- DL manuals

- Oki

- Printer

- OKIPAGE 14i

- Service Manual

Oki OKIPAGE 14i Service Manual

Summary of OKIPAGE 14i

Page 1

Okipage 14i led page printer service manual.

Page 2

Table of contents page service manual for okipage 14i 0 introduction introduction 1 1 specifications 1.1 system configuration 2 1.2 printer configuration 3 1.3 optional configuration 4 1.4 specification 5 1.5 safety standards 6 ....1.5.1 certification label 7 ....1.5.2 warning label 8 ....1.5.3 warn...

Page 3

Table of contents page ....3.3.7 face up stacker assy 33 ....3.3.8 eject roller assy 34 ....3.3.9 motor assy 35 ....3.3.10 hopping roller shaft assy 36 ....3.3.11 stacker cover assy 37 ....3.3.12 registration roller 38 ....3.3.13 roller transfer assy 39 ....3.3.14 fusing unit 40 ....3.3.15 back-up r...

Page 4

Table of contents page 6.3 tips for correcting image problems 67 6.4 preparation for troubleshooting 68 6.5 troubleshooting flow 69 ....6.5.1 lcd status message/problem list 70 ....6.5.2 lcd message troubleshooting 71 ........(1) the printer does not work normally after the power is turned on. 72 .....

Page 5

Table of contents page centronics parallel interface 99 b universal serial bus (usb) universal serial bus (usb) c loop test (rs-232c interface) loop test (rs-232c interface) 100 d diagnostics test 1. Maintenance modes 101 ....1.1 user maintenance mode 102 ....1.2 system maintenance mode 103 ....1.3 ...

Page 6

Table of contents page ....5.1 interconnection diagram 126 ....5.2 pcb layout 127 6. Parts list 128 product accessory 3: high capacity 2nd paper feeder high capacity second paper feeder maintenance 129 1. Outline 130 ....1.1 functions 130 ....1.2 external view and component names 131 2. Mechanism de...

Page 7

Table of contents page ....2) cable ....3) signal ....4) appearance ....5) physical dimensions ....6) list of protocols ....7) tcp/ip ....8) netware ....9) ethertalk ....10) netbeui ....11) oki original port ....12) others ....13) setup ....14) troubleshooting.

Page 8

Service manual for okipage 14i chapter 0 introduction page: 2 introduction this service handbook describes the field maintenance methods for okipage 14i digital led printer. This manual is written for use by the maintenance personnel. Please note that you should refer to the printer handbook and pri...

Page 9

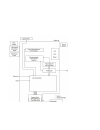

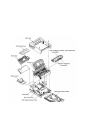

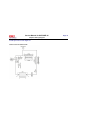

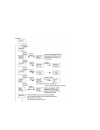

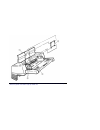

Service manual for okipage 14i chapter 1 specifications page: 3 1.1 system configuration okipage 14i consists of control and engine blocks in the standard configuration, as shown in figure 1-1. In addition, the options marked with asterisk (*) are available..

Page 11

Figure 1-1 copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 12

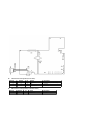

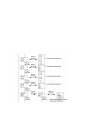

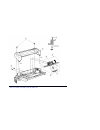

Service manual for okipage 14i chapter 1 specifications page: 4 1.2 printer configuration the printer unit consists of the following hardware components: electrophotographic processor l paper feeder l controller l operator panel l power supply unit l the printer unit configuration is shown in figure...

Page 14

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 15

Service manual for okipage 14i chapter 1 specifications page: 5 1.3 optional configuration the options shown below are available for use with okipage 14i. These are available separately from the printer unit. (1) high capacity second paper feeder (2) multi-purpose feeder (3) expansion board.

Page 16

(4) rs-232c serial interface board (5) network interface board (10 base).

Page 17

(6) network interface board (10/100 base) (7) dram simm memory dram simm memory is available with memory of 1 mb (min.) to 32 mb (max.). The access time of simm memories are 60ns, 70ns, 80ns, and 100ns. (8) flash memory simm.

Page 18

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 19

Service manual for okipage 14i chapter 1 specifications page: 6 1.4 specification (1) type: desktop (2) outside dimensions height: 8.5" (215 mm) width 13.6" (345 mm) depth 15.7" (400mm) (3) weight 19.8 lbs. (4) development method exposure method dry electrophotography led stationary head (5) paper u...

Page 20

- width: 3.4" x 8.5" (86 to 216 mm) - length: 5.5" to 14" (140 to 355.6 mm) - automatic feed: 16 to 28 lbs (60 to 135 g/m 2 ) - manual feed: label, ohp paper (transparency), envelope (24 to 28 lbs.) (6) printing speed: first print: 14 seconds typical for the letter size paper. [except multi-purpose ...

Page 21

Temperature (25) (26.8) o f o c minimum difference between wet and dry bulb temperatures 35.6 (2) 35.6 (2) ----- o f o c 1. Storage conditions specified above apply to printers in packed condition. 2. Temperature and humidity must be in the range where no condensation occurs. (13) noise during opera...

Page 22

Service manual for okipage 14i chapter 1 specifications page: 7 1.5 safety standards 1.5.1 certification label 1.5.2 warning label 1.5.3 warning/caution marking copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updat...

Page 23

Service manual for okipage 14i chapter 1 specifications page: 8 1.5.1 certification label the safety certification label is affixed to the printer in the position described below. Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange ...

Page 24

Service manual for okipage 14i chapter 1 specifications page: 9 1.5.2 warning label the warning labels are affixed to the sections which may cause bodily injury. Follow the instructions on warning labels during maintenance. Copyright 2000, oki data, division of oki america, inc. All rights reserved....

Page 25

Service manual for okipage 14i chapter 1 specifications page: 10 1.5.3 warning/caution marking the following warning and caution markings are made on the power supply/sensor board..

Page 26

* no fuse is mounted here for 200v series. English - heatsink and transformer core present risk of electric shock. Test before touching. French - le dissipateur thermique et le noyau du transformateur présentent des risques de choc électrique. Testez avant de manipuler. Spanish - las disipadores de ...

Page 27

Portuguese - o dissipador de calor e o núcleo do fransiormador apresentam risco de choque elétrico. Teste antes de focar. English - circuits maybe live after fuses open. French - il se peut que les circuits soient sous tension une fois que les fusibles ont éfé rerirés. Spanish - las circuitos pueden...

Page 28

Service manual for okipage 14i chapter 2 operation page: 11 operation description okipage 14i consists of a main control board, a power supply/sensor board, an operator panel, an electrophotographic process mechanism, and revision for illumination of led head. The main control board receives data vi...

Page 30

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 31

Service manual for okipage 14i chapter 2 operation page: 12 2.1 main control board the main control board consists of a single chip cpu, two program/font roms, four drams, an eeprom, a host interface circuit, and a mechanism driving circuit. (1) single chip cpu the single chip cpu is a custom cpu (3...

