- DL manuals

- Oki

- Printer

- OKIPAGE 10e

- Maintenance Manual

Oki OKIPAGE 10e Maintenance Manual

Summary of OKIPAGE 10e

Page 1

41154001th rev.2 1 / 173 okipage 10e led page printer maintenance manual oda / oel / int 1999.11. 30 rev.2.

Page 2

41154001th rev.2 2 / 1 1999.10.22 issue e5 miyashita 2 1999.11.30 table 8-1 188 add no.50. E5 otake revision history table rev.No. Date corrected items person in no. Page description of change change.

Page 3: Preface

41154001th rev.2 3 / preface this maintenance manual describes the field maintenance methods for okipage 10e led page printers. This manual is written for use by the maintenance personnel. Please note that you should refer to the printer handbook and printer setup for the handling and operating meth...

Page 4: Contents

41154001th rev.2 4 / contents 1. Configuration ............................................................................................. 77 1.1 system configuration ..................................................................................... 7 1.2 printer configuration ....................

Page 5

41154001th rev.2 5 / 4. Adjustment ................................................................................................... 74 4.1 adjustment types and functions ................................................................. 74 4.1.1 status monitor ........................................

Page 6

41154001th rev.2 6 / 3.3 parts replacement methods ................................................................ 139 3.3.1 link ......................................................................................................................... 140 3.3.2 separator ..............................

Page 7

41154001th rev.2 7 / 1. Configuration 1.1 system configuration okipage 10e consists of control and engine blocks in the standard configuration, as shown in figure 1-1. In addition, the options marked with asterisk(*) are available..

Page 8

41154001th rev.2 8 / figure 1-1 power supply and sensor board electrophotographic processing unit paper feeding mechanism (first tray unit) rs-232c serial* interface board 1 dram simm socket 1 flash simm socket main control board operator panel paper cassette face down stacker engine unit * : option...

Page 9

41154001th rev.2 9 / 1.2 printer configuration the printer unit consists of the following hardware components: • electrophotographic processor • paper feeder • controller • operator panel • power supply unit the printer unit configuration is shown in figure 1-2. Figure 1-2 upper cover operator panel...

Page 10

41154001th rev.2 10 / (3) 1mb memory expausion board 1.3 optional configuration the options shown below are available for use with okipage 10e. These are available separately from the printer unit. (1) high capacity second paper feeder (2) multi purpose feeder.

Page 11

41154001th rev.2 11 / (4) rs-232c serial interface board (5) dram simm memory dram simm memory is available with memory of 2, 4, 8, 16 or 32mb. The access time of simm memories are 60ns, 70ns, 80ns, and 100ns. (6) flash simm flash simm is available with memory of 4mb and 8mb..

Page 12

41154001th rev.2 12 / 1.4 specification (1) type desktop (2) external dimensions height 7.9” (200 mm) width 13.0” (330 mm) depth 15.6” (395 mm) (3) weight approx. 10 kg (4) developing method dry electrophotography exposing method led stationary head (5) paper used • standard paper – xerox 4200 (20 l...

Page 13

41154001th rev.2 13 / (10) power input 120 vac + 5.5%, -15% 230 vac ± 10% (11) power consumption peak: approx. 460w typical operation: approx. 215w idle: approx. 61w power save mode: approx. 18w (12) temperature and humidity 1. Storage conditions specified above apply to printers in packed condition...

Page 14

41154001th rev.2 14 / 1.5 safety standards 1.5.1 certification label the safety certification label is affixed to the printer in the position described below. 1.5.2 warning label the warning labels are affixed to the sections which may cause bodily injury. Follow the instructions on warning labels d...

Page 15

41154001th rev.2 15 / 1.5.3 warning/caution marking the following warning and caution markings are made on the power supply/sensor board. English heatsink and transformer core present risk of electric shock. Test before touching. French le dissipateur thermique et le noyau du transformateur présente...

Page 16

41154001th rev.2 16 / 2. Operation description okipage 10e consists of a main control board, a power supply/sensor board, an operator panel, an electrophotographic process mechanism, and revision for illumination of led head. The main control board receives data via the host i/f, it then decodes, ed...

Page 17

41154001th rev.2 17 / figure 2-1 okipage 10e block diagram 1mb memory board (option) rs232c interface board (option) or program & font rom 6mb mask rom resident ram 1m x 16 bit. Dram (4mb) for optional board main control board power supply board data bus (32bit) eeprom 74ls07 inlet sensor 1 inlet se...

Page 18

41154001th rev.2 18 / 2.1 main control board the main control board consists of a single chip cpu, two program/font roms, two drams, an eeprom, a host interface circuit, and a mechanism driving circuit. (1) single chip cpu the single chip cpu is a custom cpu (32-bit internal bus, 32-bit external bus...

Page 19

41154001th rev.2 19 / 2.2 power supply/sensor board the power supply/sensor board consists of an ac filter circuit, a low voltage power supply circuit, a high voltage power supply circuit, heater drive circuit, and photosensors. (1) low voltage power supply circuit this circuit generates the followi...

Page 20

41154001th rev.2 20 / figure 2-2 the sensor layout diagram is shown in figure 2-2. Outlet sensor exit roller heat roller transfer roller paper sensor registration roller inlet sensor 1 inlet sensor 2 toner sensor paper end sensor hopping roller paper feeding direction sensor function sensing state i...

Page 21

41154001th rev.2 21 / 2.3 electrophotographic process 2.3.1 electrophotographic process mechanism this mechanism actuates the printing of image data supplied by the main control board on the paper by electrophotographic process. The layout of the electrophotographic process mechanism is shown in fig...

Page 22

41154001th rev.2 22 / figure 2-3 paper cassette eject sensor lever eject roller assy heat roller charge roller developing roller toner cartridge led head image drum unit back-up roller cleaning roller transfer roller paper sensor plate inlet sensor plate registration roller hopping roller.

Page 23

41154001th rev.2 23 / (1) image drum unit the image drum unit consists of a sensitive drum, a charger, and a developer. The unit forms a toner image on the sensitive drum, using a electrostatic latent image formed by the led head. (2) registration motor the registration motor is a pulse motor of 48 ...

Page 24

41154001th rev.2 24 / 2.3.2 electrophotographic process the electrophotographic processing is outlined below. The electrophotographic printing process is shown in figure 2-4. 1 charging the surface of the image drum is charged uniformly with a negative charge by applying the negative voltage to the ...

Page 25

41154001th rev.2 25 / paper eject roller (face down) power supply paper eject roller paper eject (face up) cleaning roller led head image data registration roller hopping roller heater roller power supply doctor blade power supply (bias voltage) toner supply roller toner cartridge paper eject fusing...

Page 26

41154001th rev.2 26 / print-n out sensor off prdy-n dm-on-n rm-on insns outsns-n feed stop in sensor off feed start figure 2-5.

Page 27

41154001th rev.2 27 / 2.3.3 process operation descriptions (1) hopping and feeding hopping and feeding motions are actuated by a single registration motor in the mechanism as shown below: the registration motor turning in direction "a" drives the hopping roller. The registration motor turning in dir...

Page 28

41154001th rev.2 28 / (b) feeding 1 when hopping is completed, the registration motor turning in direction "b" (counter- clockwise direction) drives the registration roller to advance the paper (in this case, the hopping gear also turns, but the hopping roller is prevented from turning by the one-wa...

Page 29

41154001th rev.2 29 / (2) charging charging is actuated by the application of the dc voltage to the charge roller that is in contact with the image drum surface. The charge roller is composed of two layers, a conductive layer and a surface protective layer, both having elasticity to secure good cont...

Page 30

41154001th rev.2 30 / (3) exposure light emitted by the led head irradiates the image drum surface with a negative charge. The surface potential of the irradiated portion of the image drum drops, forming an electrostatic latent image associated with the image signal. Power supply led head charge rol...

Page 31

41154001th rev.2 31 / the image roller surface is charged to about –750 v by the contact charge of the charge roller. When the light from the led head irradiates the image drum surface, the light energy generates positive and negative carriers in the cgl. The positive carriers are moved to the ctl b...

Page 32

41154001th rev.2 32 / (4) developing toner is attracted to the electrostatic latent image on the image drum surface, converting it into a visible toner image. Developing takes place through the contact between the image drum and the developing roller. 1 as the toner supply roller rotates while rubbi...

Page 33

41154001th rev.2 33 / note: the bias voltage required during the developing process is supplied to the toner supply roller and the developing roller, as shown below. –500 vdc is supplied to the toner supply roller, –265 vdc to the developing roller. Image drum base developing roller connected and bi...

Page 34

41154001th rev.2 34 / (5) transfer the transfer roller is composed of conductive sponge material, and is designed to get the image drum surface and the paper in a close contact. Paper is placed over the image drum surface, and the positive charge, opposite in polarity to that of the toner, is applie...

Page 35

41154001th rev.2 35 / (6) fusing when the transfer is completed, the toner image is fused to the paper by heat and pressure as the paper with unfused toner image passes between the heater roller and the back-up roller. The heater roller with teflon coating incorporates a 400w heater (halogen lamp), ...

Page 36

41154001th rev.2 36 / (7) cleaning when the transfer is completed, the residual toner left on the image drum is attracted to the cleaning roller temporarily by static electricity, and the image drum surface is cleaned. (8) cleaning of rollers the charge, transfer and cleaning rollers are cleaned for...

Page 37

41154001th rev.2 37 / 2.4 paper jam detection the paper jam detection function monitors the paper condition when the power is turned on and during printing. When any of the following conditions arises, this function interrupts the printing process. If any of the following errors is encountered, prin...

Page 38

41154001th rev.2 38 / note: hyphen "-" in the table represents "not checked." paper feed check list paper length list minus type of error monitor standard value error plus paper feed error paper feed jam paper feed jam paper size error paper exit jam paper feed jam 72.0 20.0 140.5 depends on the pap...

