. To select the test patterns, press the [setup] key. Press the [setup] key. Press the [setup] key. Press the [setup...

Page 18

Control panel key test checks if the mfp responds normally when the hardware key and the software key on the control panel is pressed, by observing the lcd screen if the pressed key is displayed or not on the lcd screen. This test aims at checking all of the keys. Therefore, all keys should be press...

Page 19

2.5 scanner maintenance shading data loading shading data of fbs and that of radf (both-side copy model only) are loaded. This item should be executed whenever any of the following items is performed. • when the scanner lamp is replaced * • when the mirror carriage adjustment is performed * • when t...

Page 20

20 scan position adjustment side registration adjustment - the separate setting items are prepared for fbs, adf (front side) and adf (back side) independently. Setting for flat bed scanning (fbs) perform adjustment so that the scan start position in the horizontal scanning direction during fbs scann...

Page 21

Back end position adjustment precaution the rear end position adjustment should be executed after the top end position adjustment is completed. In addition, scanning is stopped before the rear end is reached if amount of the specified scanning lines are scanned in the copy mode and scan mode even th...

Page 22

Tighten the screws at the locations as specified in the illustration, and press the [close] button. When the mirror carriage is locked in the specified position, select the menus [setup] – [shutdown] to execute the shutdown operation. Then turn off the power. How to release the mirror carriage mode ...

Page 23

23 2.6 fax maintenance country code select the country in which the mfp is going to be installed. (oda) north america in this setting, any country code can be selected regardless of the okiuser setting. When the screen exits the service menu after this setting is changed, the mfp reboots automatical...

Page 24

Rx (during reception) when set to enable switching time between ced – dis *4: 1000 ms when set to disable switching time between ced – dis *4: 75 ms switching time between ced – dis *4: when the ced signal at 2100 hz is sent out during reception of overseas communication, the echo suppression stops ...

Page 25

Pulse make ratio default 40% sets the make ratio of dp (10 pps) during call. Mf (tome) duration on period range 0 - 1 ms to 255 ms default 80ms sets the on period of mf (tone) duration send. When the setting value is “0”, the mfp runs at the initial value of each country. When the set value is excep...

Page 26

26 tonal send test tonal test procedure press the [tonal] button on the "line test” screen. Select a signal to test. When the [stop] key is pressed, signal send is interrupted. When the [close] button is pressed, the screen returns to the “line test” screen. When the [reset] key is pressed, screen r...

Page 27

Engine diagnostic mode (self-diagnostic) how to enter self-diagnostic mode (level 1) 1. From the service menu, select [printer maintenance] and [engine diag. Mode] to enter the self-diagnostic mode. 2. When the screen enters the self-diagnostic mode (level 1), the "diagnostic mode” is displayed. Pre...

Page 28

Level 1 diagnostic screens 28.

Page 29

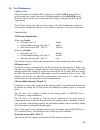

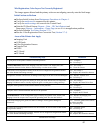

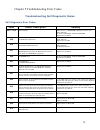

29 item self-diagnostic menu adjustment contents switch scan test (see section 2.7.1) switch scan input sensor and switch check motor clutch test (see section 2.7.2) motor&cltch test motor and clutch operational test executing test print (see section 2.7.3) test print pu internal test pattern print ...

Page 30

30

Page 31

2.7.1 switch scan test this self-diagnostic menu is used to check the input sensors and switches of the print engine. 1. Enter the self-diagnostic mode (level 1) and press the (2) key or (8) key until "switch scan” is displayed in the top of the screen. Press the (6) key to execute. (the (2) key inc...

Page 32

32 switch scan test location 1 location 2 location 3 location 4 display detail on printer lcd sensor tested display condition sensor tested display condition sensor tested display condition sensor tested display condition paper r oute: pu entrance sensor 1 h - absent l – present entrance sensor 2 h ...

Page 33

2.7.2 motor & clutch test this self-diagnostic menu is used to test the motors and clutches of the print engine. 1. Enter the self-diagnostic mode (level 1) and press the (2) key or (8) key until [motor & clutch test] is displayed in the top of the screen. Press the (6) key to execute. The (2) key i...

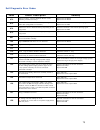

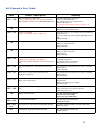

Page 34: Unit Name Display

34 unit name display drive restriction conditions id motor drives when all of the ids (k/y/m/c) are removed. Belt motor drives when all of the ids (k/y/m/c) are removed. Fuser motor fuser mtr rev fuser_rls regist motor t1 hopping motor front motor regist shutter exit solenoid duplex motor duplex clu...

Page 35: Display Setup

35 2.7.3 test print this self-diagnostic menu is used to print the test pattern contained in the pu. Other test patterns are contained in the controller. 1. Enter the self-diagnostic mode (level 1) and press the (2) key or (8) key until [test print] is displayed in the top of the screen. Press the (...

