- DL manuals

- Oki

- Software

- OKIPAGE 8w Lite

- Service Handbook

Oki OKIPAGE 8w Lite Service Handbook

Summary of OKIPAGE 8w Lite

Page 1

Okipage 8z led page printer service handbook oki data 2000. 6.30

Page 2: Preface

Preface this service handbook describes the field maintenance procedures for the okipage 8 z. This manual is written for use by service persons. Please note that you should refer to the printer user's manual for operating procedures..

Page 3: Contents

Contents 1. Configuration ..................................................................................... 1 - 1 1.1 system configuration ........................................................................ 1 - 1 1.2 printer configuration .......................................................

Page 4

4. Adjustment ........................................................................................... 4 - 1 4.1 adjustment types and functions ...................................................... 4 - 1 4.1.1 printer driver ..........................................................................

Page 5: Configuration

1. Configuration.

Page 6

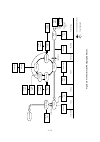

1 - 1 electro-photographic processor paper feed mechanism engine unit hopper plate main high-voltage power supply board sub high-voltage powersupply board power supply unit main control board , , 4mb memory expansion board figure 1-1 1. Configuration 1.1 system configuration the okipage 8 z consists...

Page 7

1 - 2 ep unit (type 6) upper cover assy top cover assy heat assy main control board high-voltage power supply board (p6l) high-voltage power supply board (p2h) 1.2 printer configuration the printer unit consists of the following five hardware components: • electro-photographic processor • paper feed...

Page 8

1 - 3 1.3 option (1) 4mb option memory board.

Page 9

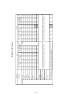

1 - 4 1.4 specification (1) type desktop (2) outside dimensions height 5.9” (150 mm) (excludes protruding width 12.2” (310 mm) portion) depth 7.5” (191 mm) (3) weight 3.8 kg (4) development method dry non-magnetic development system exposure method led stationary head (5) paper used • standard paper...

Page 10

1 - 5 (12) temperature and humidity temperature during operation in storage 10 to 32 ˚c –10 to +43 ˚c 20 to 80% rh (relative humidity) 10 to 90% rh (relative humidity) no condensation is permissible. Humidity caution: temperature and humidity in storage are measured with the okipage 8 z being packed...

Page 11

1 - 6 1.5 safety standards 1.5.1 certification label the safety certification label is affixed to the following location of the okipage 8z: 1.5.2 warning label warning labels are affixed to the locations that may cause bodily injury. During maintenance, do work with enough care while following instr...

Page 12: Operation Description

2. Operation description.

Page 13

2 - 1 2. Operation description the okipage 8 z consists of a main control board, a high-voltage power supply board, a power supply unit, and an electro-photographic processor. The okipage 8 z receives print data from a higher-level interface and sequentially stores it in memory. The okipage 8 z deco...

Page 14

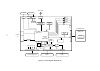

2 - 2 figure 2-1 block diagram (okipage 8z) plunger led head main motor pj head1 head2 5v 0v 0v motor motor driver mtd2005f eeprom 1kb cpu (nkk 3 or 5) serial i/f data bus (x 16) address bus cent ls07 +26v+5v 0v 0vp power hivol hivol2 hc244 lsi lc26023a rst osc 7mhz osc 10mhz option dram 2mb power s...

Page 15

2 - 3 2.1 main control board the main control board consists of a one-chip cpu, a program rom, a dram, an eeprom, a host interface circuit, and a mechanism driving circuit. The mechanism driving circuit consists of a led head, a main motor, and an electromagnetic clutch. (1) one-chip cpu • okipage 8...

Page 16

2 - 4 (2) program rom program rom contains a program for the equipment. Eprom is used as program rom. When mask rom in the one-chip cpu explained in (1) above is valid, the eprom is not mounted. (for details on short wiring setting, see section 7.2.) (3) dram dram is used as resident memory. (4) eep...

Page 17

2 - 5 used to generate a logic circuit and a high voltage. Used to drive the motor and electromagnetic clutch. Output voltage application +5 v +26v output application ch db sb cb tr voltage –1.3 kv –265 v/+265 v –520 v/ 0 v +400 v/–1.3 kv +500 v ~ +3.5 kv/–750 v voltage to be applied to a charge rol...