Page 32

16k-bit electrically erasable prom (eeprom), is loaded with the following kinds of data: menu data l various counter data (page counter, drum counter) l adjusting parameters (led head drive time, print start position, paper feed length) l (5) parallel interface parallel data is received from a host ...

Page 33

Service manual for okipage 14i chapter 2 operation page: 13 2.2 power supply/sensor board the power supply/sensor board consists of an ac filter circuit, a low voltage power supply circuit, a high voltage power supply circuit, heater drive circuit, and photosensors. (1) low voltage power supply circ...

Page 34

Figure 2-2 sensor function sensing state inlet sensor 1 detects the leading part of the paper and gives the monitor timing for switching from hopping operation to feeding operation. Monitors paper feeding situation and paper size based on the paper arrival time and running time. On: paper exists. Of...

Page 35

The time of arrival to and leaving past the sensor. Off: no paper exists. Paper end sensor detects the end of the paper. On: paper exists. Off: no paper exists. Toner sensor detects the lack of toner. - - - - - copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki ...

Page 36

Service manual for okipage 14i chapter 2 operation page: 14 2.3 electrophotographic process 2.3.1 electrophotographic process mechanism 2.3.2 electrophotogrpahic process 2.3.3 process operation descriptions 2.3.4 revision of led head illumination copyright 2000, oki data, division of oki america, in...

Page 37

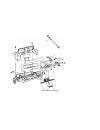

Service manual for okipage 14i chapter 2 operation page: 15 2.3.1 electrophotographic process mechanism this mechanism actuates the printing of image data supplied by the main control board on the paper by electrophotographic process. The layout of the electrophotographic process mechanism is shown ...

Page 39

(1) image drum unit the image drum unit consists of a sensitive drum, a charger, and a developer. The unit forms a toner image on the sensitive drum, using a electrostatic latent image formed by the led head. (2) registration motor the registration motor is a pulse motor of 48 steps/rotation with tw...

Page 40

Service manual for okipage 14i chapter 2 operation page: 16 2.3.2 electrophotographic process the electrophotographic processing is outlined below. The electrophotographic printing process is shown in figure 2-4 (see below). 1 charging the surface of the image drum is charged uniformly with a negati...

Page 42

Figure 2-4.

Page 44

Figure 2-5 copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 45

Service manual for okipage 14i chapter 2 operation page: 17 2.3.3 process operation descriptions (1) hopping and feeding hopping and feeding motions are actuated by a single registration motor in the mechanism as shown below: the registration motor turning in direction "a" drives the hopping roller....

Page 46

(b) feeding 1 when hopping is completed, the registration motor turning in direction "b" (counter-clockwise direction) drives the registration roller to advance the paper (in this case, the hopping gear also turns, but the hopping roller is prevented from turning by the one-way bearing). 2 the paper...

Page 47

(2) charging charging is actuated by the application of the dc voltage to the charge roller that is in contact with the image drum surface. The charge roller is composed of two layers, a conductive layer and a surface protective layer, both having elasticity to secure good contact with the image dru...

Page 48

Forming an electrostatic latent image associated with the image signal. The image drum is coated with an underlayer (ul), a carrier generation layer (cgl), and carrier transfer layer (ctl) on aluminum base. The organic photo conductor layer (opc), comprising ctl and cgl, is about 20 mm thick. The im...

Page 49

The positive carriers moved to the ctl combine with the negative charges on the image drum surface accumulated by the contact charge of the charge roller, lowering the potential on the image drum surface. The resultant drop in the potential of the irradiated portion of the image drum surface forms a...

Page 50

2 the toner attracted to the developing roller is scraped off by the doctor blade, forming a thin coat of toner on the developing roller surface. 3 toner is attracted to the exposed portion (low-potential part) of the image drum at the contact of the image drum and the developing roller, making the ...

Page 51

(5) transfer the transfer roller is composed of conductive sponge material, and is designed to get the image drum surface and the paper in a close contact. Paper is placed over the image drum surface, and the positive charge, opposite in polarity to that of the toner, is applied to the paper from th...

Page 52

(6) fusing when the transfer is completed, the toner image is fused to the paper by heat and pressure as the paper with unfused toner image passes between the heater roller and the back-up roller. The heater roller with teflon coating incorporates a 400w heater (halogen lamp), which generates heat. ...

Page 53

(7) cleaning when the transfer is completed, the residual toner left on the image drum is attracted to the cleaning roller temporarily by static electricity, and the image drum surface is cleaned..

Page 54

(8) cleaning of rollers the charge, transfer and cleaning rollers are cleaned for the following cases: warming up when the power is turned on. L warming up after the opening and closing of the cover. L when the number of sheets accumulated reaches 10 or more, and the printout operation ends. L chang...

Page 55

Service manual for okipage 14i chapter 2 operation page: 18 2.3.4 revision of led head illumination an led correcting head, which is capable of correcting the illumination of the led for each dot, is being used in this printer. Led illumination correction function of 16 steps is carried out by using...

Page 56

The printing operation is carried out in the following sequence. First, the printing data datai3 through datai0 are stored, sequentially shifted, in the shift registers of the led drivers, by the printing data synchronous clock, clocki. Then the printing data stored in shift registers are latched by...

Page 57

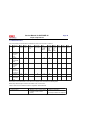

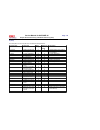

Service manual for okipage 14i chapter 2 operation page: 19 2.4 paper jam detection the paper jam detection function monitors the paper condition when the power is turned on and during printing. When any of the following conditions arises, this function interrupts the printing process. If any of the...

Page 58

Paper feed timing chart paper feed check list type of error monitor standard value error plus error minus paper feed error hopping start to in sensor on 2.835 1.417 - paper feed jam in sensor on to write sensor on .7874 .8661 - paper feed jam write sensor on to out sensor on 5.531 .9843 - paper size...

Page 59

Min. Max. A4 11.69 9.921 13.46 a5 8.268 6.496 10.04 b5 10.12 8.346 11.89 letter 11.0 9.228 12.77 legal 13 13.0 11.23 14.77 legal 14 14.0 12.23 15.77 exec 10.50 8.728 12.27 a6 5.827 4.055 7.598 monarch 7.50 5.728 9.272 com-9 8.874 7.102 10.65 com-10 9.50 7.728 11.27 dl 8.661 6.89 10.43 c5 9.016 7.244...

Page 60

Service manual for okipage 14i chapter 2 operation page: 20 2.5 cover open when the stacker cover is opened, the cover open microswitch on the power supply/sensor board is turned off to cut +5v supply to the high voltage power supply circuit. This results in the interruption of all high-voltage outp...

Page 61

Service manual for okipage 14i chapter 2 operation page: 21 2.6 toner low detection device l l the toner low detection device consists of a stirring gear which rotates at a constant rate, a stirring bar and a magnet on the stirring bar. The stirring bar rotation is driven by the link to the protrusi...