Page 36

Print patterns 36 pattern 1 pattern 2 pattern 3 pattern 4 pattern 5 pattern 6 note! If the solid print data (pattern 7) that is contained in the local print function is used for test print with 100% setting of each color, it causes offset. To prevent offset, select the print setting of each color so...

Page 37

Monitoring printer environmental conditions the following printer environmental conditions can be monitored during generation of test prints. The following messages are displayed during test print. P *** = number of test prints (unit: sheet) w*** = print wait time (unit: sheet) pressing the (2) key ...

Page 38

Utmp: fuser motor standard speed correction parameter (fuser target temperature) [unit: dec] reg: hopping motor standard speed timer value (i/o setting value) [unit: hex] ext: fuser motor standard speed timer value (i/o setting value) [unit: hex] pressing the (2) key switches the display. When the (...

Page 39

2.7.4 color registration error correction test this self-diagnostic menu is used for adjustment and to investigate cause of the color registration error of the mfp. 1. Enter the self-diagnostic mode (level 1) and press the (2) key or (8) key until [test print] is displayed in the top of the screen. ...

Page 40: Display Details

Blt reflect rslt is executed >> the key operations when blt reflect rslt is executed the key operations are the same as those above. When the (4) key is pressed, the screen exits the test. (screen returns to the item 1 condition.) color registration correction test items display details reg adj exec...

Page 41: Display Details

Dens adj execute is executed >> • the density error correction test is executed. (the [on line] lamp blinks.) • when the test is complete, the test result (ok or error name) is displayed in the upper column of the display window and **** result is displayed in the lower column of the display window....

Page 42

2.7.6 consumable item counter display this self-diagnostic menu is used to display the consumption status of the consumable items. 1. Enter the self-diagnostic mode and press the (2) key or (8) key until [consumable status] is displayed on the screen. Press the (6) key to execute. The (2) key increm...

Page 43

Printed sheets counter display this self-diagnostic menu is used to display the number of printed sheets status of the mfp. 1. Enter the self-diagnostic mode and press the (2) key or (8) key until [printer status] is displayed on the screen. Press the (6) key to execute. The (2) key increments the t...

Page 44

Upper display lower display function factory mode sets up the factory work mode. This is a production mode. Note! The unit should always be set for shipping mode or erratic operation may result. Factory mode shipping mode sets up the shipping mode for normal operation. Belt unit ****** checks the fu...

Page 45

Display setting operation function enable to detect toner sensor disable not to detect sets enable/disable of the toner sensor operation enable to check belt unit check__enable disable not to check sets enable/disable of the belt installation check job. Enable to check id unit check disable not to c...

Page 46

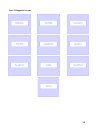

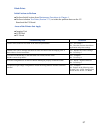

2.8 initialization functions items that can be initialized by the administrator the following table shows the setup items that can be initialized by administrator. The gray colored items indicate that the data is stored in the cu side. The white items indicate that the data is stored in the scanner ...

Page 47

Initialization functions admin page 2 47.

Page 48

Initialization functions admin page 3 *1 the group counter – reset is confidential and menu is not open in fcs. *4 when hdd disable is set, only administrator can log on. (because the access control mode setup values is stored in flash, but the user information is not stored in hdd.) 48.

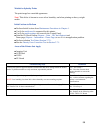

Page 49

Items that can be initialized by the service engineer the initialization operations that can be performed by service engineer are shown below. The following table shows the setup items that can be initialized by the service engineer. Descriptions regarding description in the table are added. The gra...

Page 50

Initialization functions service engineer page 2 50

Page 51

Initialization functions service engineer page 3 51.

Page 52

Initialization functions service engineer page 4 *2 only the setups that change their initial values depending on destination or counter code are initialized. *3. [filename (standard)] and [e-mail edit fixed phrase] under the menus [scanner function] - [e-mail setting] are initialized. *4 when hdd d...

Page 53

53 chapter 3 troubleshooting print quality 3.1 print quality problems overview print-quality defects can be attributed to printer components, consumables, media, internal software, external software applications, and environmental conditions. To successfully troubleshoot print-quality problems, elim...

Page 54

54 3.2 using new consumable units for testing purposes the mc-860 / cx2633 will allow you to utilize new consumable units for print quality diagnosis and troubleshooting purposes. Note! When using new units (drum, transfer belt, fuser) to assist in troubleshooting, you should temporarily set the pri...

Page 55

55 3.4 print-quality troubleshooting light prints in all colors the overall image density is too light in all colors. If the image is light in only one color, see "light print in only one color". Initial actions to perform ■ perform initial actions from maintenance procedures in chapter 1 . ■ verify...

Page 56

56 light prints in only one color only one color; yellow, magenta, cyan, or black, is too light on the printed image. Initial actions to perform ■ perform initial actions from maintenance procedures in chapter 1 . ■ print the id check pattern (reports – print – id check pattern) and demo page (repor...

Page 57

57 blank prints initial actions to perform ■ perform initial actions from maintenance procedures in chapter 1 . ■ perform isolation test prints (section 2.7.3) to isolate the problem between the cu board and the pu board. Areas of the printer that apply ■ imaging unit ■ led head ■ pu board troublesh...