Page 18

2 - 6 figure 2-2 (2) sensors the high-voltage power supply board consists of the high-voltage power supply circuit that supplies power to the electro-photographic processor system and the photosensor that detects a paper feeding system and toners. Figure 2-2 shows the sensor layout drawing. Sensor f...

Page 19

2 - 7 2.4 electro-photographic processor the electro-photographic processor prints out the image data to be sent from the main control board on sheets of paper. Figure 2-3 shows the layout drawing of the electro-photographic processor. (1) image drum unit the image drum unit makes a toner adhere to ...

Page 20

2 - 8 figure 2-3 layout drawing of electro-photographic processor exit roller heat roller (ø 19.910) 6.85 10 off on 26.50 outlet sensor cleaning roller (ø 9.000) charge roller (ø 9.000) 6.77 led head drum roller (ø 16.000) developing roller (ø 14.000) 17.23 12.72 23.18 20.32 64.60 single tray transf...

Page 21

2 - 9 main motor electromagnetic clutch off on hopping roller non-rotation rotation non-rotation regist gear drum gear operation warm-up hopping prinitng non-rotation rotation rotation rotation rotation rotation normal rotation reverse rotation off (3) pulse motor (main) this pulse motor of 48 steps...

Page 22

2 - 10 figure 2-4 schematic drawing of okipage 8 z paper feeding exit roller heat roller transfer roller cleaning roller ch roller drum roller developing roller outlet sensor paper sensor hopping roller tray printing feed roller manual feed sensor manual printing 2 roller to be driven by reverse rot...

Page 23

2 - 11 2.5 electro-photographic process (1) electro-photographic process the electro-photographic process is outlined below. 1 charging the surface of the opc drum is charged negatively and uniformly by applying the dc voltage to the ch roller. 2 exposure light emitted from the led head irradiates t...

Page 24

2 - 12 figure 2-5 flow for electro-photographic process control signal exposure transfer paper supply charging paper delivery paper feeding fusing cleaning development paper sensor led head power supply charge roller power supply transfer roller cleaning roller paper eject roller outlet sensor power...

Page 25

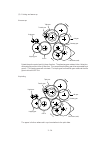

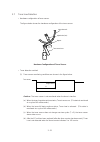

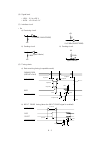

2 - 13 2.5.1 explanation of each process operation (1) hopping as shown in the figure below, the clutch for hopping is turned on/off according to current on/ off to a coil. When the clutch is off when the clutch is on when the clutch is on, the hopping gear engages with the clutch plate to rotate th...

Page 26

2 - 14 b" b' b hopping gear gear a pulse motor (main) planetary gear idle gear triple gear transfer gear regist gear a" a' a hopping gear gear a pulse motor (main) planetary gear idle gear triple gear transfer gear regist gear rotate the pulse motor (main) in the a direction. The planetary gear rota...

Page 27

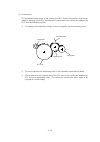

2 - 15 led head charge roller led head image drum paper opc drum high- voltage power supply charge roller opc drum high- voltage power supply (3) charging charging is performed by applying dc voltage to the charge roller that is in contact with the surface of the opc drum. (4) exposure light emitted...

Page 28

2 - 16 2 the toner applied to the developing roller is thin-coated by the developing blade. 3 a toner adheres to the exposure part of the opc drum in the contact part between the opc drum and developing roller. This causes the electrostatic latent image to be changed to a visible image. (5) developm...

Page 29

2 - 17 opc drum transfer roller paper high-voltage power supply (6) transfer the transfer roller is composed of conductive sponge material. This roller is set so that the surface of the opc drum and sheets of paper will adhere closely. A sheet of paper is placed on the surface of the opc drum and th...

Page 30

2 - 18 cleaning roller opc drum transfer roller high-voltage power supply separation claw heater heater roller thermistor pressure spring back-up roller (7) fusing the transferred unfused toner image is fused to a sheet of paper because heat and pressure are applied when it passes between the heat r...

Page 31

2 - 19 2.6 paper jam detection the okipage 8 z monitors the paper status when the power supply is on and during printing. In the following cases, the okipage 8 z interrupts the printing process as a paper jam. Printing can be recovered by opening the cover, removing the jammed paper, and closing the...

Page 32

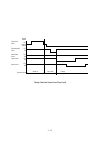

2 - 20 off reverse rotation off on pulse motor (main) electromagnetic clutch off on manual feed sensor off on paper sensor off on operation mode warm-up paper feed printing outlet sensor normal rotation timing chart for paper feed (tray feed).