Page 62

Operation during toner low state when the stirring bar reaches the maximum height, it falls to the minimum height due to its own weight, since there is no resistance provided by the toner on l the other side. Because of this, the time interval during which it is in encounter with the magnet of the s...

Page 63

When the toner low state is detected 2 times consecutively, toner low is established. L when the toner full state is detected 2 times consecutively, toner low is canceled. L when there is no change with the toner sensor for 2 cycles (4.875 sec. X 2) or more, then the toner sensor alarm is activated....

Page 64

Service manual for okipage 14i chapter 3 disassembly page: 22 3.1 precautions for parts replacement the section explains the procedures for replacement of parts, assemblies, and units in the field. Only the disassembly procedures are explained here. For reassembly, reverse the steps of disassembly p...

Page 65

(4) use specified service tools. (5) when disassembling, follow the procedure in sequence laid out in this manual. Parts may be damaged if these sequences are not followed. (6) since screws, collars and other small parts are likely to be lost, they should temporarily be attached to the original posi...

Page 66

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 67

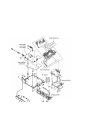

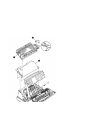

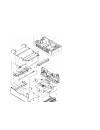

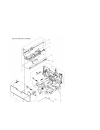

Service manual for okipage 14i chapter 3 disassembly page: 23 3.2 parts layout - [lower base unit] this section describes the layout of main parts of the equipment. [lower base unit].

Page 69

Upper cover unit base unit copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 70

Service manual for okipage 14i chapter 3 disassembly page: 24 [upper cover unit] copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 71

Service manual for okipage 14i chapter 3 disassembly page: 25 [base unit].

Page 73

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 74

Service manual for okipage 14i chapter 3 disassembly page: 26 3.3 how to change parts this section explains how to change parts and assemblies listed in the disassembly diagram below. 3.3.1 upper cover 3.3.2 led head 3.3.3 operator panel assy 3.3.4 lower base unit 3.3.5 pulse motor (main/drum) 3.3.6...

Page 75

3.3.20 main control pcb 3.3.21 power supply board and contact assy 3.3.22 cassette guide (l) 3.3.23 cassette guide (r) 3.3.24 spacer bearing (l/r) copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this mat...

Page 76

Service manual for okipage 14i chapter 3 disassembly page: 27 3.3.1 upper cover assy (1) with the power switch turned off, unplug the ac power cord from the outlet. (2) disconnect the interface cable (1). (3) press the knobs (2) on left and right sides and open the stacker cover assy (3). (4) take o...

Page 78

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 79

Service manual for okipage 14i chapter 3 disassembly page: 28 3.3.2 led head (1) press the latches on left and right sides and open the stacker cover assy (1). (2) open the hook section on the left side of the stacker cover and remove the led head (2). Note: be sure not to touch directly or push on ...

Page 81

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 82

Service manual for okipage 14i chapter 3 disassembly page: 29 3.3.3 operator panel assy (1) unlock two latches on the upper cover from the rear side, lift the operator panel assy (1) from the back and remove it. (2) remove the sumi card (operator panel) (2) from the connector (cn1) (3). Note: you ca...

Page 84

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 85

Service manual for okipage 14i chapter 3 disassembly page: 30 3.3.4 lower base unit (1) remove the upper cover (see 3.3.1). (2) remove the operator panel assy (see 3.3.3). (3) remove the face up stacker assy (see 3.3.7) (4) remove the connecting cables (2) and (3) of the pulse motors from the connec...

Page 87

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 88

Service manual for okipage 14i chapter 3 disassembly page: 31 3.3.5 pulse motor main/drum (1) remove the upper cover (see 3.3.1). (2) remove the lower base unit (see 3.3.4). (3) remove two screws (1) and remove the pulse motor (main drum) (2) from the motor bracket (3)..

Page 89

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 90

Service manual for okipage 14i chapter 3 disassembly page: 32 3.3.6 pulse motor (registration) (1) remove the upper cover (see 3.3.1). (2) remove the lower base unit (see 3.3.4). (3) remove two screws (1) and remove the pulse motor (registration) (2) from the motor bracket (3)..

Page 91

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 92

Service manual for okipage 14i chapter 3 disassembly page: 33 3.3.7 face up stacker assy (1) remove the upper cover (see 3.3.1). (2) remove the operator panel assy (see 3.3.3). (3) remove the screw (1) and remove the sumi card (operator panel cable) (2) off the latch section of face up stacker (4). ...

Page 94

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 95

Service manual for okipage 14i chapter 3 disassembly page: 34 3.3.8 eject roller assy (1) remove the upper cover assy (see 3.3.1). (2) remove the operator panel assy (see 3.3.3). (3) remove the face up stacker assy (see 3.3.7) (4) remove the lower base unit (see 3.3.4). (5) disengage the eject rolle...

Page 96

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 97

Service manual for okipage 14i chapter 3 disassembly page: 35 3.3.9 motor assy (1) remove the upper cover assy (see 3.3.1). (2) remove the operator panel assy (see 3.3.3). (3) remove the face up stacker assy (see 3.3.7) (4) remove the lower base unit (see 3.3.4) (5) remove the heat sink from the pul...

Page 98

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 99

Service manual for okipage 14i chapter 3 disassembly page: 36 3.3.10 hopping roller shaft assy (1) remove the upper cover assy (see 3.3.1). (2) remove the operator panel assy (see 3.3.3). (3) remove the face up stacker assy (see 3.3.7) (4) remove the lower base unit (see 3.3.4). (5) remove the motor...

Page 101

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 102

Service manual for okipage 14i chapter 3 disassembly page: 37 3.3.11 stacker cover assy (1) remove the upper cover assy (see 3.3.1). (2) remove the operator panel assy (see 3.3.3). (3) remove the face up stacker assy (see 3.3.7) (4) remove the reset lever r (1). (5) detach the reset spring (2) from ...

Page 104

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 105

Service manual for okipage 14i chapter 3 disassembly page: 38 3.3.12 registration roller (1) remove the upper cover (see 3.3.1). (2) remove the operator panel assy (see 3.3.3). (3) remove the face up stacker assy (see 3.3.7) (4) remove the lower base unit (see 3.3.4). (5) remove the motor assy (see ...

Page 106

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 107

Service manual for okipage 14i chapter 3 disassembly page: 39 3.3.13 roller transfer assy (1) with the power switch turned off, unplug the ac cord from the outlet. (2) open the stacker cover. (3) release the roller transfer assy (1) by unlocking the latch of the main unit (never apply excessive forc...

Page 109

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 110

Service manual for okipage 14i chapter 3 disassembly page: 40 3.3.14 fusing unit (1) remove the upper cover assy (see 3.3.1). (2) remove the operator panel assy (see 3.3.3). (3) remove the face up stacker assy (see 3.3.7) (4) remove the lower base unit (see 3.3.4). (5) remove the stacker cover assy ...

Page 112

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 113

Service manual for okipage 14i chapter 3 disassembly page: 41 3.3.15 back-up roller (1) remove the fusing unit assy (see 3.3.14). (2) lift the left side of the back-up roller (1), and pull it out to the left side (at this time, two bushings (back-up) (2) and the bias springs (back-up) (3) will also ...

