- DL manuals

- Pacific

- Sander

- Rhino PFS 8

- Owner's Manual & Operating Instructions

Pacific Rhino PFS 8 Owner's Manual & Operating Instructions

Summary of Rhino PFS 8

Page 1

Rhino pfs 8 8” drum sander (expandable drum) owners manual & operating instructions may 2010 ref. 179 part # r000513 from serial number 05400 (110 volt) pacific pac ific.

Page 2

North american safety instructions use and application warning: this floor sanding machine must be grounded. This floor-sanding machine shall be grounded while in use to protect the operator from electric shock. The machine is provided with a three-conductor cord and a moulded three-contact groundin...

Page 3

Contents warning mains cable wiring - plug spare parts specification safety set up preparation operation floor sanding technique floor types i i i 1 1,2 assembly and transport 2 installing abrasive belt 2 2 3,4 drum floor sander 4 edger sander 4 hand sanding 4 sanding plank & strip floors 4 parquet ...

Page 4

Specification the pacific rhino pfs 8 drum floor sander will sand hard and soft wood floors, cork and composition floors that require rapid sanding and leveling to a fine finish. A powerful motor drives a finely balanced sanding drum covered in centrifugal drum rubber which grips a continuous abrasi...

Page 5

14. Never expose the machine to rain or damp. Always store in a dry place. 15. Stop the floor sander immediately if damage to the machine or abrasive belt is suspected. 16. Never allow the power cable to come into contact with the sanding drum when the floor sander is in operation. If the power cabl...

Page 6

In damage to the abrasive paper and sanding drum. 3. Punch all nails below the surface of the floor using a suitable nail punch and hammer. Any screws used to fix boards should be counter sunk below the surface. During sanding any nails or screws that become exposed must be punched or counter sunk f...

Page 7

Carry out maintenance as recommended in maintenance and servicing. Danger - never leave the floor sander unattended with dust in the dust bag. Always remove the dust bag and dispose of into a suitable container. Pacific rhino pfs 8 drum sander pacific wolverine edger sander hand sanding - a powerful...

Page 8

5 unsanded boards sanded boards level very uneven floors by sanding diagonally in both directions unsanded boards unsanded boards level uneven floors. Sand main floor area. Sand and blend edges in with main floor area . Floor sanding technique plank and strip floors parquet and wood block floor - sa...

Page 9

6 floor sander abrasive guide do not over-sand use only as heavy grade abrasive as it takes to do the job. Progress from first grade used through following grades to remove all visible sanding marks. Do not miss a grade. Abrasive grade floor type and condit ion grit p24 open coat (very coarse non-gl...

Page 10

Service & routine maintenance caution - maintenance and repairs must be carried out by authorized personnel only. To prevent injury, always remove the power cable from the power supply before undertaking any work on the machine. Do not operate the floor sander unless it is fully assembled and all gu...

Page 11

Support the pfs 8 with the rubber wedge supplied in the owners pack. Place the wedge on the floor and roll the rhino pfs 8 onto the wedge in the centre of the machine until it comes to a stop to prevent the drum rubber developing a flat spot. 1. Check that power supply is disconnected. Tilt the mach...

Page 12

Vii. Remove the four brushes. Remove the two ‘jacking’ screws. Viii. Thoroughly clean the brush assembly and housing using a soft brush and a suitable vacuum cleaner. Ix. Inspect the four brushes for damage or wear and if any one brush is found to be damaged or worn to a length of 5/8“ (16mm) or les...

Page 13

Xvii. Secure the brush block assembly using the remaining four screws ref.34. Do not over tighten. Xviii. Finally check that all cables are well clear of moving parts before refitting the guard wall and securing with the 3 screws ref.82.. Note: to inspect and replace the motor brushes while retainin...

Page 14

11 trouble shooting fault cause action the machine does not run. The power cable is not connect the power cable to the connected to the power supply. Power supply. The overload protection has allow to cool, switch on. Been activated. The motor brushes are worn. Replace the motor brushes. The voltage...

Page 15

12 rhino pfs 8 parts diagram 39 7 11 10 14 19 15 16 26 21 17 17 18 45 20 59 55 24 51 52 53 50 96 53 56 67 60 65 66 64 63 61 62 83 81 75 2 78 86 73 72 36 35 28 80 79 29 142 152 144 142 143 145 146 84 82 77 86 74 58 54 23 9 1 2 3 4 22 12 6 5 8 127 85 48 25 200 57 201 { 49 46 47 66 27 floor sander.

Page 16

13 rhino pfs 8 parts diagram ht8 ex multi-speed drum floor sander owners manual & operating instructions april 2006 ref. 179 part # 024960 printed in t he uk © hiretech abc from serial number (220/240 volt) & (110/120 volt) 174 173 169 149 98 176 250 31 167 124 131 159 101 103 102 168 165 164 31 30 ...

Page 17

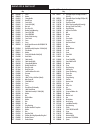

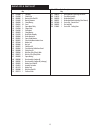

14 rhino pfs 8 parts list 001 r962308 1 screw 002 r980652 2 washer 003 r162019 1 clamp handle 004 r163907 1 handle cross 005 r101205 1 strain relief 005 r163691 1 strain relief (na) 006 r101206 1 nut lock 007 r163849 1 dust cover kit 008 r163837 1 bracket switch mounting 009 r163839 1 switch 110/120...

Page 18

Rhino pfs 8 parts list 121 r163008 1 fan motor 123 r167802 1 shield pulley 124 r024885 3 bearing drum shaft ex 125 r163682 2 bearing armature 126 r062003 2 clamp bearing 127 r962345 10 screw 128 r168212 1 spacer motor pulley 129 r163304 3 flange pulley 130 r166909 1 pulley motor 131 r024870 1 clamp ...

Page 19

16 rhino pfs 8 circuit diagram imited armature field field cable cable ref. 39 2 1 4 3 6 5 u/v o/c cable ref. 20 switch under voltage and overload protected note: terminals 3 & 4 not used u/v coil leads green/yellow (green - n. America) brown (black - n. America) blue (white - n. America) fitting a ...

Page 20

17 service & repair contact your reseller for the name of your local service agent. Service and repairs undertaken by non-approved service agents will void the product warranty. If you should have difficulty in obtaining service please contact pacific floor care at the following address. Pacific flo...