Page 39

41154001th rev.2 39 / 2.5 cover open when the stacker cover is opened, the cover open microswitch on the power supply/sensor board is turned off to cut +5v supply to the high voltage power supply circuit. This results in the interruption of all high-voltage outputs. At the same time, the cvopn signa...

Page 40

41154001th rev.2 40 / 2.6 toner low detection • device the toner low detection device consists of a stirring gear which rotates at a constant rate, a stirring bar and a magnet on the stirring bar. The stirring bar rotation is driven by the link to the gouged portion in the stirring gear. • operation...

Page 41

41154001th rev.2 41 / toner full state toner low state • when the toner low state is detected 2 times consecutively, toner low is established. • when the toner full state is detected 2 times consecutively, toner low is cancelled. • when there is no change with the toner sensor for 2 cycles (2.63 sec...

Page 42

41154001th rev.2 42 / 3. Parts replacement this section explains the procedures for replacement of parts, assemblies, and units in the field. Only the disassembly procedures are explained here. For reassembly, reverse the disassembly procedure. 3.1 precautions for parts replacement (1) before starti...

Page 43

41154001th rev.2 43 / [service tools] the tools required for field replacement of printed circuit boards, assemblies and units are listed in table 3-1. Table 3-1 service tools no. Q' ty application remarks service tools 1 2 3 4 5 6 7 8 1 1 1 1 1 1 1 1 2~2.5 mm screws 3~5 mm screws cleans led head no...

Page 44

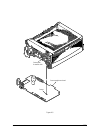

41154001th rev.2 44 / 3.2 parts layout this section explains the layout of main components of the equipment. [lower base unit] figure 3-1 pulse motor (main/drum) pulse motor (registration) registration roller spacer bearing r spacer bearing l back-up roller eject roller assy stacker cover assy disel...

Page 45

41154001th rev.2 45 / [upper cover unit] figure 3-2 upper cover.

Page 46

41154001th rev.2 46 / [base unit] figure 3-3 cassette guide(l) paper cassette cassette guide (r) dc fan assy face up stacker assy operator panel assy power supply/ sensor board transformer main control board.

Page 47

41154001th rev.2 47 / 3.3 how to change parts this section explains how to change parts and assemblies listed in the disassembly diagram below. In the parts replacement procedure, those parts marked with the part number inside ● with white letters are rspl parts. Printer unit upper cover assy (3.3.1...

Page 48

41154001th rev.2 48 / 3.3.1 upper cover assy (1) with the power switch turned off, unplug the ac power cord from the outlet. (2) disconnect the interface cable 1 . (3) press the knobs 2 on left and right sides and open the stacker cover assy 3 . (4) take out the image drum unit 4 . (5) remove two sc...

Page 49

41154001th rev.2 49 / 3.3.2 ic card cover (1) open the ic card cover 1 , press it from both sides at the hinges in the directions of arrows shown below and remove it. 1.

Page 50

41154001th rev.2 50 / 3.3.3 led head (1) press the knobs on left and right sides and open the stacker cover assy 1 . (2) open the hook section on the left side of the stacker cover and remove the led head 2 . Note: • be sure not to touch directly or push on the sla part of the led head. • do not rem...

Page 51

41154001th rev.2 51 / 3.3.4 operator panel assy (1) unlock two latches on the upper cover from the rear side, lift the operator panel assy 1 from the back and remove it. (2) remove the sumi card (operator panel) 2 from the connector (cn1) 3 . Note : you can remove the operator panel assy while the u...

Page 52

41154001th rev.2 52 / 3.3.5 lower base unit (1) remove the upper cover assy (see 3.3.1). (2) remove the operator panel assy (see 3.3.4). (3) remove the face up stacker assy (see 3.3.8). (4) remove the connecting cables 2 and 3 of the pulse motors from the connectors (dm, rm) of the m5g-pcb 1 . (5) r...

Page 53

41154001th rev.2 53 / 3.3.6 pulse motor (main/drum) (1) remove the upper cover assy (see 3.3.1). (2) remove the lower base unit (see 3.3.5). (3) remove two screws 1 and remove the pulse motor (main/drum) 2 from the motor bracket 3 . 2 1 1 3 view a view a.

Page 54

41154001th rev.2 54 / 3.3.7 pulse motor (registration) (1) remove the upper cover assy (see 3.3.1). (2) remove the lower base unit (see 3.3.5). (3) remove two screws 1 and remove the pluse motor (registration) 2 from the motor bracket 3 . 2 1 1 3 view a view a.

Page 55

41154001th rev.2 55 / 1 3 2 4 3.3.8 face up stacker assy (1) remove the upper cover assy (see 3.3.1). (2) remove the operator panel assy (see 3.3.4). (3) remove the screw 1 and remove the sumi card (operator panel cable) 2 off the latch section of face up stacker 4 . Remove both the shield plate 3 a...

Page 56

41154001th rev.2 56 / 3.3.9 eject roller assy (1) remove the upper cover assy (see 3.3.1). (2) remove the operator panel assy (see 3.3.4). (3) remove the face up stacker assy (see 3.3.8). (4) remove the lower base unit (see 3.3.5). (5) disengage the eject roller assy 1 from the lower base 2 by press...

Page 57

41154001th rev.2 57 / 3.3.10 motor assy (1) remove the upper cover assy (see 3.3.1). (2) remove the operator panel assy (see 3.3.4). (3) remove the face up stacker assy (see 3.3.8). (4) remove the lower base unit (see 3.3.5). (5) stand the lower base unit on its side as shown, and unlock two latches...

Page 58

41154001th rev.2 58 / 3.3.11 hopping roller shaft assy (1) remove the upper cover (see 3.3.1). (2) remove the operator panel assy (see 3.3.4). (3) remove the face up stacker assy (see 3.3.8). (4) remove the lower base unit (see 3.3.5). (5) remove the motor assy (see 3.3.10). (6) with the lower base ...

Page 59

41154001th rev.2 59 / 3.3.12 stacker cover assy (1) remove the upper cover assy (see 3.3.1). (2) remove the operator panel assy (see 3.3.4). (3) remove the face up stacker assy (see 3.3.8). (4) remove the reset lever r 1 . (5) detach the reset spring 2 from the lower base unit 3 , turn the reset lev...

Page 60

41154001th rev.2 60 / 3.3.13 registration roller (1) remove the upper cover (see 3.3.1). (2) remove the operator panel assy (see 3.3.4). (3) remove the face up stacker assy (see 3.3.8). (4) remove the lower base unit (see 3.3.5). (5) remove the motor assy (see 3.3.10). (6) with the lower base unit s...

Page 61

41154001th rev.2 61 / 3.3.14 roller transfer assy (1) with the power switch turned off, unplug the ac cord from the outlet. (2) open the stacker cover. (3) release the roller transfer assy 1 by unlocking the latch of the main unit (never apply excessive force when unlocking the latch). (4) lift the ...

Page 62

41154001th rev.2 62 / 3.3.15 fusing unit (1) remove the upper cover (see 3.3.1). (2) remove the operator panel assy (see 3.3.4). (3) remove the face up stacker assy (see 3.3.8). (4) remove the stacker cover assy (see 3.3.12). (5) remove four screws 1 , lift and remove the fusing unit 2 . Caution: fu...

Page 63

41154001th rev.2 63 / 3.3.16 back-up roller (1) remove the fusing unit assy (see 3.3.15). (2) lift the left side of the back-up roller 1 , and pull it out to the left side (at this time, two bushings (back-up) 2 and the bias springs (back-up) 3 will also come off). 3 2 1 2 3.

Page 64

41154001th rev.2 64 / 3.3.17 sensor plate (inlet) (1) remove the upper cover (see 3.3.1). (2) remove the operator panel assy (see 3.3.4). (3) remove the face up stacker assy (see 3.3.8). (4) remove the lower base unit (see 3.3.5). (5) press the clamps of three sensor plates (inlet and paper) 1 , and...

Page 65

41154001th rev.2 65 / 3.3.18 sensor plate (outlet) (1) remove the upper cover assy (see 3.3.1). (2) remove the operator panel assy (see 3.3.4). (3) remove the eject roller assy (see 3.3.9). (4) remove the face up stacker assy (see 3.3.8). (5) remove the lower base unit (see 3.3.5). (6) remove the fu...

Page 66

41154001th rev.2 66 / 3.3.19 manual feed guide assy (1) remove the upper cover assy (see 3.3.1). (2) open the manual feed guide assy 1 , and release the engagement on both sides with the main unit by carefully bending the manual feed guide assy 1 . Note : when remounting, verify the proper the engag...

Page 67

41154001th rev.2 67 / 3.3.20 sensor plate (paper supply) (1) remove the upper cover assy (see 3.3.1). (2) remove the operator panel assy (see 3.3.4). (3) remove the face up stacker assy (see 3.3.8). (4) remove the lower base unit (see 3.3.5). (5) press the clamps of the sensor plate (paper supply) 1...

Page 68

41154001th rev.2 68 / 3.3.21 m5g-pcb (1) remove the upper cover assy (see 3.3.1). (2) remove the operator panel assy (see 3.3.4). (3) remove the face up stacker assy (see 3.3.8). (4) remove the lower base unit (see 3.3.5). (5) remove the connector (2ndtray) 6 . (6) remove three screws 1 . (7) move t...

Page 69

41154001th rev.2 69 / 3.3.22 transformer (1) remove the upper cover assy (see 3.3.1). (2) remove the operator panel assy (see 3.3.4). (3) remove the face up stacker assy (see 3.3.8). (4) remove the connectors (cn1 and cn2). (5) remove two screws 1 , and remove the transformer 2 . Note : when reinsta...