Page 33

2 - 21 2.7 toner low detection • hardware configuration of toner sensor the figure below shows the hardware configuration of the toner sensor. Caution: the toner sensor is not monitored when the drum is inactive. (a) when the toner-low state continues twice, toner low occurs. (this state is monitore...

Page 34

2 - 22 (2) the basic rotation cycle of the toner sensor is as follows: 2.8 cover open opening the stacker cover turns off the microswitch on the high-voltage power supply board to suspend +5 v supply to the high voltage power supply. This results in the stop of all high-voltage outputs. At the same ...

Page 35

2 - 23 2.9 detecting id existence in this model, a micro switch may be activated, applying a high voltage to the machine under a state where the cover is slightly opened. In this case, there is a fear that, when a user insert his hand through the opening, he may be shocked unless an id has been inst...

Page 36

2 - 24 image drum (id) not installed / toner sensor error specification 1. Toner sensor error/id not installed state should not be stored in the eeprom. 2. A shift to id not installed and toner sensor error shall be made at cover open or close. Power on abnormal toner sensor waveform id not installe...

Page 37

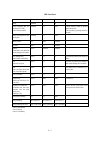

2 - 25 manual light medium- light mediu m medium- heavy heav y special1 (china) special2 (swedish archive) ohp light medium- light mediu m medium- heavy heavy special1 (china) special2 (swedish archive) oh p media type tra y feeding tray paper size excutive letter legal 14 legal 13 a4 jis b5 a5 a6 m...

Page 38: Parts Replacement

3. Parts replacement.

Page 39

3 - 1 3. Parts replacement this chapter explains how to replace parts, assemblies, and units in the field. The replacement procedures to be explained here include dismounting, not mounting. When mounting parts, assemblies, and units, reverse the dismounting steps. 3.1 precautions for parts replaceme...

Page 40

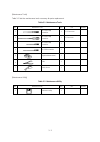

3 - 2 [maintenance tools] table 3-1 lists the maintenance tools necessary for parts replacement. Table 3-1 maintenance tools no. No. 1-100 philips screwdriver q'ty use remarks maintenance tools 1 2 3 4 5 6 7 no. 2-100 philips screwdriver no. 3-100 philips screwdriver no. 5-200 screwdriver digital mu...

Page 41

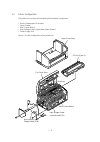

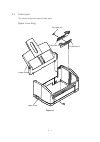

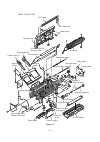

3 - 3 3.2 parts layout this section explains the layout of main parts. [upper cover assy] figure 3-1 hopper plate guide side (r) guide side (l) spur gear (a) upper cover.

Page 42

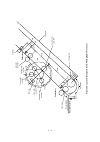

3 - 4 [base frame unit] figure 3-2 ep unit (type 6) power sensor e pulse motor (main) hopping roller roller holder magnet h (hopping shaft) hopping shaft assy side plate m registration roller heat assy idle gear heat paper holder paper guide (r) transfer roller pressure roller (b) (back up roller) t...

Page 43

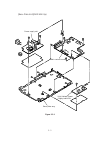

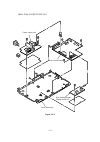

3 - 5 [base plate unit](okipage 8p) figure 3-3-1 high voltage power supply board p6l base plate assy power supply unit main control board.

Page 44

3 - 6 high voltage power supply board p6l base plate assy power supply unit main control board [base plate unit](okipage 8 z) figure 3-3-2.

Page 45

3 - 7 3.3 replacing parts this section explains how to replace parts and assemblies. 3.3.1 hopper plate (1) remove two claws and dismount hopper plate 1 . 1.

Page 46

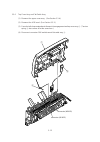

3 - 8 3.3.2 led head and head spring (1) open top cover assy 1 . (2) dismount the left clamp and led head 2 . Then, dismount flat cable assy 3 . (3) dismount two head springs 4 . 2 1 4 4 3.

Page 47

3 - 9 3.3.3 transfer roller (1) open top cover assy 1 and dismount ep unit (type 6) 2 . (2) remove the right claw. Then, dismount transfer roller 3 , two regist bearings 4 , and gear t 5 . 1 2 3 4 4 5 label.

