- DL manuals

- Pacific

- Sander

- Rhino PFS 8

- Owner's Manual & Operating Instructions

Pacific Rhino PFS 8 Owner's Manual & Operating Instructions

Summary of Rhino PFS 8

Page 1

Rhino pfs 8 8” drum sander (clamp bar drum) owners manual & operating instructions may 2010 ref. 179 part # r000511 from serial number 05400 (110 volt) pacific pac ific.

Page 2

North american safety instructions use and application warning: this floor sanding machine must be grounded. This floor sanding machine shall be grounded while in use to protect the operator from electric shock. The machine is provided with a three-conductor cord and a three-contact grounding type a...

Page 3

Contents warning mains cable wiring - plug spare parts specification safety set up preparation operation floor sanding technique floor types i i i 1 1 assembly and transport 2 installing abrasive disc 2 2 3 drum floor sander 4 edger sander 4 hand sanding 4 sanding plank & strip floors 4 parquet & bl...

Page 4

Specification the pacific rhino pfs 8 drum sander will sand hard and soft wood floors, cork and composition floors that require rapid sanding and leveling to a fine finish. A powerful motor drives a finely balanced sanding drum which is covered in a unique drum rubber providing a high quality finish...

Page 5

Set up assembly and transport installing abrasive paper 1. The breaks down into three component parts, the main body, handle assembly and dust tube for easy handling and transport. To assemble loosen the clamp bracket ref.21 and slide the handle assembly into the handle bracket ref.51. Adjust the he...

Page 6

Operation 1. Move the floor sander to the location of your work. 2. Connect the power cable to a suitable power supply ideally located behind or to one side of the machine and work area. 3. Wear a dust mask and ear protection. 4. Hold both handles with the main cable held in a small loop in the left...

Page 7

Floor sanding technique pacific rhino pfs 8 drum sander pacific wolverine edger sander hand sanding - a powerful floor sander designed for the rapid leveling and sanding of all types of wood flooring excluding thin laminated or veneered floors. Load the sander with abrasive making sure that it is sk...

Page 8

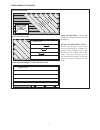

5 floor sanding technique unsanded boards sanded boards level very uneven floors by sanding diagonally in both directions unsanded boards unsanded boards level uneven floors. Sand main floor area. Sand and blend edges in with main floor area . Plank and strip floors parquet and wood block floor - sa...

Page 9

6 floor sander abrasive guide do not over-sand use only as heavy grade abrasive as it takes to do the job. Progress from first grade used through following grades to remove all visible sanding marks. Do not miss a grade. Abrasive grade floor type and condition grit p24 open coat (very coarse non-glo...

Page 10

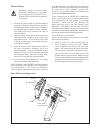

Service & routine maintenance caution - maintenance and repairs must be carried out by authorized personnel only. To prevent injury, always remove the power cable from the power supply before undertaking any work on the machine. Do not operate the floor sander unless it is fully assembled and all gu...

Page 11

Must slide freely in the brush holders. 4. To inspect and replace motor brushes ref.104, with the brush block assembly removed. I. Remove the three screws ref.82 and remove the wall end guard ref.84 to expose the motor brush assembly. Ii. Remove the four retaining screws ref.31 from the shield wall ...

Page 12

Electrical testing caution - testing for electrical safety should be undertaken by a competent person and all results recorded. Do not exceed 1250 volt insulation test duration of 3 seconds. 1. Examine the power cable and handle cable for damage, if the outer insulation shows more than the slightest...

Page 13

6. 7. Record the test results. 8. Complete a functional (run) test and record results. 9. After carrying out the tests disconnect the machine from the test station and snap the 'low volt coil' 'c' back into position and replace cover 'b'. 10. Replace the switch cover 'a' taking care to avoid trappin...

Page 14

11 trouble shooting problem cause action the machine does not run. The power cable is not connect the power cable to the connected to the power supply. Power supply. The overload protection has allow to cool, switch on. Been activated. The motor brushes are worn. Replace the motor brushes. The volta...

Page 15

12 rhino pfs 8 parts diagram 39 7 11 10 14 19 15 16 26 21 17 17 18 45 20 59 55 24 51 52 53 50 96 53 56 67 60 65 66 64 63 61 62 83 81 75 2 78 86 73 72 36 35 28 80 79 29 84 82 77 86 74 58 54 23 9 1 2 3 4 49 46 22 12 6 5 8 127 85 48 47 25 200 57 201 { floor sander.

Page 16

13 rhino pfs 8 parts digram service t ool p a cific 142 143 124 145 144 146 149 98 173 176 174 175 174 167 250 127 152 124 126 159 101 103 102 168 169 165 164 31 30 140 109 104 100 117 115 116 119 121 119 123 86 127 125 128 126 130 97 101 103 102 129 110 43 96 113 125 111 114 118 98 34 98 99 92 91 9...

Page 17

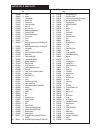

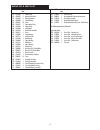

14 rhino pfs 8 parts list 1 r962308 1 screw 2 r980652 2 washer 3 r162019 1 clamp handle 4 r163907 1 handle cross 5 r101205 1 strain relief 5 r163691 1 strain relief (na) 6 r101206 1 nut lock 7 r163849 1 dust cover kit 8 r163837 1 bracket switch mounting 9 r163839 1 switch 110/120v 10 r163870 1 gaske...

Page 18

Rhino pfs 8 parts list 123 r167802 1 shield pulley 124 r902550 2 bearing drum shaft 125 r163682 2 bearing armature 126 r062003 2 clamp bearing 127 r962345 10 screw 128 r168212 1 spacer motor pulley 129 r163304 3 flange pulley 130 r166909 1 pulley motor 140 r163789 1 brush block assembly 142 r962411 ...

Page 19

16 rhino pfs 8 circuit diagram imited armature field field cable cable ref. 39 2 1 4 3 6 5 u/v o/c cable ref. 20 switch under voltage and overload protected note: terminals 3 & 4 not used u/v coil leads green black white fitting a replacement switch 2 4 6 i nstruction for north america ce () u. Ac96...

Page 20

17 service & repair contact your reseller for the name of your local service agent. Service and repairs undertaken by non-approved service agents will void the product warranty. If you should have difficulty in obtaining service please contact pacific floor care at the following address. Pacific flo...