- DL manuals

- Pacific Living

- Oven

- PL8430SSBG070

- User Manual

Pacific Living PL8430SSBG070 User Manual

1

Outdoor Pizza Oven

MODEL # PL8430SSBG070

WARNING

Improper

installation,

adjustment, alteration, service or

maintenance can cause injury or

property damage. Read this

instruction manual thoroughly

before installing or servicing this

equipment.

WARNING

1. Do not store or use gasoline or

other flammable vapors and

liquids in the vicinity of this or

any other appliance.

2. An LP tank not connected for

use should not be stored in the

vicinity of this or any other

appliance.

DANGER

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flames.

3. Open the oven door.

4. If the odor continues, keep

away from the appliance and

immediately

call

your

gas

supplier or fire department.

WARNING

For Outdoor Use Only

ATTACH YOUR RECEIPT HERE

Serial Number____________________ Purchase Date____________________

Summary of PL8430SSBG070

Page 1

1 outdoor pizza oven model # pl8430ssbg070 warning improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Read this instruction manual thoroughly before installing or servicing this equipment. Warning 1. Do not store or use gasoline or other flamma...

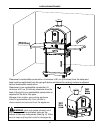

Page 2: Oven Operation 1-2-3

2 questions, problems, missing parts? Before returning to your retailer, call our customer service department at 1-866-410-0408, monday - friday, 8 a.M. - 5 p.M., pst. Oven operation 1-2-3 before cooking: step 1 keep your oven a safe distance away from your property.* step 2 always perform a leak te...

Page 3

Table of contents 3 safety information…………………………………….………...….………….………….…. ………4 package contents…..………………..…..….……...…...................………………………………..6 hardware contents……………………………………………………………….……………………7 preparation…..………………..…………………..….……………………………………………..….8 assembly instructions……………………..……………….……...

Page 4

Safety information 4 please read and understand this entire manual before attempting to assemble, operate or install the product. If you have any questions regarding the product, please call customer service at 1-866-410-0408 monday to friday from 8 a.M. To 5 p.M. Pst. 1. The installation of this ap...

Page 5

Safety information 5 16. The cylinder used must include a collar to protect the cylinder valve. 17. Do not store a spare lp-gas cylinder under or near this appliance. 18. Never fill the cylinder beyond 80 percent full. 19. If the information in “17” and “18” is not followed exactly, a fire causing d...

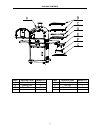

Page 6

Package contents 6 part description quantity part description quantity a main body 1 d bottom grill 1 b cooking grill 2 e fat cup 1 c pizza stone 1 f smoker box 1 g flame tamer 1.

Page 7

Natural gas conversion 7 the following list is included inside the pizza oven carton: battery 1 pc the following list is not included inside the pizza oven carton, but needed when the user is assembling the pizza oven. Phillips head screwdriver 1 pc the following list is not included inside the pizz...

Page 8

Natural gas conversion 8 preparation before beginning assembly of product, make sure all parts are present. Compare parts with package contents list and hardware contents list. If any part is missing or damaged, do not attempt to assemble the product. Assembly tip! (please lightly tighten the screws...

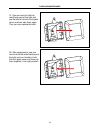

Page 9

Natural gas conversion 9 3. Use screw m6*12×2 pcs to fix the left side panel onto the base panel of the stand. (note: the panel should have the “small holes at the top” to the front of the cart assembly) 4. Use screw m6*12×2 pcs to fix the right side panel onto the base panel of the stand. (note: th...

Page 10

Natural gas conversion 10 6. Use screw m6*12×5 pcs to attach the stand base panel onto the base panel, between the two side panels. 7. Use screw m4*10×4 pcs to fix the stand door horizontal beam between the two side panels. (note: please fasten the upper two screws first, and then the lower two scre...

Page 11

Natural gas conversion 11 9. Use screw m5*10×8 pcs to attach triangle×2 pcs on the bottom of the base panel, leaning against the two side panels. (note: it is critical that you only insert the screws with a few turns until all are in before you tighten them) 10. Use screw m3*12×2 pcs and nut m3×2 pc...

Page 12

Natural gas conversion 12 12. Put the oven assembly on the stand-top panel. Use screw m6*12×4 pcs to fasten the oven onto the stand. (note: these screws can be tightened at this time) 13. Use screw m5*10×16 pcs to attach side shelf bracket×4 pcs onto the drawer side panels. (note: arrows face up) 14...

Page 13

Natural gas conversion 13 14. Use screw m6*12×8 pcs and special nut tb31-05-03×8 pcs to hang side shelf×2 pcs onto the four brackets. (note: these screws can be tightened at this time) 15. Use screw m4*8×3 pcs to fix the chimney assembly onto the top of the oven exterior. (note: these screws can be ...

Page 14

Natural gas conversion 14 16. Use screw m5*35×4 pcs to fix the back heat shield onto the back panel of the oven. The order is: screw→back heat shield→heat insulation washer→flat washer→ oven back panel. 17. Put the following accessories into the oven and close the oven door: - base grill×1 pc - pizz...