Page 48

3 - 10 3.3.4 upper cover assy (1) turn off the power switch and unplug the ac cord from the ac socket. (2) disconnect interface cable 1 . (3) open top cover assy 2 and dismount ep unit (type 6) 3 . (4) move paper guide (l) 4 and paper guide (r) 5 on the rear of the printer to the center. (5) remove ...

Page 49

3 - 11 3.3.5 high-voltage power supply board (p2h/ p6l) (1) dismount upper cover assy. (see section 3.3.4.) (2) remove three screws 1 and remove the cover 2 and draw out high-voltage power supply board 3 . (3) disconnect all the cables 4 from high-voltage power supply board 3 and dismount high- volt...

Page 50

3 - 12 3.3.6 top cover assy and flat cable assy (1) dismount the upper cover assy. (see section 3.3.4.) (2) dismount the led head. (see section 3.3.2.) (3) press the left clamp outward and dismount the engagement and top cover assy 1 . (tension spring 2 also comes off at the same time.) (4) disconne...

Page 51

3 - 13 3.3.7 paper holder (1) dismount the upper cover assy. (see section 3.3.4.) (2) dismount paper holder 1 . (3) unlock and dismount paper guide (l) 2 and paper guide (r) 3 . (4) remove the claw and dismount hopper spring 4 . (5) remove the claw and dismount stopper spring 5 . 1 2 3 4 5.

Page 52

3 - 14 3.3.8 side plate m and idle gear perform parts replacement while making the base frame assy stand so that side plate m will face upward. (1) dismount the upper cover assy. (see section 3.3.4.) (2) remove two screws 1 and two claws, then dismount plate side m 2 . (3) dismount earth plate 3 , t...

Page 53

3 - 15 3.3.9 heat assy this section explains how to dismount the heat assy and parts in the assy. (1) dismount the upper cover assy. (see section 3.3.4.) (2) dismount the high-voltage power supply board. (see section 3.3.5.) (3) remove two screws 1 , disconnect connector 2 , and dismount heat assy 3...

Page 54

3 - 16 1 2 1 3.

Page 55

3 - 17 7 9 8 8 c 5 a b 0 6 d d 4 voltage display side.

Page 56

3 - 18 3.3.10 drive shaft e (eject) and eject roller (1) dismount the upper cover assy. (see section 3.3.4.) (2) dismount top cover assy. (see section 3.3.6.) (3) remove two screws 1 from heat assy (section3.3.9), life the heat assy, and dismount idle gear e (a) 2 and idle gear e (b) 3 . (4) unlock ...

Page 57

3 - 19 3.3.11 pressure roller b (back up roller) (1) dismount the upper cover assy. (see section 3.3.4.) (2) dismount the high-voltage power supply board. (see section 3.3.5.) (3) dismount the heat assy. (see section 3.3.9.) (4) dismount the engagement with the left ground, then pressure roller b 1 ...

Page 58

3 - 20 3.3.12 separator guide (1) dismount the upper cover assy. (see section 3.3.4.) (2) dismount the high-voltage power supply board. (see section 3.3.5.) (3) remove four screws 1 . (4) dismount inlet 2 from base frame 3 . 2 > insert a screwdriver into the hole on the side of base frame 3 , remove...

Page 59

3 - 21 1 1 3 1 1 2 6 8 9 4 a 4 4 b b a 7 screw driver (-) screw driver clamp lever cn2 okipage 8p.

Page 60

3 - 22 1 1 3 1 1 2 6 8 9 4 a 4 4 b b a screw driver (-) screw driver clamp lever cn2 okipage 8 z.

Page 61

3 - 23 3.3.13 pulse motor (main) (1) dismount the upper cover assy. (see section 3.3.4.) (2) dismount the high-voltage power supply board. (see section 3.3.5.) (3) dismount side plate m. (see section 3.3.8.) (4) dismount the base frame. (see section 3.3.12.) (5) remove two screws 1 and dismount puls...

Page 62

3 - 24 3.3.14 hopping shaft assy (1) dismount the upper cover assy. (see section 3.3.4.) (2) dismount the high-voltage power supply board. (see section 3.3.5.) (3) dismount the base frame. (see section 3.3.12.) (4) dismount the paper holder assy. (see section 3.3.7.) (5) dismount the sheet guide. (s...