Page 70

41154001th rev.2 70 / 3.3.23 power supply/sensor board and contact assy (1) remove the upper cover assy (see 3.3.1). (2) remove the lower base unit (see 3.3.5). (3) remove the m5g-pcb (see 3.3.21). (4) remove the transformer (see 3.3.22). (5) remove the ac inlet 1 from the base plate 2 . (6) remove ...

Page 71

41154001th rev.2 71 / 3.3.24 cassette guide l assy (1) remove the paper cassette. (2) remove the upper cover assy (see 3.3.1). (3) remove the lower base unit (see 3.3.5). (4) remove the m5g-pcb (see 3.3.21). (5) remove the transformer (see 3.3.22). (6) remove the power supply/sensor board (see 3.3.2...

Page 72

41154001th rev.2 72 / 3.3.25 cassette guide r assy (1) remove the paper cassette. (2) remove the upper cover assy (see 3.3.1). (3) remove the lower base unit (see 3.3.5). (4) remove the m5g-pcb (see 3.3.21). (5) remove two screws 1 , and remove the guide rails 2 . (6) remove the screw 3 , and remove...

Page 73

41154001th rev.2 73 / 3.3.26 spacer bearing (l/r) (1) remove the back-up roller (see 3.3.16). (2) remove spacer bearing (l/r) with a tip of screw driver. Spacer bearing l spacer bearing r.

Page 74

41154001th rev.2 74 / 4. Adjustment this chapter explains adjustment necessary when a part is replaced. This adjustment is made by changing the parameter values set in eeprom on the main control board. The status monitor or maintenance utility can be used to change these values. Only servicemen and ...

Page 75

41154001th rev.2 75 / 4.1.2 engine maintenance utility see appendix c 4.2 adjustment when replacing a part the table below lists the parts that requires adjustment when they are replaced. 4.2.1 setting of led head drive time caution: when the luminous intensity of a new led head is the same as that ...

Page 76

41154001th rev.2 76 / (4) choose the led head, mounted on the printer, in the list box of led head marking no. (see p.130) (5) press button to see up the led head for the printer. (6) press button to end. 4.2.2 uploading and downloading eeprom data when the main control board is replaced, eeprom dat...

Page 77

41154001th rev.2 77 / 5. Periodical maintenance 5.1 periodical replacement parts the parts are to be replaced periodically as specified below: white lines or stripes (void, light printing) 5.2 cleaning remove any toner or dust accumulated inside the printer. Clean in and around the printer with a pi...

Page 78

41154001th rev.2 78 / (1) set the led head cleaner to the led lens array as shown in the figure, then slide the cleaner back and forth horizontally several times to clean the head. Note: gently press the led head cleaner onto the led lens array. (2) throw the cleaner pad away. Led lens array led hea...

Page 79

41154001th rev.2 79 / 5.2.2 cleaning page function there is a charge roller cleaning function with this printer, which can be executed by the user. (1) while the printer is in off-line mode, press the key for at least 5 seconds. The printer enters the cleaning mode. (2) the ready lamp and manual lam...

Page 80

41154001th rev.2 80 / 6. Troubleshooting procedures 6.1 troubleshooting tips (1) check the basic check points written in the user’s manual. (2) gather detailed failure information as much as possible from the customer. (3) check the printer under the condition close to that under which the failure o...

Page 81

41154001th rev.2 81 / led functions status error (red) ready (amber) remark manual feed (amber) flash 1: slow blinking flash 2: blinking flash 3: fast blinking ready during suspending data proc- essing (in off-line) (data is left in the buffer) during receiving data or proc- essing data manual reque...

Page 82

41154001th rev.2 82 / 6.5 troubleshooting if a trouble occurs in the printer, troubleshoot according to the following procedures: 6.5.1 status monitor message list table 6-1 lists the statuses and troubles to be displayed on the status monitor in the message format. Trouble trouble indicated by the ...

Page 83

Code category status message display content remedy 41154001th rev.2 83 / table 6-1 warming-up status online (ready) status power save status the toner amount of the toner cartridge is small. The i/d unit is not installed or the toner sensor is faulty. Life of i/d drum the paper is in the manual fee...

Page 84

Code category status message display content remedy 41154001th rev.2 84 / table 6-1 (cont'd) paper of improper size was fed. 2.52" (64 mm) l 15.77" (400.56 mm) a paper jam occurred when sheets of paper were being supplied. A paper jam occurred during paper feeding. A paper jam occurred during paper ...

Page 85

41154001th rev.2 85 / table 6-1 (cont'd) an error occurred during eeprom check. An error occurred during option ram check. A heater timeout error occurred. The thermistor is open. A thermistor short occurred. A watchdog timeout occurred. A motor timeout occurred. Replace the main control board. (whe...

Page 86

41154001th rev.2 86 / 6.5.2 status message troubleshooting if the problems cannot be corrected by using the status message/problem list, follow the troubleshooting flowcharts given here to deal with them. 1. 2. 3. 4. 5. 6. Trouble the printer does not work normally after the power is turned on. Jam ...

Page 87

41154001th rev.2 87 / 1 the printer does not work normally after the power is turned on. • turn the power off, then back on. • is the power led ( ) lamp on? • no is the ac cord being connected properly? • no connect the ac cord properly. • yes is +5 v being applied between pins 11 and 21 of power co...

Page 88

41154001th rev.2 88 / • take the measurement of the following voltage readings at connector cn2 on the power supply/sensor board: voltage between pins 1 and 3: ... About 40 v ac voltage between pins 5 and 6: ... About 9.2 v ac are the voltages within the normal range? • yes is fuse f3 on the power s...

Page 89

41154001th rev.2 89 / [jam error] 2 -1 paper input jam • does the jam error occur when the power is turned on? • yes is the paper at the inlet sensor? • yes remove the paper. • no is the operation of the inlet sensor plate normal (moves freely when it is touched)? • no replace the inlet sensor plate...

Page 90

41154001th rev.2 90 / [jam error] 2 -2 paper feed jam • does the paper feed jam occur when the power is turned on? • yes is the paper on the paper sensor plate? • yes remove the paper. • no is the operation of the paper sensor plate normal (moves freely when it is touched)? • no replace the paper se...

Page 91

41154001th rev.2 91 / 2 -2-a • no check the gears (transfer roller gear, idle gear and reduction gear). • yes is the fusing unit being installed properly? • no install the fusing unit properly. • yes is the image drum cartridge being set properly? • no set the image drum cartridge properly. • yes cl...

Page 92

41154001th rev.2 92 / 3 paper size error • is paper of the specified size being used? • no use paper of the specified size. • yes are inlet sensor plates 1 and 2 operating properly (moves freely when they are touched)? • no replace the inlet sensor plate or clean the inlet sensor on the power supply...

Page 93

41154001th rev.2 93 / heater contacts themistor contacts figure 6-2 4 fusing unit error status message : thermister open error : thermister short check error : fuser error • turn the power off, then back on again. • yes is the thermistor open or shorted? Measure the resistance between thermistor con...

Page 94

41154001th rev.2 94 / 5 synchronous serial i/o error (status message : ssio error) or i/f timeout between printer and optional tray (status message : tray2 timeout error or feeder timeout error) • is an option tray (high capacity second paper feeder or power envelope feeder) being used? • yes is the...

Page 95

41154001th rev.2 95 / 6.5.3 image troubleshooting procedures for troubleshooting for abnormal image printouts are explained below. Figure 6-3 below shows typical abnormal images. Figure 6-3 problem flowchart number images are light or blurred entirely (figure 6-3 a ) dark background density (figure ...

Page 96

41154001th rev.2 96 / 1 images are light or blurred entirely. • is toner low (is the toner low message displayed)? • yes supply toner. • no is paper of the specified grade being used? • no use paper of the specified grade. • yes is the lens surface of the led head dirty? • yes clean the lens. • no i...

Page 97

41154001th rev.2 97 / 2 dark background density • has the image drum been exposed to external light? • yes install the image drum in the printer and wait about 30 minutes. • no perform the cleaning page function (see section 5.2.2). • has the problem been solved? • yes end • no is the heat roller of...

Page 98

41154001th rev.2 98 / 4 black vertical belts or stripes • perform the cleaning page function (see section 5.2.2). • has the problem been solved? • yes end. • no replace the image drum cartridge. • has the problem been solved? • yes end note: after replacing the image drum cartridge, reset the drum c...

Page 99

41154001th rev.2 99 / 6 prints voids • is the contact plate of the transfer roller in proper contact with the power supply/sensor board (see figure 6-5)? • no adjust the contact plate so that it touches the power supply/sensor board and the shaft of the transfer roller properly. • yes replace the tr...

Page 100

41154001th rev.2 100 / 7 poor fusing (images are blurred or peels off when the printed characters and images on the paper are touched by hand) • is paper of the specified grade being used? • no use paper of the specified grade. • yes is the tension between the back-up roller (7.52kg) and the surface...

Page 101

41154001th rev.2 101 / 8 white vertical belts or streaks • are the led lens dirty? • yes clean the led lens. • no is the contact plate of the transfer roller in proper contact with the power supply/sensor board (see figure 6-5)? • no adjust the contact plate to make a proper contact with the power s...

Page 102

41154001th rev.2 102 / figure 6-4 contacts hea ter ac hea ter ac char ge r oll er groun d (d rum) cleaning r ol ler deve lo ping ro ller tone r s upply rol ler the rmi stor the rm is tor g f f g e d c b a.

Page 103

41154001th rev.2 103 / figure 6-5 contact power supply/sensor board contact plate for transfer roller.

Page 104

41154001th rev.2 104 / 7. Wiring diagram 7.1 interconnect signal diagram sqcr-n trsel-p sclk-n thermcmp-p psin1-n cvopn-n wrsns-n dout-p 0vl rxd2-p +5v +5v +5v +5v 0vl 0vl +38v +38v trsel2-n heaton-n 0vp -8v 0vp +8v 0vp trsel3-n option cent rm dm fan m rmph1-p rmph1-n rmph2-p rmph2-n registration mo...