Page 115

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 116

Service manual for okipage 14i chapter 3 disassembly page: 42 3.3.16 sensor plate (inlet) (1) remove the upper cover (see 3.3.1). (2) remove the operator panel assy (see 3.3.3). (3) remove the face up stacker assy (see 3.3.7) (4) remove the lower base unit (see 3.3.4). (5) press the clamps of three ...

Page 118

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 119

Service manual for okipage 14i chapter 3 disassembly page: 43 3.3.17 sensor plate (outlet), sensor wire assy (1) remove the upper cover (see 3.3.1). (2) remove the operator panel assy (see 3.3.3). (3) remove the eject roller assy (see 3.3.8). (4) remove the face up stacker assy (see 3.3.7) (5) remov...

Page 121

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 122

Service manual for okipage 14i chapter 3 disassembly page: 44 3.3.18 manual feed guide assy (1) remove the upper cover (see 3.3.1). (2) open the manual feed guide assy (1), and release the engagement on both sides with the main unit by carefully bending the manual feed guide assy (1). Note: at the t...

Page 124

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 125

Service manual for okipage 14i chapter 3 disassembly page: 45 3.3.19 sensor plate (paper supply) (1) remove the upper cover (see 3.3.1). (2) remove the operator panel assy (see 3.3.3). (3) remove the face up stacker assy (see 3.3.7) (4) remove the lower base unit (see 3.3.4) (5) press the clamps of ...

Page 127

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 128

Service manual for okipage 14i chapter 3 disassembly page: 46 3.3.20 main control m7e-pcb (1) remove the upper cover (see 3.3.1). (2) remove the operator panel assy (see 3.3.3). (3) remove the face up stacker assy (see 3.3.7) (4) remove the lower base unit (see 3.3.4). (5) remove the connector (2ndt...

Page 129

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 130

Service manual for okipage 14i chapter 3 disassembly page: 47 3.3.21 power supply/sensor board, high voltage unit and contact assy (1) remove the upper cover assy (see 3.3.1). (2) remove the lower base unit (see 3.3.4). (3) remove the m7e-pcb (see 3.3.20). (4) remove the ac inlet (1) from the base p...

Page 132

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 133

Service manual for okipage 14i chapter 3 disassembly page: 48 3.3.22 cassette guide l assy (1) remove the paper cassette. (2) remove the upper cover (see 3.3.1). (3) remove the lower base unit (see 3.3.4). (4) remove the main control m7e-pcb (see 3.3.20) (5) remove the power supply/sensor board (see...

Page 135

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 136

Service manual for okipage 14i chapter 3 disassembly page: 49 3.3.23 cassette guide r assy (1) remove the paper cassette. (2) remove the upper cover assy (see 3.3.1). (3) remove the lower base unit (see 3.3.4). (4) remove the m7e-pcb (see 3.3.20). (5) remove two screws (1), and remove the guide rail...

Page 138

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 139

Service manual for okipage 14i chapter 3 disassembly page: 50 3.3.24 spacer bearing (l/r) (1) remove the back-up roller (see 3.3.15). (2) remove spacer bearing (l/r) with a tip of screw driver..

Page 141

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 142

Service manual for okipage 14i chapter 4 adjustments page: 51 4. Adjustment this chapter provides explanations concerning the adjustment necessary when replacing a part. The adjustment is made by changing the parameter value set in eeprom on the main control board. The parameter can be set by the ke...

Page 143

Service manual for okipage 14i chapter 4 adjustments page: 52 4.1 maintenance modes and functions 4.1.1 user maintenance mode 4.1.2 system maintenance mode 4.1.3 engine maintenance mode 4.1.4 eeprom initialization copyright 2000, oki data, division of oki america, inc. All rights reserved. See the o...

Page 144

Service manual for okipage 14i chapter 4 adjustments page: 53 4.1.1 user maintenance mode to enter into the user maintenance mode, turn the power switch on while holding the menu key down. Function there are five functions as follows: menu reset l opepane menu disable l hex dump l x-adjust l drum co...

Page 145

Service manual for okipage 14i chapter 4 adjustments page: 54 4.1.2 system maintenance mode this mode is used only by maintenance personnel and it should not be released to the end-users. To enter into the system maintenance mode, turn the power switch on while holding the recover key down. Function...

Page 146

Service manual for okipage 14i chapter 4 adjustments page: 55 4.1.3 engine maintenance mode note: this mode is used only by maintenance personnel, and it should not be released to the end users. (1) to enter into the engine maintenance mode, turn the power on while holding enter and form feed keys d...

Page 147

(bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 148

Service manual for okipage 14i chapter 4 adjustments page: 56 4.1.4 eeprom initialization the corresponding are the eeprom is initialized for each event as shown in table 4-1. No. Eeprom area menu level 1 menu level 2 f/w revision area customer information user maintenan ce area note1) system mainte...

Page 149

Receiving buffer sidm emulation switch enable/disable operator panel menu function enable/disable x / y adjust 2nd feed destination left alignment based printing shift cleaning cycle jam recovery enable/disable to reset. As a common spec. Copyright 2000, oki data, division of oki america, inc. All r...

Page 150

Service manual for okipage 14i chapter 4 adjustments page: 57 4.2 adjustment when replacing a part adjustment is necessary when replacing any of the following parts. Part replaced adjustment image drum cartridge reset the image drum counter (refer to user's manual). Main control board eeprom data up...

Page 151

Service manual for okipage 14i chapter 4 adjustments page: 58 4.2.1 uploading/downloading eeprom data when the controller printed circuit board is replaced, the contents of the old eeprom shall be copied to the new eeprom on the new board to preserve customer settings. For the purpose, use the eepro...

Page 152

Service manual for okipage 14i chapter 5 maintenance page: 59 5.1 periodical replacement parts part name condition for replacement cleaning remarks toner cartridge (type 5) about 2,000 sheets of paper have been printed led head consumables toner cartridge (type 8) about 4,000 sheets of paper have be...

Page 153

Service manual for okipage 14i chapter 5 maintenance page: 60 5.2 cleaning remove any toner or dust accumulated inside the printer. Clean in and around the printer with a piece of cloth when necessary. Use the handy cleaner (service tool) to clean inside the printer. Note: do not touch the image dru...

Page 154

Service manual for okipage 14i chapter 5 maintenance page: 61 5.2.1 cleaning of led lens array clean the led lens array or replace the toner cartridge when white lines or stripes (void, light printing) are generated vertically down the page, as shown below. Note: the led lens array must be cleaned w...

Page 155

(2) throw the cleaner pad away. Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 156

Service manual for okipage 14i chapter 5 maintenance page: 62 5.2.2 cleaning page function there is a charge roller cleaning function with this printer, which can be executed by the user. (1) while the printer is in off-line mode, press both and keys simultaneously for at least 2 seconds. The printe...