Page 63

3 - 25 3.3.15 resist roller (1) dismount the upper cover assy. (see section 3.3.4.) (2) dismount idle gear r 3 and gear r 4 . (3) move resist roller 1 to the right and dismount it by lifting. (two resist bearings 2 also come off at the same time. Take care not to lose them.) 2 1 3 2 4.

Page 64

3 - 26 3.3.16 paper sensor e, paper sensor exit and toner sensor assy (1) dismount the upper cover assy. (see section 3.3.4.) (2) dismount the high-voltage power supply board. (see section 3.3.5.) (3) dismount the base frame. (see section 3.3.12.) (4) dismount the paper holder assy. (see section 3.3...

Page 65

3 - 27 3.3.17 base plate (1) dismount the upper cover assy. (see section 3.3.4.) (2) dismount the base frame. (see section 3.3.12.) (3) remove two screws 1 , disconnect connector 2 , and dismount power supply unit 3 . (4) dismount insulation sheet 4 . (5) remove five screws 5 and dismount main contr...

Page 66

3 - 28 okipage 8 z 1 1 2 5 5 5 8 a 9 7 0 6 3 4.

Page 67: Adjustment

4. Adjustment.

Page 68

4 - 1 4. Adjustment this chapter explains adjustment necessary when a part is replaced. This adjustment is made by changing the parameters values set in eeprom on the main control board. The printer driver or maintenance utility can be used to change these values. Only servicemen and maintenance per...

Page 69

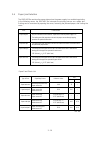

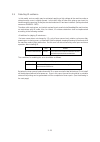

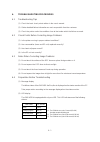

4 - 2 4.1.2 engine maintenance utility see appendix d. 4.2 adjustment when replacing a part the table below lists the parts that requires adjustment when they are replaced. Luminous intensity display 027 135 figure 4-2 part to be replaced adjustment led head ep unit reset the drum counter. (refer to...

Page 70

4 - 3 4.2.2 uploading and downloading eeprom data when the main control board is replaced, eeprom data must be reflected on a new main control board. Use “eeprom operations” in the option tab of the maintenance utility to reflect eeprom data on the new main control board. (see figure 4-4.) reflect e...

Page 71: Periodical Maintenance

5. Periodical maintenance.

Page 72

5 - 1 5. Periodical maintenance 5.1 periodical replacement parts table 5-1 lists the part and unit to be replaced periodically. Table 5-1 routine replacement parts toner cartridge (type 6) part name replacement time part to be checked simultaneously remarks ep unit (type 6) when "toner low" is displ...

Page 73

5 - 2 led head cleaner led lens array figure 5-2 (1) set the led head cleaner in the led lens array, as shown in the figure below, and slide the cleaner left and right several time to clean the head. Caution: do not press the led head cleaner against the led lens array..

Page 74: Troubleshooting Procedures

6. Troubleshooting procedures.

Page 75

6 - 1 6. Troubleshooting procedures 6.1 troubleshooting tips (1) check the basic check points written in the user’s manual. (2) gather detailed failure information as much as possible from the customer. (3) check the printer under the condition close to that under which the failure occurred. 6.2 che...

Page 76

6 - 2 led functions status error (red) ready (amber) remark manual feed (amber) flash 1: slow blinking flash 2: blinking flash 3: fast blinking ready during suspending data pro- cessing (in off-line) (data is left in the buffer) during receiving data or pro- cessing data manual request low toner war...

Page 77

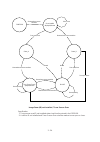

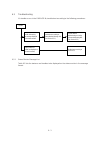

6 - 3 trouble trouble indicated by the message displayed on the status monitor. Image problem (or trouble not displayed on the status monitor) perform detailed troubleshooting according to the troubleshooting flow. (see section 6.5.2.) troubleshoot according to section 6.5.3. Troubleshoot according ...

Page 78

6 - 4 status code category status message display content remedy table 6-1 warming-up status online (ready) status power save status the toner amount of the toner cartridge is small. The ep unit is not installed or the toner sensor is faulty. Life of ep drum the paper is in the manual feed mode. Pri...

Page 79

6 - 5 status code category status message display content remedy table 6-1 (cont'd) 30 00 31 00 32 00 33 00 42 00 4f 00 40 01 40 10 60 10 60 30 paper of improper size was fed. 2.52" (64 mm) l 15.77" (400.56 mm) a paper jam occurred when sheets of paper were being supplied. A paper jam occurred durin...