Page 58

58 mottled or splotchy prints the print image has a mottled appearance. Note! This defect is known to occur at low humidity, and when printing on heavy weight media. Initial actions to perform ■ perform initial actions from maintenance procedures in chapter 1 . ■ verify the media used is supported b...

Page 59

59 unexpected colors the colors produced by the printer are dramatically different from the color expected. Initial actions to perform ■ perform initial actions from maintenance procedures in chapter 1 . ■ verify the media used is supported by this printer. ■ verify the media settings are correct at...

Page 60

Repeating bands, lines, marks, or spots this is usually caused by a damaged roller. In some instances, the spots may be dark instead of white and are repeated. Initial actions to perform ■ perform initial actions from maintenance procedures in chapter 1 . ■ verify the media used is supported by this...

Page 61

61 mis-registration, color layers not correctly registered the image appears blurred and the primary colors are not aligning correctly onto the final image. Initial actions to perform ■ perform initial actions from maintenance procedures in chapter 1 . ■ verify the media used is supported by this pr...

Page 62

62 12. Are the led head ribbon cables undamaged, properly routed and seated? Yes – go to step 13. No - reseat, correctly route or replace the wiring harness. 13. Swap the led head of the problem color with any other led head. Print a supplies page. Has the problem moved with the led head? Yes – repl...

Page 63

4.1 troubleshooting paper feed 4.1.1 paper feed sensor details diagram showing paper detection sensors in the print engine 63.

Page 64

Paper jam code table for the print engine code number jam location related sensors 370 duplex reversal dup-in, dup-r 371 duplex input dup-f, dup-r 372 feed error at duplex in1 373 multi-feed in duplex unit dup-b 380 feed in2, wr 381 transport in1, in2, wr, fuser-in, exit 382 exit exit, fuser-in 383 ...

Page 65

Sensor location table for the radf sensor description pi 10 cover open/close sensor pi 11 document set sensor pi 16 delivery reversal sensor pi 17 read sensor pi 18 registration paper sensor 4.1.2 jam removal procedure front cover block (code: 372, 380, 390, 391, 400) open the front cover. If either...

Page 66

Fuser unit (code: 381, 382, 383, 385) caution! The fuser unit gets very hot. Be very careful not to touch the fuser unit with your hands. (1) raise the scanner and open the top cover. (2) raise the fuser unit lock lever (lever shown in blue) in the direction shown by the arrow. (3) hold the handle a...

Page 67

(1) remove the four image drum cartridges and place them on a flat workbench. (2) cover the removed image drum cartridge with a black paper. (3) draw out the jammed paper gently with care. #3 #2 #1 #5 #4 (4) return the image drum cartridges back to the original positions. 67.

Page 68

Duplex unit (code: 370, 371, 373) note! Before removing the duplex unit, be sure to turn off the power of the mfp. (1) remove the duplex unit. (2) press the jam release lever of the duplex unit to open the duplex unit cover. (3) draw out the jammed paper gently with care. 68.

Page 69

Second tray unit (option) (code: 391, 393) this manual describes the jam clear method using tray 2 as an example. Tray 3 can also be cleared using the same method. (1) remove the paper tray from the second tray unit, and remove the paper. (2) after the jammed paper is removed, open the mp tray, push...

Page 70

(2) draw out the jammed paper gently with care. If the jammed paper cannot be removed, go to step (4). Note! Do not pull the document out with excessive force. (3) when the jammed paper is removed, go to step (9). (4) open the inside cover. (5) if top end of the jammed paper is visible, pull it out ...

Page 71

(6) when the jammed paper is removed, close the inside cover and go to step 9. (7) rotate the dial so that the jammed document is unloaded. (8) raise the document tray. Remove the jammed document gently. (9) close the document cover. 71.

Page 72

72 chapter 5 troubleshooting error codes troubleshooting self diagnostic codes self diagnostic error codes code cause/description remedy 002 - 005 cpu exception power off/on. If ram dimm is installed, remove and power off/on. Re-mount ram dimm / replace ram dimm replace the cu board 020 cu rom hash ...

Page 73

73 self diagnostic error codes code cause/description remedy 072 engine i/f error. I/f error between pu-cu. Is cu assembly installed correctly? Replace the cu board replace the pu board 073 video error. Error is detected when expanding of the video data. (illegal data is received.) decrease resoluti...

Page 74

74 self diagnostic error codes code cause/description remedy 131 - 134 led head detection is abnormal. (131 =y, 132 = m, 133 = c, 134= k) is the led head installed normally? Is the led head fuse blown? Install the led head unit properly. Check the led head fuse. Turn off the power once and back on. ...

Page 75

75 self diagnostic error codes code cause/description remedy 231 rfid reader is not installed. Rfid read device error check connections of the rfid r/w pcb. Replace the rfid r/w pcb replace the p6x pcb. 901 - 904 belt temperature is abnormal. 901: short circuit. 902: open circuit. 903: high temperat...