Page 157

Service manual for okipage 14i chapter 6 troubleshooting page: 63 6.1 troubleshooting tips (1) check the problem solving section in the printer handbook. (2) gather as much information about the situation as possible. (3) inspect the equipment under the conditions close to those in which the problem...

Page 158

Service manual for okipage 14i chapter 6 troubleshooting page: 64 6.2 points to check before correcting image problems (1) is the printer being run in proper ambient conditions? (2) are supplies (toner) and routine replacement part (image drum cartridge) being replaced properly? (3) is the printing ...

Page 159

Service manual for okipage 14i chapter 6 troubleshooting page: 65 6.3 tips for correcting image problems (1) do not touch, or bring foreign matter into contact with the surface of the image drum. (2) do not expose the image drum to direct sunlight. (3) keep hands off the fuser unit as it heats up du...

Page 160

Service manual for okipage 14i chapter 6 troubleshooting page: 66 6.4 preparation for troubleshooting (1) operator panel display the failure status of the printer is displayed by the liquid crystal display (lcd) of the operator panel. Take proper corrective action as directed by messages which are b...

Page 161

Service manual for okipage 14i chapter 6 troubleshooting page: 67 6.5 troubleshooting flow should there be a problem with the printer, carry out troubleshooting according to the following procedure flow: 6.5.1 lcd status message/problem list the status and problems which may be displayed by messages...

Page 162

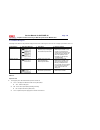

Service manual for okipage 14i chapter 6 troubleshooting page: 68 6.5.1 lcd status message/problem list the status and problems which may be displayed by messages on the lcd are listed in table 6-1 below. N = exception aaaaaaaa = error address category lcd status message code (nn) problem or status ...

Page 163

Following remedial actions. Code (nn) error remedy 10 an error was detected by program rom check. Replace the main control board. 20 an error was detected by font rom check. Replace the main control board. 30 an error was detected by resident ram check. Replace the main control board. 40 an error wa...

Page 164

Data bus for option drams. 70 a failure occurred with the fan motor. - check the fan motor for proper connection and for any presence of foreign matter in the fan (see section 6.5.2 (6). - replace the fan or the main control board. 71 a failure occurred with the fuser (timeout error etc). See sectio...

Page 165

Error f3 optional status error f4 bg program error. - turn the power off, then back on again. - replace the main control board. Note: when replacing the main control board, be sure to install the eeprom from the old board onto the new board. Controller errors (continued) f5 system timer program erro...

Page 166

Paper feeder option cover was opened. Error display. - check the connection between the main control board and tqsb-2-pcb. - replace the main control board tqsb-2-pcb or connector. Jam errors a jam occurred during paper hopping from the tray. Tray: tray1, tray2, feeder, manual - check the paper in t...

Page 167

By the first line message is requested. The paper size may be one of the followings: paper: letter, executiv, legal 14, legal 13, a4 size, a5 size, a6 size, b5 size, com-9, com-10, monarch, dl env, c5 env tray. Size error manual loading of paper indicated by the first line message is requested. The ...

Page 168

Emulate: auto, pcl, ppr, fx, hex daily status the printer is processing data. Normal operation. Daily status the printer is printing a page. Normal operation. Daily status the printer is processing data in the on-line mode. Ready on: the data that is not printed remains in the buffer. Ready flashing...

Page 169

Indicate that the controller is undergoing an initialization when the power is turned on. This message is displayed after the turning on the leds as described above. Daily status indicates in hold mode due to downloading to flash memory. Normal operation. Daily status indicates that an error occurs ...

Page 170

Daily status postscript mode only. This message is displayed during canceling of a job. The message goes off when the job cancellation is completed. Normal operation. Daily status the data which remained unprinted in the buffer is deleted and the printer is initialized to user default settings. The ...

Page 171

Ready on: executed by command entry. Ready flashing: executed by key operation. Daily status message displayed when the power is turned on. When the power is turned on, the leds are turned on for approximately 1 second, conducting a test to verify the conditions of the leds and lcd. Normal operation...

Page 172

Mmm : total page daily status this message is displayed when the printer is performing the cleaning print. Normal operation. Daily status manual loading of paper indicated by the second line message is being requested for cleaning. The paper size (#) may be one of the following: # : letter request, ...

Page 173

Status will appear after 100 sheets from a toner low indication). It is indicated by being combined with other messages in the first line. Normal operation can be continued. Daily status displays that the amount of toner is nearly empty. After 100 sheets from a toner low indication, this status will...

Page 174

The drum must be replaced. Daily status indicates an error from the result of checking eeprom id no. The printer will display this for a few seconds and reset the eeprom to the factory default for a continuous operation. It will occur with a new eeprom. Daily status reformat error including cpcmcia ...

Page 175

Service manual for okipage 14i chapter 6 troubleshooting page: 69 6.5.2 lcd message troubleshooting if the problems cannot be corrected by using the lcd status message/problem list, follow the troubleshooting flowcharts given here to deal with them. No. Trouble flowchart number 1. The printer does n...

Page 176

Service manual for okipage 14i chapter 6 troubleshooting page: 70 (1) the printer does not work normally after the power is turned on..

Page 178

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 179

Service manual for okipage 14i chapter 6 troubleshooting page: 71 (2) [jam error] paper input jam paper feed jam paper exit jam copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx....

Page 180

Service manual for okipage 14i chapter 6 troubleshooting page: 72 paper input jam.

Page 182

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 183

Service manual for okipage 14i chapter 6 troubleshooting page: 73 paper feed jam.

Page 185

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 186

Service manual for okipage 14i chapter 6 troubleshooting page: 74 paper exit jam copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 187

Service manual for okipage 14i chapter 6 troubleshooting page: 75 (3) paper size error.

Page 188

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 189

Service manual for okipage 14i chapter 6 troubleshooting page: 76 (4) fusing unit error (error 71) (error 72) (error 73).

Page 190

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 191

Service manual for okipage 14i chapter 6 troubleshooting page: 77 (5) ssio error (error 74) copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 192

Service manual for okipage 14i chapter 6 troubleshooting page: 78 (6) fan error (error 70) copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 193

Service manual for okipage 14i chapter 6 troubleshooting page: 79 6.5.3 image troubleshooting procedures for troubleshooting for the cases of abnormal image printouts are explained below. Figure 6-3 below shows typical abnormal images. Problem flowchart number images are light or blurred entirely (f...

Page 194

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 195

Service manual for okipage 14i chapter 6 troubleshooting page: 80 (1) images are light or blurred entirely.

Page 197

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 198

Service manual for okipage 14i chapter 6 troubleshooting page: 81 (2) dark background density copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 200

Service manual for okipage 14i chapter 6 troubleshooting page: 82 (3) blank paper is output copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 201

Service manual for okipage 14i chapter 6 troubleshooting page: 83 (4) black vertical belts or stripes copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 203

Service manual for okipage 14i chapter 6 troubleshooting page: 84 (5) cyclical defect frequency remedy image drum 3.71" (94.2mm) clean or replace the image drum unit. Developing roller 1.86" (47.12mm) replace the image drum unit. Toner supply roller 2.96" (75.27mm) replace the image drum unit. Charg...