Page 80

6 - 6 status code category status message display content remedy table 6-1 (cont'd) 60 40 60 60 60 80 60 90 60 91 60 92 60 c0 an error occurred during eeprom check. An error occurred during option ram check. A heater timeout error occurred. A thermistor error occurred. The thermistor is open. A ther...

Page 81

6 - 7 6.5.2 status message troubleshooting some failures cannot be corrected according to the status message trouble list. Troubleshoot these failures according to the following troubleshooting flowcharts: caution: when replacing the main control board troubleshooted according to the troubleshoot- i...

Page 82

6 - 8 1 the okipage 8 z malfunctions after the power supply has been turned on. • turn the power supply off, then on again. • is the led lamp on? • no is the ac cable connected correctly? • no connect the ac cable correctly. • yes is +5 v supplied between cn1 pin 7 and cn1 pin 13 of the high-voltage...

Page 83

6 - 9 [jam error] 2 -1 paper input jam • does a paper input jam occur when the power supply is turned on? • yes is the jammed paper on paper sensor e? • yes remove the jammed paper. • no is paper sensor e (manual feed/paper) operating normally? • no replace paper sensor e (manual feed or paper). • y...

Page 84

6 - 10 [jam error] 2 -2 paper feed jam • does a paper feed jam occur when the power supply is turned on? • yes is the jammed paper on paper sensor e (paper/exit)? • yes remove the jammed paper. • no is paper sensor e (exit/paper) operating normally? • no replace paper sensor e (exit or paper). • yes...

Page 85

6 - 11 3 paper size error • is the paper of the specified size being use? • no use paper of the specified size. • yes is paper sensor e (paper) operating normally? • no replace paper sensor e (paper) or clean the inlet sensor on the high-voltage power supply board. • yes is the paper sensor (exit) o...

Page 86

6 - 12 4 heat assy error • turn the power supply off, then on again. • does the halogen lamp of the heat assy go on? • no is the halogen lamp or thermostat disconnected? • yes replace the heat assy, halogen lamp, or thermostat. • no replace the power supply unit. • yes are the cn2 connectors of the ...

Page 87

6 - 13 a light or blurred images entirely b dark background density c blank paper d black vertical stripes e cyclical defect f white vertical belts or streaks figure 6-3 image problems 6.5.3 image troubleshooting this section explains how to troubleshoot when an image problem is output as a result o...

Page 88

6 - 14 1 an image is light or blurred entirely. • is the toner low? (is "toner low" being displayed?) • yes supply a toner. • no is the specified paper being used? • no use the specified paper. • yes is the lens of the led head dirty? • yes clean the led head. • no is the led head installed correctl...

Page 89

6 - 15 2 dark background density • has the opc drum being exposed to external light? • yes set the opc drum in the okipage 8 z and wait for about 30 minutes. • no is the heat roller of the heat assy dirty? • yes clean the heat roller. • no is the terminal of the ep unit in correct contact with the c...

Page 90

6 - 16 4 vertical black belt/stripe • replace the ep unit. • has this error been recovered? • yes end caution: after replacing the ep unit, reset the drum counter. (refer to "replacing the drum cartridge" in "user's manual".) • no replace the led head. • has this error been recovered? • yes end caut...

Page 91

6 - 17 6 a blank paper is output. • is the contact plate of the transfer roller in correct contact with the high-voltage power supply board? • no contact the contact plate of the transfer roller correctly. • yes replace the transfer roller. • has this error been recovered? • yes end • no is the term...

Page 92

6 - 18 7 poor fusing • is the specified paper being used? • no use the specified paper. (xerox 4200 (20 lbs)) • yes is the bias spring normal? (tension: 3.25 kg) • no replace the bias spring. • yes are the heater connector of the heat assy and the cn1 connector of the power supply unit connected cor...

Page 93

6 - 19 8 vertical white belt/spripe • is the lens of the led head dirty? • yes clean the led head. • no is the contact plate of the transfer roller in correct contact with the high-voltage power supply board? (see figure 6-5 e .) • no contact the contact plate of the transfer roller correctly. • yes...

Page 94

6 - 20 figure 6-4 contents a : toner supply roller b : developing roller c : charge roller d : cleaning roller e : transfer roller f : heat roller a e d f b c.