Page 15

Natural gas conversion 15 preparation: before beginning conversion, make sure all parts are present. Compare parts with package contents. If any part is missing or damaged, do not attempt to convert. Contact customer service for replacement parts. 1. Turn off gas supply, and then remove cap on gas s...

Page 16

Natural gas conversion 16 important: after your outdoor kitchen is converted to natural gas, the working pressure for natural gas is 7-inche water column (wc). Gas pressure is affected by gas line size and the length of gas line run from house. Follow the recommendations in the chart below. From hou...

Page 17

Natural gas conversion 17 20. Loosen the screws that are used to fasten the burner (see picture at right). Use a 10x12 mm spanner to remove the thermocouple out from the burner. Next, pull out the ignition wire from the electronic igniter. Finally, take out the whole burner. 21. Use a screwdriver to...

Page 18

Natural gas conversion 18 23. Put the burner back into the oven and insert the ignition wire into the original position. Use the 10x12 mm spanner to fix the thermocouple back into the oven again. Finally, fasten the burner with the original screws. 24. Put back the two cooking grills, smoker box, pi...

Page 19

Natural gas conversion 19 26. Use the screw driver to put the conversion screw into the knob. 27. When converting to natural gas, please be aware that the low heat setting of the main burners and searing burner is “ng low,” as shown on the control panel. “lp low” setting is not applied when converti...

Page 20

Natural gas conversion 20 burner lp gas natural gas main burner 16,000 btu / hr 16,000 btu / hr caution: if low flames or burner problems are observed after converting from lpg to ng, the natural gas lines may not be large enough. Refer to the “from house to grill” chart below for natural gas supply...

Page 21

Care and maintenance 21 never attach an unregulated gas line to the appliance. Connection to an unregulated gas line can cause excessive heat or fire. Verify the type of gas supply to be used, either natural gas (n.G.) or liquid propane (l.P.), and make sure the serial plate agrees with that of the ...

Page 22

Care and maintenance 22 l.P. Gas installation gas grills that are set to operate with l.P. Gas come with a high capacity hose and regulator assembly. (note: only use the pressure regulator and hose assembly supplied with the grill or a replacement pressure regulator and hose assembly specified by th...

Page 23

Care and maintenance 23 do not use a wrench to tighten because it could damage the quick coupling nut and result in a hazardous condition. 7. Open the tank valve fully (counterclockwise). Use a soapy water solution to check all connections for leaks before attempting to light your grill. See “pre-op...

Page 24

Care and maintenance 24 pig 7 external thread thermally sensitive nut type i valve hand wheel propane regulator disconnecting a liquid propane gas (lp gas) tank from your grill: 1. Turn the burner knobs and lp gas tank valve to the full off position. (turn clockwise to close.) 2. Detach the hose and...

Page 25: Warning

Care and maintenance 25 valve outlet and inlet connection ansi/cga-v-1. Cylinders must not be stored in a building, garage, or any other enclosed area. (the l.P. Cylinder must have an overfill protection device and a collar to protect the cylinder valve.) the l.P. Gas supply cylinder must be constru...

Page 26

Care and maintenance 26 5. Turn off the burner control knobs. 6. Turn the top knob of the fuel supply cylinder counterclockwise two (2) rotations to open. 7. Apply the soap solution to connections of the fuel supply assembly. If no soap bubbles appear, there is no gas leak. If bubbles form at the co...

Page 27

Care and maintenance 27 clearance to combustible construction: a minimum of 61 cm (24 inches) from the sides and back must be maintained from the gas grill above and below the cooking surface to adjacent vertical combustible construction. Clearance to non-combustible construction: a minimum of 61 cm...

Page 28: Present!!

Care and maintenance 28 heat or smoke away from the heat and smoke exhaust holes. General rules do not leave the grill unattended while cooking! 1. Make sure the grill has been leak-tested and is properly located. 2. Light the grill burners using the instructions provided in this manual. 3. Turn the...

Page 29

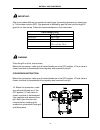

Care and maintenance 29 grill burner lighting warning: do not lean over grill when lighting. Turn off lp supply at cylinder when appliance is not in use. Main burner lighting illustration: 1. Check that the control knobs are in the off position. 2. Open valve at tank fully by turning counterclockwis...

Page 30

Care and maintenance 30 using the grill light light operation instruction 1. Make sure the light’s power switch on the control panel is in the “off” position. 2. Connect power plug to properly grounded outlet. 3. Turn the light’s power switch to “on.” warning keep any electrical supply cord away fro...

Page 31

Care and maintenance 31 poor combustion:wavy,yellow flames-too little air out of acjustment:hard blue flames-too much air normal:soft blue flames general cleaning important: before cleaning, make sure all controls are off and the grill is cool. Always follow label instructions on cleaning products. ...

Page 32

Care and maintenance 32 note: allow the drip tray to cool before attempting to clean. Important: do not leave the grill outside during inclement weather unless it is covered. Rain water can collect inside of the grill, the grill cart or the drip tray if left uncovered. If the drip tray is not cleane...