Page 204

Service manual for okipage 14i chapter 6 troubleshooting page: 85 (6) prints voids.

Page 206

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 207

Service manual for okipage 14i chapter 6 troubleshooting page: 86 (7) poor fusing poor fusing (images are blurred or peels off when the printed characters and images on the paper are touched by hand) copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data busine...

Page 208

Service manual for okipage 14i chapter 6 troubleshooting page: 87 (8) white vertical belts or streaks.

Page 210

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 211

Service manual for okipage 14i chapter 6 troubleshooting page: 88 figure 6-4 copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 212

Service manual for okipage 14i chapter 6 troubleshooting page: 89 figure 6-5.

Page 213

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange.

Page 214

(bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 215

Service manual for okipage 14i chapter 7 wiring diagram page: 90 7.1 interconnect signal diagram.

Page 217

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 218

Service manual for okipage 14i chapter 7 wiring diagram page: 91 7.2 pcb layout and connector signal list (1) main control board (m7e-2-pcb).

Page 219

(2) power supply board.

Page 220

Fan connector pin assignment (to fan motor) l l opening pin no. I/o signal description 1 1 o fanpow power supply for fan driving 2 2 c ov ground 3 3 i fanalm-n fan alarm dm connector pin assignment (to main/drum motor) l l opening pin no. I/o signal description 1 1 o dmph1-p coil 1-p.

Page 221

2 2 o dmph1-n coil 1-n 3 3 o dmph2-p coil 2-p 4 4 o dmph2-n coil 2-n excitation sequence l l step no. Step no. Step no. Step no. Pin no. Line color 1 2 3 4 2 yellow + - - + 4 black + + - - 1 orange - + + - 3 brown - - + + turning direction clockwise when viewed from the output axis. Rm connector pin...

Page 222

5 o hdd3-p data 3 6 c 0vled ground for led 7 o hdd0-p data 0 8 o hdd1-p data 1 9 o +3.3v +3.3v power supply for led driving 10 o hddld-p load 11 o hdstb1-n strobe 1 12 o hdstb2-n strobe 2 13 o hdstb3-n strobe 3 14 o hdstb4-n strobe 4 o: out c: common head2 connector pin assignment (to led head) l l ...

Page 223

O: out c: common envelope connector pin assignment (to option feeder i/f) l l pin no. I/o signal description 1 o paperin-n paper sense 1 2 o optsclk-n clock 3 o data-n data 4 i paperin-n opt send data ready 5 c ovp analog ground 6 o 38v +30v power supply 7 c 0v logic ground 8 o 5v +5v power supply i...

Page 224

10 9 10 rxd2-p i serial data input 9 ovl c ground for logic 12 11 12 +5v i logic circuit supply voltage 11 +5v i logic circuit supply voltage 14 13 14 +3.3v i led head supply voltage 13 +3.3v i led head supply voltage 16 15 16 ovl c logic ground 15 ovl c logic ground 18 17 18 +38v i motor and fan dr...

Page 225

18 36 18 o p-logic-h +5v power supply 36 i selin-n select in o: out i: in c: common usb connector pin assignment (to usb i/f) l l pin no. I/o* signal description 2 1 1 i voc +5 power 3 4 2 io d- usb data 3 io d+ usb data 4 c 0v ground * i: in o: out c: common option connector pin assignment (to opti...

Page 226

16 66 16 o a10 logic power supply 66 i/o d7 data bit 7 17 67 17 o +5v address bit 11 67 i/o d24 data bit 24 18 68 18 o a11 address bit 12 68 i/o d8 data bit 8 19 69 19 o a12 logic ground 69 i/o d25 data bit 25 20 70 20 c 0v address bit 13 70 i/o d9 data bit 9 21 71 21 o a13 address bit 14 71 i/o d26...

Page 227

40 90 40 o cs1-n rom/sram select 1 90 o dcas0-n dcas0 41 91 41 o cs2-n rom/sram select 2 91 o rd-n rd-n 42 92 42 o cs3-n rom/sram select 3 92 o wr-n wr-n 43 93 43 i csrreq- p scc send request 93 i int1-n interrupt request 1 44 94 44 c 0v logic ground 94 i int2-n interrupt request 2 45 95 45 i scsreq...

Page 228

Service manual for okipage 14i chapter 7 wiring diagram page: 92 7.3 resistance check unit circuit diagram illustration resistance registration motor between pins 1 and 2: 9 ohms between pins 3 and 4: 9.5 ohms main/drum motor between pins 1 and 2: 4.2 ohms between pins 3 and 4: 4.2 ohms fusing unit ...

Page 229

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 230

Service manual for okipage 14i chapter 8 parts list page: 93 lower base unit.

Page 232

Figure 8-1 lower base unit no. Name/rating use remarks oda part no. 1 hopping roller shaft 1 51112601 2 bearing 2 51607402 3 hopping roller one-way clutch gear 2 51228901 4 registration roller 1 41281101 5 bearing (registration) 1 51607501 6 roller-transfer assy 1 40437802 7 bearing tr 1 40438001 8 ...

Page 233

37 toner cartridge (type 5) (starter 2k) 1 consumabl e 40433203 toner cartridge (type 8) (replacement 4k) 1 consumabl e 41331701 38 reduction gear 1 41279201 39 fg plate (o.P.) 1 53347201 40 hopping roller rubber 1 53342401 41 static film 52203802 42 led contact 1 51014601 43 washer c 1 50517201 44 ...

Page 234

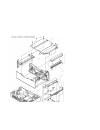

Service manual for okipage 14i chapter 8 parts list page: 94 upper cover unit figure 8-2 upper cover unit no. Name/rating use remarks oda part no. 1 upper cover 1 40715101.

Page 235

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 236

Service manual for okipage 14i chapter 8 parts list page: 95 base unit.

Page 238

Figure 8-3 base unit no. Name/rating use remarks oda part no. 1 plate base 1 41279901 2 cassette guide (l) assy 1 51011201 3 cassette guide (r) assy 1 51011301 4 sensor plate (paper supply) 1 51011401 5 plate insulator 1 41301601 6 main control board (board-m7e) 1 41249206 7 pcb assy - hv1 1 4122850...

Page 239

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 240

Service manual for okipage 14i chapter a centronics parallel interface page: 96 centronics parallel interface 1) connector printer side : 36-pin receptacle (single port) type 57re-40360-730b-d29a (made by daiichi denshi), cn-ax05841a36at (made by ougat) or l equivalent cable side : 36-pin plug type ...

Page 242

Connector pin arrangement l (4) signal level low : 0 v to + 0.8 v high : + 2.4 to 5.0 v 5) specifications item description mode compatibility mode, nibble mode, ecp mode data bit length 8 bits (in the compatibility mode) input prime valid/invalid receive buffer, 8k, 20k, 50k, 100k, 1m bytes control ...