Page 95

6 - 21 figure 6-5 contents a : toner supply roller b : developing roller c : charge roller d : cleaning roller e : ground (drum) a b d c e.

Page 96: Wiring Diagram

7. Wiring diagram.

Page 97

7 - 1 7.1 interconnect signal diagram (okipage 8 z) main control board (u 8s pcb) power supply unit high-voltage power supply board p 3h high-voltage power supply board p6l cent (parallel interface) head1 36 18 19 1 1 stb-n 2 pdata1-p 3 pdata2-p 4 pdata3-p 5 pdata4-p 6 pdata5-p 7 pdata6-p 8 pdata7-p...

Page 98

7.2 pcb layout 7.2.2 main control board( u8s pcb) cn 4 cn 4 cn 7 cn 7 c n 5 c n 5 c n 2 c n 2 cn 1 cn 1 c n 3 c n 3 h e a d h e a d c n 6 c n 6 pcb-u8s pcb-u8s u8 s - u8 s - ok i ok i oki japan 7-2.

Page 99

7 - 3 7.2.3 high-voltage power supply board p 3h ps2 ps1 ps4 cvsw ps3 cn7 cn1 p6l cn1.

Page 100: Parts List

8. Parts list.

Page 101

8 - 1 8. Parts list figure 8-1 cover assy upper 7 6 5 4 1 2 *1.

Page 102

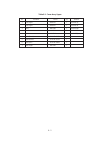

8 - 2 1 cover-upper 40412501 1 okipage 8p cover-upper 40412601 1 okipage 8 z 2 lens 1 40413101 1 okipage 8p lens 2 40413201 1 okipage 8 z 3 switch 40413001 1 okipage 8p 4 guide side (l) 2pp4128-1256p1 1 5 guide slide (r) 2pp4128-1257p1 1 6 gear spur a 4pp4128-1260p1 1 7 plate-hopper 40412901 1 table...

Page 103

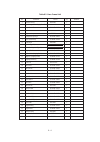

8 - 3 figure 8-2 base frame unit d d e f c [ u r j e d i c b a 0 9 8 7 5 o 6 3 3 1 2 i g h f k n p l l q s z k g w t t o m t t z y t v l \ ] ^ b.

Page 104

8 - 4 table 8-2 base frame unit no. Part name part no. Q'ty remarks 1 frame unit assy 40593201 1 2 high-voltage power supply board p 3h 4 1226501 1 3 paper sensor e 3pp4083-1191p1 2 4 5 separator assy 40721301 1 6 compression spring s 4pp4083-1246p1 1 7 toner sensor assy 3pa4083-1193g1 1 8 pulse mot...

Page 105

8 - 5 35 bias spring (l) (back up roller) 4pp4083-1136p1 1 36 bearing bu (back up roller) 3pp4083-1161p1 2 37 pressure roller b (back up roller) 40594601 1 38 paper guide (r) 40249501 1 39 paper guide (l) 40249401 1 40 paper holder 1pp4083-1231p1 1 41 paper sensor exit 3pp4083-1192p1 1 42 hopper spr...

Page 106

8 - 6 figure 8-3 heat assy 2 1 8 5 3 4.

Page 107

8 - 7 no. Part name part no. Q'ty remarks table 8-3 heat assy 1 heat roller 3pb4083-1202p1 1 2 halogen lamp 40649301 1 120v halogen lamp 40649302 1 230v 3 thermostat 4pb4083-1204p1 1 4 thermistor 4pb4083-1205p1 1 5 heat cord 4pb4083-1213p1 1.

Page 108

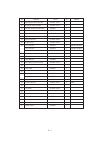

8 - 8 6 3 4 2 a 0 1 7 figure 8-4-2 base plate unit (okipage 8z).

Page 109

8 - 9 1 base plate assy 40592201 1 2 insulation sheet a 40722501 1 3 power supply unit 4yb4049-1853p1 1 120v power supply unit 4yb4049-1854p1 1 230v 4 main control board 4 1222702 1 for op 8z ( u8s-) main control board 40433802 1 for op 8p (hby-) 5 6 program rom 40681701 1 op8 z eprom 7 ac cord 3ys4...

Page 110: Appendix

Appendix.