Page 105

41154001th rev.2 105 / 7.2 pcb layout and connector signal list (1) main control board (m5g-pcb) cent option option head1 dm power fan 2 1 2 1 26 246 1 2 3 3 1 2 5 6 4 7 8 1 2 1 5 4 3 87 6 18 41 4 135 25 rm envelope panel 2ndtray 2 1 14 13 50 1 100 51 18 36 1 19 36 19 18 1 50 99 100 49 1 2 51 52 led...

Page 106

41154001th rev.2 106 / (2) power supply/sensor board cn1 sw1 cn3 25 26 1 2 ps1 ps2 ps3 ps4 tr out sw2 ps6 ps5 cn2 f3 f2 f1 * in case of 200v series, there is no f2 on the power supply/sensor board. *.

Page 107

41154001th rev.2 107 / • fan connector pin assignment (to fan motor) • dm connector pin assignment (to main/drum motor) 1 2 3 1 2 3 o c i signal description fanpow ov fanalm-n power supply for fan driving ground fan alarm pin no. I/o* opening 1 2 3 4 1 2 3 4 o o o o signal description dmph1-p dmph1-...

Page 108

41154001th rev.2 108 / • rm connector pin assignment (to registration motor) 1 2 3 4 1 2 3 4 o o o o signal description rmph1-p rmph1-n rmph2-p rmph2-n coil 1-n coil 1-p coil 2-p coil 2-n pin no. I/o* 2 4 1 3 line color step no. Yellow black orange brown 1 + + - - pin no. 2 - + + - 3 - - + + 4 + - -...

Page 109

41154001th rev.2 109 / • head1 connector pin assignment (to led head) 14 12 10 8 6 4 2 14 13 12 11 10 9 8 7 6 5 4 3 2 1 c o o o o o o n/c o c c c c c signal description pin no. I/o* 13 11 9 7 5 3 1 * o: out c: common fg hdstb4-n hdstb3-n hdstb2-n hdstb1-n hddld-p hdclk-p hdd0-p 0vlogic 5v 5v 0vled 0...

Page 110

41154001th rev.2 110 / • envelope connector pin assignment (to option feeder i/f) 8 7 4 6 1 2 3 4 5 6 7 8 o o o i c o c o signal description paperin-n optsclk-n data-n paperin-n ovp 38v 0v 5v paper sense 1 clock data opt send data ready analog groud +38v power supply logic gound +5v power supply pin...

Page 111

41154001th rev.2 111 / • power connector pin assignment (to power supply/sensor board) signal sqcr-n sclk-n psin1-n wrsns-n ovl +5v +5v ovl +38v trsel2-n 0vp 0vp 0vp i/o* i i i i c i i c i o c c c pin no. 2 4 6 8 10 12 14 16 18 20 22 24 26 signal trsel-p thermcmp-p cvopn-n dout-p rxd2-p +5v +5v ovl ...

Page 112

41154001th rev.2 112 / • cent connector pin assignment (to centro parallel i/f) i/o* c c c c c c c c c c c c i o c o i pin no. Description strobe data bit 0 data bit 1 data bit 2 data bit 3 data bit 4 data bit 5 data bit 6 data bit 7 acknowledge busy paper end select auto feed not connected ground +...

Page 113

41154001th rev.2 113 / • option connector pin assignment (to option ram or rs232c board) pin no. Pin no. Signal a0 0v a1 a2 rsdtr0-n a3 a4 0v a5 a6 +5v a7 a8 0v a9 a10 +5v a11 a12 0v a13 a14 +5v a15 a16 0v a17 a18 +5v a19 a20 0v a21 a22 a23 0v 0v 0v rsrts0-n cs00n cs2-n cs3-n scrreq-p 0v scsreq-p io...

Page 114

41154001th rev.2 114 / 7.3 resistance check orange yellow brown black m 1 2 3 4 1 2 3 4 thermostat heater thermistor unit registration motor main/drum motor fusing unit circuit diagram illustration resistance between pins 1 and 2: 18.6 Ω between pins 3 and 4: 18.6 Ω between pins 1 and 2: 2.9 Ω betwe...

Page 115

41154001th rev.2 115 / unit transformer fan circuit diagram illustration resistance primary side between pins 1 and 2: 8.4 Ω (120v) 28.8 Ω (230v) secondary side between pins 1 and 3: 1.2 Ω between pins 5 and 6: 1.5 Ω 1 2 1 3 black (120v) blown (230v) white (120v) blue (230v) red red 5 6 orange orang...

Page 116

41154001th rev.2 116 / 8. Parts list figure 8-1 lower base unit view a view a 29 7 14 42 26 35 13 11 27 28 39 2 40 1 2 3 24 17 21, 22 37 36 19 25 45 43 10 9,47 8 44 10 46 20 41 5 4 2 12 16 15 3 33 38 34 31 32 9,47 23 6 18 50

Page 117

41154001th rev.2 117 / table 8-1 lower base unit (1/2) no. Name/rating part no. Use remarks oda part no. Hopping roller shaft bearing hopping roller one-way clutch gear registration roller bearing (registration) roller-transfer b assy bearing tr back-up roller bias spring back-up roller bushing rese...

Page 118

41154001th rev.2 118 / no. Name/rating part no. Use remarks oda part no. Fg plate (o.P.) hopping roller rubber diselectritication film led contact washer c washer b spacer-bearing r spacer-bearing l bias spring a sensor wire assembly 39 40 41 42 43 44 45 46 47 48 49 50 1 1 1 1 1 1 1 1 2 1 4pp4083-76...

Page 119

41154001th rev.2 119 / figure 8-2 upper cover unit 2 3 1.

Page 120

41154001th rev.2 120 / table 8-2 upper cover unit no. Name/rating part no. Use remarks oda part no. Upper cover ic card cover cover-lid 1 2 3 1 1 1 1pp4128-1133p001 2pp4128-1155p001 40104801 53070301 53069301.

Page 121

41154001th rev.2 121 / figure 8-3 base unit 15 16 28 9 17 6 13 2 19 20 26 18 21 23 1 4 18 21 24 14 25 27 3 12 19 20 8 5 7 10 11 22.

Page 122

41154001th rev.2 122 / table 8-3 base unit no. Name/rating part no. Use remarks oda part no. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 1 1 1 1 1 1 120v 230v 120v 230v 120v 220~240v oda oel/int 40919401 3pp4083-7670g...

Page 123

41154001th rev.2 123 / appendix a rs-232c serial interface (option) 1) connector • printer side : 25-pin receptacle type db-25s (made by canon) or equivalent • cable side : 25-pin plug type db-25s (made by canon) shell type db-c8-j10-f2-1 (made by nihon kouku denshi) or equivalent note: plug shall b...

Page 124

41154001th rev.2 124 / 4) signal level • mark polarity : -3v to -15v (logic = 1) • space polarity : +3v to +15v (logic = 0) 5) interface circuit a) receiving circuit 75188 or equivalent input output +3v -3v +9v -9v output 45 ns 55 ns 75188 or equivalent input output +3v -3v input +12v -12v b) sendin...

Page 125

41154001th rev.2 125 / 8) interface parameter setting when the option rs232c board is mounted, the following settings are possible by dos soft operator panel. Refer to the dos soft operator panel manual. • flow control • baud rate • bit length • parity.

Page 126

41154001th rev.2 126 / appendix b centronics parallel interface 1) connector • printer side : 36-pin receptacle (single port) type 57re-40360-730b-d29a (made by daiichi denshi), cn-ax05841a36at (made by ougat) or equivalent • cable side : 36-pin plug type 57-30360 (made by daiichi denshi) or equival...

Page 127

41154001th rev.2 127 / 3) table of parallel i/f signals • connector pin arrangement pin no. Signal name signal direction functions 1 2 3 4 5 6 7 8 9 11 12 13 14 15 16 18 19 30 31 32 33 34 35 36 data strobe data bit - 1 data bit - 2 data bit - 3 data bit - 4 data bit - 5 data bit - 6 data bit - 7 dat...

Page 128

41154001th rev.2 128 / 4) signal level • low : 0 v to +0.8 v • high : +2.4 v to 5.0 v 5) specifications 6) timing charts a) data receiving timing item description mode data bit length input prime receive buffer control compatibility mode, nibble mode, ecp mode 8 bits (in the compatibility mode) vali...

Page 129

41154001th rev.2 129 / b) on-line → off-line switching timing by on-line sw c) off-line → on-line switching timing by on-line sw d) input prime timing (when set to the effective input prime signal) on-line sw busy 100 ms max. Select select acknowledge on-line sw busy 0 min. 100 ms max. 0.5 µ s to 10...

Page 130

41154001th rev.2 130 / appendix c maintenance utility gui manual (okipage 10e) 1. Main menu dialog the picture shown below will be displayed when the maintenance utility is started up. This window sets the engine menu, indicates and initializes the counter values, and displays the information of thi...

Page 131

41154001th rev.2 131 / 1.2 engine menu setting group this area shows the engine menu, the settings of which can be changed. The details of each item are as follows. Shown message print position setting item corrects the start position of print. Setting range -4.00mm~ +3.5mm f/w default 0.00mm shown ...

Page 132

41154001th rev.2 132 / shown message strb time setting item sets the strobe time. Setting range 0.54, 0.50, 056, 0.40 f/w default 0.50 * setting of strb time is enabled only when the optical head is set at d600-4w. 1.3 engine counter reset group it indicates values of the counters in this printer. I...

Page 133

41154001th rev.2 133 / 2. Explanation of buttons 2.1 test print buttons they print the menu page, demo pages and font pages, performs cleaning of rollers, and transmit a test print file. When the test print button is pressed, a dialog, the following picture will pop up. The details of the following ...