Page 244

7) interface parameter setting.

Page 247

Service manual for okipage 14i chapter b universal serial bus (usb) page: 97 universal serial bus (usb) universal serial bus specification revision 1.1 compliance. 1) connector printer side : "b" receptacle (upstream input to the usb device) l cable side : series "b" plug l 2) cable cable length : m...

Page 248

Self - powered device l 6) data signaling rate full - speed function - 12mb/s l 7) interface circuit 8) signal level input / output level l parameter symbol min. Max. Units input levels: 2.0 high (driven) vih 2.7 v high (floating) vihz 3.6 v low vil .8 v output levels: low ol 0.0 0.3 v high (driven)...

Page 249

Note: the width of eop is defined in bit times relative to the device type receiving the eop. The bit time is approximate. 9) timing chart.

Page 251

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 252

Service manual for okipage 14i chapter c loop test (rs-232c interface) page: 98 loop test (rs-232c interface) 1) connect the test connector test connector connection diagram 2) select "loop test" in the system maintenance mode. The codes transmitted from the td signals are comparatively checked with...

Page 253

Service manual for okipage 14i chapter d diagnostics test page: 99 1. Maintenance modes the maintenance modes consist of the user maintenance mode which are released to the user, and the system and engine maintenance modes in the l maintenance personnel level not released to the user. Press the menu...

Page 254

Service manual for okipage 14i chapter d diagnostics test page: 100 1.1 user maintenance mode to enter the user maintenance mode, turn the power on while keeping the menu key pressed down. L this mode uses the menu for function selection. L the user maintenance mode provides the following functions:...

Page 255

(8) ecp receive disable (9) designated for 2nd tray command for pcl5 emulation is set. (10) place page (11) setting (12) jam recovery & print performance for continuous mode (13) power save mode disable.

Page 257

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 258

Service manual for okipage 14i chapter d diagnostics test page: 101 1.2 system maintenance mode to enter the system maintenance mode, turn the power on while keeping the recover key pressed down. L this mode adopts the menu for function selection. L the system maintenance mode provides the following...

Page 259

Head drive time setting fine adjustment of printing start position standard tray paper feed amount setting transition to the operation mode occurs upon completion of resetting. L press the menu key to update each category. L the operation returns to the first category after updating the last categor...

Page 261

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 262

Service manual for okipage 14i chapter d diagnostics test page: 102 1.3 engine maintenance mode the engine maintenance mode is activated when the power is turned on while keeping the form feed key and enter key pressed down. L this mode adopts the menu for function selection. L the method for exit f...

Page 265

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 266

Service manual for okipage 14i chapter d diagnostics test page: 103 1.4 user factory set operation the desired destination can be set by turning the power on while depressing two keys corresponding to the destination according to the following table. Destination keys to be depressed oda menu oel men...

Page 267

Service manual for okipage 14i chapter product accessory 1: rs-232c serial interface (option) page: 104 rs-232c serial interface (option) 1) connector printer side : 25-pin receptacle - type db-25s (made by canon) or equivalent l cable side : 25-pin plug - type db-25s (made by canon) shell - type db...

Page 268

When the ready/busy protocol is used for the buffer busy control method, the busy signal can be set to the pin-20 (dtr) in the menu. 4) signal level mark polarity : -3v to -15v (logic = 1) l space polarity : +3v to +15v (logic = 0) l 5) interface circuit a) receiving circuit b) sending circuit.

Page 269

6) receive margin 37% main. At all reception rates. 7) communications protocol a) ready/busy protocol b) x-on/x-off protocol 8) interface parameter setting.

Page 272

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 273

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 105 1. Preface this maintenance manual is intended for the service person and describes the field maintenance methods for multi-purpose feeder option of okipage 14i series led page printer. Refer to th...

Page 274

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 106 1.1 functions this optional multi-purpose feeder is installed on the front section of the printer, and it supplies paper automatically through the operation of pulse motor, which is driven by signa...

Page 275

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 107 1.2 external view and component names figure 1-1 copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to thi...

Page 276

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 108 2. Mechanism description - general mechanism the multi-purpose feeder feeds the paper into the printer by receiving the signal from the printer, which drives the pulse motor inside the multi-purpos...

Page 277

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 109 2.2 hopper mechanism the hopper automatically feeds the printer with the paper being set, single sheet at a time. After the paper is set in the multi-purpose feeder, the pulse motor moves the paper...

Page 278

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 110 3. Parts replacement this section covers the procedures for the disassembly, reassembly and installations in the field. This section describes the disassembly procedures, and for reassembly procedu...

Page 279

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 111 3.1 precautions concerning parts replacement (1) parts replacements must be carried out, by first turning the printer power switch off "o" and removing the multi-purpose feeder from the printer. (2...

Page 280

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 281

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 112 3.2 parts layout this section describes the layout of the main components..

Page 282

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 283

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 113 3.3 parts replacement methods this section describes the parts replacement methods for the components listed in the disassembly order diagram below. Multi-purpose feeder link - (see 3.3.1) separato...

Page 284

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 114 3.3.1 link (1) open paper feed cover (1), and disengage the paper feed cover (1) and link (3), while lifting the paper hold (2). (2) remove the paper hold (2) off the arm (4). (3) disengage the lin...

Page 285

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 286

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 115 3.3.2 separator (1) turn the power switch off "o" and remove the connector cord. (2) disengage the link and paper feeder cover (see 3.3.1). (3) remove the 2 screws (1), disengage the locks at 2 loc...

Page 287

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 288

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 116 3.3.3 olev-11 pcb (1) remove the upper frame (see 3.3.2 steps (1) through (3)). (2) remove the connector (1). (3) remove the 2 screws (2), and remove the olev-11 pcb (3). When mounting the printed ...

Page 289

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 290

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 117 3.3.4 pulse motor (1) remove the upper frame (see 3.3.2 steps (1) through (3)). (2) remove the olev-11 pcb (see 3.3.3). (3) remove the 2 screws (1), and remove the stepping motor (2). Copyright 200...

Page 291

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 118 3.3.5 planet gear (1) remove the upper frame (see 3.3.2 steps (1) through (3)). (2) remove the olev-11 pcb (see 3.3.3). (3) remove the 2 screws (1), and remove the motor bracket assembly (2) and pl...

Page 292

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 119 3.3.6 roller-a and b while only the removal procedure for roller-a is described here, the removal procedure for roller-b is basically same. When removing roller-b, however, be careful not to deform...

Page 293

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 294

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 120 4. Troubleshooting - precautions prior to the troubleshooting (1) go through the basic checking items provided in the printer handbook. (2) obtain detailed information concerning the problem from t...

Page 295

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 121 4.1 precautions prior to the troubleshooting (1) go through the basic checking items provided in the printer handbook. (2) obtain detailed information concerning the problem from the user. (3) go t...

Page 296

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 122 4.2 preparations for the troubleshooting (1) display on the operator panel the status of the problem is displayed on the lcd (liquid crystal display) on the operator panel. Go through the appropria...