Page 33

Care and maintenance 33 note: always scrub in the direction of the grain. Grill light bulb replacement important safety instructions lighted lamp is hot: warning -to reduce the risk of fire, electric shock, exposure to excessive uv radiation, or injury to persons. 1. Turn off/unplug and allow to coo...

Page 34

Care and maintenance 34 28. Turn off/unplug and allow to cool before replacing bulb (lamp). Next, open the door and remove the two cooking grills, smoker box, pizza stone, base grill and flame tamer. 29. Use screw driver to loosen m5*35 screw * 4 pcs that fix the heat shield. And then remove the hea...

Page 35

Care and maintenance 35 31. Use one hand to hold the metal back part of the light and one handle to hold the front glass cover and then take them apart. Then you can replace the bulb. 32. After replacement, use one hand to hold the metal back part of the light and one handle to hold the front glass ...

Page 36

Care and maintenance 36 33. Use m4*10 screw to fix the light assy. On to the back panel of the oven. 34. Use screw m5*35×4 pcs to fix the back heat shield onto the back panel of the oven. The order is: screw→back heat shield→heat insulation washer→flat washer→ oven back panel. 35. Finally, put back ...

Page 37

Care and maintenance 37 cleaning method follow steps 28 to 31 above for glass cover removal. Use a damp towel to clean the surface of glass cover. Make sure the glass cover is completely dry before reinstalling. Warning make sure the light switch is on “off” position and power plug is disconnected f...

Page 38

Care and maintenance 38 5. Do not use an outdoor cooking gas appliance for purposes other than intended. 6. When connecting, first connect plug to the outdoor cooking gas appliance then plug appliance into the outlet. 7. Use only a ground fault interrupter (gfi) protected circuit with this outdoor c...

Page 39

Care and maintenance 39 38. Use spanner 19# to loosen the nut that fix the temp. Gauge. And then you can completely separate the oven door exterior and interior so as to do the cleaning. 39. After cleaning, you need to re-assemble the oven door. Put the door interior onto the exterior and make every...

Page 40

Care and maintenance 40 41. Use m4*10 screw * 4 pcs to fix the door onto the oven. Now you have finished cleaning the oven door..

Page 41

Troubleshootinge 41 many solutions given here can make your grilling experience safer and more enjoyable. You can also call the customer service department at 1-866-410-0408, 8 a.M. – 5 p.M., pst, monday to friday. Problem possible cause corrective action grill will not light. 1. The ignition wire c...

Page 42

Troubleshootinge 42 burner orifice size main burner Φ1.8 mm 2. Clear ports of any obstructions. 3. Refill the lp tank. Low heat, lp gas. The propane regulator assembly incorporates an excess flow device designed to supply the grill with sufficient gas flow. Rapid changes in pressure can trigger the ...

Page 43

Warranty 43 proof of purchase is required to access this warranty program, which is in effect from the date of purchase. Customers will be subject to parts, shipping, and handling fees if unable to provide proof of the purchase or after the warranty has expired. If you have any questions or problems...

Page 44

Exploded diagram 44 for replacement parts, call our customer service department at 1-866-410-0408, 8 a.M. – 5 p.M., pst, monday to friday. 74 69 70 71 72 73 68 63 57 62 59 58 61 60 44 40 39 53 52 51 49 50 48 47 38 37 45 46 15 7 31 20 30 29 19 18 17 32 33 34 35 36 16 14 13 12 11 10 9 8 67 56 65 66 64...

Page 45

Exploded diagram 45 no. Part name qty no. Part name qty 1 heat spacer 4 38 grease tray left bracket 1 2 back heat-shield 1 39 oven back support 1 3 light assy. 1 40 grease tray right bracket 1 4 light bracket 1 41 oven right supporting assy. 1 5 handle latch 1 42 light transformer 1 6 gas pipe 1 43 ...

Page 46

Replacement parts list 46 1 、 bg070-01 oven exterior * 1 pc 2. Bg070-02-00b oven interior * 1 pc 3. Bg070-24 burner bracket beam * 1 pc 4. Bg070b-03-01 oven back panel * 1 pc 5. Bg070-03a oven back heat shield * 1 pc 6. Bg070-10-00b burner assy. * 1 pc 7. Bg070-18 cooking grate * 2 pcs 8. Bg070-17b ...

Page 47

Replacement parts list 47 25. Bg070b-38 oven door glass * 2 pc 26. Bg070-30 temp. Gauge * 1 pc 27. Bg070-12-00 oven door handle assy. * 1 pc 28. Bg070-76-00 sideshelf * 2 pcs 29. Bg070b-30-01 left sideshelf bracket * 2 pcs 30. Bg070b-30-02 right sideshelf bracket * 2 pcs 31. Bg070b-57-00 oven left h...

Page 48

Replacement parts list 48 49. Bg070b-53 trolley top panel * 1 pc 50. Bg070b-54 trolley door horizontal beam * 1 pc 51. Bg070b-50-00 trolley left sidepanel assy. * 1 pc 52. Bg070b-51-00 trolley right sidepanel assy. * 1 pc 53. Bg070b-52 trolley back panel assy. * 1 pc 54. Bg070b-55 trolley door exter...