Page 134

41154001th rev.2 134 / appendix d multi-purpose feeder 1. Outline 1.1 functions this multi-purpose feeder is installed on the front section of the printer, and it supplies paper automatically through the operation of pulse motor, which is driven by signals sent from the printer. The main functions a...

Page 135

41154001th rev.2 135 / 2. Mechanism description 2.1 general mechanism the multi-purpose feeder feeds the envelopes and paper into the printer by receiving the signal from the printer, which drives the pulse motor inside the multi-purpose feeder, and this motion is transmitted to rotate roller-a and ...

Page 136

41154001th rev.2 136 / 3. Parts replacement this section covers the procedures for the disassembly, reassembly and installations in the field. This section describes the disassembly procedures, and for reassembly procedures, basically proceed with the disassembly procedures in the reverse order. 3.1...

Page 137

41154001th rev.2 137 / [service tools] table 3-1 shows the tools required for the replacement of printed circuit boards, assemblies and units in the field. Table 3-1 service tools no. Service tools q'ty application remarks no. 1-100 philips screwdriver no. 2-100 philips screwdriver no. 3-100 screwdr...

Page 138

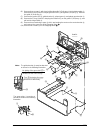

41154001th rev.2 138 / 3.2 parts layout this section describes the layout of the main components. Figure 3-1 upper frame pulse motor olev-11-pcb separator roller-b roller-a link.

Page 139

41154001th rev.2 139 / 3.3 parts replacement methods this section describes the parts replacement methods for the components listed in the disassem- bly order diagram below. Multi-purpose feeder link (3.3.1) separator (3.3.2) olev-11-pcb (3.3.3) pulse motor (3.3.4) planet gear (3.3.5) roller-a (3.3....

Page 140

41154001th rev.2 140 / 3.3.1 link (1) open paper feed cover 1 , and disengage the paper feed cover 1 and link 3 , while lifting the paper hold 2 . (2) remove the paper hold 2 off the arm 4 . (3) disengage the link 3 from the arm 4 , and remove it. * be careful not to deform the link and arm. 1 3 2 4.

Page 141

41154001th rev.2 141 / 3.3.2 separator (1) turn the power switch off “o” and remove the connector cable. (2) disengage the link and paper feeder cover (see 3.3.1). (3) remove 2 screws 1 , disengage the locks at 2 locations on the upper frame 2 with a screwdriver, and remove the upper frame 2 . (4) r...

Page 142

41154001th rev.2 142 / 3.3.3 olev-11-pcb (1) remove the upper frame [ see 3.3.2 steps (1) through (3) ]. (2) remove the connector 1 . (3) remove 2 screws 2 , and remove the olev-11 pcb 3 . When reinstalling the printed circuit board, be careful to make sure that the sensor plate is being set correct...

Page 143

41154001th rev.2 143 / 3.3.4 pulse motor (1) remove the upper frame [ see 3.3.2 steps (1) through (3) ]. (2) remove the olev-11-pcb (see 3.3.3). (3) remove 2 screws 1 , and remove the pulse motor 2 . 2 1.

Page 144

41154001th rev.2 144 / 3.3.5 planet gear (1) remove the upper frame [ see 3.3.2 steps (1) through (3) ]. (2) remove the olev-11-pcb (see 3.3.3). (3) remove 2 screws 1 , and remove the motor bracket assembly 2 and planet gear 3 . 3 2 1.

Page 145

41154001th rev.2 145 / 3.3.6 roller-a and b while only the removal procedure for roller-a is described here, the removal procedure for roller- b is basically same. When removing roller-b, however, be careful not to deform the sensor plate. (1) remove the upper frame [ see 3.3.2 steps (1) through (3)...

Page 146

41154001th rev.2 146 / 4. Troubleshooting 4.1 precautions prior to the troubleshooting (1) go through the basic checking items provided in the printer handbook. (2) obtain detailed information concerning the problem from the user. (3) go through checking in the conditions similar to that in which th...

Page 147

41154001th rev.2 147 / 4.3 troubleshooting method when a problem occurs, go through the troubleshooting according to the following procedure. Problem occurs problem displayed on the status monitor troubleshooting according to the led status message list (see 4.3.1) carry out detailed troubleshooting...

Page 148

41154001th rev.2 148 / • ( jam error ) paper inlet jam • does paper jam at the inlet when the power is turned on? • yes is the paper located above the sensor plate (inlet)? • yes remove the paper. • no is the sensor plate (inlet) operating normally? • no replace the sensor plate (inlet). • yes repla...

Page 149

41154001th rev.2 149 / 5. Connection diagram 5.1 interconnection diagram olev - 11-pcb cn3 m pulse motor cn2 to the printer or high capacity second paper feeder 2 m-t3 1 m-t4 4 m-t1 3 m-t2 optpsin-n optsclk-n optsd-p optsdr-n ovp + 30v ovl + 5v-p fg fg 1 2 3 4 5 6 7 8 9 10

Page 150

41154001th rev.2 150 / 5.2 pcb layout olev-11-pcb cn3 cn2 sen2.

Page 151

41154001th rev.2 151 / 6. Parts list figure 6-1 multi-purpose feeder 9 5 7 6 4 1 2 3 8.

Page 152

41154001th rev.2 152 / table 6-1 multi-purpose feeder no. Description oki-j part no. Q'ty remark oda part no. Roller-a roller-b planet gear link separator pulse motor olev-11-pcb connector cable separator assy 1 2 3 4 5 6 7 8 9 1 1 1 1 1 1 1 1 1 1 same as printer unit. For oda for oel/int 3pb4083-55...

Page 153

41154001th rev.2 153 / appendix e high capacity second paper feeder maintenance manual 1. Outline 1.1 functions the printer is mounted on top of this high capacity second paper feeder. The high capacity second paper feeder supplies paper automatically through the operation of pulse motor (hopping), ...

Page 154

41154001th rev.2 154 / 2. Mechanism description 2.1 general mechanism the high capacity second paper feeder feeds the paper into the printer by receiving the signal from the printer, which drives the pulse motor inside the high capacity second paper feeder, and this motion is transmitted to rotate t...

Page 155

41154001th rev.2 155 / 3. Parts replacement this section covers the procedures for the disassembly, reassembly and installations in the field. This section describes the disassembly procedures, and for reassembly procedures, basically proceed with the disassembly procedures in the reverse order. 3.1...

Page 156

41154001th rev.2 156 / [service tools] table 3-1 shows the tools required for the replacement of printed circuit boards, assemblies and units in the field. Table 3-1 service tools no. Service tools q'ty application remarks no. 1-100 philips screwdriver no. 2-100 philips screwdriver no. 3-100 screwdr...

Page 157

41154001th rev.2 157 / 3.2 parts layout this section describes the layout of the main components. Figure 3-1 guide r (2nd) assy (includes stepping motor and tqsb-2 pcb) stepping motor guide l (2nd) assy hopping frame assy one-way clutch gear hopping roller assy upper plate cassette assy.

Page 158

41154001th rev.2 158 / 3.3 parts replacement methods this section describes the parts replacement methods for the components listed in the disassem- bly order diagram below. High capacity paper feeder stepping motor (hopping) (3.3.1) tqsb-2 pcb (3.3.2) hopping roller shaft assy and one-way clutch ge...

Page 159

41154001th rev.2 159 / 3.3.1 stepping motor (hopping) (1) turn the printer power switch off, pull out the ac cord from the outlet. Remove the printer off high capacity second paper feeder. (2) take the paper cassette assy 1 out of high capacity second paper feeder. (3) remove six screws 2 and remove...

Page 160

41154001th rev.2 160 / (6) remove three screws 9 which are holding the guide r (2nd) assy 0 to the bottom plate a . Remove the screw b which is keeping the rear cover c and guide r (2nd) assy 0 . Remove the guide r (2nd) assy 0 . (7) remove the protect (m) d , guide bracket e , planet gears f and pl...

Page 161

41154001th rev.2 161 / 3.3.2 tqsb-2 pcb (1) remove the pulse motor (see 3.3.1). (2) remove the connector o from the tqsb-2 pcb p . (3) remove the screw q and remove the tqsb-2 pcb p . Note : refer to detall a in the previous page. 3.3.3 hopping roller shaft assy and one-way clutch gear (1) follow up...

Page 162

41154001th rev.2 162 / 4. Troubleshooting 4.1 precautions prior to the troubleshooting (1) go through the basic checking items provided in the printer handbook. (2) obtain detailed information concerning the problem from the user. (3) go through checking in the conditions similar to that in which th...

Page 163

41154001th rev.2 163 / 4.3 troubleshooting method when a problem occurs, go through the troubleshooting according to the following procedure. 4.3.1 led status message list the listing of the statuses and problems displayed in the form of messages on the status monitor is provided in table 4-1. Table...

Page 164

41154001th rev.2 164 / • ( jam error ) paper inlet jam • does paper jam at the inlet when the power is turned on? • yes is the paper located above the sensor plate (inlet)? • yes remove the paper. • no is the sensor plate (inlet) operating normally? • no replace the sensor plate (inlet). • yes repla...

Page 165

41154001th rev.2 165 / tqsb-2 pcb "motor" m stepping motor 2 m-t3 1 m-t4 4 m-t1 3 m-t2 "pu" to printer optsin-n optsclk-n optsd-p optsdr-n ovp + 30v ovl + 5v 1 2 3 4 5 6 7 8 5. Connection diagram 5.1 interconnection diagram.

Page 166

41154001th rev.2 166 / 5.2 pcb layout tqsb-2 pcb controller motor driver sen2 sen1 osc pu motor.

Page 167

41154001th rev.2 167 / figure 6-1 high capacity second paper feeder 1 2 4 3 5 6. Parts list.