Page 297

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 123 4.3 troubleshooting method when a problem occurs, go through the troubleshooting according to the following procedure. 4.3.1 lcd status message list copyright 2000, oki data, division of oki americ...

Page 298

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 124 4.3.1 lcd status message list the listing of the statuses and problems displayed in the form of messages on the lcd or pc display is provided in table 4-1. Classification lcd status message descrip...

Page 299

No - when the paper is fed in, does the paper inlet jam occur? L yes - is the paper being fed to above sensor plate (inlet)? L yes - is the sensor plate (inlet) operating normally? L no - replace the sensor plate (inlet). L yes - clean the inlet sensor on the power supply/sensor board or replace the...

Page 300

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 125 5. Connection diagram 5.1 interconnection diagram 5.2 pcb layout copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for an...

Page 301

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 126 5.1 interconnection diagram copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange.

Page 302

(bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 303

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 127 5.2 pcb layout olev-11 pcb copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bp...

Page 304

Service manual for okipage 14i chapter product accessory 2: multi-purpose feeder maintenance page: 128 6. Parts list.

Page 305

Figure 6-1 multi-purpose feeder.

Page 306

Table 6-1 multi-purpose feeder no. Description oda part no. Q’ty remark 1 roller-a 53343801 1 2 roller-b 53343901 1 3 planet gear 51229601 1 4 link 53344101 1 5 separator 53344201 1 6 pulse motor 56510701 1 same as printer unit. 7 olev-11-pcb 55074811 1 8 connector cable 56631203 1 for oda 9 separat...

Page 307

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 129 high capacity second paper feeder maintenance preface this maintenance manual is intended for the service person and describes the field maintenance methods for high capacity second paper feeder opti...

Page 308

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 130 1. Outline 1.1 functions 1.2 external view and component names copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any up...

Page 309

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 131 1.1 functions the printer is mounted on top of this high capacity second paper feeder. The high capacity second paper feeder supplies paper automatically through the operation of pulse motor (hopping...

Page 310

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 132 1.2 external view and component names figure 1-1 external view and component names copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner excha...

Page 311

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 133 2. Mechanism description - general mechanism 2.1 general mechanism 2.2 hopper mechanism copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner ...

Page 312

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 134 2.1 general mechanism the high capacity second paper feeder feeds the paper into the printer by receiving the signal from the printer, which drives the pulse motor inside the high capacity second pap...

Page 313

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 135 2.2 hopper mechanism the hopper automatically feeds the printer with the paper being set, single sheet at a time. When the paper is loaded in the paper cassette, it is then transported by the pulse m...

Page 314

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 136 3. Parts replacement this section covers the procedures for the assembly, disassembly and installations in the field. This section describes the disassembly procedures, and for assembly procedures, b...

Page 315

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 137 3.1 precautions concerning parts replacement (1) parts replacements must be carried out, by first turning the printer power switch off "o" and removing the high capacity second paper feeder from the ...

Page 316

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 317

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 138 3.2 parts layout this section describes the layout of the main components..

Page 319

Figure 3-1 copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 320

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 139 3.3 parts replacement methods this section describes the parts replacement methods for the components listed in the disassembly order diagram below. 3.3.1 stepping motor (hopping) 3.3.2 tqsb-2 pcb 3....

Page 321

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 140 3.3.1 stepping motor (hopping) (1) turn the printer power switch off, pull out the ac cord from the outlet. Remove the printer off high capacity second paper feeder. (2) take the paper cassette assy ...

Page 323

(6) remove three screws (9) which are holding the guide r (2nd) assy (10) to the bottom plate (11). Remove the screw (12) which is keeping the rear cover (13) and guide r (2nd) assy (10). Remove the guide r (2nd) assy (10). (7) remove the protect (m) (14), guide bracket (15), planet gears (16) and p...

Page 325

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 326

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 141 3.3.2 tqsb-2 pcb (1) remove the pulse motor (see 3.3.1). (2) remove the connector (25) from the tqsb-2 pcb (26). (3) remove the screw (27) and remove the tqsb-2 pcb (26). Note : refer to detaii a in ...

Page 327

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 142 3.3.3 hopping roller shaft assembly and one-way clutch gear (1) follow up to step (3) of 3.3.1 and remove the hopping frame assy. (2) remove the screw (1) and remove the earth plate (2). Remove the s...

Page 328

Copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange.

Page 329

(bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 330

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 143 4. Troubleshooting - precautions prior to the troubleshooting 4.1 precautions prior to the troubleshooting 4.2 preparations for the troubleshooting copyright 2000, oki data, division of oki america, ...

Page 331

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 144 4.1 precautions prior to the troubleshooting (1) go through the basic checking items provided in the printer handbook. (2) obtain detailed information concerning the problem from the user. (3) go thr...

Page 332

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 145 4.2 preparations for the troubleshooting (1) display on the operator panel the status of the problem is displayed on the lcd (liquid crystal display) on the operator panel. Go through the appropriate...

Page 333

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 146 4.3 troubleshooting method when a problem occurs, go through the troubleshooting according to the following procedure. 4.3.1 lcd status message list copyright 2000, oki data, division of oki america,...

Page 334

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 147 4.3.1 lcd status message list the listing of the statuses and problems displayed in the form of messages on the lcd or pc display is provided in table 4-1. Table 4-1 classification lcd status message...

Page 335

( jam error ) paper inlet jam does paper jam at the inlet when the power is turned on? L yes - is the paper located above the sensor plate (inlet)? L yes - remove the paper. L no - is the sensor plate (inlet) operating normally? L no - replace the sensor plate (inlet). L yes - replace the power supp...

Page 336

No - replace the stepping motor. L yes - replace the tqsb-2 pcb. L copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 337

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 148 5. Connection diagram 5.1 interconnection diagram 5.2 pcb layout copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any ...

Page 338

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 149 5.1 interconnection diagram copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx...

Page 339

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 150 5.2 pcb layout tqsb-2 pcb copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.O...

Page 340

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 151 6. Parts list high capacity second paper feeder 2nd tray assembly section 1 cabinet & cassette assembly section 2 mechanical assembly 2nd tray parts list copyright 2000, oki data, division of oki ame...

Page 341

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 152 high capacity second paper feeder.

Page 343

Figure 6-1 high capacity second paper feeder table 6-1 high capacity second paper feeder no. Description oda part no. Q’ty remarks 1 hopping roller shaft 50409501 1 2 one-way clutch gear 51401101 1 3 pulse motor 56512201 1 4 tqsb-2 pcb 55078102 1 5 cassette assy (2nd tray) 50107304 1 copyright 2000,...

Page 344

Service manual for okipage 14i chapter product accessory 3: high capacity 2nd paper feeder page: 154 section 1 cabinet & cassette assembly.

Page 346

2nd paper tray parts list copyright 2000, oki data, division of oki america, inc. All rights reserved. See the oki data business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 347