Page 111

A - 1 appendix a local printing (1) the following operation enables the okipage 8 z to print data by itselt. With the cover open, turn on the ac switch and then close the cover. The following print patterns are printed..

Page 112

B - 1 appendix b parallel interface (1) connector • printer side : 36-pin receptacle type: 57re-40360-730b-d29a (daiichi denshi) or equivalent • cable side : 36-pin plug type: 57-30360 (daiichi denshi) or equivalent (2) cable • cable length : 6 feet (1.8 m) max. (ieee std 1284-1994 compliant is reco...

Page 113

B - 2 (3) parallel i/f signals pin no. Signal name direction function (compatible mode) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 18 19 30 31 32 33 34 35 36 data strobe data bit - 1 data bit - 2 data bit - 3 data bit - 4 data bit - 5 data bit - 6 data bit - 7 data bit - 8 acknowledge busy paper end sel...

Page 114

B - 3 (4) signal level • low : 0 v to +0.8 v • high : +2.4 v to 5.0 v (5) interface circuit • 8 z a) receiving circuit b) sending circuit b) sending circuit r = 3.3k Ω (1.0-k Ω strobe) +5v r (open collector) +5v 3.3k Ω (6) timing charts a) data receiving timing (compatible mode) parallel data (data ...

Page 115

B - 4 c) data sending timing (nibble mode) acknowledge busy 6 7 4 5 2 3 data bit 3 data bit 7 fault 6 7 4 5 2 3 data bit 0 data bit 4 select . / , - * + data bit 1 data bit 5 paper end & ' . / $ % , - " # * + data bit 2 data bit 6.

Page 116

C - 1 appendix c maintenance utility 1. Outline of maintenance utility the maintenance utility is an application program that operates on microsoft windows 3.1 or higher. The maintenance utility has the following functions: • transmission of menu setting command to initialize and change setting valu...

Page 117

C - 2 4. Detail of each function 4.1 engine menu setting engine menu setting is used to set, display, and change the following menu items: (see figure d-1.) (1) print position used to adjust the print start position. (2) led head marking no. Used to adjust the exposure time of the led head. (3) led ...

Page 118

C - 3 (1) drum count number of revolutions of mounted ep drum (2) total drum count total number of revolutions of ep drum after shipment (3) page count total number of printed pages after shipment clicking the "reset" button cleans each counter. (4) reset all used to clear all counters. 4.3 printer ...

Page 119

C - 4 4.6 about about is used to display the following information: engine maintenance utility version information printer version information and memory size information printer device id information see figure c-4. 4.7 reload reload is used to reload menu setting values. 4.8 exit clicking the exit...

Page 120

C - 5 figure c-1 main menu dialog figure c-2 test print dialog.

Page 121

C - 6 figure c-3 option menu dialog.

Page 122

C - 7 figure c-4 about dialog.

Page 123

D1 d universal serial bus (usb) universal serial bus specification revision 1.0 compliance. 1) connector ⋅ printer side : “b” receptacle (upstream input to the usb device) ⋅ cable side : serise “b” plug 2) cable ⋅ cable length : max 5 m (a cable must be met usb spec rev 1.1 for normal operation) not...

Page 124

D2 9) signal level ⋅ input / output level parameter symbol min. Max. Units input levels: high(driven) v ih 2.0 v high(floating) v ihz 2.7 3.6 v low v il 0.8 v output levels: low ol 0.0 0.3 v high(driven) oh 2.8 3.6 v output signal crossover voltage v crs 1.3 2.0 v ⋅ signaling levels signaling levels...

Page 125

D3 10) timing chart a) packet voltage levels b) disconnect detection c) full-speed device connect detection voh(min) vih(min) vil(max) vol(max) vss bus idle sop first bit of packet voh(min) vih(min) vil(max) vol(max) vss last bit of packet se0 portion of eop bus driven to j state at end of eop bus f...

Page 126

D4 d) differential data jitter e) differential-to-eop transition skew and eop width f) receiver jitter tolerance tperiod differential data lines (vcrs) conesecutive transitions n * tperiod + txdj1 crossover points paired transitions n * tperiod + txdj2 tperiod = 12mbps( ± 0.25%) txdj1 = min-3.5ns~ma...

Page 127

Xxxxxxxxth oki data corporation 4-11-22, shibaura, minato-ku, tokyo 108, japan tel: (03) 5445-6162 fax: (03) 5445-6189.