Page 168

41154001th rev.2 168 / table 6-1 high capacity paper feeder no. Description oki-j part no. Q'ty remark hopping roller shaft assy one-way clutch gear stepping motor tqsb-2 pcb cassette assy (2nd tray) 1 2 3 4 5 1 1 1 1 1 3pa4122-1367g001 4pb4122-1382p001 3pb4122-1399p001 4ya4046-1651g002 1pa4122-1362...

Page 169

41154001th rev.2 169 / 2nd tray assembly section1 cabinet & cassette assembly section1 cabinet & cassette assembly section2 mechanical assembly.

Page 170

41154001th rev.2 170 / section1 cabinet & cassette assembly 8 1 2 3 4 5 6 7.

Page 171

41154001th rev.2 171 / section2 mechanical assembly 21 9 11 10 12 13 23 22 14 24 27 26 15 16 17 19 18 20 a a b b.

Page 172

41154001th rev.2 172 / table 6-2 2nd tray parts list no. Description oki parts no. Q'ty/u plate, upper sheet guide assembly front cover assembly inner guide assembly cassette assembly (2nd tray) separation frame assembly cover, rear stick finger hopping flame assembly bush, metal (adf) gear (z70) le...

Page 173

41154001th rev.2 173 / 173 addition of notch addition of groove cassette addition of projection part addition of latch tale guide *** for the rev. No. Of the parts list for the cassette assembly (2nd tray) should be applied no.10. The no.10 includes a change of cassette and tale guide. Note : casset...

Page 174: Okipage 10E

41266201th rev.1 1 / 135 okipage 10e led page printer troubleshooting manual with component parts list oda/oel/int 1999. 9. 24 rev.1.

Page 175: Contents

41266201th rev.1 2 / contents 1. Outline......................................................................................................... 3 2. Tools ............................................................................................................ 3 3. Circuit description ............

Page 176

41266201th rev.1 3 / 1. Outline this manual has been written to provide guidance for troubleshooting of the okipage 10e printer (primarily for its printed circuit boards), based on the assumption that the reader has a thorough knowledge concerning the printer. Read the maintenance manual for this pr...

Page 177

41266201th rev.1 4 / 3. Circuit description 3.1 outline the main control board controls the reception of data transferred through a host i/f and processes command analysis, bit image development, raster buffer read. It also controls the engine and the operator panel. Its block diagram is shown in fi...

Page 178

41266201th rev.1 5 / figure 3-1 block diagram 1mb memory board (option) rs232c interface board (option) or program & font rom 6mb mask rom resident ram 1m x 16 bit dram (4mb) for optional board main control board power supply board data bus (32bit) eeprom 7407 inlet sensor 1 inlet sensor 2 paper sen...

Page 179

41266201th rev.1 6 / figure 3-2 memory expansion board block diagram (option) option connector a2 to a23 cs3, eepcs, eeclk eepdat ios1 cas0 to cas3 ras2 to ras4 ore, rd, wr d0 to d31 pd2, 3 bsy rd wr ras3, 4 wr ras2 ore wr dram 1m byte als244 als244 als244 als244 simm1 dram simm simm2 flash simm.

Page 180

41266201th rev.1 7 / figure 3-3 rs-232c serial interface board block diagram (option) a2 to a23 cs3, eepcs, eepclk eepdat ios1 txd, rst, dtr rxd rs-232c connector cas0 to cas3 ras2 to ras4 ore, rd, wr d0 to d31 pd2, 3 bsy rd wr ras3, 4 wr als244 als244 75188 als244 als244 simm1 dram simm simm2 flash...

Page 181

41266201th rev.1 8 / 3.2 cpu and memory (1) cpu (mhm2029-004k) cpu core risc cpu (mips r3000 compatible) cpu clock 7.067 mhz internal cpu clk 28.268 mhz (2) program and font roms rom capacity 6m bytes (24m bit mask rom two pieces) rom type 24m bits (1.5m x 16 bits) access time 100 ns (3) resident ra...

Page 182

41266201th rev.1 9 / figure 3-4 block diagram of cpu & memory circuit cpu cs0 cs2 cs3 cs0 rd ras0 rd/wr cas0, 1, 2, 3 ras2, 3, 4, 5 cas0, 1, 2, 3 rd/wr main control board ras0 ras2 ras3 ras4 ras5 cas0 cas1 cas2 cas3 option board ic4, ic5 dram (1m x 16 bits) 2 pieces dram 1m byte ras2 wr d00 to d32 a...

Page 183

41266201th rev.1 10 / figure 3-5 timing chart of cpu & memory circuit (28.268 mhz) sysclk a00-a25-p dras0~5-n dcas0~3-n rd-n d00~d31-p 0 17.7 35.4 53.1 70.8 88.4 106.1 123.8 141.5 159.2 176.9 (ns) t2 t1 t3 t2 29.32 12.25 27.3 (dras0-n) (dras1~5-n) t4 t2 t2 t3 17.91 data 14.6 varid varid no simm 60 n...

Page 184

41266201th rev.1 11 / 3.3 reset control when power is turned on, a clrst-n signal is generated by the rising sequence of +38v and +8v power supply. Power off power on +38v +38v +8v q10 input clrst-n +5v +8v ic10-10 ic10-11 +38v +8v +5v ic10 to option board cpu 11 10 d2 (15v) 172 + – 13.

Page 185

41266201th rev.1 12 / instruction start bit operation address data code read (read) 1 10 a7 to a0 write enabled (wen) 1 00 11xxxxxx write (write) 1 1 01 a7 to a0 write all address (wral) 1 00 01xxxxxx d15 to d0 write disabled (wds) 1 00 00xxxxxx erase 1 11 a7 to a0 chip erasable (eral) 1 00 10xxxxxx...

Page 186

41266201th rev.1 13 / 3.5 centronics parallel interface the cpu sets a busy-p signal to on at the same time when it reads the parallel data (pdata1- p to pdata 8-p) from the parallel port at the fall of pstb-n signal. Furthermore, it makes the store processing of received data into a receive buffer ...

Page 187

41266201th rev.1 14 / 3.6 operator panel operator panel have four led lamps and a switch on the operator panel board. 5 2 4 3 1 6 3 4 6 1 flexible cable 124 147 113 114 2 5 cn1 cpu panel alarm(red) 5v 5v 5v 5v 5v 5v 0v 0v paper(amber) ready(green) power(green).

Page 188

41266201th rev.1 15 / 3.7 led head control when a paper form is made to arrive at the data write position on print start, the sending of data to the led head starts as synchronized with the page synchronous signal/line synchronous signal (cpu internal signal). Bit image data developed on the raster ...

Page 189

41266201th rev.1 16 / r1 r2 out adj tl317 ps #1~#576 #577~#1152 #1153~#1824 1825~ #2496 in c2 c1 8 6 1 ic26 9 data 7 clock 6 load 2 stb4 led array26 ic20 led array20 ic13(~ic19) led array13(~19) ic7(~ic12) led array7(~12) ic1(~ic6) led array1(~6) 3 stb3 4 stb2 5 stb1 10 vss 1 13, 14 vss 2 11, 12 vdd...

Page 190

41266201th rev.1 17 / * cpu internal signal hdld-p hddto-p hdclk-p hddto-p hdclk-p hddto-p line synchronous signal* strb1-n strb2-n strb3-n strb4-n page synchronous signal* 0.6 µ s 2560 clock 2.19 msec.

Page 191

41266201th rev.1 18 / 3.8 motor control (1) registration and main (drum) motors a registration motor and a drum motor are driven by means of control signals from the cpu and a driver ic. (2) drum motor cpu a2918sw mtd2005f m main (drum) motor m dmph1-p 132 13 rmph2-n 4 12 rmph2-p 3 8 rmph1-n 2 7 rmp...

Page 192

41266201th rev.1 19 / (3) registration motor (4) drive control time t0 to t3 determines the motor speed, while the difference of phase direction between phase signals dmph1-p and dmph2-p (rmph1-p and rmph2-p) determines the rotation direction. Dmon1-n and rmon-n signals control a motor coil current....

Page 193

41266201th rev.1 20 / 3.9 fuser temperature control for the temperature control by heater control, the variation in the resistance of the thermistor is a/d converted in ic2 and the resultant digital value is read and transferred to the cpu. The cpu turns on or off the heaton-n signal according to th...

Page 194

41266201th rev.1 21 / the temperature control is described below. When vt rises to v2 or more, the heater is turned off (by setting heaton-n signal to low). When vt drops to v1 or less, the heater is turned on (by setting heaton-n signal to high). In this way, the temperature can be kept within the ...

Page 195

41266201th rev.1 22 / for heater breakdown detection, the heater must first be turned on. When a temperature rise which corresponds to the switching on of the heater does not occur, then a heater breakdown is detected. To shorten the breakdown detection time, the following circuit is used. Immediate...

Page 196

41266201th rev.1 23 / 3.10 fan motor control the stop/rotation of the fan motor is controlled by fanon1-p and fanon2-n signals. When the fan motor rotates normally, fanalm-p signal generated in the hole element built in the fan motor is input to the cpu. Fan motor start: initial request, heater on, ...

Page 197

41266201th rev.1 24 / 3.11 cover open when the cover is opened, a cover open microswitch is opened. This makes a cvopn-n signal low, thereby the cpu detects the open state. Furthermore, opening the cover stops applying a +5v power to the high voltage power supply unit, resulting in stopping all high...

Page 198

41266201th rev.1 25 / 3.12 power supply board (1) low voltage power supply an ac power from an inlet is input to a transformer via fuses, ac switch and noise filter and then lowered to a 32 vac power and a 10 vac power. The 32 vac power is converted to a +38 vdc output through a rectifying/smoothing...

Page 199

41266201th rev.1 26 / (3) sensor control off main control board power supply board psout-n wrsns-n paper-n psin1-n tnrsns-n psin2-n ic2 +5v ps1 ps2 ps4 ps3 ps6 ps5 on transparent shield sensor signal 7 6 8 4 3 5 +5v.

Page 200

41266201th rev.1 27 / (4) high-voltage power supply circuit this high-voltage power supply circuit receives the high-voltage generation timing control command that is transmitted in serial through the power supply interface from the control section. It decodes this command by lsi (ic2) and outputs h...

Page 201

41266201th rev.1 28 / 3.13 option tray control the kinds of option trays, high capacity second paper feeder and multi purpose feeder can be connected to the printer. The trays are distinguished by two digit id numbers. The option trays and the printer communicate with each other through bi-direction...

Page 202

41266201th rev.1 29 / option tray connection and block diagram 5v 5v 0v 0v 30v 5v 0v pu 2nd tray tr2 270 Ω 3 d1 d2 ic3 ic1 6 0c 5 4 3 0c 2 1 tqsb-2 (option) ic2 65-43 f0 f2 g2 e0 c2 g0 f1 c1 c0 d0 e1 a b c d sw1 1, 2 3, 4 11 29 24 20 21 4 7 22 560 Ω 2 1 0c 10 9 28 9 5 3 8 6 ms4646 a b 10 19 25 4 mb1...

Page 203

41266201th rev.1 30 / option tray serial interface time chart optsd-p min. 3000 µ s option tray control serial interface time chart b7 b6 b5 b4 b3 b2 b1 b0 b7 b6 b5 b4 b3 b2 b1 b0 b7 b6 b5 b4 b3 b2 b1 b0 1.5 µ s4 0 µ s2 1 µ s min. 1300 µ s max. 3000 µ s optsclk-n optsdr-n next command (cpu → tray) r...

Page 204

41266201th rev.1 31 / option tray motor control time chart motor on (c2) phase change (c1, c0) paper sensor (optpsin-n) triggered by cpu automatically stops # of phase changes after paper sensor detection is downloaded by cpu motor control time chart.

Page 205

41266201th rev.1 32 / 3.14 memory expansion option board the memory expansion option board is provided with two dram chips and two simm slots. The simm1 slot is used for installation of a dram simm. The simm2 slot is used for installation of flash simm. With the board, a printer will have 5m bytes o...

Page 206

41266201th rev.1 33 / 3.15 rs-232c serial interface option board rs-232c serial interface board block diagram (option) the rs-232c serial interface option board is provided with a rs-232c i/f and two simm slots. The simm1 slot is used for installation of a dram simm. The simm2 slot is used for insta...

Page 207

41266201th rev.1 34 / (1) rs-232c interface the serial data rxd from the host system, whose line voltage is clamped at the ttl level by d4/d512, are received by the cpu built-in serial controller. Dsr and cts signals are terminated through 5.6k Ω resistors. Send signals txd, rts and dtr are put out ...

Page 208

41266201th rev.1 35 / (2) simm memory module the board is provided with two slots for a 72-pin dram simm memory module and flash simm. The simm1 slot is used for installation of a 72-pin dram simm memory module. Up to 6 types of simm memory module can be installed. 1m byte, 2m bytes, 4m bytes, 8m by...

Page 209

41266201th rev.1 36 / 4. Troubleshooting 4.1 troubleshooting table (a) power supply board (ol1- or ol2-pcb) note: activate the status monitor to refer to the window displayed. Identify the type of the failure. When all the leds of the printer are flashing, you can identify the type by pressing the s...

Page 210

41266201th rev.1 37 / (b) main control board (1/2) failure flowchart no. Program rom error. B - 1 resident ram error. B - 2 eeprom error. B - 3 option ram error. B - 4 cooling fan error. B - 5 option tray i/f timeout error watchdog timer timeout occurs frequently, or illegal cpu version. Program err...

Page 211

41266201th rev.1 38 / (b) main control board (2/2) failure flowchart no. B - 14 paper input jam occurs frequently. #: tray1, tray2, feeder, manual b - 15 b - 16 cover open occurs frequently. Data sent through the centronics i/f cannot be received. Led message ready off valyd off flash2 off valyd off...

Page 212

41266201th rev.1 39 / note 1: follow the next table. Priority content ready manual feed error status message error nn flash 3 flash 3 flash 3 2 notifies that abnormal condition has occurred to the device. If the condition is not cleared, make a serviceman call. The lamp display changes every time th...

Page 213

41266201th rev.1 40 / (d) multi purpose feeder (olev) (e) memory expansion option board (mm6) failure flowchart no. Option ram error. E - 1 led message ready flash3 invalyd flash3 flash3 manual error status monitor failure flowchart no. F - 1 error host i/f occurs frequently. Led message ready inval...

Page 214

41266201th rev.1 41 / 4.2 troubleshooting flowchart a-1 paper input jam occurs frequently. • is ps3 (inlet sensor 1) operating normally? • no replace ps3. ▼ • yes is ps5 (inlet sensor 2) operating normally? • no replace ps5. ▼ • yes replace ic2 (lc26023a). A-2 paper feed jam occurs frequently. • is ...

Page 215

41266201th rev.1 42 / a-5 the message “#paper out” remains displayed on the status monitor. • is ps4 (paper end sensor) operating normally? • no replace ps4. ▼ • yes replace ic2 (lc26023a). A-6 the message “printer cover open” remains displayed on the status monitor. • is sw2 (cover open switch) ope...

Page 216

41266201th rev.1 43 / a-9 thermistor open error (error 72), thermistor short error (error 73). • is the voltage output between (l) and (n) of the connector acout correct (240v or 120v)? • yes replace ic2 (lc26023a). ▼ • has the problem been solved? • yes end. ▼ • no thermistor of fuser failure. ▼ • ...

Page 217

41266201th rev.1 44 / a-10 serial interface does not connect to the host device. • is the voltage waveform between pins 5 and 6 of the connector (cn2) same as the waveform shown below? • no replace the transformer t1. ▼ • has the problem been solved? • yes end. ▼ • no replace the diode d10. ▼ • yes ...

Page 218

41266201th rev.1 45 / b-1 program rom error (error 10). • replace ic2 and ic3. B-2 resident ram error (error 30). • are negative pulses being put out to pin 14 (draso-n) of ic4, ic5(msm5118160d- 60js etc)? • no failure of 03e (mhm2029-004k). ▼ • yes are negative pulses being sent to pin 30, 31 (dcas...

Page 219

41266201th rev.1 46 / b-5 cooling fan error (error 70). • is the fan rotating? • no is +38v power being supplied to pin 1 (fan pow) of the connector (fan)? • no is the output at pin 109 (fanon-p) of ic1 (mhm2029- 004k) at high level? • no failure of ic1 (mhm2029-004k). ▼ • yes is +38v power being su...

Page 220

41266201th rev.1 47 / b-10 print overrun occurs frequently. • is an option board mounted? • yes go to the flowchart b-4 . ▼ • no set dram simm memory module on an option board, then mount it to the printer. • has the problem been solved? • yes print data is too complex to print out, so it is necessa...

Page 221

41266201th rev.1 48 / b-13 paper input jam. • is the hopping motor rotating normally? • no are the waveforms of rmph1-p and rmph2-p signals as shown in section 3.8 (3) being sent to pins 26 and 17 of ic8 (mtd2005f) respectively? • no failure of ic1 (mhm2029-004k). ▼ • yes when the motor is rotating,...

Page 222

41266201th rev.1 49 / b-15 data sent through the centronics i/f cannot be received. • is the signal at pin 11 (busy-p) of the connector (cent) low? • no is the signal at pin 3 (pbusy-p) of ic11 (7407) change at data reception as shown below? On-line off-line pbusy-p low high • no failure of ic1 (mhm...

Page 223

41266201th rev.1 50 / c-1 paper input jams occur frequently. • has the fuse f1 opened? • no is the high voltage (around 38v) being sent to pin 2 of d1 and pin 2 of d2? • no replace d1 or d2. ▼ • yes is the signal level at pin 22 of ic2 at low level? • no replace ic2. ▼ • yes are the signals at pins ...

Page 224

41266201th rev.1 51 / c-4 the printer does not recognize high capacity second paper feeder. • do signal levels at pin 2 (optsclk-n) and 3 (optsd-p) pu alter at power-up time? • no replace cable. • no replace d1 or d2. ▼ • yes do signal levels at pin 4, 7, and 9 of ic2 alter at power-up time? • no is...

Page 225

41266201th rev.1 52 / d-1 paper input jams occur frequently. • is the motor rotating? • no has the fuse f1 opened? • no is the high voltage (around 38v) being sent to pin 2 of d1 and pin 2 of d2? • no replace d1 or d2. ▼ • yes is the signal level at pin 22 of ic2 at low level? • no replace ic2. ▼ • ...

Page 226

41266201th rev.1 53 / d-3 the printer does not recognize multi purpose feeder. • do signal levels at pin 2 (optsclk-n) and 3 (optsd-p) cn1 alter at power-up time? • no replace option tray cable. ▼ • yes do signal levels at pin 4, 7, and 9 of ic2 alter at power-up time? • no is signal level at pin 2 ...

Page 227

41266201th rev.1 54 / e-1 option ram error (error 60) • remove the dram simm. Has the problem been solved? • yes failure of dram simm. ▼ • are negative pulses being sent to pin 83 (dras2-n), pin 84 (dras3-n), pin 85 (dras4-n), pin 86 (dras5-n) of the connector (cn1)? • no failure of ic1 (mhm2029-004...

Page 228

41266201th rev.1 55 / f-1 error host i/f occurs frequently. • is the connection at the connector (cn2) properly engaged? • no replace the connector (cn2). ▼ • yes is the voltage at pin 14 of q11 (75188) about +8v and the voltage at pin 1 of q11 (75188) about -8v? • no check the connection of the con...

Page 229

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 56 / 5. Circuit diagram figure 5-1(1/11~11/11) main control board (m5g-pcb, rev.2) (40938202) figure 5-2(1/1) operator panel board (opp-pcb, rev.2) (40959101) figure 5-3(1/4~4/4) power supply board (ol1-pcb, rev.6...

Page 230

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 57 / figure 5-1 main control board (m5g-pcb, rev.2) (1/11).

Page 231

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 58 / figure 5-1 main control board (m5g-pcb, rev.2) (2/11).

Page 232

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 59 / figure 5-1 main control board (m5g-pcb, rev.2) (3/11).

Page 233

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 60 / figure 5-1 main control board (m5g-pcb, rev.2) (4/11).

Page 234

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 61 / figure 5-1 main control board (m5g-pcb, rev.2) (5/11).

Page 235

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 62 / figure 5-1 main control board (m5g-pcb, rev.2) (6/11).

Page 236

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 63 / figure 5-1 main control board (m5g-pcb, rev.2) (7/11).

Page 237

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 64 / figure 5-1 main control board (m5g-pcb, rev.2) (8/11).

Page 238

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 65 / figure 5-1 main control board (m5g-pcb, rev.2) (9/11).

Page 239

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 66 / figure 5-1 main control board (m5g-pcb, rev.2) (10/11).

Page 240

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 67 / figure 5-1 main control board (m5g-pcb, rev.2) (11/11).

Page 241

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 68 / figure 5-2 operator panel board (opp-pcb, rev.2) (1/1).

Page 242

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 69 / figure 5-3 power supply board (ol1-pcb, rev.6) (1/4).

Page 243

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 70 / figure 5-3 power supply board (ol1-pcb, rev.6) (2/4).

Page 244

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 71 / figure 5-3 power supply board (ol1-pcb, rev.6) (3/4).

Page 245

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 72 / figure 5-3 power supply board (ol1-pcb, rev.6) (4/4).

Page 246

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 73 / figure 5-4 power supply board (ol2-pcb, rev.6) (1/4).

Page 247

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 74 / figure 5-4 power supply board (ol2-pcb, rev.6) (2/4).

Page 248

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 75 / figure 5-4 power supply board (ol2-pcb, rev.6) (3/4).

Page 249

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 76 / figure 5-4 power supply board (ol2-pcb, rev.6) (4/4).

Page 250

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 77 / figure 5-5 high capacity second paper feeder board (tqsb-2-pcb, rev.1) (1/1) 1 2 3 4 fg fg1 pu optsin-n optsclk-n optsd-p optsdr-n 0vp +30v 0vl +5v 1 2 3 4 5 6 7 8 motor 00-8263-0412-00-000 size zc-105 r3 1 1...

Page 251

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 78 / figure 5-6 multi purpose feeder board (olev-pcb, rev.4) (1/2) tr2 cn1 tcs7698-01-201 cn2 tcs7698-01-201 cn3 00-8263-0412-00-000 s3 1 2 3 l2 1 2 l3 1 2 l4 1 2 s1 1 2 s4 1 2 s2 1 2 d4 1 2 rd3.9e-b r9 2 1 r11 1 ...

Page 252

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 79 / figure 5-6 multi purpose feeder board (olev-pcb, rev.4) (2/2) connector name :00-8263-0412-00-00 parts number :224a3357p0040 ports symbol :cn3 pin no. 1 2 3 4 signal name m-t4 m-t3 m-t2 m-t1 location 01yb 01y...

Page 253

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 80 / figure 5-7 memory expansion bord (mm6-pcb, rev.4) (1/5).

Page 254

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 81 / figure 5-7 memory expansion bord (mm6-pcb, rev.4) (2/5) 4.7k 1/10w 4.7k 1/10w 4.7k 1/10w 4.7k 1/10w 4.7k.

Page 255

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 82 / figure 5-7 memory expansion bord (mm6-pcb, rev.4) (3/5).

Page 256

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 83 / figure 5-7 memory expansion bord (mm6-pcb, rev.4) (4/5).

Page 257

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 84 / figure 5-7 memory expansion bord (mm6-pcb, rev.4) (5/5) 4.7k.

Page 258

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 85 / figure 5-8 rs-232c interface board (smif-pcb, rev.4) (1/5).

Page 259

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 86 / figure 5-8 rs-232c interface board (smif-pcb, rev.4) (2/5) 4.7k 1/10w 4.7k 1/10w 4.7k 1/10w 4.7k 1/10w.

Page 260

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 87 / figure 5-8 rs-232c interface board (smif-pcb, rev.4) (3/5).

Page 261

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 88 / figure 5-8 rs-232c interface board (smif-pcb, rev.4) (4/5) 4.7k 1/10w.

Page 262

1 2 34 56 78 9 x y 1 a b c d e f g h a b c d e f g 23 4 5 6 7 8 9 x y 41266201th rev.1 89 / figure 5-8 rs-232c interface board (smif-pcb, rev.4) (5/5) 3.3k 1/10w 5.6k 1/10w 5.6k 1/10w 5.6k 1/10w 3.3k 1/10w 0.1u 25 0.1u 25 0.1u 25.

Page 263

Ref. Symbol type/name part no. Q'ty remarks no. 41266201th rev.1 90 / 6. Component parts list main control board (m5g-pcb, rev. 2) 40938202 operator panel board (opp-2-pcb, rev. 2) 40959101 power supply board (ol1-pcb, rev. 6) 40217703 power supply board (ol2-pcb, rev. 6) 40217704 high capacity seco...

Page 264

Ref. Symbol type/name part no. Q'ty remarks no. 41266201th rev.1 91 / power 1 26 2 25 c8 c6 osc1 cent 36 18 19 1 1 option eb3 r27 r28 r29 r31 r33 r60 r74 r73 r40 rm18 rm13 rm15 r37 r38 r39 r7 r8 r18 r19 r20 r21 r22 r23 r24 r25 r26 r41 r42 r32 r30 ic11 rm16 rm31 c21 ic1 r2 r53 r54 s1 rm29 rm30 rm26 r...

Page 265

Ref. Symbol type/name part no. Q'ty remarks no. 41266201th rev.1 92 / m5g-pcb assy. (main control board) rev. 2 (40938202-2/9) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 d5,bf1 d3 d4,d503 d501 d2 d1 r1 r54 r553 r555 r556 r533 r58 r536 r554 r2 40401401 610a0332n0001 611a0000n0001 611a0000n0002 613a023...

Page 266

Ref. Symbol type/name part no. Q'ty remarks no. 41266201th rev.1 93 / 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 3235003f0562 3235003f0621 3235003j0101 3235003j0102 3235003j0103 3235003j0105 3235003j0112 3235003j0122 3235003j0125 3235003j0151 3235003j0152 3235003j0153 3235003j0202 3235003j02...

Page 267

Ref. Symbol type/name part no. Q'ty remarks no. 41266201th rev.1 94 / 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 3235003j0242 3235003j0272 3235003j0302 3235003j0332 3235003j0333 3235003j0392 3235003j0470 3235003j0472 3235005j0473 3235003j0511 3235003j0512 3235005j0560 3235003j0562 3235003j06...

Page 268

Ref. Symbol type/name part no. Q'ty remarks no. 41266201th rev.1 95 / 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 323a5019j0750 324a1001j0209 324a1001j0518 3255003p0001 3345003j0220 3345003j0331 334a5012j0101 334a5012j0151 334a5012j0332 334a5012j0680 3033003c0100 3033003c0101 3033003c0330 303300...

Page 269

Ref. Symbol type/name part no. Q'ty remarks no. 41266201th rev.1 96 / 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 m5g-pcb assy. (main control board) rev. 2 (40938202-6/9) 12 4 1 1 18 3 1 2 1 2 1 1 1 3036003k0102 3036003k0222 3036003k0561 3036003z0103 3036003z0104 3036008z1105 304a1007c1221 304a1...

Page 270

Ref. Symbol type/name part no. Q'ty remarks no. 41266201th rev.1 97 / 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 m5g-pcb assy. (main control board) rev. 2 (40938202-7/9) 1 1 1 1 2 1 1 1 1 1 3 2 2 1 7200903m9001 7201826m0001 720a0523n00011 720a1816n0001 41087601 8162331n0000 8510440n0001 817...

Page 271

Ref. Symbol type/name part no. Q'ty remarks no. 41266201th rev.1 98 / 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 m5g-pcb assy. (main control board) rev. 2 (40938202-8/9) 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2201001p0360 221a1630p0081 2244102p0060 224a3222p0261 224a3357p0040 224a3357p...

Page 272

Ref. Symbol type/name part no. Q'ty remarks no. 41266201th rev.1 99 / 118 119 120 121 122 123 124 125 126 127 128 129 130 m5g-pcb assy. (main control board) rev. 2 (40938202-9/9) 6 5 4 2 2 kh-31036-25 kh-31036-50 lh-31313-158 3n3-hh psw2w3-8c s3,bf2,bf3,bf5,bf7, bf9 s1,em3,em5,em8,em10 eb1~eb4 link ...

Page 273

Ref. Symbol type/name part no. Q'ty remarks no. 41266201th rev.1 100 / opp-printed circuit board (operator panel board) rev. 2 (40959101-1/2) r504 r503 r502 r501 tr503 tr502 tr501 power cn1 sw1 s1 ready paper ararm 5 6 1 2.

Page 274

Ref. Symbol type/name part no. Q'ty remarks no. 41266201th rev.1 101 / opp-printed circuit board (operator panel board) rev. 2 (40959101-2/2) rm73b2a301j res-met rn -c rm73b2a331j res-met rn -c skhhal switch-push - 06fe-st-vk-n connector-pcb - dtc123yk tr-npn/h-freq -c slb-24yr3f photo-led - slb-24y...

Page 275